Crystal oscillator

Encyclopedia

Electronic oscillator

An electronic oscillator is an electronic circuit that produces a repetitive electronic signal, often a sine wave or a square wave. They are widely used in innumerable electronic devices...

circuit that uses the mechanical resonance

Resonance

In physics, resonance is the tendency of a system to oscillate at a greater amplitude at some frequencies than at others. These are known as the system's resonant frequencies...

of a vibrating crystal

Crystal

A crystal or crystalline solid is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. The scientific study of crystals and crystal formation is known as crystallography...

of piezoelectric material to create an electrical signal with a very precise frequency

Frequency

Frequency is the number of occurrences of a repeating event per unit time. It is also referred to as temporal frequency.The period is the duration of one cycle in a repeating event, so the period is the reciprocal of the frequency...

. This frequency is commonly used to keep track of time (as in quartz wristwatches

Quartz clock

A quartz clock is a clock that uses an electronic oscillator that is regulated by a quartz crystal to keep time. This crystal oscillator creates a signal with very precise frequency, so that quartz clocks are at least an order of magnitude more accurate than good mechanical clocks...

), to provide a stable clock signal

Clock signal

In electronics and especially synchronous digital circuits, a clock signal is a particular type of signal that oscillates between a high and a low state and is utilized like a metronome to coordinate actions of circuits...

for digital

Digital

A digital system is a data technology that uses discrete values. By contrast, non-digital systems use a continuous range of values to represent information...

integrated circuits, and to stabilize frequencies for radio transmitters and receivers. The most common type of piezoelectric resonator used is the quartz crystal, so oscillator circuits designed around them became known as "crystal oscillators."

Quartz crystals are manufactured for frequencies from a few tens of kilohertz to tens of megahertz. More than two billion (2×109) crystals are manufactured annually. Most are used for consumer devices such as wristwatches, clock

Clock

A clock is an instrument used to indicate, keep, and co-ordinate time. The word clock is derived ultimately from the Celtic words clagan and clocca meaning "bell". A silent instrument missing such a mechanism has traditionally been known as a timepiece...

s, radio

Radio

Radio is the transmission of signals through free space by modulation of electromagnetic waves with frequencies below those of visible light. Electromagnetic radiation travels by means of oscillating electromagnetic fields that pass through the air and the vacuum of space...

s, computer

Computer

A computer is a programmable machine designed to sequentially and automatically carry out a sequence of arithmetic or logical operations. The particular sequence of operations can be changed readily, allowing the computer to solve more than one kind of problem...

s, and cellphones. Quartz crystals are also found inside test and measurement equipment, such as counters, signal generator

Signal generator

Signal generators, also known variously as function generators, RF and microwave signal generators, pitch generators, arbitrary waveform generators, digital pattern generators or frequency generators are electronic devices that generate repeating or non-repeating electronic signals...

s, and oscilloscope

Oscilloscope

An oscilloscope is a type of electronic test instrument that allows observation of constantly varying signal voltages, usually as a two-dimensional graph of one or more electrical potential differences using the vertical or 'Y' axis, plotted as a function of time,...

s.

History

PiezoelectricityPiezoelectricity

Piezoelectricity is the charge which accumulates in certain solid materials in response to applied mechanical stress. The word piezoelectricity means electricity resulting from pressure...

was discovered by Jacques

Jacques Curie

Paul-Jacques Curie was a French physicist and professor at the University of Montpellier. He and his brother, Pierre Curie, studied pyroelectricity in the 1880s, leading to their discovery of some of the mechanisms behind piezoelectricity....

and Pierre Curie

Pierre Curie

Pierre Curie was a French physicist, a pioneer in crystallography, magnetism, piezoelectricity and radioactivity, and Nobel laureate. He was the son of Dr. Eugène Curie and Sophie-Claire Depouilly Curie ...

in 1880. Paul Langevin

Paul Langevin

Paul Langevin was a prominent French physicist who developed Langevin dynamics and the Langevin equation. He was one of the founders of the Comité de vigilance des intellectuels antifascistes, an antifascist organization created in the wake of the 6 February 1934 far right riots...

first investigated quartz resonators for use in sonar

Sonar

Sonar is a technique that uses sound propagation to navigate, communicate with or detect other vessels...

during World War I. The first crystal-controlled oscillator

Electronic oscillator

An electronic oscillator is an electronic circuit that produces a repetitive electronic signal, often a sine wave or a square wave. They are widely used in innumerable electronic devices...

