.gif)

Fatigue (material)

Encyclopedia

In materials science

Materials science

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress

Stress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

values are less than the ultimate tensile stress limit

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

, and may be below the yield stress limit

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

of the material.

Fatigue occurs when a material is subjected to repeated loading and unloading. If the loads are above a certain threshold, microscopic cracks will begin to form at the surface. Eventually a crack will reach a critical size, and the structure will suddenly fracture. The shape of the structure will significantly affect the fatigue life; square holes or sharp corners will lead to elevated local stresses where fatigue cracks can initiate. Round holes and smooth transitions or fillets are therefore important to increase the fatigue strength of the structure.

Fatigue life

ASTMASTM International

ASTM International, known until 2001 as the American Society for Testing and Materials , is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services...

defines fatigue life, Nf, as the number of stress cycles of a specified character that a specimen sustains before failure

Structural failure

Structural failure refers to loss of the load-carrying capacity of a component or member within a structure or of the structure itself. Structural failure is initiated when the material is stressed to its strength limit, thus causing fracture or excessive deformations...

of a specified nature occurs.

One method to predict fatigue life of materials is the Uniform Material Law (UML). UML was developed for fatigue life prediction of aluminum and titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

alloys by the end of 20th century and extended to high-strength steels. and cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

. For some materials there is a theoretical value for stress amplitude below which it will not fail for any number of cycles, called a fatigue limit, endurance limit, or fatigue strength

Fatigue limit

Fatigue limit, endurance limit, and fatigue strength are all expressions used to describe a property of materials: the amplitude of cyclic stress that can be applied to the material without causing fatigue failure. Ferrous alloys and titanium alloys have a distinct limit, an amplitude below which...

.

Characteristics of fatigue

- In metals and alloys, the process starts with dislocationDislocationIn materials science, a dislocation is a crystallographic defect, or irregularity, within a crystal structure. The presence of dislocations strongly influences many of the properties of materials...

movements, eventually forming persistent slip bands that nucleate short cracks. - Fatigue is a stochasticStochasticStochastic refers to systems whose behaviour is intrinsically non-deterministic. A stochastic process is one whose behavior is non-deterministic, in that a system's subsequent state is determined both by the process's predictable actions and by a random element. However, according to M. Kac and E...

process, often showing considerable scatter even in controlled environments. - The greater the applied stress range, the shorter the life.

- Fatigue life scatter tends to increase for longer fatigue lives.

- Damage is cumulative. Materials do not recover when rested.

- Fatigue life is influenced by a variety of factors, such as temperatureTemperatureTemperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot...

, surface finishSurface finishSurface finish, also known as surface texture, is the characteristics of a surface. It has three components: lay, surface roughness, and waviness.-Lay:...

, microstructure, presence of oxidizing or inertInert-Chemistry:In chemistry, the term inert is used to describe a substance that is not chemically reactive.The noble gases were previously known as inert gases because of their perceived lack of participation in any chemical reactions...

chemicals, residual stresses, contact (frettingFrettingFretting refers to wear and sometimes corrosion damage at the asperities of contact surfaces. This damage is induced under load and in the presence of repeated relative surface motion, as induced for example by vibration...

), etc. - Some materials (e.g., some steelSteelSteel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

and titaniumTitaniumTitanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

alloys) exhibit a theoretical fatigue limitFatigue limitFatigue limit, endurance limit, and fatigue strength are all expressions used to describe a property of materials: the amplitude of cyclic stress that can be applied to the material without causing fatigue failure. Ferrous alloys and titanium alloys have a distinct limit, an amplitude below which...

below which continued loading does not lead to structural failureStructural failureStructural failure refers to loss of the load-carrying capacity of a component or member within a structure or of the structure itself. Structural failure is initiated when the material is stressed to its strength limit, thus causing fracture or excessive deformations...

. - In recent years, researchers (see, for example, the work of Bathias, Murakami, and Stanzl-Tschegg) have found that failures occur below the theoretical fatigue limit at very high fatigue lives (109 to 1010 cycles). An ultrasonic resonance technique is used in these experiments with frequencies around 10–20 kHz.

- High cycle fatigue strength (about 103 to 108 cycles) can be described by stress-based parameters. A load-controlled servo-hydraulic test rig is commonly used in these tests, with frequencies of around 20–50 Hz. Other sorts of machines—like resonant magnetic machines—can also be used, achieving frequencies up to 250 Hz.

- Low cycle fatigue (typically less than 103 cycles) is associated with widespread plasticity in metals; thus, a strain-based parameter should be used for fatigue life prediction in metals and alloys. Testing is conducted with constant strain amplitudes typically at 0.01–5 Hz.

Timeline of early fatigue research history

- 1837: Wilhelm AlbertWilhelm AlbertWilhelm August Julius Albert was a German mining administrator, best remembered as the first person to record observations of metal fatigue....

publishes the first article on fatigue. He devised a test machine for conveyor chains used in the ClausthalClausthal-ZellerfeldClausthal-Zellerfeld is a town in Lower Saxony, Germany. It is located in the southwestern part of the Harz mountains. Its population is approximately 15,000, Clausthal-Zellerfeld is also the seat of the Samtgemeinde Oberharz....

minesMiningMining is the extraction of valuable minerals or other geological materials from the earth, from an ore body, vein or seam. The term also includes the removal of soil. Materials recovered by mining include base metals, precious metals, iron, uranium, coal, diamonds, limestone, oil shale, rock...

