Ceramic engineering

Encyclopedia

Ceramic materials

Ceramic materials

Ceramic materials are inorganic, non-metallic materials and things made from them. They may be crystalline or partly crystalline. They are formed by the action of heat and subsequent cooling...

may have a crystalline or partly crystalline structure, with long-range order on atomic scale. Glass ceramics may have an amorphous or glassy structure, with limited or short-range atomic order. They are either formed from a molten mass that solidifies on cooling, formed and matured by the action of heat, or chemically synthesized at low temperatures using, for example, hydrothermal

Hydrothermal synthesis

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term "hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase...

or sol-gel synthesis.

The special character of ceramic materials gives rise to many applications in materials engineering, electrical engineering

Electrical engineering

Electrical engineering is a field of engineering that generally deals with the study and application of electricity, electronics and electromagnetism. The field first became an identifiable occupation in the late nineteenth century after commercialization of the electric telegraph and electrical...

, chemical engineering

Chemical engineering

Chemical engineering is the branch of engineering that deals with physical science , and life sciences with mathematics and economics, to the process of converting raw materials or chemicals into more useful or valuable forms...

and mechanical engineering

Mechanical engineering

Mechanical engineering is a discipline of engineering that applies the principles of physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the production and usage of heat and mechanical power for the...

. As ceramics are heat resistant, they can be used for many tasks that materials like metal and polymers are unsuitable for. Ceramic materials are used in a wide range of industries, including mining, aerospace, medicine, refinery, food and chemical industries, packaging science, electronics, industrial and transmission electricity, and guided lightwave transmission.

History

The word "ceramicCeramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

" is derived from the Greek

Greek language

Greek is an independent branch of the Indo-European family of languages. Native to the southern Balkans, it has the longest documented history of any Indo-European language, spanning 34 centuries of written records. Its writing system has been the Greek alphabet for the majority of its history;...

word κεραμικός (keramikos) meaning pottery

Pottery

Pottery is the material from which the potteryware is made, of which major types include earthenware, stoneware and porcelain. The place where such wares are made is also called a pottery . Pottery also refers to the art or craft of the potter or the manufacture of pottery...

. It is related to the older Indo-European language root "to burn",

"Ceramic" may be used as a noun in the singular to refer to a ceramic material or the product of ceramic manufacture, or as an adjective. The plural "ceramics" may be used to refer the making of things out of ceramic materials. Ceramic engineering, like many sciences, evolved from a different discipline by today's standards. Materials science engineering is grouped with ceramics engineering to this day.

Abraham Darby first used coke

Coke (fuel)

Coke is the solid carbonaceous material derived from destructive distillation of low-ash, low-sulfur bituminous coal. Cokes from coal are grey, hard, and porous. While coke can be formed naturally, the commonly used form is man-made.- History :...

in 1709 in Shropshire, England, to improve the yield of a smelting process. Coke is now widely used to produce carbide ceramics. Potter Josiah Wedgwood

Josiah Wedgwood

Josiah Wedgwood was an English potter, founder of the Wedgwood company, credited with the industrialization of the manufacture of pottery. A prominent abolitionist, Wedgwood is remembered for his "Am I Not A Man And A Brother?" anti-slavery medallion. He was a member of the Darwin–Wedgwood family...

opened the first modern ceramics factory in Stoke-on-Trent

Stoke-on-Trent

Stoke-on-Trent , also called The Potteries is a city in Staffordshire, England, which forms a linear conurbation almost 12 miles long, with an area of . Together with the Borough of Newcastle-under-Lyme Stoke forms The Potteries Urban Area...

, England, in 1759. Austrian chemist Karl Bayer

Karl Bayer

Karl Josef Bayer was an Austrian chemist who invented the Bayer process of extracting alumina from bauxite, essential to this day to the economical production of aluminium....

, working for the textile industry in Russia, developed a process

Bayer process

The Bayer process is the principal industrial means of refining bauxite to produce alumina .Bauxite, the most important ore of aluminium, contains only 30–54% alumina, Al2O3, the rest being a mixture of silica, various iron oxides, and titanium dioxide. The alumina must be purified before it can...

to separate alumina from bauxite

Bauxite

Bauxite is an aluminium ore and is the main source of aluminium. This form of rock consists mostly of the minerals gibbsite Al3, boehmite γ-AlO, and diaspore α-AlO, in a mixture with the two iron oxides goethite and hematite, the clay mineral kaolinite, and small amounts of anatase TiO2...

ore in 1888. The Bayer process is still used to purify alumina for the ceramic and aluminum industries. Brothers Pierre and Jacques Curie

Pierre Curie

Pierre Curie was a French physicist, a pioneer in crystallography, magnetism, piezoelectricity and radioactivity, and Nobel laureate. He was the son of Dr. Eugène Curie and Sophie-Claire Depouilly Curie ...

discovered piezoelectricity

Piezoelectricity

Piezoelectricity is the charge which accumulates in certain solid materials in response to applied mechanical stress. The word piezoelectricity means electricity resulting from pressure...

in Rochelle salt circa 1880. Piezoelectricity is one of the key properties of electroceramics

Electroceramics

Electroceramics is a class of ceramic materials used primarily for their electrical properties.While ceramics have traditionally been admired and used for their mechanical, thermal and chemical stability, their unique electrical, optical and magnetic properties have become of increasing importance...

.

E.G. Acheson

Edward Goodrich Acheson

Edward Goodrich Acheson was an American chemist. Born in Washington, Pennsylvania, he was the inventor of carborundum, and later a manufacturer of carborundum and graphite. Thomas Edison put him to work on September 12, 1880 at his Menlo Park, New Jersey laboratory under John Kruesi...

heated a mixture of coke and clay

Clay

Clay is a general term including many combinations of one or more clay minerals with traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.- Formation :Clay minerals...

in 1893, and invented carborundum, or synthetic silicon carbide

Silicon carbide

Silicon carbide , also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive...

. Henri Moissan

Henri Moissan

Ferdinand Frederick Henri Moissan was a French chemist who won the 1906 Nobel Prize in Chemistry for his work in isolating fluorine from its compounds.-Biography:...

also synthesized SiC and tungsten carbide

Tungsten carbide

Tungsten carbide is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. Colloquially, tungsten carbide is often simply called carbide. In its most basic form, it is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery,...

in his electric arc furnace

Electric arc furnace

An electric arc furnace is a furnace that heats charged material by means of an electric arc.Arc furnaces range in size from small units of approximately one ton capacity up to about 400 ton units used for secondary steelmaking...

in Paris about the same time as Acheson. Karl Schröter used liquid-phase sintering

Sintering

Sintering is a method used to create objects from powders. It is based on atomic diffusion. Diffusion occurs in any material above absolute zero, but it occurs much faster at higher temperatures. In most sintering processes, the powdered material is held in a mold and then heated to a temperature...

to bond or "cement" Moissan's tungsten carbide particles with cobalt in 1923 in Germany. Cemented (metal-bonded) carbide

