Composite material

Encyclopedia

Materials science

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

or naturally occurring material

Material

Material is anything made of matter, constituted of one or more substances. Wood, cement, hydrogen, air and water are all examples of materials. Sometimes the term "material" is used more narrowly to refer to substances or components with certain physical properties that are used as inputs to...

s made from two or more constituent materials with significantly different physical

Physical property

A physical property is any property that is measurable whose value describes a physical system's state. The changes in the physical properties of a system can be used to describe its transformations ....

or chemical properties

Chemical property

A chemical property is any of a material's properties that becomes evident during a chemical reaction; that is, any quality that can be established only by changing a substance's chemical identity...

which remain separate and distinct at the macroscopic or microscopic scale within the finished structure.

A common example of a composite would be disc brake

Disc brake

The disc brake or disk brake is a device for slowing or stopping the rotation of a wheel while it is in motion.A brake disc is usually made of cast iron, but may in some cases be made of composites such as reinforced carbon–carbon or ceramic matrix composites. This is connected to the wheel and/or...

pads, which consists of hard ceramic particles embedded in soft metal matrix. Another example is found in shower

Shower

A shower is an area in which one bathes underneath a spray of water.- History :...

stalls and bathtub

Bathtub

A bath , bathtub , or tub is a large container for holding water in which a person may bathe . Most modern bathtubs are made of acrylic or fiberglass, but alternatives are available in enamel over steel or cast iron, and occasionally waterproof finished wood...

s which are made of fibreglass. Imitation granite

Granite

Granite is a common and widely occurring type of intrusive, felsic, igneous rock. Granite usually has a medium- to coarse-grained texture. Occasionally some individual crystals are larger than the groundmass, in which case the texture is known as porphyritic. A granitic rock with a porphyritic...

and cultured marble sink

Sink

A sink is a bowl-shaped plumbing fixture used for washing hands, for dishwashing or other purposes. Sinks generally have taps that supply hot and cold water and may include a spray feature to be used for faster rinsing...

s and countertops are also widely used. The most advanced examples perform routinely on spacecraft in demanding environments.

Wattle and daub

Wattle and daub

Wattle and daub is a composite building material used for making walls, in which a woven lattice of wooden strips called wattle is daubed with a sticky material usually made of some combination of wet soil, clay, sand, animal dung and straw...

is one of the oldest manmade composite materials, at over 6000 years old. Concrete

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

is also a composite material, and is used more than any other man-made material in the world. As of 2006, about 7.5 billion cubic metres of concrete are made each year—more than one cubic metre for every person on Earth.

Composition

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

is a natural composite of Cellulose fibres in a matrix

Matrix (biology)

In biology, matrix is the material between animal or plant cells, in which more specialized structures are embedded, and a specific part of the mitochondrion that is the site of oxidation of organic molecules. The internal structure of connective tissues is an extracellular matrix...

of lignin

Lignin

Lignin or lignen is a complex chemical compound most commonly derived from wood, and an integral part of the secondary cell walls of plants and some algae. The term was introduced in 1819 by de Candolle and is derived from the Latin word lignum, meaning wood...

. The earliest man-made

Artificial

See also: Synthetic ' or ' may refer to:* Artificial beaches* Artificial chemistry* Artificial consciousness* Artificial creation* Artificial elements* Artificial flower* Artificial food* Artificial fuel* Artificial harmonic...

composite materials were straw

Straw

Straw is an agricultural by-product, the dry stalks of cereal plants, after the grain and chaff have been removed. Straw makes up about half of the yield of cereal crops such as barley, oats, rice, rye and wheat. It has many uses, including fuel, livestock bedding and fodder, thatching and...

and mud

Mud

Mud is a mixture of water and some combination of soil, silt, and clay. Ancient mud deposits harden over geological time to form sedimentary rock such as shale or mudstone . When geological deposits of mud are formed in estuaries the resultant layers are termed bay muds...

combined to form brick

Brick

A brick is a block of ceramic material used in masonry construction, usually laid using various kinds of mortar. It has been regarded as one of the longest lasting and strongest building materials used throughout history.-History:...

s for building

Building

In architecture, construction, engineering, real estate development and technology the word building may refer to one of the following:...

construction

Construction

In the fields of architecture and civil engineering, construction is a process that consists of the building or assembling of infrastructure. Far from being a single activity, large scale construction is a feat of human multitasking...

. The ancient brick-making process can still be seen on Egyptian tomb paintings in the Metropolitan Museum of Art

Metropolitan Museum of Art

The Metropolitan Museum of Art is a renowned art museum in New York City. Its permanent collection contains more than two million works, divided into nineteen curatorial departments. The main building, located on the eastern edge of Central Park along Manhattan's Museum Mile, is one of the...

.

Composites are made up of individual materials referred to as constituent materials. There are two categories of constituent materials: matrix and reinforcement. At least one portion of each type is required. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special mechanical and physical properties to enhance the matrix properties. A synergism produces material properties unavailable from the individual constituent materials, while the wide variety of matrix and strengthening materials allows the designer of the product or structure to choose an optimum combination.