. - 1839: Jean-Victor PonceletJean-Victor PonceletJean-Victor Poncelet was a French engineer and mathematician who served most notably as the commandant general of the École Polytechnique...

describes metals as being tired in his lectures at the military school at MetzMetzMetz is a city in the northeast of France located at the confluence of the Moselle and the Seille rivers.Metz is the capital of the Lorraine region and prefecture of the Moselle department. Located near the tripoint along the junction of France, Germany, and Luxembourg, Metz forms a central place...

. - 1842: William John Macquorn RankineWilliam John Macquorn RankineWilliam John Macquorn Rankine was a Scottish civil engineer, physicist and mathematician. He was a founding contributor, with Rudolf Clausius and William Thomson , to the science of thermodynamics....

recognises the importance of stress concentrationStress concentrationA stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

s in his investigation of railroad axleAxleAn axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

failures. The Versailles train crashVersailles train crashThe Versailles rail accident occurred on May 8, 1842 in the cutting at Meudon Bellevue , France. Following the King's fete celebrations at the Palace of Versailles, a train returning to Paris crashed at Meudon after the leading locomotive broke an axle. The carriages behind piled into the wrecked...

was caused by axle fatigue. - 1843: Joseph Glynn reports on fatigue of axle on locomotive tender. He identifies the keywayKeyway (engineering)In mechanical engineering, a key is a machine element used to connect a rotating machine element to a shaft. Through this connection the key prevents relative rotation between the two parts and allows torque to be transmitted through...

as the crack origin. - 1848: Railway Inspectorate report one of the first tyre failures, probably from a rivet hole in tread of railway carriage wheel. It was likely a fatigue failure.

- 1849: Eaton HodgkinsonEaton HodgkinsonEaton A. Hodgkinson was an English engineer, a pioneer of the application of mathematics to problems of structural design.-Early life:...

is granted a small sum of money to report to the UK Parliament on his work in ascertaining by direct experiment, the effects of continued changes of load upon iron structures and to what extent they could be loaded without danger to their ultimate security. - 1854: Braithwaite reports on common service fatigue failures and coins the term fatigue.

- 1860: Systematic fatigue testing undertaken by Sir William FairbairnWilliam FairbairnSir William Fairbairn, 1st Baronet was a Scottish civil engineer, structural engineer and shipbuilder.-Early career:...

and August WöhlerAugust WöhlerAugust Wöhler was a German engineer, best remembered for his systematic investigations of metal fatigue.Born in the town of Soltau, the son of local teacher Georg Heinrich Wöhler showed early mathematical ability and won a scholarship to study at the Technische Hochschule in Hannover, under the...

. - 1870: Wöhler summarises his work on railroad axles. He concludes that cyclic stress range is more important than peak stress and introduces the concept of endurance limit.

- 1903: Sir James Alfred EwingJames Alfred EwingSir James Alfred Ewing KCB FRS FRSE MInstitCE was a Scottish physicist and engineer, best known for his work on the magnetic properties of metals and, in particular, for his discovery of, and coinage of the word, hysteresis.It was said of Ewing that he was 'Careful at all times of his appearance,...

demonstrates the origin of fatigue failure in microscopic cracks. - 1910: O. H. Basquin proposes a log-log relationship for SN curves, using Wöhler's test data.

- 1945: A. M. Miner popularises A. Palmgren's (1924) linear damage hypothesis as a practical design tool.

- 1954: L. F. Coffin and S. S. Manson explain fatigue crack-growth in terms of plasticPlasticity (physics)In physics and materials science, plasticity describes the deformation of a material undergoing non-reversible changes of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the...

strainStrain (materials science)In continuum mechanics, the infinitesimal strain theory, sometimes called small deformation theory, small displacement theory, or small displacement-gradient theory, deals with infinitesimal deformations of a continuum body...

in the tip of cracks. - 1961: P. C. Paris proposes methods for predicting the rate of growth of individual fatigue cracks in the face of initial scepticism and popular defence of Miner's phenomenological approach.

- 1968: Tatsuo EndoTatsuo Endowas a Japanese engineer who, in 1968 along with M. Matsuishi, developed the rainflow-counting algorithm for fatigue analysis of structures while a visiting professor at the University of Illinois.-Bibliography:...

and M. Matsuishi devise the rainflow-counting algorithmRainflow-counting algorithmThe rainflow-counting algorithm is used in the analysis of fatigue data in order to reduce a spectrum of varying stress into a set of simple stress reversals. Its importance is that it allows the application of Miner's rule in order to assess the fatigue life of a structure subject to complex...

and enable the reliable application of Miner's rule to random loadings. - 1970: W. Elber elucidates the mechanisms and importance of crack closure in slowing the growth of a fatigue crack due to the wedging effect of plastic deformation left behind the tip of the crack.

High-cycle fatigue

Historically, most attention has focused on situations that require more than 104 cycles to failure where stress is low and deformation primarily elasticElasticity (physics)

In physics, elasticity is the physical property of a material that returns to its original shape after the stress that made it deform or distort is removed. The relative amount of deformation is called the strain....