Carbide

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by chemical bonding type as follows: salt-like, covalent compounds, interstitial compounds, and "intermediate" transition metal carbides...

edges greatly increase the durability of hardened steel

Hardened steel

The term hardened steel is often used for a medium or high carbon steel that has been given the heat treatments of quenching followed by tempering. The quenching results in the formation of metastable martensite, the fraction of which is reduced to the desired amount during tempering. This is the...

cutting tools. W.H. Nernst

Walther Nernst

Walther Hermann Nernst FRS was a German physical chemist and physicist who is known for his theories behind the calculation of chemical affinity as embodied in the third law of thermodynamics, for which he won the 1920 Nobel Prize in chemistry...

developed cubic-stabilized zirconia

Cubic zirconia

Cubic zirconia is the cubic crystalline form of zirconium dioxide . The synthesized material is hard, optically flawless and usually colorless, but may be made in a variety of different colors. It should not be confused with zircon, which is a zirconium silicate...

in the 1920s in Berlin. This material is used as an oxygen sensor in exhaust systems. The main limitation on the use of ceramics in engineering is brittleness.

Military

Military

A military is an organization authorized by its greater society to use lethal force, usually including use of weapons, in defending its country by combating actual or perceived threats. The military may have additional functions of use to its greater society, such as advancing a political agenda e.g...

requirements of World War II (1939–1945) encouraged developments, which created a need for high-performance materials and helped speed the development of ceramic science and engineering. Throughout the 1960s and 1970s, new types of ceramics were developed in response to advances in atomic energy, electronics, communications, and space travel. The discovery of ceramic superconductors in 1986 has spurred intense research to develop superconducting ceramic parts for electronic devices, electric motors, and transportation equipment.

There is an increasing need in the military sector for high-strength, robust materials which have the capability to transmit light around the visible (0.4–0.7 micrometers) and mid-infrared (1–5 micrometers) regions of the spectrum. These materials are needed for applications requiring transparent armor. Transparent armor is a material or system of materials designed to be optically transparent, yet protect from fragmentation or ballistic impacts. The primary requirement for a transparent armor system is to not only defeat the designated threat but also provide a multi-hit capability with minimized distortion of surrounding areas. Transparent armor windows must also be compatible with night vision equipment. New materials that are thinner, lightweight, and offer better ballistic performance are being sought.

Such solid-state components have found widespread use for various applications in the electro-optical field including: optical fibers for guided lightwave transmission, optical switches, laser amplifiers and lenses

Lens (optics)

A lens is an optical device with perfect or approximate axial symmetry which transmits and refracts light, converging or diverging the beam. A simple lens consists of a single optical element...

, hosts for solid-state lasers and optical window materials for gas lasers, and infrared (IR) heat seeking devices

Infrared homing

Infrared homing refers to a passive missile guidance system which uses the emission from a target of electromagnetic radiation in the infrared part of the spectrum to track and follow it. Missiles which use infrared seeking are often referred to as "heat-seekers", since infrared is just below the...

for missile guidance

Missile guidance

Missile guidance refers to a variety of methods of guiding a missile or a guided bomb to its intended target. The missile's target accuracy is a critical factor for its effectiveness...

systems and IR night vision.

Education

India- Indian Institute Of Technology, Banaras Hindu University, Varanasi

The founder of Banaras Hindu University, Pandit Madan Mohan Malviyaji instituted a course in Ceramic Technology as early as 1924 with the noble objective of advancing glass and ceramic technology in India.

In the Year 1956, Department of Glass Technology and Department of Ceramic Technology were merged to form the Department of Silicate Technology, offering a four year degree course by injecting into its curriculum balanced engineering and scientific contents. In the year 1968 the Department was renamed as Department of Ceramic Engineering. Presently this department is unique in the country which offers B.Tech., M.Tech. and PhD Programmes in the areas of Ceramic Engineering and Technology. The Department has so far produced more than 1000 graduates, 100 postgraduates and 30 PhDs.

The Department is pursuing active research in the emerging areas of glass, glass ceramics, refractories, electronic ceramic, cement and pottery & porcelain. Research papers are being published in reputed national and international journals regularly. Considering the important role that the department of Ceramic Engineering has played, the University Grants Commission has granted funds under ‘Special Assistance and COSIST’ Programmes. Many R& D projects have been sponsored by AICTE, DST, CSIR and UGC. The Department celebrated its Platinum Jubilee during 1999 for 75 years of Ceramic education and organized a ‘National Seminar on Challenges of 21st century’.

Czech Republic

- The Secondary Technical School Of Ceramics was founded in 1872 in Znojmo. In 1922 it moved to Karlovy Vary.

- The Ceramic Technical School At Bechyne was founded in 1884.

Japan - The Ceramic Society of Japan was founded in 1891 in Tokyo.

Germany

- The Ceramic Society Of Germany was founded in Berlin in 1919.

- Staatliche Fachschule fur Porzellan (Government Technical College for Porcelain) was founded in Selb in 1908. In 1973 it was transferred to Nuremberg Polytechnic, when it was incorporated into a professional training organisation for ceramics which also includes the Staatliche Fachschule fur Keramtechnik and a college for block release courses in ceramic trades, testing and laboratory work.

France - the "Ecole Nationale Supérieure de Céramique Industrielle" (ENSCI) funded in Sèvres (Paris) in 1893 and transferred to Limoges in 1979 educate students in engineered and traditionnal ceramic, glass and cement fields. This school proposes exchange programs with other European and International schools like Alfred University.

Poland – the Bunzlau Ceramic Technical College operated from 1887 to 1945.

Spain

- The ‘Official Ceramic School’ open in Madrid in 1911.

- The Ceramic School Of Manises – was founded in 1914.

United States - the first ceramic engineering course and department in the USA were established by Edward Orton, Jr.

Edward Orton, Jr.

Edward Orton, Jr. was a prominent Columbus philanthropist and businessman.-Early years:...

, a professor of geology and mining engineering, at Ohio State University

Ohio State University

The Ohio State University, commonly referred to as Ohio State, is a public research university located in Columbus, Ohio. It was originally founded in 1870 as a land-grant university and is currently the third largest university campus in the United States...

in 1894. Orton and eight other refractory professionals founded the American Ceramic Society

American Ceramic Society

The American Ceramic Society is a non-profit professional organization for the ceramics community, with a focus on scientific research, emerging technologies, and applications in which ceramic materials are an element...

(ACerS) at the 1898 National Brick Manufacturers' Association convention in Pittsburgh. Orton was the first ACerS General Secretary, and his office at OSU served as the society headquarters in the beginning. Charles F. Binns established the New York State School of Clay-Working and Ceramics, now Alfred University

Alfred University

Alfred University is a small, comprehensive university in the Village of Alfred in Western New York, USA, an hour and a half south of Rochester and two hours southeast of Buffalo. Alfred has an undergraduate population of around 2,000, and approximately 300 graduate students...

, in 1900. Binns was the third ACerS president, and Orton the 32nd.