Engineered composite materials must be formed to shape. The matrix material can be introduced to the reinforcement before or after the reinforcement material is placed into the mould

Molding (process)

Molding or moulding is the process of manufacturing by shaping pliable raw material using a rigid frame or model called a pattern....

cavity or onto the mould surface. The matrix material experiences a melding event, after which the part shape is essentially set. Depending upon the nature of the matrix material, this melding event can occur in various ways such as chemical polymerization

Polymerization

In polymer chemistry, polymerization is a process of reacting monomer molecules together in a chemical reaction to form three-dimensional networks or polymer chains...

or solidification from the melted state.

A variety of moulding methods can be used according to the end-item design requirements. The principal factors impacting the methodology are the natures of the chosen matrix and reinforcement materials. Another important factor is the gross quantity of material to be produced. Large quantities can be used to justify high capital expenditures for rapid and automated manufacturing technology. Small production quantities are accommodated with lower capital expenditures but higher labour and tooling costs at a correspondingly slower rate.

Most commercially produced composites use a polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

matrix material often called a resin solution. There are many different polymers available depending upon the starting raw ingredients. There are several broad categories, each with numerous variations. The most common are known as polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

, vinyl ester, epoxy

Epoxy

Epoxy, also known as polyepoxide, is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives....

, phenolic, polyimide

Polyimide

Polyimide is a polymer of imide monomers. The structure of imide is as shown. Polyimides have been in mass production since 1955...

, polyamide

Polyamide

A polyamide is a polymer containing monomers of amides joined by peptide bonds. They can occur both naturally and artificially, examples being proteins, such as wool and silk, and can be made artificially through step-growth polymerization or solid-phase synthesis, examples being nylons, aramids,...

, polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

, PEEK

PEEK

Polyether ether ketone is a colourless organic polymer thermoplastic used in engineering applications.-Synthesis:PEEK polymers are obtained by step-growth polymerization by the dialkylation of bisphenolate salts. Typical is the reaction of 4,4'-difluorobenzophenone with the disodium salt of...

, and others. The reinforcement materials are often fibres but also commonly ground minerals. The various methods described below have been developed to reduce the resin content of the final product, or the fibre content is increased. As a rule of thumb, lay up results in a product containing 60% resin and 40% fibre, whereas vacuum infusion gives a final product with 40% resin and 60% fibre content. The strength of the product is greatly dependent on this ratio.

Moulding methods

In general, the reinforcing and matrix materials are combined, compacted and processed to undergo a melding event. After the melding event, the part shape is essentially set, although it can deform under certain process conditions. For a thermoset polymeric matrix material, the melding event is a curing reaction that is initiated by the application of additional heat or chemical reactivity such as an organic peroxide. For a thermoplastic polymeric matrix material, the melding event is a solidification from the melted state. For a metal matrix material such as titanium foil, the melding event is a fusing at high pressure and a temperature near the melt point.For many moulding methods, it is convenient to refer to one mould piece as a "lower" mould and another mould piece as an "upper" mould. Lower and upper refer to the different faces of the moulded panel, not the mould's configuration in space. In this convention, there is always a lower mould, and sometimes an upper mould. Part construction begins by applying materials to the lower mould. Lower mould and upper mould are more generalized descriptors than more common and specific terms such as male side, female side, a-side, b-side, tool side, bowl, hat, mandrel, etc. Continuous manufacturing processes use a different nomenclature.

The moulded product is often referred to as a panel. For certain geometries and material combinations, it can be referred to as a casting. For certain continuous processes, it can be referred to as a profile. Applied with a pressure roller, a spray device or manually. This process is generally done at ambient temperature and atmospheric pressure

Atmospheric pressure

Atmospheric pressure is the force per unit area exerted into a surface by the weight of air above that surface in the atmosphere of Earth . In most circumstances atmospheric pressure is closely approximated by the hydrostatic pressure caused by the weight of air above the measurement point...

. Two variations of open moulding are Hand Layup and Spray-up.

A process using a two-sided mould set that shapes both surfaces of the panel. On the lower side is a rigid mould and on the upper side is a flexible membrane or vacuum bag. The flexible membrane can be a reusable silicone material or an extruded polymer film. Then, vacuum is applied to the mould cavity. This process can be performed at either ambient or elevated temperature with ambient atmospheric pressure acting upon the vacuum bag. Most economical way is using a venturi vacuum

Aspirator

An aspirator, also called an eductor-jet pump or filter pump, is a device that produces vacuum by means of the Venturi effect. In an aspirator, fluid flows through a tube which then narrows. When the tube narrows, the fluid's speed increases, and because of the Venturi effect, its pressure...

and air compressor or a vacuum pump.

A vacuum bag is a bag made of strong rubber

Rubber

Natural rubber, also called India rubber or caoutchouc, is an elastomer that was originally derived from latex, a milky colloid produced by some plants. The plants would be ‘tapped’, that is, an incision made into the bark of the tree and the sticky, milk colored latex sap collected and refined...