.

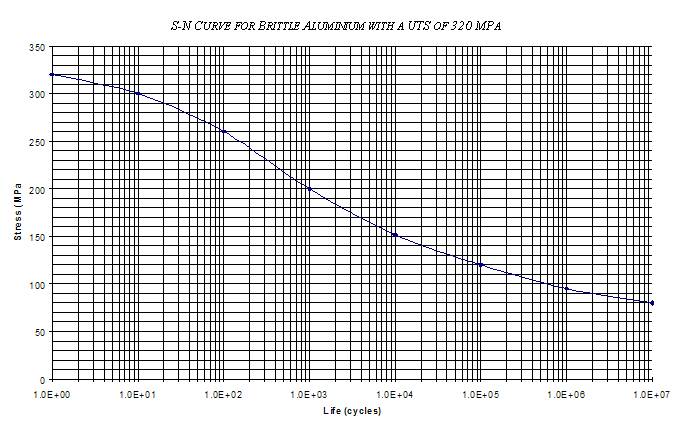

The S-N curve

In high-cycle fatigue situations, materials performance is commonly characterized by an S-N curve, also known as a WöhlerAugust Wöhler

August Wöhler was a German engineer, best remembered for his systematic investigations of metal fatigue.Born in the town of Soltau, the son of local teacher Georg Heinrich Wöhler showed early mathematical ability and won a scholarship to study at the Technische Hochschule in Hannover, under the...

curve . This is a graph of the magnitude of a cyclic stress (S) against the logarithmic scale

Logarithmic scale

A logarithmic scale is a scale of measurement using the logarithm of a physical quantity instead of the quantity itself.A simple example is a chart whose vertical axis increments are labeled 1, 10, 100, 1000, instead of 1, 2, 3, 4...

of cycles to failure (N).

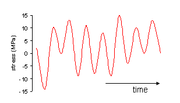

S-N curves are derived from tests on samples of the material to be characterized (often called coupons) where a regular sinusoidal stress is applied by a testing machine which also counts the number of cycles to failure. This process is sometimes known as coupon testing. Each coupon test generates a point on the plot though in some cases there is a runout where the time to failure exceeds that available for the test (see censoring

Censoring (statistics)

In statistics, engineering, and medical research, censoring occurs when the value of a measurement or observation is only partially known.For example, suppose a study is conducted to measure the impact of a drug on mortality. In such a study, it may be known that an individual's age at death is at...

). Analysis of fatigue data requires techniques from statistics

Statistics

Statistics is the study of the collection, organization, analysis, and interpretation of data. It deals with all aspects of this, including the planning of data collection in terms of the design of surveys and experiments....

, especially survival analysis and linear regression

Linear regression

In statistics, linear regression is an approach to modeling the relationship between a scalar variable y and one or more explanatory variables denoted X. The case of one explanatory variable is called simple regression...

.

Probabilistic nature of fatigue

As coupons sampled from a homogeneous frame will manifest variation in their number of cycles to failure, the S-N curve should more properly be an S-N-P curve capturing the probability of failure after a given number of cycles of a certain stress. Probability distributions that are common in data analysis and in design against fatigue include the lognormal distribution, extreme value distributionExtreme value theory

Extreme value theory is a branch of statistics dealing with the extreme deviations from the median of probability distributions. The general theory sets out to assess the type of probability distributions generated by processes...

, Birnbaum–Saunders distribution, and Weibull distribution.

Complex loadings

- Reduce the complex loading to a series of simple cyclic loadings using a technique such as rainflow analysisRainflow-counting algorithmThe rainflow-counting algorithm is used in the analysis of fatigue data in order to reduce a spectrum of varying stress into a set of simple stress reversals. Its importance is that it allows the application of Miner's rule in order to assess the fatigue life of a structure subject to complex...

; - Create a histogramHistogramIn statistics, a histogram is a graphical representation showing a visual impression of the distribution of data. It is an estimate of the probability distribution of a continuous variable and was first introduced by Karl Pearson...

of cyclic stress from the rainflow analysis to form a fatigue damage spectrumFatigue damage spectrumThe Fatigue Damage Spectrum of a vibration is obtained by tracing the fatigue damage experienced by a linear Single Degree of Freedom System according to its natural frequency, for given damping ratio and for a given value of parameter b .Regardless of the...

; - For each stress level, calculate the degree of cumulative damage incurred from the S-N curve; and

- Combine the individual contributions using an algorithm such as Miner's rule.

Miner's rule

In 1945, M. A. Miner popularised a rule that had first been proposed by A. Palmgren in 1924. The rule, variously called Miner's rule or the Palmgren-Miner linear damage hypothesis, states that where there are k different stress magnitudes in a spectrum, Si (1 ≤ i ≤ k), each contributing ni(Si) cycles, then if Ni(Si) is the number of cycles to failure of a constant stress reversal Si, failure occurs when:

C is experimentally found to be between 0.7 and 2.2. Usually for design purposes, C is assumed to be 1.

This can be thought of as assessing what proportion of life is consumed by stress reversal at each magnitude then forming a linear combination of their aggregate.

Though Miner's rule is a useful approximation in many circumstances, it has several major limitations:

- It fails to recognise the probabilistic nature of fatigue and there is no simple way to relate life predicted by the rule with the characteristics of a probability distribution. Industry analysts often use design curves, adjusted to account for scatter, to calculate Ni(Si).