, using a crystal of Rochelle salt, was built in 1917 and patented in 1918 by Alexander M. Nicholson at Bell Telephone Laboratories, although his priority was disputed by Walter Guyton Cady

Walter Guyton Cady

Dr. Walter Guyton Cady was a noted American physicist and electrical engineer. He was a pioneer in piezoelectricity, and in 1921 developed the first crystal oscillator....

. Cady built the first quartz crystal oscillator in 1921.

Other early innovators in quartz crystal oscillators include G. W. Pierce

G. W. Pierce

George Washington Pierce was an American physicist. He was a professor of physics at Harvard University and inventor in the development of electronic telecommunications....

and Louis Essen

Louis Essen

Louis Essen FRS O.B.E. was an English physicist whose most notable achievements were in the precise measurement of time and the determination of the speed of light...

.

Quartz crystal oscillators were developed for high-stability frequency references during the 1920s and 1930s. By 1926 quartz crystals were used to control the frequency of radio broadcasting stations and were popular with amateur radio operators. In 1928, Warren Marrison (of Bell Telephone Laboratories) developed the first quartz crystal clock. This invention replaced the escapement and pendulum (as the timing reference), relying instead on the natural vibrations occurring in the quartz crystal as the oscillator. This improved timing accuracies to 1 sec in 30 years (or 30 ms/year). Utilizing the early work at Bell Labs, AT&T eventually established their Frequency Control Products division, later spun off and known today as Vectron International.

A number of firms started producing quartz crystals for electronic use during this time. Using what are now considered primitive methods, about 100,000 crystal units were produced in the United States during 1939. During World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

, the demand for accurate frequency control of military and naval radio

Radio

Radio is the transmission of signals through free space by modulation of electromagnetic waves with frequencies below those of visible light. Electromagnetic radiation travels by means of oscillating electromagnetic fields that pass through the air and the vacuum of space...

s and radar

Radar

Radar is an object-detection system which uses radio waves to determine the range, altitude, direction, or speed of objects. It can be used to detect aircraft, ships, spacecraft, guided missiles, motor vehicles, weather formations, and terrain. The radar dish or antenna transmits pulses of radio...

s spurred rapid development of the quartz crystal manufacturing industry. Suitable types of quartz became a critical war material, and much of it was eventually supplied by Brazil

Brazil

Brazil , officially the Federative Republic of Brazil , is the largest country in South America. It is the world's fifth largest country, both by geographical area and by population with over 192 million people...

.

In 1968, Juergen Staudte invented a process for manufacturing quartz crystal oscillators while working at North American Aviation (now Rockwell). Staudte patented his invention, which used a photolithographic process that is similar to the way integrated circuits are made. In 1970 he left North American Aviation to start his own company, Statek, in Orange, California. Statek began manufacturing and marketing the quartz oscillators in 1971.

Although crystal oscillators still most commonly use quartz crystals, devices using other materials are becoming more common, such as ceramic resonator

Ceramic resonator

A ceramic resonator is an electronic component that when combined with other appropriate components, can produce oscillations at a specific frequency...

s.