-coated fabric

Fabric

A fabric is a textile material, short for "textile fabric".Fabric may also refer to:*Fabric , the spatial and geometric configuration of elements within a rock*Fabric , a nightclub in London, England...

or a polymer film used to bond

Bond

Bond, bonds, bonded, and bonding may refer to:* Peace-bonding, something which makes a weapon unusable as a weapon- Fiduciary :* Bond , in finance, a type of debt security...

or laminate

Laminate

A laminate is a material that can be constructed by uniting two or more layers of material together. The process of creating a laminate is lamination, which in common parlance refers to the placing of something between layers of plastic and gluing them with heat and/or pressure, usually with an...

materials. In some applications the bag encloses the entire material, or in other applications a mold

Mold

Molds are fungi that grow in the form of multicellular filaments called hyphae. Molds are not considered to be microbes but microscopic fungi that grow as single cells called yeasts...

is used to form one face of the laminate with the bag being single sided to seal the outer face of the laminate to the mold. The open end is sealed and the air is drawn out of the bag through a nipple using a vacuum pump

Vacuum pump

A vacuum pump is a device that removes gas molecules from a sealed volume in order to leave behind a partial vacuum. The first vacuum pump was invented in 1650 by Otto von Guericke.- Types :Pumps can be broadly categorized according to three techniques:...

. As a result, uniform pressure approaching one atmosphere

Atmosphere (unit)

The standard atmosphere is an international reference pressure defined as 101325 Pa and formerly used as unit of pressure. For practical purposes it has been replaced by the bar which is 105 Pa...

is applied to the surfaces of the object inside the bag, holding parts together while the adhesive

Adhesive

An adhesive, or glue, is a mixture in a liquid or semi-liquid state that adheres or bonds items together. Adhesives may come from either natural or synthetic sources. The types of materials that can be bonded are vast but they are especially useful for bonding thin materials...

cures

Curing (chemistry)

Curing is a term in polymer chemistry and process engineering that refers to the toughening or hardening of a polymer material by cross-linking of polymer chains, brought about by chemical additives, ultraviolet radiation, electron beam or heat...

. The entire bag may be placed in a temperature-controlled oven, oil bath or water bath and gently heated to accelerate curing.

In commercial woodworking facilities vacuum bags are used to laminate curved and irregular shaped workpieces.

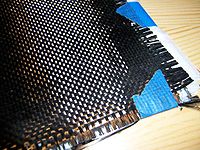

Vacuum bagging is widely used in the composites industry as well. Carbon fiber fabric and fiberglass, along with resins and epoxies are common materials laminated together with a vacuum bag operation.

Typically, polyurethane or vinyl materials are used to make the bag, which is commonly open at both ends. This gives access to the piece, or pieces to be glued. A plastic rod is laid onto the bag, which is then folded over the rod. A plastic sleeve with an opening in it, is then snapped over the rod. This procedure forms a seal at both ends of the bag, when the vacuum is ready to be drawn.

A "platen" is used inside the bag for the piece being glued to lay on. The platen has a series of small slots cut into it, to allow the air under it to be evacuated. The platen must have rounded edges and corners to prevent the vacuum from tearing the bag.

When a curved part is to be glued in a vacuum bag, it is important that the pieces being glued be placed over a solidly built form, or have an air bladder placed under the form. This air bladder has access to "free air" outside the bag. It is used to create an equal pressure under the form, preventing it from being crushed.

Pressure bag moulding

This process is related to vacuum bag moulding in exactly the same way as it sounds. A solid female mould is used along with a flexible male mould. The reinforcement is placed inside the female mould with just enough resin to allow the fabric to stick in place (wet lay up). A measured amount of resin is then liberally brushed indiscriminately into the mould and the mould is then clamped to a machine that contains the male flexible mould. The flexible male membrane is then inflated with heated compressed air or possibly steam. The female mould can also be heated. Excess resin is forced out along with trapped air. This process is extensively used in the production of composite helmets due to the lower cost of unskilled labor. Cycle times for a helmet bag moulding machine vary from 20 to 45 minutes, but the finished shells require no further curing if the moulds are heated.Autoclave moulding

A process using a two-sided mould set that forms both surfaces of the panel. On the lower side is a rigid mould and on the upper side is a flexible membrane made from silicone or an extruded polymer film such as nylon. Reinforcement materials can be placed manually or robotically. They include continuous fibre forms fashioned into textile constructions. Most often, they are pre-impregnated with the resin in the form of prepreg fabrics or unidirectional tapes. In some instances, a resin film is placed upon the lower mould and dry reinforcement is placed above. The upper mould is installed and vacuum is applied to the mould cavity. The assembly is placed into an autoclaveAutoclave (industrial)

Industrial autoclaves are pressure vessels used to process parts and materials which require exposure to elevated pressure and temperature. The manufacture of high-performance components from advanced composites often requires autoclave processing....

. This process is generally performed at both elevated pressure and elevated temperature. The use of elevated pressure facilitates a high fibre volume fraction and low void content for maximum structural efficiency.

Resin transfer moulding (RTM)

A process using a two-sided mould set that forms both surfaces of the panel. The lower side is a rigid mould. The upper side can be a rigid or flexible mould. Flexible moulds can be made from composite materials, silicone or extruded polymer films such as nylon. The two sides fit together to produce a mould cavity. The distinguishing feature of resin transfer moulding is that the reinforcement materials are placed into this cavity and the mould set is closed prior to the introduction of matrix material. Resin transfer moulding includes numerous varieties which differ in the mechanics of how the resin is introduced to the reinforcement in the mould cavity. These variations include everything from vacuum infusion (for resin infusion see also boat buildingBoat building

Boat building, one of the oldest branches of engineering, is concerned with constructing the hulls of boats and, for sailboats, the masts, spars and rigging.-Parts:* Bow - the front and generally sharp end of the hull...