Significant contributions by Corning Incorporated a global leader of specialty glass and ceramics have been made and further committed to the update of the Sullivan Park Research and Development campus with $300 million in facility improvements with an estimated completion date of 2013. The largest known grant in history, localized to the education of Ceramic Engineering.

Modern industry

.jpg)

- Zirconium dioxideZirconium dioxideZirconium dioxide , sometimes known as zirconia , is a white crystalline oxide of zirconium. Its most naturally occurring form, with a monoclinic crystalline structure, is the rare mineral baddeleyite. The high temperature cubic crystalline form is rarely found in nature as mineral tazheranite O2...

ceramics are used in the manufacture of knives. The blade of the ceramic knifeCeramic knifeA ceramic knife is a knife made out of very hard and tough ceramic, often zirconium dioxide . These knives are usually produced by dry pressing zirconia powder and firing them through solid-state sintering. The resultant blade is sharpened by grinding the edges with a diamond-dust-coated grinding...

will stay sharp for much longer than that of a steel knife, although it is more brittle and can be snapped by dropping it on a hard surface.

- Ceramics such as alumina, boron carbideBoron carbideBoron carbide is an extremely hard boron–carbon ceramic material used in tank armor, bulletproof vests, and numerous industrial applications...

and silicon carbide have been used in bulletproof vestBulletproof vestA ballistic vest, bulletproof vest or bullet-resistant vest is an item of personal armor that helps absorb the impact from firearm-fired projectiles and shrapnel from explosions, and is worn on the torso...

s to repel large-caliber rifleRifleA rifle is a firearm designed to be fired from the shoulder, with a barrel that has a helical groove or pattern of grooves cut into the barrel walls. The raised areas of the rifling are called "lands," which make contact with the projectile , imparting spin around an axis corresponding to the...

fire. Such plates are known commonly as small-arms protective insertSmall-arms protective insertThe Small Arms Protective Insert is a ceramic plate fielded by the US military. It was first used in the Interceptor body armor, a ballistic vest. It is now also used in the Improved Outer Tactical Vest as well as the Modular Tactical Vest, in addition to commercially available "plate carriers"...

s (SAPI). Similar material is used to protect cockpits of some military airplanes, because of the low weight of the material.

- Silicon nitrideSilicon nitrideSilicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen...

parts are used in ceramic ball bearings. Their higher hardness means that they are much less susceptible to wear and can offer more than triple lifetimes. They also deform less under load meaning they have less contact with the bearing retainer walls and can roll faster. In very high speed applications, heat from friction during rolling can cause problems for metal bearings; problems which are reduced by the use of ceramics. Ceramics are also more chemically resistant and can be used in wet environments where steel bearings would rust. The major drawback to using ceramics is a significantly higher cost. In many cases their electrically insulating properties may also be valuable in bearings.

- In the early 1980s, Toyota researched production of an adiabatic ceramic engine which can run at a temperature of over 6000 °F (3300 °C). Ceramic engines do not require a cooling system and hence allow a major weight reduction and therefore greater fuel efficiency. Fuel efficiencyFuel efficiencyFuel efficiency is a form of thermal efficiency, meaning the efficiency of a process that converts chemical potential energy contained in a carrier fuel into kinetic energy or work. Overall fuel efficiency may vary per device, which in turn may vary per application, and this spectrum of variance is...

of the engine is also higher at high temperature, as shown by Carnot'sCarnot heat engineA Carnot heat engine is a hypothetical engine that operates on the reversible Carnot cycle. The basic model for this engine was developed by Nicolas Léonard Sadi Carnot in 1824...

theorem. In a conventional metallic engine, much of the energy released from the fuel must be dissipated as waste heatWaste heatWaste heat sometimes called Secondary heat or Low-grade heat refers to heat produced by machines, electrical equipment and industrial processes for which no useful application is found. Energy is often produced by a heat engine, running on a source of high-temperature heat...

in order to prevent a meltdown of the metallic parts. Despite all of these desirable properties, such engines are not in production because the manufacturing of ceramic parts in the requisite precision and durability is difficult. Imperfection in the ceramic leads to cracks, which can lead to potentially dangerous equipment failure. Such engines are possible in laboratory settings, but mass-production is not feasible with current technology.

- Work is being done in developing ceramic parts for gas turbineGas turbineA gas turbine, also called a combustion turbine, is a type of internal combustion engine. It has an upstream rotating compressor coupled to a downstream turbine, and a combustion chamber in-between....

enginesHeat engineIn thermodynamics, a heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. It does this by bringing a working substance from a high temperature state to a lower temperature state. A heat "source" generates thermal energy that brings the working substance...

. Currently, even blades made of advanced metal alloysSuperalloyA superalloy, or high-performance alloy, is an alloy that exhibits excellent mechanical strength and creep resistance at high temperatures, good surface stability, and corrosion and oxidation resistance. Superalloys typically have a matrix with an austenitic face-centered cubic crystal structure. ...

used in the engines' hot section require cooling and careful limiting of operating temperatures. Turbine engines made with ceramics could operate more efficiently, giving aircraft greater range and payload for a set amount of fuel.

- Recently, there have been advances in ceramics which include bio-ceramics, such as dental implants and synthetic bones. Hydroxyapatite, the natural mineral component of bone, has been made synthetically from a number of biological and chemical sources and can be formed into ceramic materials. Orthopedic implants made from these materials bond readily to bone and other tissues in the body without rejection or inflammatory reactions. Because of this, they are of great interest for gene delivery and tissue engineeringTissue engineeringTissue engineering is the use of a combination of cells, engineering and materials methods, and suitable biochemical and physio-chemical factors to improve or replace biological functions...

scaffolds. Most hydroxy apatite ceramics are very porous and lack mechanical strength and are used to coat metal orthopedic devices to aid in forming a bond to bone or as bone fillers. They are also used as fillers for orthopedic plastic screws to aid in reducing the inflammation and increase absorption of these plastic materials. Work is being done to make strong, fully dense nano crystalline hydroxyapatite ceramic materials for orthopedic weight bearing devices, replacing foreign metal and plastic orthopedic materials with a synthetic, but naturally occurring, bone mineral. Ultimately these ceramic materials may be used as bone replacements or with the incorporation of protein collagens, synthetic bones.

- High-tech ceramic is used in watchmaking for producing watch cases. The material is valued by watchmakers for its light weight, scratch-resistance, durability and smooth touch. IWCInternational Watch CompanyInternational Watch Co, also known as IWC, is a high-end Swiss watch manufacturer located in Schaffhausen, Switzerland. IWC is an active member of the Federation of the Swiss Watch Industry FH....

is one of the brands that initiated the use of ceramic in watchmaking. The case of the IWC 2007 Top Gun edition of the Pilot's Watch Double chronographDouble chronographDouble chronograph is a watch that includes two separate stopwatch mechanisms in order to estimate two separate events of different durations. It is often confused with the flyback chronograph.-Functioning:...

is crafted in high-tech black ceramic.