Operation

A crystalCrystal

A crystal or crystalline solid is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. The scientific study of crystals and crystal formation is known as crystallography...

is a solid

Solid

Solid is one of the three classical states of matter . It is characterized by structural rigidity and resistance to changes of shape or volume. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire volume available to it like a...

in which the constituent atom

Atom

The atom is a basic unit of matter that consists of a dense central nucleus surrounded by a cloud of negatively charged electrons. The atomic nucleus contains a mix of positively charged protons and electrically neutral neutrons...

s, molecule

Molecule

A molecule is an electrically neutral group of at least two atoms held together by covalent chemical bonds. Molecules are distinguished from ions by their electrical charge...

s, or ion

Ion

An ion is an atom or molecule in which the total number of electrons is not equal to the total number of protons, giving it a net positive or negative electrical charge. The name was given by physicist Michael Faraday for the substances that allow a current to pass between electrodes in a...

s are packed in a regularly ordered, repeating pattern extending in all three spatial dimensions.

Almost any object made of an elastic

Elasticity (physics)

In physics, elasticity is the physical property of a material that returns to its original shape after the stress that made it deform or distort is removed. The relative amount of deformation is called the strain....

material could be used like a crystal, with appropriate transducer

Transducer

A transducer is a device that converts one type of energy to another. Energy types include electrical, mechanical, electromagnetic , chemical, acoustic or thermal energy. While the term transducer commonly implies the use of a sensor/detector, any device which converts energy can be considered a...

s, since all objects have natural resonant

Resonance

In physics, resonance is the tendency of a system to oscillate at a greater amplitude at some frequencies than at others. These are known as the system's resonant frequencies...

frequencies of vibration

Vibration

Vibration refers to mechanical oscillations about an equilibrium point. The oscillations may be periodic such as the motion of a pendulum or random such as the movement of a tire on a gravel road.Vibration is occasionally "desirable"...

. For example, steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

is very elastic and has a high speed of sound. It was often used in mechanical filter

Mechanical filter

A mechanical filter is a signal processing filter usually used in place of an electronic filter at radio frequencies. Its purpose is the same as that of a normal electronic filter: to pass a range of signal frequencies, but to block others. The filter acts on mechanical vibrations which are the...

s before quartz. The resonant frequency depends on size, shape, elasticity

Elasticity (physics)

In physics, elasticity is the physical property of a material that returns to its original shape after the stress that made it deform or distort is removed. The relative amount of deformation is called the strain....

, and the speed of sound

Speed of sound

The speed of sound is the distance travelled during a unit of time by a sound wave propagating through an elastic medium. In dry air at , the speed of sound is . This is , or about one kilometer in three seconds or approximately one mile in five seconds....

in the material. High-frequency crystals are typically cut in the shape of a simple, rectangular plate. Low-frequency crystals, such as those used in digital watches, are typically cut in the shape of a tuning fork

Tuning fork

A tuning fork is an acoustic resonator in the form of a two-pronged fork with the prongs formed from a U-shaped bar of elastic metal . It resonates at a specific constant pitch when set vibrating by striking it against a surface or with an object, and emits a pure musical tone after waiting a...

. For applications not needing very precise timing, a low-cost ceramic resonator

Ceramic resonator

A ceramic resonator is an electronic component that when combined with other appropriate components, can produce oscillations at a specific frequency...

is often used in place of a quartz crystal.

When a crystal of quartz

Quartz

Quartz is the second-most-abundant mineral in the Earth's continental crust, after feldspar. It is made up of a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall formula SiO2. There are many different varieties of quartz,...

is properly cut and mounted, it can be made to distort in an electric field

Electric field

In physics, an electric field surrounds electrically charged particles and time-varying magnetic fields. The electric field depicts the force exerted on other electrically charged objects by the electrically charged particle the field is surrounding...

by applying a voltage

Voltage

Voltage, otherwise known as electrical potential difference or electric tension is the difference in electric potential between two points — or the difference in electric potential energy per unit charge between two points...

to an electrode

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit...

near or on the crystal. This property is known as piezoelectricity

Piezoelectricity

Piezoelectricity is the charge which accumulates in certain solid materials in response to applied mechanical stress. The word piezoelectricity means electricity resulting from pressure...

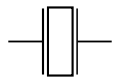

. When the field is removed, the quartz will generate an electric field as it returns to its previous shape, and this can generate a voltage. The result is that a quartz crystal behaves like a circuit composed of an inductor

Inductor

An inductor is a passive two-terminal electrical component used to store energy in a magnetic field. An inductor's ability to store magnetic energy is measured by its inductance, in units of henries...

