Metallurgy

Encyclopedia

Materials science

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

that studies the physical and chemical behavior of metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

lic elements

Chemical element

A chemical element is a pure chemical substance consisting of one type of atom distinguished by its atomic number, which is the number of protons in its nucleus. Familiar examples of elements include carbon, oxygen, aluminum, iron, copper, gold, mercury, and lead.As of November 2011, 118 elements...

, their intermetallic compounds

Intermetallics

Intermetallics or intermetallic compounds is a term that is used in a number of different ways. Most commonly it refers to solid-state phases involving metals. There is a "research definition" adhered to generally in scientific publications, and a wider "common use" term...

, and their mixtures, which are called alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s. It is also the technology

Technology

Technology is the making, usage, and knowledge of tools, machines, techniques, crafts, systems or methods of organization in order to solve a problem or perform a specific function. It can also refer to the collection of such tools, machinery, and procedures. The word technology comes ;...

of metals: the way in which science is applied to their practical use. Metallurgy is distinguished from the craft

Craft

A craft is a branch of a profession that requires some particular kind of skilled work. In historical sense, particularly as pertinent to the Medieval history and earlier, the term is usually applied towards people occupied in small-scale production of goods.-Development from the past until...

of metalworking

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

.

Etymology and pronunciation

The word was originally (1593) an alchemistAlchemist

An alchemist is a person who practices alchemy. Alchemist may also refer to:-People and groups:*The Alchemist , a hip hop music producer and rapper*Alchemist , an Australian progressive metal band...

's term for the extraction of metals from minerals: the ending -urgy signifying a process, especially manufacturing: it was in this sense it was used by the 1797 Encyclopaedia Britannica. In the late 19th century it was extended to the more general scientific study of metals and alloys and related processes. The roots are borrowed from Ancient Greek: μεταλλουργός, matallourgos, "worker in metal", from μέταλλον, metallon, "metal" + ἔργον, ergon, "work". In English, the /meˈtælədʒi/ pronunciation is the more common one in the UK and Commonwealth. The /ˈmetələrdʒi/ pronunciation is the more common one in the USA, and is the first-listed variant in various American dictionaries (e.g., Merriam-Webster Collegiate, American Heritage).

History

Millennium

A millennium is a period of time equal to one thousand years —from the Latin phrase , thousand, and , year—often but not necessarily related numerically to a particular dating system....

BC, and was found in the archaeological sites of Majdanpek

Majdanpek

Majdanpek is a town and municipality in Bor District of Serbia. According to 2011 census, the municipality of Majdanpek has a population of 18,179 people, while the town of Majdanpek has a population of 7,367....

, Yarmovac and Plocnik

Plocnik

Pločnik is a village in the municipality of Prokuplje, Toplica District, Republic of Serbia. According to the 2002 population census, it's populated by 182, all of whom declared Serbs....

all three in Serbia

Serbia

Serbia , officially the Republic of Serbia , is a landlocked country located at the crossroads of Central and Southeast Europe, covering the southern part of the Carpathian basin and the central part of the Balkans...

. To date, the earliest copper smelting is found at the Belovode site, these examples include a copper axe from 5,500BC belonging to the Vinča culture

Vinca culture

The Vinča culture is a Neolithic archaeological culture in Southeastern Europe, dated to the period 5500–4500 BCE. Named for its type site, Vinča-Belo Brdo, a large tell settlement discovered by Serbian archaeologist Miloje Vasić in 1908, it represents the material remains of a prehistoric society...

. Other signs of human metallurgy are found from the third millennium

Millennium

A millennium is a period of time equal to one thousand years —from the Latin phrase , thousand, and , year—often but not necessarily related numerically to a particular dating system....

BC in places like Palmela

Palmela

Palmela is a town and a municipality in Portugal with a total area of and a total population of 58,222 inhabitants.The municipality is composed of 5 parishes, and is located in Setúbal District, about south of Lisbon.The municipal holiday is June 1....

(Portugal), Cortes de Navarra (Spain), and Stonehenge

Stonehenge

Stonehenge is a prehistoric monument located in the English county of Wiltshire, about west of Amesbury and north of Salisbury. One of the most famous sites in the world, Stonehenge is composed of a circular setting of large standing stones set within earthworks...

(United Kingdom). However, as often happens with the study of prehistoric times, the ultimate beginnings cannot be clearly defined and new discoveries are continuous and ongoing.

Silver

Silver

Silver is a metallic chemical element with the chemical symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metal...

, copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

, tin

Tin

Tin is a chemical element with the symbol Sn and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group 14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4...

and meteoric iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

can also be found native, allowing a limited amount of metalworking

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

in early cultures. Egyptian weapons made from meteoric iron in about 3000 B.C. were highly prized as "Daggers from Heaven". However, by learning to get copper and tin

Tin

Tin is a chemical element with the symbol Sn and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group 14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4...

by heating rocks and combining those two metals to make an alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

called bronze

Bronze

Bronze is a metal alloy consisting primarily of copper, usually with tin as the main additive. It is hard and brittle, and it was particularly significant in antiquity, so much so that the Bronze Age was named after the metal...

, the technology of metallurgy began about 3500 B.C. with the Bronze Age

Bronze Age

The Bronze Age is a period characterized by the use of copper and its alloy bronze as the chief hard materials in the manufacture of some implements and weapons. Chronologically, it stands between the Stone Age and Iron Age...

.

The extraction of iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

from its ore into a workable metal is much more difficult. It appears to have been invented by the Hittites

Hittites

The Hittites were a Bronze Age people of Anatolia.They established a kingdom centered at Hattusa in north-central Anatolia c. the 18th century BC. The Hittite empire reached its height c...

in about 1200 B.C., beginning the Iron Age

Iron Age

The Iron Age is the archaeological period generally occurring after the Bronze Age, marked by the prevalent use of iron. The early period of the age is characterized by the widespread use of iron or steel. The adoption of such material coincided with other changes in society, including differing...

. The secret of extracting and working iron was a key factor in the success of the Philistines

Philistines

Philistines , Pleshet or Peleset, were a people who occupied the southern coast of Canaan at the beginning of the Iron Age . According to the Bible, they ruled the five city-states of Gaza, Askelon, Ashdod, Ekron and Gath, from the Wadi Gaza in the south to the Yarqon River in the north, but with...

.

Historical developments in ferrous metallurgy can be found in a wide variety of past cultures and civilizations. This includes the ancient and medieval kingdoms and empires of the Middle East

Middle East

The Middle East is a region that encompasses Western Asia and Northern Africa. It is often used as a synonym for Near East, in opposition to Far East...

and Near East

Near East

The Near East is a geographical term that covers different countries for geographers, archeologists, and historians, on the one hand, and for political scientists, economists, and journalists, on the other...

, ancient Iran

Iran

Iran , officially the Islamic Republic of Iran , is a country in Southern and Western Asia. The name "Iran" has been in use natively since the Sassanian era and came into use internationally in 1935, before which the country was known to the Western world as Persia...

, ancient Egypt

Egypt

Egypt , officially the Arab Republic of Egypt, Arabic: , is a country mainly in North Africa, with the Sinai Peninsula forming a land bridge in Southwest Asia. Egypt is thus a transcontinental country, and a major power in Africa, the Mediterranean Basin, the Middle East and the Muslim world...

, ancient Nubia

Nubia

Nubia is a region along the Nile river, which is located in northern Sudan and southern Egypt.There were a number of small Nubian kingdoms throughout the Middle Ages, the last of which collapsed in 1504, when Nubia became divided between Egypt and the Sennar sultanate resulting in the Arabization...

, and Anatolia

Anatolia

Anatolia is a geographic and historical term denoting the westernmost protrusion of Asia, comprising the majority of the Republic of Turkey...

(Turkey

Turkey

Turkey , known officially as the Republic of Turkey , is a Eurasian country located in Western Asia and in East Thrace in Southeastern Europe...

), Ancient Nok, Carthage

Carthage

Carthage , implying it was a 'new Tyre') is a major urban centre that has existed for nearly 3,000 years on the Gulf of Tunis, developing from a Phoenician colony of the 1st millennium BC...

, the Greeks

Greeks

The Greeks, also known as the Hellenes , are a nation and ethnic group native to Greece, Cyprus and neighboring regions. They also form a significant diaspora, with Greek communities established around the world....

and Roman

Ancient Rome

Ancient Rome was a thriving civilization that grew on the Italian Peninsula as early as the 8th century BC. Located along the Mediterranean Sea and centered on the city of Rome, it expanded to one of the largest empires in the ancient world....

s of ancient Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

, medieval Europe, ancient and medieval China

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

, ancient and medieval India

India

India , officially the Republic of India , is a country in South Asia. It is the seventh-largest country by geographical area, the second-most populous country with over 1.2 billion people, and the most populous democracy in the world...

