Cladding (metalworking)

Encyclopedia

Cladding is the bonding together of dissimilar metal

s. It is distinct from welding

or gluing

as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die

as well as pressing

or rolling sheets together under high pressure

.

The United States Mint

uses cladding to manufacture coin

s from different metals. This allows a cheaper metal to be used as a filler.

Laser cladding is a method of depositing material by which a powdered or wire feedstock material is melted and consolidated by use of a laser

Laser cladding is a method of depositing material by which a powdered or wire feedstock material is melted and consolidated by use of a laser

in order to coat part of a substrate or fabricate a near-net shape part (additive manufacturing

technology) .

It is often used to improve mechanical properties or increase corrosion resistance, repair worn out parts, and fabricate metal matrix composite

s.

A great deal of research is now being concentrated on developing automatic laser cladding machines. Many of the process parameters must be manually set, such as laser power, laser focal point, substrate velocity, powder injection rate, etc., and thus require the attention of a specialized technician to ensure proper results. However, many groups are focusing their attention on developing sensors to measure the process online. Such sensors monitor the clad's geometry (height and width of deposited track), metallurgical properties (such as the rate of solidification, and hence the final microstructure), and temperature information of both the immediate melt pool and its surrounding areas. With such sensors, control strategies are being designed such that constant observation from a technician is no longer required to produce a final product. Further research has been directed to forward processing where system parameters are developed around specific metallurgical properties for user defined applications (such as microstructure, internal stresses, delusion zone gradients, and clad contact angle).

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

s. It is distinct from welding

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

or gluing

Adhesive

An adhesive, or glue, is a mixture in a liquid or semi-liquid state that adheres or bonds items together. Adhesives may come from either natural or synthetic sources. The types of materials that can be bonded are vast but they are especially useful for bonding thin materials...

as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die

Die (manufacturing)

A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Like molds, dies are generally customized to the item they are used to create...

as well as pressing

Machine press

A machine press, commonly shortened to press, is a machine tool that changes the shape of a workpiece.-Servomechanism:A servomechanism press, also known as a servo press or a electro press, is a press driven by an AC servo motor. The torque produced is converted to a linear force via a ball screw....

or rolling sheets together under high pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

.

The United States Mint

United States Mint

The United States Mint primarily produces circulating coinage for the United States to conduct its trade and commerce. The Mint was created by Congress with the Coinage Act of 1792, and placed within the Department of State...

uses cladding to manufacture coin

Coin

A coin is a piece of hard material that is standardized in weight, is produced in large quantities in order to facilitate trade, and primarily can be used as a legal tender token for commerce in the designated country, region, or territory....

s from different metals. This allows a cheaper metal to be used as a filler.

Laser cladding

Laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of photons. The term "laser" originated as an acronym for Light Amplification by Stimulated Emission of Radiation...

in order to coat part of a substrate or fabricate a near-net shape part (additive manufacturing

Additive manufacturing

Additive manufacturing is defined by ASTM as the "process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies, such as traditional machining...

technology) .

It is often used to improve mechanical properties or increase corrosion resistance, repair worn out parts, and fabricate metal matrix composite

Metal matrix composite

A metal matrix composite is composite material with at least two constituent parts, one being a metal. The other material may be a different metal or another material, such as a ceramic or organic compound. When at least three materials are present, it is called a hybrid composite...

s.