) to vacuum assisted resin transfer moulding (VARTM). This process can be performed at either ambient or elevated temperature.

Other

Other types of moulding include press moulding, transfer moulding, pultrusionPultrusion

Pultrusion is a continuous process for manufacture of composite materials with constant cross-section. Reinforced fibers are pulled through a resin, possibly followed by a separate preforming system, and into a heated die, where the resin undergoes polymerization...

moulding, filament winding

Filament winding

Filament winding is a fabrication technique for manufacturing composite material, usually in the form of cylindrical structures. The process involves winding filaments under varying amounts of tension over a male mould or mandrel. The mandrel rotates while a carriage moves horizontally, laying...

, casting

Casting

In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process...

, centrifugal casting and continuous casting

Continuous casting

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form...

. There are also forming capabilities including CNC filament winding, vacuum infusion, wet lay-up, compression moulding, and thermoplastic

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

moulding, to name a few. The use of curing ovens and paint booths is also needed for some projects.

Tooling

Some types of tooling materials used in the manufacturing of composites structures include invarInvar

Invar, also known generically as FeNi36 , is a nickel steel alloy notable for its uniquely low coefficient of thermal expansion . The name, Invar, comes from the word invariable, referring to its lack of expansion or contraction with temperature changes.It was invented in 1896 by Swiss scientist...

, steel, aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

, reinforced silicone rubber

Silicone rubber

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations...

, nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

, and carbon fiber

Carbon fiber

Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber...

. Selection of the tooling material is typically based on, but not limited to, the coefficient of thermal expansion, expected number of cycles, end item tolerance, desired or required surface condition, method of cure, glass transition temperature of the material being moulded, moulding method, matrix, cost and a variety of other considerations.

Mechanics

The physical properties of composite materials are generally not isotropic (independent of direction of applied force) in nature, but rather are typically anisotropic (different depending on the direction of the applied force or load). For instance, the stiffness of a composite panel will often depend upon the orientation of the applied forces and/or moments. Panel stiffness is also dependent on the design of the panel. For instance, the fibre reinforcement and matrix used, the method of panel build, thermoset versus thermoplastic, type of weave, and orientation of fibre axis to the primary force.In contrast, isotropic materials (for example, aluminium or steel), in standard wrought forms, typically have the same stiffness regardless of the directional orientation of the applied forces and/or moments.

The relationship between forces/moments and strains/curvatures for an isotropic material can be described with the following material properties: Young's Modulus

Young's modulus

Young's modulus is a measure of the stiffness of an elastic material and is a quantity used to characterize materials. It is defined as the ratio of the uniaxial stress over the uniaxial strain in the range of stress in which Hooke's Law holds. In solid mechanics, the slope of the stress-strain...

, the shear Modulus and the Poisson's ratio

Poisson's ratio

Poisson's ratio , named after Siméon Poisson, is the ratio, when a sample object is stretched, of the contraction or transverse strain , to the extension or axial strain ....

, in relatively simple mathematical relationships. For the anisotropic material, it requires the mathematics of a second order tensor and up to 21 material property constants. For the special case of orthogonal isotropy, there are three different material property constants for each of Young's Modulus, Shear Modulus and Poisson's ratio—a total of 9 constants to describe the relationship between forces/moments and strains/curvatures.

Techniques that take advantage of the anisotropic properties of the materials include mortise and tenon

Mortise and tenon

The mortise and tenon joint has been used for thousands of years by woodworkers around the world to join pieces of wood, mainly when the adjoining pieces connect at an angle of 90°. In its basic form it is both simple and strong. Although there are many joint variations, the basic mortise and tenon...

joints (in natural composites such as wood) and Pi Joints in synthetic composites.

Resins

Typically, most common composite materials, including fiberglass, carbon fiber, and KevlarKevlar

Kevlar is the registered trademark for a para-aramid synthetic fiber, related to other aramids such as Nomex and Technora. Developed at DuPont in 1965, this high strength material was first commercially used in the early 1970s as a replacement for steel in racing tires...

, include at least two parts, the substrate and the resin.

Polyester resin tends to have yellowish tint, and is suitable for most backyard projects. Its weaknesses are that it is UV sensitive and can tend to degrade over time, and thus generally is also coated to help preserve it. It is often used in the making of surfboards and for marine applications. Its hardener is a MEKP, and is mixed at 14 drops per oz. MEKP is composed of methyl ethyl ketone peroxide, a catalyst. When MEKP is mixed with the resin, the resulting chemical reaction causes heat to build up and cure or harden the resin.

Vinylester resin tends to have a purplish to bluish to greenish tint. This resin has lower viscosity than polyester resin, and is more transparent. This resin is often billed as being fuel resistant, but will melt in contact with gasoline. This resin tends to be more resistant over time to degradation than polyester resin, and is more flexible. It uses the same hardener as polyester resin (at the same mix ratio) and the cost is approximately the same.