, ancient and medieval Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

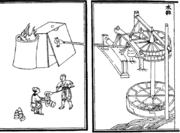

, amongst others. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace

Blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron.In a blast furnace, fuel and ore and flux are continuously supplied through the top of the furnace, while air is blown into the bottom of the chamber, so that the chemical reactions...

, cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

, hydraulic-powered trip hammer

Trip hammer

A trip hammer, also known as a helve hammer, is a massive powered hammer used in:* agriculture to facilitate the labor of pounding, decorticating and polishing of grain;...

s, and double acting piston bellows

Bellows

A bellows is a device for delivering pressurized air in a controlled quantity to a controlled location.Basically, a bellows is a deformable container which has an outlet nozzle. When the volume of the bellows is decreased, the air escapes through the outlet...

.

A 16th century book by Georg Agricola

Georg Agricola

Georgius Agricola was a German scholar and scientist. Known as "the father of mineralogy", he was born at Glauchau in Saxony. His real name was Georg Pawer; Agricola is the Latinised version of his name, Pawer meaning "farmer"...

called De re metallica

De re metallica

De re metallica is a book cataloguing the state of the art of mining, refining, and smelting metals, published in 1556. The author was Georg Bauer, whose pen name was the Latinized Georgius Agricola...

describes the highly developed and complex processes of mining metal ores, metal extraction and metallurgy of the time. Agricola has been described as the "father of metallurgy".

Extraction

Extractive metallurgy

Extractive metallurgy is the study of the processes used in the separation and concentration of raw materials. The field is an applied science, covering all aspects of the physical and chemical processes used to produce mineral-containing and metallic materials, sometimes for direct use as a...

is the practice of removing valuable metals from an ore

Ore

An ore is a type of rock that contains minerals with important elements including metals. The ores are extracted through mining; these are then refined to extract the valuable element....

and refining the extracted raw metals into a purer form. In order to convert a metal oxide

Oxide

An oxide is a chemical compound that contains at least one oxygen atom in its chemical formula. Metal oxides typically contain an anion of oxygen in the oxidation state of −2....

or sulfide

Sulfide

A sulfide is an anion of sulfur in its lowest oxidation state of 2-. Sulfide is also a slightly archaic term for thioethers, a common type of organosulfur compound that are well known for their bad odors.- Properties :...

to a purer metal, the ore must be reduced

Redox

Redox reactions describe all chemical reactions in which atoms have their oxidation state changed....

physically, chemically

Chemistry

Chemistry is the science of matter, especially its chemical reactions, but also its composition, structure and properties. Chemistry is concerned with atoms and their interactions with other atoms, and particularly with the properties of chemical bonds....

, or electrolytically

Electrolyte

In chemistry, an electrolyte is any substance containing free ions that make the substance electrically conductive. The most typical electrolyte is an ionic solution, but molten electrolytes and solid electrolytes are also possible....

.

Extractive metallurgists are interested in three primary streams: feed, concentrate (valuable metal oxide/sulfide), and tailings

Tailings

Tailings, also called mine dumps, slimes, tails, leach residue, or slickens, are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an ore...

(waste). After mining, large pieces of the ore feed are broken through crushing and/or grinding in order to obtain particles small enough where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products.

Mining may not be necessary if the ore body and physical environment are conducive to leaching. Leaching dissolves minerals in an ore body and results in an enriched solution. The solution is collected and processed to extract valuable metals.

Ore bodies often contain more than one valuable metal. Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Alloys

Common engineering metalMetal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

s include aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

, chromium

Chromium

Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

, copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

, iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

, magnesium

Magnesium

Magnesium is a chemical element with the symbol Mg, atomic number 12, and common oxidation number +2. It is an alkaline earth metal and the eighth most abundant element in the Earth's crust and ninth in the known universe as a whole...

, nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

, titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

and zinc

Zinc

Zinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

. These are most often used as alloys. Much effort has been placed on understanding the iron-carbon alloy system, which includes steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

s and cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

s. Plain carbon steels are used in low cost, high strength applications where weight and corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

are not a problem. Cast irons, including ductile iron

Ductile iron

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spherulitic graphite cast iron and SG iron, is a type of cast iron invented in 1943 by Keith Millis...

are also part of the iron-carbon system.

Stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

or galvanized steel are used where resistance to corrosion is important. Aluminium alloys and magnesium alloys are used for applications where strength and lightness are required.