, capacitor

Capacitor

A capacitor is a passive two-terminal electrical component used to store energy in an electric field. The forms of practical capacitors vary widely, but all contain at least two electrical conductors separated by a dielectric ; for example, one common construction consists of metal foils separated...

and resistor

Resistor

A linear resistor is a linear, passive two-terminal electrical component that implements electrical resistance as a circuit element.The current through a resistor is in direct proportion to the voltage across the resistor's terminals. Thus, the ratio of the voltage applied across a resistor's...

, with a precise resonant frequency. (See RLC circuit

RLC circuit

An RLC circuit is an electrical circuit consisting of a resistor, an inductor, and a capacitor, connected in series or in parallel. The RLC part of the name is due to those letters being the usual electrical symbols for resistance, inductance and capacitance respectively...

.)

Quartz has the further advantage that its elastic constants and its size change in such a way that the frequency dependence on temperature can be very low. The specific characteristics will depend on the mode of vibration and the angle at which the quartz is cut (relative to its crystallographic axes). Therefore, the resonant frequency of the plate, which depends on its size, will not change much, either. This means that a quartz clock, filter or oscillator will remain accurate. For critical applications the quartz oscillator is mounted in a temperature-controlled container, called a crystal oven

Crystal oven

A crystal oven is a temperature-controlled chamber used to maintain the quartz crystal in electronic crystal oscillators at a constant temperature, in order to prevent changes in the frequency due to variations in ambient temperature...

, and can also be mounted on shock absorbers to prevent perturbation by external mechanical vibrations.

Electrical model

Electrical impedance

Electrical impedance, or simply impedance, is the measure of the opposition that an electrical circuit presents to the passage of a current when a voltage is applied. In quantitative terms, it is the complex ratio of the voltage to the current in an alternating current circuit...

(series) and a high impedance

Electrical impedance

Electrical impedance, or simply impedance, is the measure of the opposition that an electrical circuit presents to the passage of a current when a voltage is applied. In quantitative terms, it is the complex ratio of the voltage to the current in an alternating current circuit...

(parallel) resonance point spaced closely together. Mathematically (using the Laplace transform) the impedance of this network can be written as:

or,

where s is the complex frequency (

),

),  is the series resonant frequency in radian

is the series resonant frequency in radianRadian

Radian is the ratio between the length of an arc and its radius. The radian is the standard unit of angular measure, used in many areas of mathematics. The unit was formerly a SI supplementary unit, but this category was abolished in 1995 and the radian is now considered a SI derived unit...

s per second and

is the parallel resonant frequency in radians per second.

is the parallel resonant frequency in radians per second.

Capacitance

In electromagnetism and electronics, capacitance is the ability of a capacitor to store energy in an electric field. Capacitance is also a measure of the amount of electric potential energy stored for a given electric potential. A common form of energy storage device is a parallel-plate capacitor...

across a crystal will cause the parallel resonance to shift downward. This can be used to adjust the frequency at which a crystal oscillates. Crystal manufacturers normally cut and trim their crystals to have a specified resonance frequency with a known 'load' capacitance added to the crystal. For example, a crystal intended for a 6 pF load has its specified parallel resonance frequency when a 6.0 pF capacitor

Capacitor

A capacitor is a passive two-terminal electrical component used to store energy in an electric field. The forms of practical capacitors vary widely, but all contain at least two electrical conductors separated by a dielectric ; for example, one common construction consists of metal foils separated...

is placed across it. Without this capacitance, the resonance frequency is higher.