Epoxy resin is almost totally transparent when cured. In the aerospace industry, epoxy is used as a structural matrix material or as a structural glue.

Shape memory polymer

Shape Memory Polymer

Shape-memory polymers are polymeric smart materials that have the ability to return from a deformed state to their original shape induced by an external stimulus , such as temperature change....

(SMP) resins have varying visual characteristics depending on their formulation. These resins may be epoxy-based, which can be used for auto body and outdoor equipment repairs; cyanate-ester-based, which are used in space applications; and acrylate-based, which can be used in very cold temperature applications, such as for sensors that indicate whether perishable goods have warmed above a certain maximum temperature. These resins are unique in that their shape can be repeatedly changed by heating above their glass transition

Glass transition

The liquid-glass transition is the reversible transition in amorphous materials from a hard and relatively brittle state into a molten or rubber-like state. An amorphous solid that exhibits a glass transition is called a glass...

temperature (Tg). When heated, they become flexible and elastic, allowing for easy configuration. Once they are cooled, they will maintain their new shape. The resins will return to their original shapes when they are reheated above their Tg. The advantage of shape memory polymer resins is that they can be shaped and reshaped repeatedly without losing their material properties, and these resins can be used in fabricating shape memory composites.

Categories of fiber-reinforced composite materials

FiberFiber

Fiber is a class of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together....

-reinforced composite materials can be divided into two main categories normally referred to as short fiber-reinforced materials

Short Fiber Reinforced Blends

Short Fiber Reinforced Blends are partial case of ternary composites, i.e. composites prepared of three ingredients. In particular they can be considered as a combination of an immiscible polymer blend and a short fiber reinforced composite...

and continuous fiber-reinforced materials. Continuous reinforced materials will often constitute a layered or laminated structure. The woven and continuous fibre styles are typically available in a variety of forms, being pre-impregnated with the given matrix (resin), dry, uni-directional tapes of various widths, plain weave, harness satins, braided, and stitched.

The short and long fibers are typically employed in compression moulding and sheet moulding operations. These come in the form of flakes, chips, and random mate (which can also be made from a continuous fibre laid in random fashion until the desired thickness of the ply / laminate is achieved).

Failure

Shock, impact, or repeated cyclic stresses can cause the laminate to separate at the interface between two layers, a condition known as delaminationDelamination

Delamination is a mode of failure for composite materials. Modes of failure are also known as 'failure mechanisms'. In laminated materials, repeated cyclic stresses, impact, and so on can cause layers to separate, forming a mica-like structure of separate layers, with significant loss of mechanical...

. Individual fibres can separate from the matrix e.g. fibre pull-out

Fiber pull-out

Fiber pull-out is one of the failure mechanisms in fiber-reinforced composite materials. Other forms of failure include delamination, intralaminar matrix cracking, longitudinal matrix splitting, fiber/matrix debonding, and fiber fracture...

.

Composites can fail on the microscopic

Microscopic

The microscopic scale is the scale of size or length used to describe objects smaller than those that can easily be seen by the naked eye and which require a lens or microscope to see them clearly.-History:...

or macroscopic

Macroscopic

The macroscopic scale is the length scale on which objects or processes are of a size which is measurable and observable by the naked eye.When applied to phenomena and abstract objects, the macroscopic scale describes existence in the world as we perceive it, often in contrast to experiences or...

scale. Compression failures can occur at both the macro scale or at each individual reinforcing fibre in compression buckling. Tension failures can be net section failures of the part or degradation of the composite at a microscopic scale where one or more of the layers in the composite fail in tension of the matrix or failure the bond between the matrix and fibres.

Some composites are brittle and have little reserve strength beyond the initial onset of failure while others may have large deformations and have reserve energy absorbing capacity past the onset of damage. The variations in fibres and matrices that are available and the mixture

Mixture

In chemistry, a mixture is a material system made up by two or more different substances which are mixed together but are not combined chemically...

s that can be made with blends leave a very broad range of properties that can be designed into a composite structure.

The best known failure of a brittle ceramic matrix composite occurred when the carbon-carbon composite tile on the leading edge of the wing of the Space Shuttle Columbia

Space Shuttle Columbia

Space Shuttle Columbia was the first spaceworthy Space Shuttle in NASA's orbital fleet. First launched on the STS-1 mission, the first of the Space Shuttle program, it completed 27 missions before being destroyed during re-entry on February 1, 2003 near the end of its 28th, STS-107. All seven crew...

fractured when impacted during take-off. It led to catastrophic break-up of the vehicle when it re-entered the Earth's atmosphere on 1 February 2003.

Compared to metals, composites have relatively poor bearing strength.