Glass-ceramics

In the processing of glass-ceramics, molten glass is cooled down gradually before reheating and annealing. In this heat treatment the glass partly crystallizes. In many cases, so-called 'nucleation agents' are added in order to regulate and control the crystallization process. Because there is usually no pressing and sintering, glass-ceramics do not contain the volume fraction of porosity typically present in sintered ceramics.

The term mainly refers to a mix of lithium and aluminosilicate

Aluminosilicate

Aluminosilicate minerals are minerals composed of aluminium, silicon, and oxygen, plus countercations. They are a major component of kaolin and other clay minerals....

s which yields an array of materials with interesting thermomechanical properties. The most commercially important of these have the distinction of being impervious to thermal shock. Thus, glass-ceramics have become extremely useful for countertop cooking. The negative thermal expansion

Thermal expansion

Thermal expansion is the tendency of matter to change in volume in response to a change in temperature.When a substance is heated, its particles begin moving more and thus usually maintain a greater average separation. Materials which contract with increasing temperature are rare; this effect is...

coefficient (TEC) of the crystalline ceramic phase can be balanced with the positive TEC of the glassy phase. At a certain point (~70% crystalline) the glass-ceramic has a net TEC near zero. This type of glass-ceramic

Glass-ceramic

Glass-ceramics are polycrystalline material produced through controlled crystallization of base glass. Glass-ceramic materials share many properties with both glasses and ceramics...

exhibits excellent mechanical properties and can sustain repeated and quick temperature changes up to 1000 °C.

Processing steps

The traditional ceramic process generally follows this sequence: Milling → Batching → Mixing → Forming → Drying → Firing → Assembly

- Milling is the process by which materials are reduced from a large size to a smaller size. Milling may involve breaking up cemented material (in which case individual particles retain their shape) or pulverization (which involves grinding the particles themselves to a smaller size). Milling is generally done by mechanical means, including attrition (which is particle-to-particle collision that results in agglomerate break up or particle shearing), compression (which applies a forces that results in fracturing), and impact (which employs a milling medium or the particles themselves to cause fracturing). Attrition milling equipment includes the wet scrubber (also called the planetary mill or wet attrition mill), which has paddles in water creating vortexes in which the material collides and break up. Compression mills include the jaw crusherCrusherA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials , so that pieces...

, roller crusher and cone crusher. Impact mills include the ball millBall millA ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics.-Description:...

, which has media that tumble and fracture the material. Shaft impactors cause particle-to particle attrition and compression.

- Batching is the process of weighing the oxides according to recipes, and preparing them for mixing and drying.

- Mixing occurs after batching and is performed with various machines, such as dry mixing ribbon mixersIndustrial mixerIndustrial Mixers and Blenders are used to mix or blend a wide range of materials used in different industries including the food, chemical, pharmaceutical, plastic and mineral industries. They are mainly used to mix different materials using different types of blades to make a good quality...

(a type of cement mixer), Mueller mixers, and pug mills. Wet mixing generally involves the same equipment.

- Forming is making the mixed material into shapes, ranging from toilet bowls to spark plug insulators. Forming can involve: (1) Extrusion, such as extruding "slugs" to make bricks, (2) Pressing to make shaped parts, (3) Slip casting, as in making toilet bowls, wash basins and ornamentals like ceramic statues. Forming produces a "green" part, ready for drying. Green parts are soft, pliable, and over time will lose shape. Handling the green product will change its shape. For example, a green brick can be "squeezed", and after squeezing it will stay that way.

- Drying is removing the water or binder from the formed material. Spray dryingSpray dryingSpray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals. A consistent particle size distribution is a reason for spray drying some...

is widely used to prepare powder for pressing operations. Other dryers are tunnel dryers and periodic dryers. Controlled heat is applied in this two-stage process. First, heat removes water. This step needs careful control, as rapid heating causes cracks and surface defects. The dried part is smaller than the green part, and is brittle, necessitating careful handling, since a small impact will cause crumbling and breaking.

- Firing is where the dried parts pass through a controlled heating process, and the oxides are chemically changed to cause sintering and bonding. The fired part will be smaller than the dried part.

Forming methods

Ceramic forming techniquesCeramic forming techniques

Ceramic forming techniques are ways of forming ceramic shapes. This can be used to make everyday tableware from teapots, to engineering ceramics such as computer parts. Methods for forming powders of ceramic raw materials into complex shapes are desirable in many areas of technology...

include throwing, slipcasting

Slipcasting

Slipcasting is a technique for the mass-production of pottery, especially for shapes not easily made on a wheel. A liquid clay body slip is poured into plaster moulds and allowed to form a layer, the cast, on the inside cavity of the mould...

, tape casting, injection molding, dry pressing, isostatic pressing, hot isostatic pressing (HIP) and others. Methods for forming ceramic powders into complex shapes are desirable in many areas of technology. Such methods are required for producing advanced, high-temperature structural parts such as heat engine components and turbines. Materials other than ceramics which are used in these processes may include: wood, metal, water, plaster and epoxy—most of which will be eliminated upon firing.

These forming techniques are well known for providing tools and other components with dimensional stability

Stability

-Mathematics:*Stability theory, the study of the stability of solutions to differential equations and dynamical systems**Lyapunov stability**Structural stability*Stability of a point in geometric invariant theory....

, surface quality, high (near theoretical) density and microstructural uniformity. The increasing use and diversity of specialty forms of ceramics adds to the diversity of process technologies to be used.

Thus, reinforcing fibers and filaments are mainly made by polymer, sol-gel, or CVD processes, but melt processing also has applicability. The most widely used specialty form is layered structures, with tape casting for electronic substrates and packages being preeminent. Photolithography is of increasing interest for precise patterning of conductors and other components for such packaging. Tape casting or forming processes are also of increasing interest for other applications, ranging from open structures such as fuel cells to ceramic composites.

The other major layer structure is coating, where melt spraying is very important, but chemical and physical vapor deposition and chemical (e.g., sol-gel and polymer pyrolysis) methods are all seeing increased use. Besides open structures from formed tape, extruded structures, such as honeycomb catalyst supports, and highly porous structures, including various foams, for example, reticulated foam

Reticulated foam

Reticulated foam is a very porous, low density solid foam. 'Reticulated' means like a net. Reticulated foams are extremely open foams i.e. there are few, if any, intact bubbles or cell windows. In contrast, the foam formed by soap bubbles is composed solely of intact bubbles...

, are of increasing use.

Densification of consolidated powder bodies continues to be achieved predominantly by (pressureless) sintering. However, the use of pressure sintering by hot pressing is increasing, especially for non-oxides and parts of simple shapes where higher quality (mainly microstructural homogeneity) is needed, and larger size or multiple parts per pressing can be an advantage.

The sintering process

The principles of sintering-based methods are simple ("sinter" has roots in the English "cinderCinder

A cinder is a pyroclastic material. Cinders are extrusive igneous rocks. Cinders are similar to pumice, which has so many cavities and is such low-density that it can float on water...

"). The firing is done at a temperature below the melting point of the ceramic. Once a roughly-held-together object called a "green body" is made, it is baked in a kiln

Kiln

A kiln is a thermally insulated chamber, or oven, in which a controlled temperature regime is produced. Uses include the hardening, burning or drying of materials...