- There is sometimes an effect in the order in which the reversals occur. In some circumstances, cycles of low stress followed by high stress cause more damage than would be predicted by the rule. It does not consider the effect of overload or high stress which may result in a compressive residual stress. High stress followed by low stress may have less damage due to the presence of compressive residual stress.

Paris' Relationship

In Fracture mechanicsFracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

, Anderson, Gomez and Paris derived relationships for the stage II crack growth with cycles N, in terms of the cyclical component ΔK of the Stress Intensity Factor

Stress Intensity Factor

The stress intensity factor, K, is used in fracture mechanics to predict the stress state near the tip of a crack caused by a remote load or residual stresses. It is a theoretical construct usually applied to a homogeneous, linear elastic material and is useful for providing a failure criterion...

K

where a is the crack length and m is typically in the range 3 to 5 (for metals).

This relationship was later modified (by Forman, 1967) to make better allowance for the mean stress, by introducing a factor depending on (1-R) where R = min stress/max stress, in the denominator.

Low-cycle fatigue

Where the stress is high enough for plastic deformationPlasticity (physics)

In physics and materials science, plasticity describes the deformation of a material undergoing non-reversible changes of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the...

to occur, the account in terms of stress is less useful and the strain

Strain (materials science)

In continuum mechanics, the infinitesimal strain theory, sometimes called small deformation theory, small displacement theory, or small displacement-gradient theory, deals with infinitesimal deformations of a continuum body...

in the material offers a simpler description. Low-cycle fatigue is usually characterised by the Coffin-Manson relation (published independently by L. F. Coffin in 1954 and S. S. Manson 1953):

-where:

- Δεp /2 is the plastic strain amplitude;

- εf' is an empirical constant known as the fatigue ductility coefficient, the failure strain for a single reversal;

- 2N is the number of reversals to failure (N cycles);

- c is an empirical constant known as the fatigue ductility exponent, commonly ranging from -0.5 to -0.7 for metals in time independent fatigue. Slopes can be considerably steeper in the presence of creep or environmental interactions.

A similar relationship for materials such as Zirconium, used in the nuclear industry.

Fatigue and fracture mechanics

The account above is purely empiricalEmpirical

The word empirical denotes information gained by means of observation or experimentation. Empirical data are data produced by an experiment or observation....

and, though it allows life prediction and design assurance, life improvement or design optimisation can be enhanced using fracture mechanics

Fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

. It can be developed in four stages.

- Crack nucleation;

- Stage I crack-growth;

- Stage II crack-growth; and

- Ultimate ductile failure.

Factors that affect fatigue-life

- Cyclic stress state: Depending on the complexity of the geometry and the loading, one or more properties of the stress state need to be considered, such as stress amplitude, mean stress, biaxiality, in-phase or out-of-phase shear stress, and load sequence,

- Geometry: Notches and variation in cross section throughout a part lead to stress concentrations where fatigue cracks initiate.

- Surface quality. Surface roughness cause microscopic stress concentrations that lower the fatigue strength. Compressive residual stresses can be introduced in the surface by e.g. shot peeningShot peeningShot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals. It entails impacting a surface with shot with force sufficient to create plastic deformation...

to increase fatigue life. Such techniques for producing surface stress are often referred to as peeningPeeningPeening is the process of working a metal's surface to improve its material properties, usually by mechanical means such as hammer blows or by blasting with shot . Peening is normally a cold work process...

, whatever the mechanism used to produce the stress. Low plasticity burnishingLow plasticity burnishingLow plasticity burnishing is a method of metal improvement that provides deep, stable surface compressive residual stresses with little cold work for improved damage tolerance and metal fatigue life extension...

, laser peeningLaser peeningLaser peening, or laser shock peening , is the process of hardening or peening metal using a powerful laser. Laser peening can impart a layer of residual compressive stress on a surface that is four times deeper than that attainable from conventional shot peening treatments. A coating, usually...

, and ultrasonic impact treatmentUltrasonic impact treatmentUltrasonic impact treatment is a method of metal improvement that utilizes ultrasonic energy. The physical characteristics: controlled residual compressive stress, grain refinement and grain size reduction...

can also produce this surface compressive stress and can increase the fatigue life of the component. This improvement is normally observed only for high-cycle fatigue.

- Material Type: Fatigue life, as well as the behavior during cyclic loading, varies widely for different materials, e.g. composites and polymers differ markedly from metals.

- Residual stresses: Welding, cutting, casting, and other manufacturing processes involving heat or deformation can produce high levels of tensile residual stressResidual stressResidual stresses are stresses that remain after the original cause of the stresses has been removed. They remain along a cross section of the component, even without the external cause. Residual stresses occur for a variety of reasons, including inelastic deformations and heat treatment...

, which decreases the fatigue strength.

- Size and distribution of internal defects: Casting defects such as gas porosity, non-metallic inclusionsNon-metallic inclusionsNon-metallic inclusions are chemical compounds and nonmetals that are present in steel and alloys. They are the product of chemical reactions, physical effects, and contamination that occurs during the melting and pouring process. These inclusions are categorized by origin as either endogenous or...

and shrinkage voids can significantly reduce fatigue strength.