Copper-nickel alloys (such as Monel

Monel

Monel is a trademark of Special Metals Corporation for a series of nickel alloys, primarily composed of nickel and copper, with some iron and other trace elements. Monel was created by David H. Browne, chief metallurgist for International Nickel Co...

) are used in highly corrosive environments and for non-magnetic applications. Nickel-based superalloy

Superalloy

A superalloy, or high-performance alloy, is an alloy that exhibits excellent mechanical strength and creep resistance at high temperatures, good surface stability, and corrosion and oxidation resistance. Superalloys typically have a matrix with an austenitic face-centered cubic crystal structure. ...

s like Inconel

Inconel

Inconel is a registered trademark of Special Metals Corporation that refers to a family of austenitic nickel-chromium-based superalloys. Inconel alloys are typically used in high temperature applications. It is often referred to in English as "Inco"...

are used in high temperature applications such as turbochargers, pressure vessel

Pressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

, and heat exchangers. For extremely high temperatures, single crystal

Single crystal

A single crystal or monocrystalline solid is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries...

alloys are used to minimize creep.

Production

In production engineeringIndustrial engineering

Industrial engineering is a branch of engineering dealing with the optimization of complex processes or systems. It is concerned with the development, improvement, implementation and evaluation of integrated systems of people, money, knowledge, information, equipment, energy, materials, analysis...

, metallurgy is concerned with the production of metallic components for use in consumer or engineering

Engineering

Engineering is the discipline, art, skill and profession of acquiring and applying scientific, mathematical, economic, social, and practical knowledge, in order to design and build structures, machines, devices, systems, materials and processes that safely realize improvements to the lives of...

products. This involves the production of alloys, the shaping, the heat treatment and the surface treatment of the product. The task of the metallurgist is to achieve balance between material properties such as cost, weight

Weight

In science and engineering, the weight of an object is the force on the object due to gravity. Its magnitude , often denoted by an italic letter W, is the product of the mass m of the object and the magnitude of the local gravitational acceleration g; thus:...

, strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

, toughness

Toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing; Material toughness is defined as the amount of energy per volume that a material can absorb before rupturing...

, hardness, corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

, fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

resistance, and performance in temperature

Temperature

Temperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot...

extremes. To achieve this goal, the operating environment must be carefully considered. In a saltwater environment, ferrous metals and some aluminium alloys corrode quickly. Metals exposed to cold or cryogenic conditions may endure a ductile to brittle transition and lose their toughness, becoming more brittle and prone to cracking. Metals under continual cyclic loading can suffer from metal fatigue. Metals under constant stress

Stress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

at elevated temperatures can creep

Creep (deformation)

In materials science, creep is the tendency of a solid material to slowly move or deform permanently under the influence of stresses. It occurs as a result of long term exposure to high levels of stress that are below the yield strength of the material....

.

Metalworking processes

Metals are shaped by processes such as:- casting - molten metal is poured into a shaped mouldMolding (process)Molding or moulding is the process of manufacturing by shaping pliable raw material using a rigid frame or model called a pattern....

. - forgingForgingForging is a manufacturing process involving the shaping of metal using localized compressive forces. Forging is often classified according to the temperature at which it is performed: '"cold," "warm," or "hot" forging. Forged parts can range in weight from less than a kilogram to 580 metric tons...

- a red-hot billetBillet (manufacturing)Semi-finished casting products are intermediate castings produced in a foundry that need further processing before being a finished good. There are four types: ingots, billets, blooms, and slabs.-Ingot:...

is hammered into shape. - flow forming

- rollingRolling (metalworking)In metalworking, rolling is a metal forming process in which metal stock is passed through a pair of rolls. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is termed as hot rolling...

- a billet is passed through successively narrower rollers to create a sheet. - Laser claddingCladding (metalworking)Cladding is the bonding together of dissimilar metals. It is distinct from welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.The United States Mint uses...

- metallic powder is blown through a movable laser beam (e.g. mounted on a NC 5-axis machine). The resulting melted metal reach a substrate to from a melt pool. By moving the laser head, it is possible to stack the tracks and build up a 3D piece. - extrusionExtrusionExtrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

- a hot and malleable metal is forced under pressure through a dieDie (manufacturing)A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Like molds, dies are generally customized to the item they are used to create...

, which shapes it before it cools. - sinteringSinteringSintering is a method used to create objects from powders. It is based on atomic diffusion. Diffusion occurs in any material above absolute zero, but it occurs much faster at higher temperatures. In most sintering processes, the powdered material is held in a mold and then heated to a temperature...