Testing

To aid in predicting and preventing failures, composites are tested before and after construction. Pre-construction testing may use finite element analysis (FEA) for ply-by-ply analysis of curved surfaces and predicting wrinkling, crimping and dimpling of composites. Materials may be tested after construction through several nondestructiveNondestructive testing

Nondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

methods including ultrasonics, thermography, shearography and X-ray radiography

Materials

Fibre-reinforced polymersFibre-reinforced plastic

Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually fibreglass, carbon, or aramid, while the polymer is usually an epoxy, vinylester or polyester thermosetting plastic...

or FRPs include wood (comprising cellulose fibres in a lignin and hemicellulose

Hemicellulose

A hemicellulose is any of several heteropolymers , such as arabinoxylans, present along with cellulose in almost all plant cell walls. While cellulose is crystalline, strong, and resistant to hydrolysis, hemicellulose has a random, amorphous structure with little strength...

matrix), carbon-fibre reinforced plastic or CFRP, and glass-reinforced plastic

Glass-reinforced plastic

Fiberglass , is a fiber reinforced polymer made of a plastic matrix reinforced by fine fibers of glass. It is also known as GFK ....

or GRP. If classified by matrix then there are thermoplastic composites, short fibre thermoplastics, long fibre thermoplastics or long fibre-reinforced thermoplastics. There are numerous thermoset composites, but advanced systems usually incorporate aramid

Aramid

Aramid fibers are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic rated body armor fabric and ballistic composites, in bicycle tires, and as an asbestos substitute. The name is a portmanteau of "aromatic polyamide"...

fibre and carbon fibre in an epoxy resin matrix.

Shape memory polymer composites are high-performance composites, formulated using fibre or fabric reinforcement and shape memory polymer resin as the matrix. Since a shape memory polymer resin is used as the matrix, these composites have the ability to be easily manipulated into various configurations when they are heated above their activation temperatures and will exhibit high strength and stiffness at lower temperatures. They can also be reheated and reshaped repeatedly without losing their material properties. These composites are ideal for applications such as lightweight, rigid, deployable structures; rapid manufacturing; and dynamic reinforcement.

Concrete

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

is probably the most common artificial composite material of all and typically consists of loose stones (aggregate) held with a matrix of cement

Cement

In the most general sense of the word, a cement is a binder, a substance that sets and hardens independently, and can bind other materials together. The word "cement" traces to the Romans, who used the term opus caementicium to describe masonry resembling modern concrete that was made from crushed...

. Concrete is a very robust material, much more robust than cement, however concrete cannot survive tensile loading. Therefore metal cables are often added to tension the concrete to form reinforced concrete

Reinforced concrete

Reinforced concrete is concrete in which reinforcement bars , reinforcement grids, plates or fibers have been incorporated to strengthen the concrete in tension. It was invented by French gardener Joseph Monier in 1849 and patented in 1867. The term Ferro Concrete refers only to concrete that is...

.

Composites can also use metal fibres reinforcing other metals, as in metal matrix composite

Metal matrix composite

A metal matrix composite is composite material with at least two constituent parts, one being a metal. The other material may be a different metal or another material, such as a ceramic or organic compound. When at least three materials are present, it is called a hybrid composite...

s or MMC. The benefit of magnesium is that it does not degrade in outer space. Ceramic matrix composites include bone

Bone

Bones are rigid organs that constitute part of the endoskeleton of vertebrates. They support, and protect the various organs of the body, produce red and white blood cells and store minerals. Bone tissue is a type of dense connective tissue...

(hydroxyapatite reinforced with collagen

Collagen

Collagen is a group of naturally occurring proteins found in animals, especially in the flesh and connective tissues of mammals. It is the main component of connective tissue, and is the most abundant protein in mammals, making up about 25% to 35% of the whole-body protein content...

fibres), Cermet

Cermet

A cermet is a composite material composed of ceramic and metallic materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used...

(ceramic and metal) and concrete

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

. Ceramic matrix composites

Ceramic Matrix Composite

Ceramic matrix composites are a subgroup of composite materials as well as a subgroup of technical ceramics. They consist of ceramic fibers embedded in a ceramic matrix, thus forming a ceramic fiber reinforced ceramic material...

are built primarily for fracture toughness

Fracture toughness

In materials science, fracture toughness is a property which describes the ability of a material containing a crack to resist fracture, and is one of the most important properties of any material for virtually all design applications. The fracture toughness of a material is determined from the...

, not for strength.

Organic matrix/ceramic aggregate composites include asphalt concrete, mastic asphalt, mastic roller hybrid, dental composite

Dental composite

Dental composite resins are types of synthetic resins which are used in dentistry as restorative material or adhesives. Synthetic resins evolved as restorative materials since they were insoluble, aesthetic, insensitive to dehydration, easy to manipulate and reasonably inexpensive...

, syntactic foam

Syntactic foam

Syntactic foams are composite materials synthesized by filling a metal, polymer or ceramic matrix with hollow particles called microballoons, "syntactic" meaning "put together"...

and mother of pearl

Nacre

Nacre , also known as mother of pearl, is an organic-inorganic composite material produced by some mollusks as an inner shell layer; it is also what makes up pearls. It is very strong, resilient, and iridescent....

. Chobham armour

Chobham armour

Chobham armour is the name informally given to a composite armour developed in the 1960s at the British tank research centre on Chobham Common, Surrey, England...

is a special type of composite armour

Composite armour

Composite armour is a type of vehicle armour consisting of layers of different material such as metals, plastics, ceramics or air. Most composite armour are lighter than their all-metal equivalent, but instead occupy a larger volume for the same resistance to penetration...

used in military applications.