- Direction of loading: For non-isotropic materials, fatigue strength depends on the direction of the principal stress.

- Grain size: For most metals, smaller grains yield longer fatigue lives, however, the presence of surface defects or scratches will have a greater influence than in a coarse grained alloy.

- Environment: Environmental conditions can cause erosion, corrosion, or gas-phase embrittlement, which all affect fatigue life. Corrosion fatigueCorrosion fatigueCorrosion fatigue is fatigue in a corrosive environment. It is the mechanical degradation of a material under the joint action of corrosion and cyclic loading. Nearly all engineering structures experience some form of alternating stress, and are exposed to harmful environments during their service...

is a problem encountered in many aggressive environments.

- Temperature: Extreme high or low temperatures can decrease fatigue strength.

Design against fatigue

Dependable design against fatigue-failure requires thorough education and supervised experience in structural engineeringStructural engineering

Structural engineering is a field of engineering dealing with the analysis and design of structures that support or resist loads. Structural engineering is usually considered a specialty within civil engineering, but it can also be studied in its own right....

, mechanical engineering

Mechanical engineering

Mechanical engineering is a discipline of engineering that applies the principles of physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the production and usage of heat and mechanical power for the...

, or materials science

Materials science

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

.

There are three principal approaches to life assurance for mechanical parts that display increasing degrees of sophistication:

- Design to keep stress below threshold of fatigue limit (infinite lifetime concept);

- Design (conservatively) for a fixed life after which the user is instructed to replace the part with a new one (a so-called lifed part, finite lifetime concept, or "safe-lifeSafe-life designIn safe-life design products are designed to survive a specific design life with a chosen reserve.The Safe-life design technique is employed in critical systems which are either very difficult to repair or may cause severe damage to life and property...

" design practice); - Instruct the user to inspect the part periodically for cracks and to replace the part once a crack exceeds a critical length. This approach usually uses the technologies of nondestructive testingNondestructive testingNondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

and requires an accurate prediction of the rate of crack-growth between inspections. This is often referred to as damage tolerant designFault-tolerant designIn engineering, fault-tolerant design is a design that enables a system to continue operation, possibly at a reduced level , rather than failing completely, when some part of the system fails...

or "retirement-for-cause".

Stopping fatigue

Fatigue cracks that have begun to propagate can sometimes be stopped by drillingDrilling

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole in solid materials. The drill bit is a multipoint, end cutting tool...

holes, called drill stops, in the path of the fatigue crack. This is not recommended as a general practice because the hole represents a stress concentration

Stress concentration

A stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

factor which depends on the size of the hole and geometry, though the hole is typically less of a stress concentration than the removed tip of the crack. The possibility remains of a new crack starting in the side of the hole. It is always far better to replace the cracked part entirely.

Material change

Changes in the materials used in parts can also improve fatigue life. For example, parts can be made from better fatigue rated metals. Complete replacement and redesign of parts can also reduce if not eliminate fatigue problems. Thus helicopter rotorHelicopter rotor

A helicopter main rotor or rotor system is a type of fan that is used to generate both the aerodynamic lift force that supports the weight of the helicopter, and thrust which counteracts aerodynamic drag in forward flight...

blades and propeller

Propeller (aircraft)

Aircraft propellers or airscrews convert rotary motion from piston engines or turboprops to provide propulsive force. They may be fixed or variable pitch. Early aircraft propellers were carved by hand from solid or laminated wood with later propellers being constructed from metal...

s in metal are being replaced by composite

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

equivalents. They are not only lighter, but also much more resistant to fatigue. They are more expensive, but the extra cost is amply repaid by their greater integrity, since loss of a rotor blade usually leads to total loss of the aircraft. A similar argument has been made for replacement of metal fuselages, wings and tails of aircraft.

Versailles train crash

Palace of Versailles

The Palace of Versailles , or simply Versailles, is a royal château in Versailles in the Île-de-France region of France. In French it is the Château de Versailles....

, a train returning to Paris crashed in May 1842 at Meudon

Meudon

Meudon is a municipality in the southwestern suburbs of Paris, France. It is in the département of Hauts-de-Seine. It is located from the center of Paris.-Geography:...

after the leading locomotive broke an axle. The carriages behind piled into the wrecked engines and caught fire. At least 55 passengers were killed trapped in the carriages, including the explorer Jules Dumont d'Urville

Jules Dumont d'Urville

Jules Sébastien César Dumont d'Urville was a French explorer, naval officer and rear admiral, who explored the south and western Pacific, Australia, New Zealand and Antarctica.-Childhood:Dumont was born at Condé-sur-Noireau...

. This accident is known in France as the "Catastrophe ferroviaire de Meudon". The accident was witnessed by the British locomotive engineer Joseph Locke

Joseph Locke

Joseph Locke was a notable English civil engineer of the 19th century, particularly associated with railway projects...

and widely reported in Britain. It was discussed extensively by engineers, who sought an explanation.