, where atomic and molecular diffusion

Diffusion

Molecular diffusion, often called simply diffusion, is the thermal motion of all particles at temperatures above absolute zero. The rate of this movement is a function of temperature, viscosity of the fluid and the size of the particles...

processes give rise to significant changes in the primary microstructural features. This includes the gradual elimination of porosity

Porosity

Porosity or void fraction is a measure of the void spaces in a material, and is a fraction of the volume of voids over the total volume, between 0–1, or as a percentage between 0–100%...

, which is typically accompanied by a net shrinkage and overall densification of the component. Thus, the pores in the object may close up, resulting in a denser product of significantly greater strength

Strength of materials

In materials science, the strength of a material is its ability to withstand an applied stress without failure. The applied stress may be tensile, compressive, or shear. Strength of materials is a subject which deals with loads, deformations and the forces acting on a material. A load applied to a...

and fracture toughness

Fracture toughness

In materials science, fracture toughness is a property which describes the ability of a material containing a crack to resist fracture, and is one of the most important properties of any material for virtually all design applications. The fracture toughness of a material is determined from the...

.

Another major change in the body during the firing or sintering process will be the establishment of the polycrystalline

Polycrystalline

Polycrystalline materials are solids that are composed of many crystallites of varying size and orientation. The variation in direction can be random or directed, possibly due to growth and processing conditions. Fiber texture is an example of the latter.Almost all common metals, and many ceramics...

nature of the solid. This change will introduce some form of grain

GRAIN

GRAIN is a small international non-profit organisation that works to support small farmers and social movements in their struggles for community-controlled and biodiversity-based food systems. Our support takes the form of independent research and analysis, networking at local, regional and...

size distribution, which will have a significant impact on the ultimate physical properties of the material. The grain sizes will either be associated with the initial particle size, or possibly the sizes of aggregates or particle cluster

Cluster (physics)

In physics, the term clusters denotes small, multiatom particles. As a rule of thumb, any particle of somewhere between 3 and 3x107 atoms is considered a cluster. Two-atom particles are sometimes considered clusters as well....

s which arise during the initial stages of processing.

The ultimate microstructure

Microstructure

Microstructure is defined as the structure of a prepared surface or thin foil of material as revealed by a microscope above 25× magnification...

(and thus the physical properties) of the final product will be limited by and subject to the form of the structural template or precursor which is created in the initial stages of chemical synthesis

Chemical synthesis

In chemistry, chemical synthesis is purposeful execution of chemical reactions to get a product, or several products. This happens by physical and chemical manipulations usually involving one or more reactions...

and physical forming. Hence the importance of chemical powder

Powder (substance)

A powder is a dry,thick bulk solid composed of a large number of very fine particles that may flow freely when shaken or tilted. Powders are a special sub-class of granular materials, although the terms powder and granular are sometimes used to distinguish separate classes of material...

and polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

processing

Chemical process

In a "scientific" sense, a chemical process is a method or means of somehow changing one or more chemicals or chemical compounds. Such a chemical process can occur by itself or be caused by somebody. Such a chemical process commonly involves a chemical reaction of some sort...

as it pertains to the synthesis of industrial ceramics, glasses and glass-ceramics.

There are numerous possible refinements of the sintering process. Some of the most common involve pressing the green body to give the densification a head start and reduce the sintering time needed. Sometimes organic binders

Binder (material)

-See also:*Adhesive or Glue*Cement*Paint...

such as polyvinyl alcohol

Polyvinyl alcohol

Polyvinyl alcohol is a water-soluble synthetic polymer .-Properties:...

are added to hold the green body together; these burn out during the firing (at 200–350 °C). Sometimes organic lubricants are added during pressing to increase densification. It is common to combine these, and add binders and lubricants to a powder, then press. (The formulation of these organic chemical additives is an art in itself. This is particularly important in the manufacture of high performance ceramics such as those used by the billions for electronics

Electronics

Electronics is the branch of science, engineering and technology that deals with electrical circuits involving active electrical components such as vacuum tubes, transistors, diodes and integrated circuits, and associated passive interconnection technologies...

, in capacitors, inductor

Inductor

An inductor is a passive two-terminal electrical component used to store energy in a magnetic field. An inductor's ability to store magnetic energy is measured by its inductance, in units of henries...

s, sensor

Sensor

A sensor is a device that measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument. For example, a mercury-in-glass thermometer converts the measured temperature into expansion and contraction of a liquid which can be read on a calibrated...

s, etc.)

A slurry can be used in place of a powder, and then cast into a desired shape, dried and then sintered. Indeed, traditional pottery is done with this type of method, using a plastic mixture worked with the hands. If a mixture of different materials is used together in a ceramic, the sintering temperature is sometimes above the melting point of one minor component - a liquid phase sintering. This results in shorter sintering times compared to solid state sintering.

Strength of ceramics

A material's strength is dependent on its microstructure. The engineering processes to which a material is subjected can alter this microstructure. The variety of strengthening mechanisms that alter the strength of a material include the mechanism of grain boundary strengtheningGrain boundary strengthening

Grain-boundary strengthening is a method of strengthening materials by changing their average crystallite size...

. Thus, although yield strength is maximized with decreasing grain size, ultimately, very small grain sizes make the material brittle. Considered in tandem with the fact that the yield strength is the parameter that predicts plastic deformation in the material, one can make informed decisions on how to increase the strength of a material depending on its microstructural properties and the desired end effect.

The relation between yield stress and grain size is described mathematically by the Hall-Petch equation which is

where ky is the strengthening coefficient (a constant unique to each material), σo is a materials constant for the starting stress for dislocation movement (or the resistance of the lattice to dislocation motion), d is the grain diameter, and σy is the yield stress.

Theoretically, a material could be made infinitely strong if the grains are made infinitely small. This is, unfortunately, impossible because the lower limit of grain size is a single unit cell of the material. Even then, if the grains of a material are the size of a single unit cell, then the material is in fact amorphous, not crystalline, since there is no long range order, and dislocations can not be defined in an amorphous material. It has been observed experimentally that the microstructure with the highest yield strength is a grain size of about 10 nanometers, because grains smaller than this undergo another yielding mechanism, grain boundary sliding. Producing engineering materials with this ideal grain size is difficult because of the limitations of initial particle sizes inherent to nanomaterials

Nanomaterials

Nanomaterials is a field that takes a materials science-based approach to nanotechnology. It studies materials with morphological features on the nanoscale, and especially those that have special properties stemming from their nanoscale dimensions...

and nanotechnology.

Microstructural uniformity

In the processing of fine ceramics, the irregular particle sizes and shapes in a typical powder often lead to non-uniform packing morphologies that result in packing densityDensity

The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

variations in the powder compact. Uncontrolled agglomeration

Agglomeration

In the study of human settlements, an urban agglomeration is an extended city or town area comprising the built-up area of a central place and any suburbs linked by continuous urban area. In France, INSEE the French Statistical Institute, translate it as "Unité urbaine" which means continuous...

of powders due to attractive van der Waals forces can also give rise to in microstructural inhomogeneities.