Additionally, thermoplastic composite materials can be formulated with specific metal powders resulting in materials with a density range from 2 g/cm³ to 11 g/cm³ (same density as lead). The most common name for this type of material is High Gravity Compound (HGC), although Lead Replacement is also used. These materials can be used in place of traditional materials such as aluminium, stainless steel, brass, bronze, copper, lead, and even tungsten in weighting, balancing (for example, modifying the centre of gravity of a tennis racquet

Racquet

A racquet or racket is a sports implement consisting of a handled frame with an open hoop across which a network of cord is stretched tightly. It is used for striking a ball in such games as squash, tennis, racquetball, and badminton...

), vibration damping, and radiation shielding applications. High density composites are an economically viable option when certain materials are deemed hazardous and are banned (such as lead) or when secondary operations costs (such as machining, finishing, or coating) are a factor.

Engineered wood

Engineered wood

Engineered wood, also called composite wood, man-made wood, or manufactured board; includes a range of derivative wood products which are manufactured by binding the strands, particles, fibers, or veneers of wood, together with adhesives, to form composite materials...

includes a wide variety of different products such as wood fibre board, plywood

Plywood

Plywood is a type of manufactured timber made from thin sheets of wood veneer. It is one of the most widely used wood products. It is flexible, inexpensive, workable, re-usable, and can usually be locally manufactured...

, oriented strand board

Oriented strand board

Oriented strand board, also known as OSB and SmartPly , is an engineered wood product formed by layering strands of wood in specific orientations. In appearance, it may have a rough and variegated surface with the individual strips Oriented strand board, also known as OSB (UK) and SmartPly (UK &...

, wood plastic composite (recycled wood fibre in polyethylene matrix), Pykrete

Pykrete

Pykrete is a composite material made of approximately 14 percent sawdust or some other form of wood pulp and 86 percent ice by weight. Its use was proposed during World War II by Geoffrey Pyke to the British Royal Navy as a candidate material for making a huge, unsinkable aircraft carrier...

(sawdust in ice matrix), Plastic-impregnated or laminated paper or textiles, Arborite

Arborite

Arborite is a brand of composite material manufactured by the Arborite Company, founded in Canada in 1948 after the initial development of the product in 1942 by Howard Smith Paper Mills....

, Formica (plastic)

Formica (plastic)

Formica is a brand of composite materials manufactured by the Formica Corporation now based in Newcastle, Tyne & Wear, a division of the New Zealand company Fletcher Building. In common use, the term refers to the company's classic product, a heat-resistant, wipe-clean, plastic laminate of paper or...

and Micarta

Micarta

Micarta is a trademark of Norplex-Micarta industrial high pressure laminates and refers to a composite of linen, canvas, paper, fiberglass, carbon fiber or other fabric in a thermosetting plastic, originally used in electrical and decorative Koekjes applications. Micarta was developed by George...

. Other engineered laminate composites, such as Mallite

Mallite

Mallite is a type of laminate composite material, formerly manufactured by the William Mallinson & Sons company. The material is formed of a core sheet of end grain balsa wood, faced by duralumin sheets. This construction endows the finished material with greater strength and rigidity than a light...

, use a central core of end grain balsa wood, bonded to surface skins of light alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

or GRP. These generate low-weight, high rigidity materials.

Products

Fiber-reinforced composite materials have gained popularity (despite their generally high cost) in high-performance products that need to be lightweight, yet strong enough to take harsh loading conditions such as aerospaceAerospace

Aerospace comprises the atmosphere of Earth and surrounding space. Typically the term is used to refer to the industry that researches, designs, manufactures, operates, and maintains vehicles moving through air and space...

components (tail

Empennage

The empennage , also known as the tail or tail assembly, of most aircraft gives stability to the aircraft, in a similar way to the feathers on an arrow...

s, wing

Wing

A wing is an appendage with a surface that produces lift for flight or propulsion through the atmosphere, or through another gaseous or liquid fluid...

s, fuselage

Fuselage

The fuselage is an aircraft's main body section that holds crew and passengers or cargo. In single-engine aircraft it will usually contain an engine, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage which in turn is used as a floating hull...

s, propeller

Propeller (aircraft)

Aircraft propellers or airscrews convert rotary motion from piston engines or turboprops to provide propulsive force. They may be fixed or variable pitch. Early aircraft propellers were carved by hand from solid or laminated wood with later propellers being constructed from metal...

s), boat and scull hulls, bicycle

Bicycle

A bicycle, also known as a bike, pushbike or cycle, is a human-powered, pedal-driven, single-track vehicle, having two wheels attached to a frame, one behind the other. A person who rides a bicycle is called a cyclist, or bicyclist....

frames and racing car bodies. Other uses include fishing rod

Fishing rod

A fishing rod or a fishing pole is a tool used to catch fish, usually in conjunction with the pastime of angling, and can also be used in competition casting. . A length of fishing line is attached to a long, flexible rod or pole: one end terminates in a hook for catching the fish...

s, storage tank

Storage tank

A storage tank is a container, usually for holding liquids, sometimes for compressed gases . The term can be used for reservoirs , and for manufactured containers. The usage of the word tank for reservoirs is common or universal in Indian English, American English and moderately common in British...

s, and baseball bats

Composite baseball bat

Composite baseball bats incorporate a recent advancement in the technology of aluminum baseball bats for high school and collegiate players. In general, composite bats are constructed with the same aluminum exterior as standard aluminum baseball bats, but have a "woven" graphite wall on the inside...