The derailment had been the result of a broken locomotive

Locomotive

A locomotive is a railway vehicle that provides the motive power for a train. The word originates from the Latin loco – "from a place", ablative of locus, "place" + Medieval Latin motivus, "causing motion", and is a shortened form of the term locomotive engine, first used in the early 19th...

axle. Rankine's

William John Macquorn Rankine

William John Macquorn Rankine was a Scottish civil engineer, physicist and mathematician. He was a founding contributor, with Rudolf Clausius and William Thomson , to the science of thermodynamics....

investigation of broken axles in Britain highlighted the importance of stress concentration

Stress concentration

A stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

, and the mechanism of crack growth with repeated loading. His and other papers suggesting a crack growth mechanism through repeated stressing, however, were ignored, and fatigue failures occurred at an ever increasing rate on the expanding railway system. Other spurious theories seemed to be more acceptable, such as the idea that the metal had somehow "crystallized". The notion was based on the crystalline appearance of the fast fracture region of the crack surface, but ignored the fact that the metal was already highly crystalline.

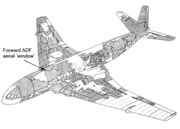

de Havilland Comet

De Havilland Comet

The de Havilland DH 106 Comet was the world's first commercial jet airliner to reach production. Developed and manufactured by de Havilland at the Hatfield, Hertfordshire, United Kingdom headquarters, it first flew in 1949 and was a landmark in aeronautical design...

passenger jets broke up in mid-air and crashed within a few months of each other in 1954. As a result systematic tests were conducted on a fuselage

Fuselage

The fuselage is an aircraft's main body section that holds crew and passengers or cargo. In single-engine aircraft it will usually contain an engine, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage which in turn is used as a floating hull...

immersed and pressurised in a water tank. After the equivalent of 3,000 flights investigators at the Royal Aircraft Establishment

Royal Aircraft Establishment

The Royal Aircraft Establishment , was a British research establishment, known by several different names during its history, that eventually came under the aegis of the UK Ministry of Defence , before finally losing its identity in mergers with other institutions.The first site was at Farnborough...

(RAE) were able to conclude that the crash had been due to failure of the pressure cabin at the forward Automatic Direction Finder

Radio direction finder

A radio direction finder is a device for finding the direction to a radio source. Due to low frequency propagation characteristic to travel very long distances and "over the horizon", it makes a particularly good navigation system for ships, small boats, and aircraft that might be some distance...

window in the roof. This 'window' was in fact one of two apertures for the aerials

Antenna (radio)

An antenna is an electrical device which converts electric currents into radio waves, and vice versa. It is usually used with a radio transmitter or radio receiver...

of an electronic navigation system in which opaque fibreglass panels took the place of the window 'glass'. The failure was a result of metal fatigue

Metal Fatigue

Metal Fatigue , is a futuristic science fiction, real-time strategy computer game developed by Zono Incorporated and published by Psygnosis and TalonSoft .-Plot:...

caused by the repeated pressurisation and de-pressurisation of the aircraft cabin. Another fact was that the supports around the windows were riveted, not bonded, as the original specifications for the aircraft had called for. The problem was exacerbated by the punch rivet construction technique employed. Unlike drill riveting, the imperfect nature of the hole created by punch riveting caused manufacturing defect cracks which may have caused the start of fatigue cracks around the rivet.

The Comet's pressure cabin had been designed to a safety factor comfortably in excess of that required by British Civil Airworthiness Requirements (2.5 times the cabin proof pressure

Proof test

A proof test is a test wherein a deliberately over-pressured round is fired from a firearm in order to verify that the firearm is not defective and will not explode on firing. The firearm is inspected after the test, and if it is found to be in sound condition, then it is marked with a proof mark...

as opposed to the requirement of 1.33 times and an ultimate load of 2.0 times the cabin pressure) and the accident caused a revision in the estimates of the safe loading strength requirements of airliner pressure cabins.

In addition, it was discovered that the stresses

Stress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

around pressure cabin apertures were considerably higher than had been anticipated, especially around sharp-cornered cut-outs, such as windows. As a result, all future jet airliner

Jet airliner

A jet airliner is an airliner that is powered by jet engines. This term is sometimes contracted to jetliner or jet.In contrast to today's relatively fuel-efficient, turbofan-powered air travel, first generation jet airliner travel was noisy and fuel inefficient...

s would feature windows with rounded corners, the curve eliminating a stress concentration. This was a noticeable distinguishing feature of all later models of the Comet. Investigators from the RAE told a public inquiry that the sharp corners

Stress concentration

A stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

near the Comets' window openings acted as initiation sites for cracks. The skin of the aircraft was also too thin, and cracks from manufacturing stresses were present at the corners.

Alexander L. Kielland oil platform capsize

The Alexander L. Kielland was a NorwegianNorway

Norway , officially the Kingdom of Norway, is a Nordic unitary constitutional monarchy whose territory comprises the western portion of the Scandinavian Peninsula, Jan Mayen, and the Arctic archipelago of Svalbard and Bouvet Island. Norway has a total area of and a population of about 4.9 million...

semi-submersible

Semi-submersible

A semi-submersible is a specialised marine vessel with good stability and seakeeping characteristics. The semi-submersible vessel design is commonly used in a number of specific offshore roles such as for offshore drilling rigs, safety vessels, oil production platforms and heavy lift cranes.The...

drilling rig

Drilling rig

A drilling rig is a machine which creates holes or shafts in the ground. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person...

that capsized whilst working in the Ekofisk oil field

Ekofisk oil field

Ekofisk is an oil field in the Norwegian sector of the North Sea about southwest of Stavanger. Discovered in 1969, it remains one of the most important oil fields in the North Sea. Production began in 1971 after the construction of a series of off-shore platforms by Phillips Petroleum Company...

in March 1980 killing 123 people. The capsize was the worst disaster in Norwegian waters since World War II. The rig, located approximately 320 km east from Dundee

Dundee

Dundee is the fourth-largest city in Scotland and the 39th most populous settlement in the United Kingdom. It lies within the eastern central Lowlands on the north bank of the Firth of Tay, which feeds into the North Sea...