Differential stresses that develop as a result of non-uniform drying shrinkage are directly related to the rate at which the solvent

Solvent

A solvent is a liquid, solid, or gas that dissolves another solid, liquid, or gaseous solute, resulting in a solution that is soluble in a certain volume of solvent at a specified temperature...

can be removed, and thus highly dependent upon the distribution of porosity. Such stresses have been associated with a plastic-to-brittle transition in consolidated bodies,

and can yield to crack propagation in the unfired body if not relieved.

In addition, any fluctuations in packing density in the compact as it is prepared for the kiln are often amplified during the sintering process, yielding inhomogeneous densification.

Some pores and other structural defect

Crystallographic defect

Crystalline solids exhibit a periodic crystal structure. The positions of atoms or molecules occur on repeating fixed distances, determined by the unit cell parameters. However, the arrangement of atom or molecules in most crystalline materials is not perfect...

s associated with density variations have been shown to play a detrimental role in the sintering process by growing and thus limiting end-point densities.

Differential stresses arising from inhomogeneous densification have also been shown to result in the propagation of internal cracks, thus becoming the strength-controlling flaws.

It would therefore appear desirable to process a material in such a way that it is physically uniform with regard to the distribution of components and porosity, rather than using particle size distributions which will maximize the green density. The containment of a uniformly dispersed assembly of strongly interacting particles in suspension requires total control over particle-particle interactions. Monodisperse

Monodisperse

A collection of objects are called monodisperse, or monosized, if they have the same size and shape when discussing particles, and the same mass when discussing polymers...

colloids provide this potential.

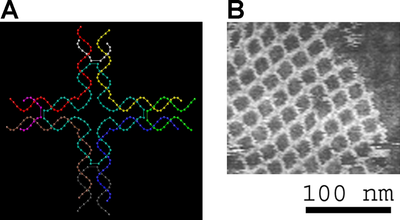

Monodisperse powders of colloidal silica, for example, may therefore be stabilized sufficiently to ensure a high degree of order in the colloidal crystal

Colloidal crystal

A colloidal crystal is an ordered array of colloid particles, analogous to a standard crystal whose repeating subunits are atoms or molecules. A natural example of this phenomenon can be found in the gem opal, where spheres of silica assume a close-packed locally periodic structure under moderate...

or polycrystalline colloidal solid which results from aggregation. The degree of order appears to be limited by the time and space allowed for longer-range correlations to be established.

Such defective polycrystalline colloidal structures would appear to be the basic elements of submicrometer colloidal materials science

Materials science

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

, and, therefore, provide the first step in developing a more rigorous understanding of the mechanisms involved in microstructural evolution in inorganic systems such as polycrystalline ceramics.

Self-assembly

Self-assembly

Self-assembly is a term used to describe processes in which a disordered system of pre-existing components forms an organized structure or pattern as a consequence of specific, local interactions among the components themselves, without external direction...

" is the most common term in use in the modern scientific community to describe the spontaneous aggregation of particles (atoms, molecules, colloids, micelles, etc.) without the influence of any external forces. Large groups of such particles are known to assemble themselves into thermodynamically stable, structurally well-defined arrays, quite reminiscent of one of the 7 crystal

Crystal

A crystal or crystalline solid is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. The scientific study of crystals and crystal formation is known as crystallography...

systems found in metallurgy

Metallurgy

Metallurgy is a domain of materials science that studies the physical and chemical behavior of metallic elements, their intermetallic compounds, and their mixtures, which are called alloys. It is also the technology of metals: the way in which science is applied to their practical use...

and mineralogy

Mineralogy

Mineralogy is the study of chemistry, crystal structure, and physical properties of minerals. Specific studies within mineralogy include the processes of mineral origin and formation, classification of minerals, their geographical distribution, as well as their utilization.-History:Early writing...

(e.g. face-centered cubic, body-centered cubic, etc.). The fundamental difference in equilibrium structure is in the spatial scale of the unit cell (or lattice parameter) in each particular case.

Thus, self-assembly is emerging as a new strategy in chemical synthesis and nanotechnology

Nanotechnology

Nanotechnology is the study of manipulating matter on an atomic and molecular scale. Generally, nanotechnology deals with developing materials, devices, or other structures possessing at least one dimension sized from 1 to 100 nanometres...

. Molecular self-assembly has been observed in various biological systems and underlies the formation of a wide variety of complex biological structures. Molecular crystals, liquid crystals, colloids, micelles, emulsions, phase-separated polymers, thin films and self-assembled monolayers all represent examples of the types of highly ordered structures which are obtained using these techniques. The distinguishing feature of these methods is self-organization in the absence of any external forces.

In addition, the principal mechanical characteristics and structures of biological ceramics, polymer composites

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

, elastomers, and cellular

Cell (biology)

The cell is the basic structural and functional unit of all known living organisms. It is the smallest unit of life that is classified as a living thing, and is often called the building block of life. The Alberts text discusses how the "cellular building blocks" move to shape developing embryos....

materials are being re-evaluated, with an emphasis on bioinspired materials and structures. Traditional approaches focus on design methods of biological materials using conventional synthetic materials. This includes an emerging class of mechanically

Mechanics

Mechanics is the branch of physics concerned with the behavior of physical bodies when subjected to forces or displacements, and the subsequent effects of the bodies on their environment....

superior biomaterials based on microstructural features and designs found in nature. The new horizons have been identified in the synthesis of bioinspired materials through processes that are characteristic of biological systems in nature. This includes the nanoscale self-assembly of the components and the development of hierarchical structures.

Ceramic composites

Ceramic Matrix Composite

Ceramic matrix composites are a subgroup of composite materials as well as a subgroup of technical ceramics. They consist of ceramic fibers embedded in a ceramic matrix, thus forming a ceramic fiber reinforced ceramic material...

. The challenge, as in wet chemical processing, is to obtain a uniform or homogeneous distribution of the dispersed particle or fiber phase.

Consider first the processing of particulate composites. The particulate phase of greatest interest is tetragonal zirconia because of the toughening that can be achieved from the phase transformation from the metastable tetragonal to the monoclinic crystalline phase, aka transformation toughening. There is also substantial interest in dispersion of hard, non-oxide phases such as SiC, TiB, TiC, boron

Boron

Boron is the chemical element with atomic number 5 and the chemical symbol B. Boron is a metalloid. Because boron is not produced by stellar nucleosynthesis, it is a low-abundance element in both the solar system and the Earth's crust. However, boron is concentrated on Earth by the...

, carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

and especially oxide matrices like alumina and mullite

Mullite

Mullite or porcelainite is a rare silicate mineral of post-clay genesis. It can form two stoichiometric forms 3Al2O32SiO2 or 2Al2O3 SiO2. Unusually, mullite has no charge balancing cations present...