Resonance modes

A quartz crystal provides both series and parallel resonance. The series resonance is a few kilohertz lower than the parallel one. Crystals below 30 MHz are generally operated between series and parallel resonance, which means that the crystal appears as an inductive reactance in operation. Any additional circuit capacitance will thus pull the frequency down. For a parallel resonance crystal to operate at its specified frequency, the electronic circuit has to provide a total parallel capacitance as specified by the crystal manufacturer.Crystals above 30 MHz (up to >200 MHz) are generally operated at series resonance where the impedance appears at its minimum and equal to the series resistance. For these crystals the series resistance is specified (<100 Ω) instead of the parallel capacitance. To reach higher frequencies, a crystal can be made to vibrate at one of its overtone

Overtone

An overtone is any frequency higher than the fundamental frequency of a sound. The fundamental and the overtones together are called partials. Harmonics are partials whose frequencies are whole number multiples of the fundamental These overlapping terms are variously used when discussing the...

modes, which occur near multiples of the fundamental resonant frequency. Only odd numbered overtones are used. Such a crystal is referred to as a 3rd, 5th, or even 7th overtone crystal. To accomplish this, the oscillator circuit usually includes additional LC circuit

LC circuit

An LC circuit, also called a resonant circuit or tuned circuit, consists of an inductor, represented by the letter L, and a capacitor, represented by the letter C...

s to select the desired overtone.

Temperature effects

A crystal's frequency characteristic depends on the shape or 'cut' of the crystal. A tuning fork crystal is usually cut such that its frequency over temperature is a parabolic curve centered around 25 °C. This means that a tuning fork crystal oscillator will resonate close to its target frequency at room temperature, but will slow down when the temperature either increases or decreases from room temperature. A common parabolic coefficient for a 32 kHz tuning fork crystal is −0.04 ppm/°C².In a real application, this means that a clock built using a regular 32 kHz tuning fork crystal will keep good time at room temperature, lose 2 minutes per year at 10 degrees Celsius above (or below) room temperature and lose 8 minutes per year at 20 degrees Celsius above (or below) room temperature due to the quartz crystal.

Electrical oscillators

Resonator

A resonator is a device or system that exhibits resonance or resonant behavior, that is, it naturally oscillates at some frequencies, called its resonant frequencies, with greater amplitude than at others. The oscillations in a resonator can be either electromagnetic or mechanical...

, amplifying it, and feeding it back to the resonator. The rate of expansion and contraction of the quartz is the resonant

Resonance

In physics, resonance is the tendency of a system to oscillate at a greater amplitude at some frequencies than at others. These are known as the system's resonant frequencies...

frequency, and is determined by the cut and size of the crystal. When the energy of the generated output frequencies matches the losses in the circuit, an oscillation can be sustained.

An oscillator crystal has two electrically conductive plates, with a slice or tuning fork of quartz crystal sandwiched between them. During startup, the circuit around the crystal applies a random noise AC

Alternating current

In alternating current the movement of electric charge periodically reverses direction. In direct current , the flow of electric charge is only in one direction....

signal to it, and purely by chance, a tiny fraction of the noise will be at the resonant frequency of the crystal. The crystal will therefore start oscillating in synchrony with that signal. As the oscillator amplifies the signals coming out of the crystal, the signals in the crystal's frequency band will become stronger, eventually dominating the output of the oscillator. The narrow resonance band of the quartz crystal filter

Electronic filter

Electronic filters are electronic circuits which perform signal processing functions, specifically to remove unwanted frequency components from the signal, to enhance wanted ones, or both...

s out all the unwanted frequencies.

The output frequency of a quartz oscillator can be either the fundamental resonance or a multiple of the resonance

Harmonic

A harmonic of a wave is a component frequency of the signal that is an integer multiple of the fundamental frequency, i.e. if the fundamental frequency is f, the harmonics have frequencies 2f, 3f, 4f, . . . etc. The harmonics have the property that they are all periodic at the fundamental...

, called an overtone

Overtone

An overtone is any frequency higher than the fundamental frequency of a sound. The fundamental and the overtones together are called partials. Harmonics are partials whose frequencies are whole number multiples of the fundamental These overlapping terms are variously used when discussing the...

frequency. High frequency crystals are often designed to operate at third, fifth, or seventh overtones.