, Scotland

Scotland

Scotland is a country that is part of the United Kingdom. Occupying the northern third of the island of Great Britain, it shares a border with England to the south and is bounded by the North Sea to the east, the Atlantic Ocean to the north and west, and the North Channel and Irish Sea to the...

, was owned by the Stavanger Drilling Company of Norway and was on hire to the U.S.

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

company Phillips Petroleum

Phillips Petroleum

Phillips Petroleum Company was founded in 1917 by L.E. Phillips and Frank Phillips, of Bartlesville, Oklahoma. Their younger brother Waite Phillips was the benefactor of Philmont Scout Ranch....

at the time of the disaster. In driving rain and mist, early in the evening of 27 March 1980 more than 200 men were off duty in the accommodation on the Alexander L. Kielland. The wind was gusting to 40 knots with waves up to 12 m high. The rig had just been winched away from the Edda production platform. Minutes before 18:30 those on board felt a 'sharp crack' followed by 'some kind of trembling'. Suddenly the rig heeled over 30° and then stabilised. Five of the six anchor cables had broken, the one remaining cable preventing the rig from capsizing. The list continued to increase and at 18.53 the remaining anchor cable snapped and the rig turned upside down.

A year later in March 1981, the investigative report concluded that the rig collapsed owing to a fatigue crack in one of its six bracings (bracing D-6), which connected the collapsed D-leg to the rest of the rig. This was traced to a small 6 mm fillet weld which joined a non-load-bearing flange plate to this D-6 bracing. This flange plate held a sonar device used during drilling operations. The poor profile of the fillet weld contributed to a reduction in its fatigue strength. Further, the investigation found considerable amounts of lamellar tearing in the flange plate and cold cracks in the butt weld. Cold cracks in the welds, increased stress concentrations due to the weakened flange plate, the poor weld profile, and cyclical stresses (which would be common in the North Sea

North Sea

In the southwest, beyond the Straits of Dover, the North Sea becomes the English Channel connecting to the Atlantic Ocean. In the east, it connects to the Baltic Sea via the Skagerrak and Kattegat, narrow straits that separate Denmark from Norway and Sweden respectively...

), seemed to collectively play a role in the rig's collapse.

Others

- The 1919 Boston Molasses DisasterBoston molasses disasterThe Boston Molasses Disaster, also known as the Great Molasses Flood and the Great Boston Molasses Tragedy, occurred on January 15, 1919, in the North End neighborhood of Boston, Massachusetts in the United States. A large molasses storage tank burst, and a wave of molasses rushed through the...

has been attributed to a fatigue failure. - The 1948 Northwest Airlines Flight 421 crash due to fatigue failure in a wing spar root

- The 1957 "Mt. Pinatubo"1957 Cebu Douglas C-47 crashThe 1957 crash of a Douglas C-47 plane named "Mt. Pinatubo" on the slopes of Mount Manunggal, Cebu, Philippines, killed the 7th President of the Philippines, Ramon Magsaysay, and 24 other passengers. The crash is estimated to have occurred at 1:40:00 AM, March 17, 1957, Philippine Standard Time...

, presidential plane of Philippine PresidentPresident of the PhilippinesThe President of the Philippines is the head of state and head of government of the Philippines. The president leads the executive branch of the Philippine government and is the commander-in-chief of the Armed Forces of the Philippines...

Ramon MagsaysayRamon MagsaysayRamón del Fierro Magsaysay was the third President of the Republic of the Philippines from December 30, 1953 until his death in a plane crash in 1957. He was elected President under the banner of the Nacionalista Party.-Early life:Ramon F...

, crashed due to engine failure caused by metal fatigue. - The 1968 Los Angeles Airways Flight 417Los Angeles Airways Flight 417Los Angeles Airways Flight 417 was a helicopter that crashed on August 14, 1968 in the city of Compton, California. All eighteen passengers and three crewmembers were fatally injured. The aircraft was destroyed by impact and fire. According to the National Transportation Safety Board the...

lost one of its main rotor blades due to fatigue failure. - The 1968 MacRobertson Miller Airlines Flight 1750MacRobertson Miller Airlines Flight 1750On 31 December 1968 a Vickers Viscount aircraft departed from Perth, Western Australia for a flight of 724 nautical miles to Port Hedland. The aircraft crashed 28 nautical miles short of its destination with the loss of all twenty-six people on board...

that lost a wing due to improper maintenance leading to fatigue failure - The 1977 Dan-Air Boeing 707 crash caused by fatigue failure resulting in the loss of the right horizontal stabilizer

- The 1980 LOT Flight 7 that crashed due to fatigue in an engine turbine shaft resulting in engine disintegration leading to loss of control