. There is also interest too incorporating other ceramic particulates, especially those of highly anisotropic thermal expansion. Examples include Al2O3, TiO2, graphite, and boron nitride.

Particulate composites have been made on a commercial basis by simply mixing powders of the two constituents. Although this approach is inherently limited in the homogeneity that can be achieved, it is the most readily adaptable for existing ceramic production technology. However, other approaches are of interest.

There are also some opportunities to utilize melt processing for fabrication of ceramic, particulate, whisker and short-fiber, and continuous-fiber composites. Clearly, both particulate and whisker composites are conceivable by solid-state precipitation after solidification of the melt. This can also be obtained in some cases by sintering, as for precipitation-toughened, partially stabilized zirconia. Similarly, it is known that one can directionally solidify ceramic eutectic mixtures and hence obtain uniaxially aligned fiber composites. Such composite processing has typically been limited to very simple shapes and thus suffers from serious economic problems due to high machining costs.

Clearly, there are possibilities of using melt casting for many of these approaches. Potentially even more desirable is using melt-derived particles. In this method, quenching is done in a solid solution or in a fine eutectic structure, in which the particles are then processed by more typical ceramic powder processing methods into a useful body. There have also been preliminary attempts to use melt spraying as a means of forming composites by introducing the dispersed particulate, whisker, or fiber phase in conjunction with the melt spraying process.

Other methods besides melt infiltration to manufacture ceramic composites with long fiber reinforcement are chemical vapor infiltration

Chemical vapor infiltration

Chemical vapor infiltration is a variant on Chemical Vapor Deposition . CVD implies deposition onto a surface, whereas CVI implies deposition within a body...

and the infiltration of fiber preforms with organic precursor

Precursor (chemistry)

In chemistry, a precursor is a compound that participates in the chemical reaction that produces another compound. In biochemistry, the term "precursor" is used more specifically to refer to a chemical compound preceding another in a metabolic pathway....

, which after pyrolysis

Pyrolysis

Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures without the participation of oxygen. It involves the simultaneous change of chemical composition and physical phase, and is irreversible...

yield an amorphous ceramic matrix, initially with a low density. With repeated cycles of infiltration and pyrolysis one of those types of ceramic matrix composite

Ceramic Matrix Composite

Ceramic matrix composites are a subgroup of composite materials as well as a subgroup of technical ceramics. They consist of ceramic fibers embedded in a ceramic matrix, thus forming a ceramic fiber reinforced ceramic material...

s is produced. Chemical vapor infiltration is used to manufacture carbon/carbon and silcon carbide reinforced with carbon

Carbon fiber

Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber...

or silicon carbide fibers.

Besides many process improvements, the first of two major needs for fiber composites is lower fiber costs. The second major need is fiber compositions or coatings, or composite processing, to reduce degradation that results from high-temperature composite exposure under oxidizing conditions.

Applications

Space Shuttle program

NASA's Space Shuttle program, officially called Space Transportation System , was the United States government's manned launch vehicle program from 1981 to 2011...

, gas burner nozzle

Nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe via an orifice....

s, ballistic protection, nuclear fuel uranium oxide pellets, bio-medical implants

Implant (medicine)

An implant is a medical device manufactured to replace a missing biological structure, support a damaged biological structure, or enhance an existing biological structure. Medical implants are man-made devices, in contrast to a transplant, which is a transplanted biomedical tissue...

, jet engine

Jet engine

A jet engine is a reaction engine that discharges a fast moving jet to generate thrust by jet propulsion and in accordance with Newton's laws of motion. This broad definition of jet engines includes turbojets, turbofans, rockets, ramjets, pulse jets...

turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

blades, and missile

Missile

Though a missile may be any thrown or launched object, it colloquially almost always refers to a self-propelled guided weapon system.-Etymology:The word missile comes from the Latin verb mittere, meaning "to send"...

nose cones.

Its products are often made from materials other than clay, chosen for their particular physical properties. These may be classified as follows:

- OxideOxideAn oxide is a chemical compound that contains at least one oxygen atom in its chemical formula. Metal oxides typically contain an anion of oxygen in the oxidation state of −2....

s: silica, alumina, zirconia - Non-oxides: carbides, borideBorideIn chemistry a boride is a chemical compound between boron and a less electronegative element, for example silicon boride . The borides are a very large group of compounds that are generally high melting and are not ionic in nature. Some borides exhibit very useful physical properties. The term...

s, nitrideNitrideIn chemistry, a nitride is a compound of nitrogen where nitrogen has a formal oxidation state of −3. Nitrides are a large class of compounds with a wide range of properties and applications....

s, silicideSilicideA silicide is a compound that has silicon with more electropositive elements.Silicon is more electropositive than carbon. Silicides are structurally closer to borides than to carbides....

s - CompositeMixtureIn chemistry, a mixture is a material system made up by two or more different substances which are mixed together but are not combined chemically...

s: particulate or whisker reinforced matrices, combinations of oxides and non-oxides (e.g. polymers).

Ceramics can be used in many technological industries. One application are the ceramic tiles on NASA

NASA

The National Aeronautics and Space Administration is the agency of the United States government that is responsible for the nation's civilian space program and for aeronautics and aerospace research...

's Space Shuttle, used to protect it and the future supersonic space planes from the searing heat of reentry into the Earth's atmosphere. They are also used widely in electronics and optics. In addition to the applications listed here, ceramics are also used as a coating in various engineering cases. An example would be a ceramic bearing coating over a titanium frame used for an airplane. Recently the field has come to include the studies of single crystals or glass fibers, in addition to traditional polycrystalline materials, and the applications of these have been overlapping and changing rapidly.

Aerospace

- EngineEngineAn engine or motor is a machine designed to convert energy into useful mechanical motion. Heat engines, including internal combustion engines and external combustion engines burn a fuel to create heat which is then used to create motion...

s; Shielding a hot running airplane engine from damaging other components. - AirframeAirframeThe airframe of an aircraft is its mechanical structure. It is typically considered to include fuselage, wings and undercarriage and exclude the propulsion system...

s; Used as a high-stress, high-temp and lightweight bearing and structural component. - Missile nose-cones; Shielding the missile internals from heat.

- Space ShuttleSpace ShuttleThe Space Shuttle was a manned orbital rocket and spacecraft system operated by NASA on 135 missions from 1981 to 2011. The system combined rocket launch, orbital spacecraft, and re-entry spaceplane with modular add-ons...

tiles - Space-debrisSpace debrisSpace debris, also known as orbital debris, space junk, and space waste, is the collection of objects in orbit around Earth that were created by humans but no longer serve any useful purpose. These objects consist of everything from spent rocket stages and defunct satellites to erosion, explosion...

ballistic shields -- Ceramic fiber woven shields offer better protection to hypervelocity (~7 km/s) particles than aluminum shields of equal weight. - Rocket Nozzles; Withstands and focuses the exhaust of the rocket booster.

Biomedical

- Artificial boneArtificial boneArtificial bone refers to bone-like material created in a laboratory that can be used in bone grafts, to replace human bone that was lost due to severe fractures, disease, etc.-Overview:...

