Tensile strength

Overview

Necking (engineering)

Necking, in engineering or materials science, is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck"...

, which is when the specimen's cross-section

Cross section (geometry)

In geometry, a cross-section is the intersection of a figure in 2-dimensional space with a line, or of a body in 3-dimensional space with a plane, etc...

starts to significantly contract. Tensile strength is the opposite of compressive strength

Compressive strength

Compressive strength is the capacity of a material or structure to withstand axially directed pushing forces. When the limit of compressive strength is reached, materials are crushed. Concrete can be made to have high compressive strength, e.g...

and the values can be quite different.

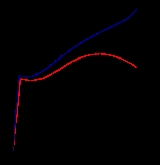

The UTS is usually found by performing a tensile test and recording the stress versus strain; the highest point of the stress-strain curve

Stress-strain curve

During tensile testing of a material sample, the stress–strain curve is a graphical representation of the relationship between stress, derived from measuring the load applied on the sample, and strain, derived from measuring the deformation of the sample, i.e. elongation, compression, or distortion...

is the UTS.

Unanswered Questions

Discussions