- The 1985 Japan Airlines Flight 123Japan Airlines Flight 123Japan Airlines Flight 123 was a Japan Airlines domestic flight from Tokyo International Airport to Osaka International Airport on August 12, 1985. The Boeing 747-146SR that made this route, registered , suffered mechanical failures 12 minutes into the flight and 32 minutes later crashed into two...

crashed after the aircraft lost its vertical stabilizer due to faulty repairs on the rear bulkhead. - The 1988 Aloha Airlines Flight 243Aloha Airlines Flight 243Aloha Airlines Flight 243 was a scheduled Aloha Airlines flight between Hilo and Honolulu in Hawaii. On April 28, 1988, a Boeing 737-200 serving the flight suffered extensive damage after an explosive decompression in flight, but was able to land safely at Kahului Airport on Maui. The only...

suffered an explosive decompression due to fatigue failure. - The 1989 United Airlines Flight 232United Airlines Flight 232United Airlines Flight 232 was a scheduled flight from Stapleton International Airport in Denver, Colorado, to O'Hare International Airport in Chicago, with continuing service to Philadelphia International Airport...

lost its tail engine due to fatigue failure. - The 1992 El Al Flight 1862El Al Flight 1862On 4 October 1992, El Al Flight 1862, a Boeing 747 cargo plane of the Israeli airline El Al, crashed into the Groeneveen and Klein-Kruitberg flats in the Bijlmermeer neighbourhood of Amsterdam, the Netherlands. For the location in the Bijlmermeer, the crash is known in Dutch as the "Bijlmerramp"...

lost both engines on its right-wing due to fatigue failure in the pylon mounting of the #3 Engine. - The 1998 Eschede train disasterEschede train disasterThe Eschede train disaster was the world's deadliest high-speed train accident. It occurred on 3 June 1998, near the village of Eschede in the Celle district of Lower Saxony, Germany. The toll of 101 people dead and 88 injured surpassed the 1971 Dahlerau train disaster as the deadliest accident in...

was caused by fatigue failure of a single composite wheel. - The 2000 Hatfield rail crashHatfield rail crashThe Hatfield rail crash was a railway accident on 17 October 2000, at Hatfield, Hertfordshire, UK. Although the accident killed fewer than other accidents, Hatfield exposed the major stewardship shortcomings of the privatised national railway infrastructure company Railtrack and the failings of...

was likely caused by rolling contact fatigue. - The 2002 China Airlines Flight 611China Airlines Flight 611China Airlines Flight 611 was a regularly scheduled flight from Chiang Kai-shek International Airport in Taoyuan to Hong Kong International Airport in Hong Kong...

had disintegrated in-flight due to fatigue failure. - The 2005 Chalk's Ocean Airways Flight 101Chalk's Ocean Airways flight 101Chalk's Ocean Airways Flight 101 was an aircraft crash that occurred off Miami Beach, Florida, in the United States on December 19, 2005. All 20 passengers and crew on board the 1947 Grumman G-73T Turbine Mallard died in the crash, which was attributed to metal fatigue on the starboard wing...

lost its right wing due to fatigue failure brought about by inadequate maintenance practices.

See also

- Air safetyAir safetyAir safety is a term encompassing the theory, investigation and categorization of flight failures, and the prevention of such failures through regulation, education and training. It can also be applied in the context of campaigns that inform the public as to the safety of air travel.-United...

- EmbedmentEmbedmentEmbedment is a phenomenon in mechanical engineering in which the surfaces between mechanical members of a loaded joint embed. It can lead to failure by fatigue as described below, and is of particular concern when considering the design of critical fastener joints.-Mechanism:The mechanism behind...

- Forensic materials engineeringForensic materials engineeringA branch of Forensic engineering, the subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal...

- FractographyFractographyFractography is the study of fracture surfaces of materials. Fractographic methods are routinely used to determine the cause of failure in engineering structures, especially in product failure and the practice of forensic engineering or failure analysis...

- Shock (mechanics)Shock (mechanics)A mechanical or physical shock is a sudden acceleration or deceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation....

- Thermo-mechanical fatigueThermo-Mechanical FatigueThermo-mechanical fatigue is the overlay of a cyclical mechanical loading, that leads to fatigue of a material, with a cyclical thermal loading...

- VibrationVibrationVibration refers to mechanical oscillations about an equilibrium point. The oscillations may be periodic such as the motion of a pendulum or random such as the movement of a tire on a gravel road.Vibration is occasionally "desirable"...

Further reading

- Andrew, W. (1995) Fatigue and Tribological Properties of Plastics and Elastomers, ISBN 1-884207-15-4

- Dieter, G. E. (1988) Mechanical Metallurgy, ISBN 0-07-100406-8

- Little, R. E. & Jebe, E. H. (1975) Statistical design of fatigue experiments ISBN 0-470-54115-6

- A. G. Palmgren (1924): Die Lebensdauer von Kugellagern (Life Length of Roller Bearings. In German). Zeitschrift des Vereines Deutscher Ingenieure (VDI Zeitschrift), ISSN 0341-7258, Vol 68, No 14, April 1924, pp 339–341.

- Subra Suresh, Fatigue of Materials, Second Edition, Cambridge University Press, 1998, ISBN 0-521-57046-8.