- a powdered metalPowder metallurgyPowder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape , and then heating the compressed material in a controlled atmosphere to bond the material . The powder metallurgy process generally consists of four basic steps: powder manufacture, powder...

is heated in a non-oxidizing environment after being compressed into a die. - metalworkingMetalworkingMetalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

- machiningMachiningConventional machining is a form of subtractive manufacturing, in which a collection of material-working processes utilizing power-driven machine tools, such as saws, lathes, milling machines, and drill presses, are used with a sharp cutting tool to physical remove material to achieve a desired...

- lathes, milling machineMilling machineA milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

s, and drillDrillA drill or drill motor is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for drilling holes in various materials or fastening various materials together with the use of fasteners. The attachment is gripped by a chuck at one end of...

s cut the cold metal to shape. - fabricationFabrication (metal)Fabrication as an industrial term refers to building metal structures by cutting, bending, and assembling. The cutting part of fabrication is via sawing, shearing, or chiseling ; torching with handheld torches ; and via CNC cutters...

- sheets of metal are cut with guillotineGuillotineThe guillotine is a device used for carrying out :executions by decapitation. It consists of a tall upright frame from which an angled blade is suspended. This blade is raised with a rope and then allowed to drop, severing the head from the body...

s or gas cutters and bent into shape.

Cold working processes, where the product’s shape is altered by rolling, fabrication or other processes while the product is cold, can increase the strength of the product by a process called work hardening

Work hardening

Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements within the crystal structure of the material. Any material with a reasonably high melting point such as metals and...

. Work hardening creates microscopic defects

Dislocation

In materials science, a dislocation is a crystallographic defect, or irregularity, within a crystal structure. The presence of dislocations strongly influences many of the properties of materials...

in the metal, which resist further changes of shape.

Various forms of casting exist in industry and academia. These include sand casting

Sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.It is relatively cheap and sufficiently refractory even for steel foundry use. A suitable bonding agent is mixed or occurs with the sand...

, investment casting

Investment casting

Investment casting is an industrial process based on and also called lost-wax casting, one of the oldest known metal-forming techniques. From 5,000 years ago, when beeswax formed the pattern, to today’s high-technology waxes, refractory materials and specialist alloys, the castings allow the...

(also called the “lost wax process”), die casting

Die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process...

and continuous casting

Continuous casting

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form...

.

Heat treatment

Metals can be heat treatedHeat treatment

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass...

to alter the properties of strength, ductility, toughness, hardness or resistance to corrosion. Common heat treatment processes include annealing

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

, precipitation strengthening

Precipitation strengthening

Precipitation hardening, also called age hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys of aluminium, magnesium, nickel and titanium, and some stainless steels...

, quenching, and tempering

Tempering

Tempering is a heat treatment technique for metals, alloys and glass. In steels, tempering is done to "toughen" the metal by transforming brittle martensite or bainite into a combination of ferrite and cementite or sometimes Tempered martensite...

,. The annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal. Quenching is the process of cooling a high-carbon steel very quickly after you have heated it, thus "freezing" the steel's molecules in the very hard martensite form, which makes the metal harder. There is a balance between hardness and toughness in any steel, where the harder it is, the less tough or impact-resistant it is, and the more impact-resistant it is, the less hard it is. Tempering relieves stresses in the metal that were caused by the hardening process; tempering makes the metal less hard while making it better able to sustain impacts without breaking.

Often, mechanical and thermal treatments are combined in what is known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high alloy special steels, super alloys and titanium alloys.

Plating

ElectroplatingElectroplating

Electroplating is a plating process in which metal ions in a solution are moved by an electric field to coat an electrode. The process uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal...

is a common surface-treatment technique. It involves bonding a thin layer of another metal such as gold

Gold

Gold is a chemical element with the symbol Au and an atomic number of 79. Gold is a dense, soft, shiny, malleable and ductile metal. Pure gold has a bright yellow color and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is a...

, silver

Silver

Silver is a metallic chemical element with the chemical symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metal...

, chromium

Chromium

Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

or zinc

Zinc

Zinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

to the surface of the product. It is used to reduce corrosion as well as to improve the product's aesthetic appearance.

Thermal spraying

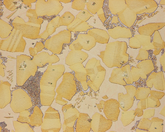

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings.Microstructure

Metallography

Metallography is the study of the physical structure and components of metals, typically using microscopy.Ceramic and polymeric materials may also be prepared using metallographic techniques, hence the terms ceramography, plastography and, collectively, materialography.-Preparing metallographic...