. The new Boeing 787

Boeing 787

The Boeing 787 Dreamliner is a long-range, mid-size wide-body, twin-engine jet airliner developed by Boeing Commercial Airplanes. It seats 210 to 290 passengers, depending on the variant. Boeing states that it is the company's most fuel-efficient airliner and the world's first major airliner to use...

structure including the wings and fuselage is composed largely of composites. Composite materials are also becoming more common in the realm of orthopedic surgery

Orthopedic surgery

Orthopedic surgery or orthopedics is the branch of surgery concerned with conditions involving the musculoskeletal system...

.

Carbon composite is a key material in today's launch vehicles and heat shield

Heat shield

A heat shield is designed to shield a substance from absorbing excessive heat from an outside source by either dissipating, reflecting or simply absorbing the heat...

s for the re-entry

Re-Entry

"Re-Entry" was the second album released by UK R&B / Hip Hop collective Big Brovaz. After the album was delayed in May 2006, the band finally release the follow-up to "Nu Flow" on 9 April 2007...

phase of spacecraft

Spacecraft

A spacecraft or spaceship is a craft or machine designed for spaceflight. Spacecraft are used for a variety of purposes, including communications, earth observation, meteorology, navigation, planetary exploration and transportation of humans and cargo....

. It is widely used in solar panel substrates, antenna reflectors and yokes of spacecraft. It is also used in payload adapters, inter-stage structures and heat shields of launch vehicle

Launch vehicle

In spaceflight, a launch vehicle or carrier rocket is a rocket used to carry a payload from the Earth's surface into outer space. A launch system includes the launch vehicle, the launch pad and other infrastructure....

s. Furthermore disk brake systems of airplanes and racing cars are using carbon/carbon material, and the composite material

Ceramic Matrix Composite

Ceramic matrix composites are a subgroup of composite materials as well as a subgroup of technical ceramics. They consist of ceramic fibers embedded in a ceramic matrix, thus forming a ceramic fiber reinforced ceramic material...

with carbon fiber

Carbon fiber

Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber...

s and silicon carbide

Silicon carbide

Silicon carbide , also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive...

matrix has been introduced in luxury vehicles and sports car

Sports car

A sports car is a small, usually two seat, two door automobile designed for high speed driving and maneuverability....

s.

In 2007, an all-composite military Humvee was introduced by TPI Composites Inc and Armor Holdings Inc, the first all-composite military vehicle

Military vehicle

A military vehicle is a vehicle that includes all land combat and transportation vehicles, which are designed for or are in significant use by military forces throughout the world. Vehicles that are armored or intended for combat are often referred to as armoured fighting vehicles....

. By using composites the vehicle is lighter, allowing higher payloads. In 2008, carbon fiber and DuPont

DuPont

E. I. du Pont de Nemours and Company , commonly referred to as DuPont, is an American chemical company that was founded in July 1802 as a gunpowder mill by Eleuthère Irénée du Pont. DuPont was the world's third largest chemical company based on market capitalization and ninth based on revenue in 2009...

Kevlar (five times stronger than steel) were combined with enhanced thermoset resins to make military transit cases by ECS Composites creating 30-percent lighter cases with high strength.

Many composite layup designs also include a co-curing or post-curing of the prepreg with various other mediums, such as honeycomb or foam. This is commonly called a sandwich structure

Sandwich structured composite

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core...

. This is a more common layup process for the manufacture of radomes, doors, cowlings, or non-structural parts.

The finishing of the composite parts is also critical in the final design. Many of these finishes will include rain-erosion coatings or polyurethane coatings.

See also

- Aluminium composite panelAluminium composite panelAluminium Composite Panel or Aluminium Composite Material is a widely-used term describing flat panels that consist of a non-aluminium core bonded between two aluminium sheets. Aluminium sheets can be coated with PVDF or Polyester paint...

- American Composites Manufacturers AssociationAmerican Composites Manufacturers AssociationThe American Composites Manufacturers Association is the world's largest trade association serving the composites industry. Its mission is to provide education and information to the composites industry, lobby for the composites industry, and develop and expand markets for composite...

- Chemical vapour infiltration

- Epoxy graniteEpoxy graniteEpoxy granite, also known as synthetic granite, is a mixture of epoxy and granite commonly used as an alternative material for machine tool bases...

- Nanocomposites

- Hybrid materialHybrid materialHybrid materials are composites consisting of two constituents at the nanometer or molecular level. Commonly one of these compounds is inorganic and the other one organic in nature. Thus, they differ form traditional composites where the constituents are at the macroscopic...

Further reading

- Handbook of Polymer Composites for Engineers By Leonard Hollaway Published 1994 Woodhead Publishing

External links

- Composites UK - The official UK trade association with a library of online information about composite materials

- Composite material key concepts

- Distance learning course in polymers and composites

- Composite Sandwich Structure of Minardi F1 Car

- Teaching support materials for the University of Plymouth composites degree