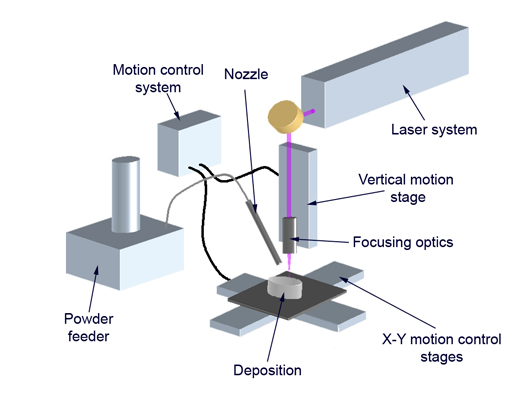

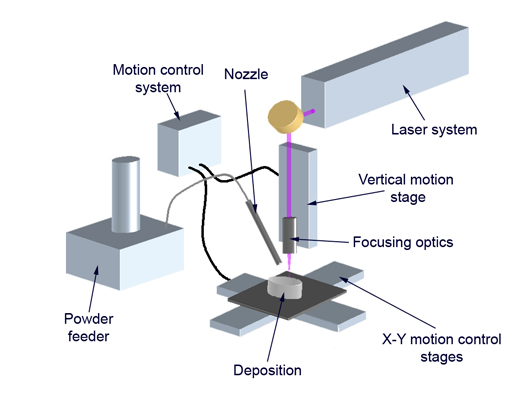

Process

The powder used in laser cladding is normally of a metallic nature, and is injected into the system by either coaxial or lateral nozzles. The interaction of the metallic powder stream and the laser causes melting to occur, and is known as the melt pool. This is deposited onto a substrate; moving the substrate allows the melt pool to solidify and thus produces a track of solid metal. This is the most common technique, however some processes involve moving the laser/nozzle assembly over a stationary substrate to produce solidified tracks. The motion of the substrate is guided by a CAD system which interpolates solid objects into a set of tracks, thus producing the desired part at the end of the trajectory.A great deal of research is now being concentrated on developing automatic laser cladding machines. Many of the process parameters must be manually set, such as laser power, laser focal point, substrate velocity, powder injection rate, etc., and thus require the attention of a specialized technician to ensure proper results. However, many groups are focusing their attention on developing sensors to measure the process online. Such sensors monitor the clad's geometry (height and width of deposited track), metallurgical properties (such as the rate of solidification, and hence the final microstructure), and temperature information of both the immediate melt pool and its surrounding areas. With such sensors, control strategies are being designed such that constant observation from a technician is no longer required to produce a final product. Further research has been directed to forward processing where system parameters are developed around specific metallurgical properties for user defined applications (such as microstructure, internal stresses, delusion zone gradients, and clad contact angle).

Advantages

- Best technique for coating any shape => increase life-time of wearing part by 6-7.

- Particular dispositions for repairing parts (ideal if the mould of the part no longer exist or too long time needed for a new fabrication).

- Most suited technique for graded material applicationFunctionally graded materialIn materials science functionally graded material may be characterized by the variation in composition and structure gradually over volume, resulting in corresponding changes in the properties of the material. The materials can be designed for specific function and applications...

. - Well adapted for near-net-shapeNear net shapeNear net shape is an industrial manufacturing technique. The name implies that the initial production of the item is very close to the final shape, reducing the need for surface finishing...

manufacturing. - Low dilution between track and substrate (unlike other welding processes and strong metallurgical bond.

- Low deformation of the substrate and small heat affected zone (HAZ).

- High cooling rate => fine microstructure.

- A lot of material flexibility (metal, ceramic, even polymer).

- Built part is free of crack and porosity.

- Compact technology.

See also

- Copper-clad steel

- Copper-clad aluminum wireCopper-clad aluminum wireCopper-clad aluminium wire, commonly abbreviated as CCAW or CCA, is a electrical conductor composed of an inner aluminium core and outer copper cladding.-Uses:...

- Laser engineered net shapingLaser engineered net shapingLaser engineered net shaping or LENS is a technology developed by Sandia National Laboratories for fabricating metal parts directly from a computer-aided design solid model by using a metal powder injected into a molten pool created by a focused, high-powered laser beam.A high power laser is used...

- rapid manufacturing

- additive manufacturingAdditive manufacturingAdditive manufacturing is defined by ASTM as the "process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies, such as traditional machining...

- http://www.ccl.fraunhofer.org/download/cladding_titanium.pdf

manufacturers

- Trumpf (Germany) : http://www.trumpf-laser.com

- POM (USA) : http://www.pomgroup.com/

- Optomec (USA) http://www.optomec.com/site/technology_lens

- Huffman corp (USA) : http://www.huffmancorp.com/products/laser_systems/index.html

- IREPA Laser (France) http://www.irepa-laser.com/index.php/fra/rechargement-alliage-de-surface/

- Accufusion (Canada) http://www.accufusion.com/

external links

- http://www.lasercladding.com/index.html

- http://www.designforlasermanufacture.com/

- http://www.alspi.com/lasercladding.htm

- http://www.laserweldingsolutions.com/

- http://www.fwgartner.com/fwgts_prodserv_qa_laser.htm

- http://www.laserline-inc.com/diode-laser-cladding-coating-laser-repair-welding.php

- http://www.optoiq.com/index/lasers-for-manufacturing/laser-surface-treatment/laser-cladding.html

- http://www.swansonindustries.com/lasercladding.php

- http://www.precoinc.com/capabilities/clad.html

- http://www.neotechservices.com/lens.html

- http://www.additive3d.com/lens.htm