, a technique invented by Henry Clifton Sorby

Henry Clifton Sorby

Henry Clifton Sorby , was an English microscopist and geologist.-Biography:Sorby was born at Woodbourne near Sheffield in Yorkshire and attended Sheffield Collegiate School. He early developed an interest in natural science, and one of his first papers related to the excavation of valleys in...

. In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope

Electron microscope

An electron microscope is a type of microscope that uses a beam of electrons to illuminate the specimen and produce a magnified image. Electron microscopes have a greater resolving power than a light-powered optical microscope, because electrons have wavelengths about 100,000 times shorter than...

, and the image contrast provides details on the composition, mechanical properties, and processing history.

Crystallography

Crystallography

Crystallography is the experimental science of the arrangement of atoms in solids. The word "crystallography" derives from the Greek words crystallon = cold drop / frozen drop, with its meaning extending to all solids with some degree of transparency, and grapho = write.Before the development of...

, often using diffraction

Diffraction

Diffraction refers to various phenomena which occur when a wave encounters an obstacle. Italian scientist Francesco Maria Grimaldi coined the word "diffraction" and was the first to record accurate observations of the phenomenon in 1665...

of x-ray

X-ray

X-radiation is a form of electromagnetic radiation. X-rays have a wavelength in the range of 0.01 to 10 nanometers, corresponding to frequencies in the range 30 petahertz to 30 exahertz and energies in the range 120 eV to 120 keV. They are shorter in wavelength than UV rays and longer than gamma...

s or electron

Electron

The electron is a subatomic particle with a negative elementary electric charge. It has no known components or substructure; in other words, it is generally thought to be an elementary particle. An electron has a mass that is approximately 1/1836 that of the proton...

s, is another valuable tool available to the modern metallurgist. Crystallography allows identification of unknown materials and reveals the crystal structure of the sample. Quantitative crystallography can be used to calculate the amount of phases present as well as the degree of strain to which a sample has been subjected.

See also

- Metallurgical failure analysisMetallurgical failure analysisMetallurgical failure analysis is the process by which a metallurgist determines the mechanism that has caused a metal component to fail. Typical failure modes involve various types of corrosion and mechanical damage...

- ArchaeometallurgyArchaeometallurgyArchaeometallurgy is the study of the history and prehistory of metals and their use through humans. It is a sub-discipline of archaeology and archaeological science...

- CALPHAD

- Carbonyl metallurgyCarbonyl metallurgyCarbonyl metallurgy is used to manufacture products of iron, nickel, steel, and other metals. Coatings are produced by vapor plating using metal carbonyl vapors...

- CupellationCupellationCupellation is a metallurgical process in which ores or alloyed metals are treated under high temperatures and carefully controlled operations in order to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, that might be present in...

- Georg AgricolaGeorg AgricolaGeorgius Agricola was a German scholar and scientist. Known as "the father of mineralogy", he was born at Glauchau in Saxony. His real name was Georg Pawer; Agricola is the Latinised version of his name, Pawer meaning "farmer"...

- GoldbeatingGoldbeatingGoldbeating is the process of hammering gold into an extremely thin unbroken sheet for use in gilding.- History :5,000 years ago, Egyptian artisans recognized the extraordinary durability and malleability of gold and became the first goldbeaters and gilders. They pounded gold using a round stone to...

- Gold phosphine complex

- Mineral industryMineral industryThe mineral industry is the branch of industry responsible for the exploitation of minerals from soil deposits. This is achieved by mining , but also by processing plants. Products of mineral industry include various building materials, such as rocks The mineral industry is the branch of industry...

- National Institute of Foundry and Forge TechnologyNational Institute of Foundry and Forge TechnologyThe National Institute of Foundry and Forge Technology is a fully residential Government of India co-educational institute located in the mineral-rich belt of India in the town of Ranchi....

- PyrometallurgyPyrometallurgyPyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals...

- Timeline of materials technologyTimeline of materials technologyMajor innovations in materials technology-BC:* 29,000–25,000 BC – First pottery appears*3rd millennium BC – Copper metallurgy is invented and copper is used for ornamentation*2nd millennium BC – Bronze is used for weapons and armour...

- Experimental ArchaeometallurgyExperimental ArchaeometallurgyExperimental Archaeometallurgy is a subset of experimental archaeology that specifically involves past metallurgical processes most commonly involving the replication of copper and iron objects as well as testing the methodology behind the production of ancient metals and metal objects...