; Dentistry applications, teeth. - Biodegradable splints; Reinforcing bones recovering from osteoporosis

- Implant material

Electronics

- CapacitorCapacitorA capacitor is a passive two-terminal electrical component used to store energy in an electric field. The forms of practical capacitors vary widely, but all contain at least two electrical conductors separated by a dielectric ; for example, one common construction consists of metal foils separated...

s - Integrated CircuitIntegrated circuitAn integrated circuit or monolithic integrated circuit is an electronic circuit manufactured by the patterned diffusion of trace elements into the surface of a thin substrate of semiconductor material...

packages - TransducerTransducerA transducer is a device that converts one type of energy to another. Energy types include electrical, mechanical, electromagnetic , chemical, acoustic or thermal energy. While the term transducer commonly implies the use of a sensor/detector, any device which converts energy can be considered a...

s - Insulators

Optical

- Optical fibers; Guided Lightwave Transmission

- Switches

- LaserLaserA laser is a device that emits light through a process of optical amplification based on the stimulated emission of photons. The term "laser" originated as an acronym for Light Amplification by Stimulated Emission of Radiation...

amplifierAmplifierGenerally, an amplifier or simply amp, is a device for increasing the power of a signal.In popular use, the term usually describes an electronic amplifier, in which the input "signal" is usually a voltage or a current. In audio applications, amplifiers drive the loudspeakers used in PA systems to...

s - LensLens (optics)A lens is an optical device with perfect or approximate axial symmetry which transmits and refracts light, converging or diverging the beam. A simple lens consists of a single optical element...

es - Infrared Heat Seeking Devices

Biomaterials

Most natural (or biological) materials are complex composites whose mechanical properties are often outstanding, considering the weak constituents from which they are assembled. These complex structures, which have risen from hundreds of million years of evolution, are inspiring the design of novel materials with exceptional physical properties for high performance in adverse conditions. Their defining characteristics such as hierarchy, multifunctionality, and the capacity for self-healing, are currently being investigated.

The basic building blocks begin with the 20 amino acids and proceed to polypeptides, polysaccharides, and polypeptides–saccharides. These, in turn, compose the basic proteins, which are the primary constituents of the ‘soft tissues’ common to most biominerals. With well over 1000 proteins possible, current research emphasizes the use of collagen, chitin, keratin, and elastin. The ‘hard’ phases are often strengthened by crystalline minerals, which nucleate and grow in a biomediated environment that determines the size, shape and distribution of individual crystals. The most important mineral phases have been identified as hydroxyapatite, silica, and aragonite

Aragonite

Aragonite is a carbonate mineral, one of the two common, naturally occurring, crystal forms of calcium carbonate, CaCO3...

. Using the classification of Wegst and Ashby, the principal mechanical characteristics and structures of biological ceramics, polymer composites, elastomers, and cellular materials have been presented. Selected systems in each class are being investigated with emphasis on the relationship between their microstructure over a range of length scales and their mechanical response.

Thus, the crystallization of inorganic materials in nature generally occurs at ambient temperature and pressure. Yet the vital organisms through which these minerals form are capable of consistently producing extremely precise and complex structures. Understanding the processes in which living organisms control the growth of crystalline minerals such as silica could lead to significant advances in the field of materials science, and open the door to novel synthesis techniques for nanoscale composite materials, or nanocomposites.

Nacre

Nacre , also known as mother of pearl, is an organic-inorganic composite material produced by some mollusks as an inner shell layer; it is also what makes up pearls. It is very strong, resilient, and iridescent....

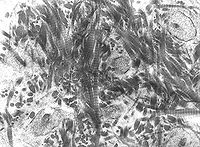

) portion of the abalone

Abalone

Abalone , from aulón, are small to very large-sized edible sea snails, marine gastropod molluscs in the family Haliotidae and the genus Haliotis...

shell. Those shells exhibit the highest mechanical strength and fracture toughness of any non-metallic substance known. The nacre from the shell of the abalone has become one of the more intensively studied biological structures in materials science. Clearly visible in these images are the neatly stacked (or ordered) mineral tiles separated by thin organic sheets along with a macrostructure of larger periodic growth bands which collectively form what scientists are currently referring to as a hierarchical composite structure. (The term hierarchy simply implies that there are a range of structural features which exist over a wide range of length scales).

Future developments reside in the synthesis of bio-inspired materials through processing methods and strategies that are characteristic of biological systems. These involve nanoscale self-assembly of the components and the development of hierarchical structures.

See also

- Chemical EngineeringChemical engineeringChemical engineering is the branch of engineering that deals with physical science , and life sciences with mathematics and economics, to the process of converting raw materials or chemicals into more useful or valuable forms...

- ColloidColloidA colloid is a substance microscopically dispersed evenly throughout another substance.A colloidal system consists of two separate phases: a dispersed phase and a continuous phase . A colloidal system may be solid, liquid, or gaseous.Many familiar substances are colloids, as shown in the chart below...

- Glass-ceramic-to-metal sealsGlass-ceramic-to-metal sealsGlass-to-metal seals have been around for many years, with one of the most common uses being lamp bulb seals. A more recent invention is glass-ceramic-to-metal seals.-Properties:...

- Leo MorandiLeo MorandiLeo Morandi was a promoter of the new post-war commercial ceramics industry of Sassuolo, Italy. At first he collaborated with local ceramic producers and in Salerno, Italy ; later, following the sale of a crucial innovative patent to Ceramiche Marazzi, he was able to initiate startup of...

- Materials ScienceMaterials scienceMaterials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

- Mechanical EngineeringMechanical engineeringMechanical engineering is a discipline of engineering that applies the principles of physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the production and usage of heat and mechanical power for the...

- NanoparticleNanoparticleIn nanotechnology, a particle is defined as a small object that behaves as a whole unit in terms of its transport and properties. Particles are further classified according to size : in terms of diameter, coarse particles cover a range between 10,000 and 2,500 nanometers. Fine particles are sized...

- Phase Equilibria Diagrams database

- Photonic crystalPhotonic crystalPhotonic crystals are periodic optical nanostructures that are designed to affect the motion of photons in a similar way that periodicity of a semiconductor crystal affects the motion of electrons...

- Quenching

- Three point flexural testThree point flexural testThe three point bending flexural test provides values for the modulus of elasticityin bending E_f, flexural stress \sigma_f, flexural strain \epsilon_f and the flexural stress-strain response of the material. The main advantage of a three point flexural test is the ease of the specimen preparation...

- Transparent materials

- Yttria-stabilized zirconiaYttria-stabilized zirconiaYttria-stabilized zirconia is a zirconium-oxide based ceramic, in which the particular crystal structure of zirconium oxide is made stable at room temperature by an addition of yttrium oxide...

- Ceramic Matrix CompositeCeramic Matrix CompositeCeramic matrix composites are a subgroup of composite materials as well as a subgroup of technical ceramics. They consist of ceramic fibers embedded in a ceramic matrix, thus forming a ceramic fiber reinforced ceramic material...