A major reason for the wide use of crystal oscillators is their high Q factor

Q factor

In physics and engineering the quality factor or Q factor is a dimensionless parameter that describes how under-damped an oscillator or resonator is, or equivalently, characterizes a resonator's bandwidth relative to its center frequency....

. A typical Q value for a quartz oscillator ranges from 104 to 106, compared to perhaps 102 for an LC oscillator. The maximum Q for a high stability quartz oscillator can be estimated as Q = 1.6 × 107/f, where f is the resonance frequency in megahertz.

One of the most important traits of quartz crystal oscillators is that they can exhibit very low phase noise

Phase noise

Phase noise is the frequency domain representation of rapid, short-term, random fluctuations in the phase of a waveform, caused by time domain instabilities...

.

In many oscillators, any spectral energy at the resonant frequency will be amplified by the oscillator, resulting in a collection of tones at different phases.

In a crystal oscillator, the crystal mostly vibrates in one axis, therefore only one phase is dominant.

This property of low phase noise

Phase noise

Phase noise is the frequency domain representation of rapid, short-term, random fluctuations in the phase of a waveform, caused by time domain instabilities...

makes them particularly useful in telecommunications where stable signals are needed, and in scientific equipment where very precise time references are needed.

Environmental changes of temperature, humidity, pressure, and vibration can change the resonant frequency of a quartz crystal, but there are several designs that reduce these environmental effects. These include the TCXO, MCXO, and OCXO (defined below). These designs (particularly the OCXO) often produce devices with excellent short-term stability. The limitations in short-term stability are due mainly to noise from electronic components in the oscillator circuits. Long term stability is limited by aging of the crystal.

Due to aging and environmental factors (such as temperature and vibration), it is difficult to keep even the best quartz oscillators within one part in 1010 of their nominal frequency without constant adjustment. For this reason, atomic oscillators are used for applications requiring better long-term stability and accuracy.

Spurious frequencies

For crystals operated at series resonance or pulled away from the main mode by the inclusion of a series inductor or capacitor , significant (and temperature-dependent) spurious responses may be experienced. Though most spurious modes are typically some tens of kilohertz above the wanted series resonance their temperature coefficient will be different from the main mode and the spurious response may move through the main mode at certain temperatures. Even if the series resistances at the spurious resonances appear higher than the one at wanted frequency a rapid change in the main mode series resistance can occur at specific temperatures when the two frequencies are coincidental.A consequence of these activity dips is that the oscillator may lock at a spurious frequency (at specific temperatures). This is generally minimized by ensuring that the maintaining circuit has insufficient gain to activate unwanted modes.

Spurious frequencies are also generated by subjecting the crystal to vibration this modulates the resonance frequency to a small degree by the frequency of the vibrations. SC-cut crystals are designed to minimize the frequency effect of mounting stress and they are therefore less sensitive to vibration. Acceleration effects including gravity are also reduced with SC cut crystals as is frequency change with time due to long term mounting stress variation.

There are disadvantages with SC cut shear mode crystals, these are the need for the maintaining oscillator to discriminate against other closely related unwanted modes and increased frequency change due to temperature when subject to a full ambient range. SC cut crystals are most advantageous where temperature control at their temperature of zero temperature coefficient (turnover) is possible under these circumstances an overall stability performance from premium units can approach the stability of Rubidium frequency standards.

Commonly used crystal frequencies

Crystal oscillator circuits are often designed around relatively few standard frequencies, such as 3.579545 MHz, 4.433619 MHz, 10 MHz, 14.318182 MHz, 17.734475 MHz, 20 MHz, 33.33 MHz, and 40 MHz. The popularity of the 3.579545 MHz crystals is due to low cost since they are used for NTSCNTSC

NTSC, named for the National Television System Committee, is the analog television system that is used in most of North America, most of South America , Burma, South Korea, Taiwan, Japan, the Philippines, and some Pacific island nations and territories .Most countries using the NTSC standard, as...

color television

Television

Television is a telecommunication medium for transmitting and receiving moving images that can be monochrome or colored, with accompanying sound...

receivers. Using frequency dividers, frequency multiplier

Frequency multiplier

In electronics, a frequency multiplier is an electronic circuit that generates an output signal whose output frequency is a harmonic of its input frequency. Frequency multipliers consist of a nonlinear circuit that distorts the input signal and consequently generates harmonics of the input signal...

s and phase locked loop circuits, it is practical to derive a wide range of frequencies from one reference frequency. 14.318182 MHz (four times 3.579545 MHz) is used in computer video displays to generate a bitmap

Bitmap

In computer graphics, a bitmap or pixmap is a type of memory organization or image file format used to store digital images. The term bitmap comes from the computer programming terminology, meaning just a map of bits, a spatially mapped array of bits. Now, along with pixmap, it commonly refers to...

ped video display for NTSC color monitors, such as the CGA

Color Graphics Adapter

The Color Graphics Adapter , originally also called the Color/Graphics Adapter or IBM Color/Graphics Monitor Adapter, introduced in 1981, was IBM's first color graphics card, and the first color computer display standard for the IBM PC....

used with the original IBM PC

IBM PC

The IBM Personal Computer, commonly known as the IBM PC, is the original version and progenitor of the IBM PC compatible hardware platform. It is IBM model number 5150, and was introduced on August 12, 1981...

. (The IBM PC used 14.318182 MHz, divided by three, as its 4.77 MHz clock source, using one crystal for two purposes.) The 4.433619 MHz and 17.734475 MHz values are used in PAL

PAL

PAL, short for Phase Alternating Line, is an analogue television colour encoding system used in broadcast television systems in many countries. Other common analogue television systems are NTSC and SECAM. This page primarily discusses the PAL colour encoding system...

color television equipment and devices intended to produce PAL signals.

Crystals can be manufactured for oscillation over a wide range of frequencies, from a few kilohertz up to several hundred megahertz. Many applications call for a crystal oscillator frequency conveniently related to some other desired frequency, so hundreds of standard crystal frequencies are made in large quantities and stocked by electronics distributors.

Crystal structures and materials

Quartz

Quartz is the second-most-abundant mineral in the Earth's continental crust, after feldspar. It is made up of a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall formula SiO2. There are many different varieties of quartz,...

. At the beginning of the technology, natural quartz crystals were used; now synthetic crystalline quartz grown by hydrothermal synthesis

Hydrothermal synthesis

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term "hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase...

is predominant due to higher purity, lower cost, and more convenient handling. One of the few remaining uses of natural crystals is for pressure transducers in deep wells. During World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

and for some time afterwards, natural quartz was considered a strategic material by the USA. Large crystals were imported from Brazil. Raw "lascas", the source material quartz for hydrothermal synthesis, are imported to USA or mined locally by Coleman Quartz. The average value of as-grown synthetic quartz in 1994 was USD60/kg.

Two types of quartz crystals exist: left-handed and right-handed, differing in the optical rotation

Optical rotation

Optical rotation is the turning of the plane of linearly polarized light about the direction of motion as the light travels through certain materials. It occurs in solutions of chiral molecules such as sucrose , solids with rotated crystal planes such as quartz, and spin-polarized gases of atoms...

but identical in other physical properties. Both left and right-handed crystals can be used for oscillators, if the cut angle is correct. In manufacture, right-handed quartz is generally used. The SiO4 tetrahedrons form parallel helixes; the direction of twist of the helix determines the left- or right-hand orientation. The helixes are aligned along the z-axis and merged together, sharing atoms. The mass of the helixes forms a mesh of small and large channels parallel to the z-axis; the large ones are large enough to allow some mobility of smaller ions and molecules through the crystal.

Quartz exists in several phases. At 573 °C at 1 atmosphere (and at higher temperatures and higher pressures) the α-quartz undergoes quartz inversion

Quartz inversion

The room-temperature form of quartz, α-quartz, undergoes a reversible change in crystal structure at 573 °C to form β-quartz. This phenomenon is called an inversion, and for the α to β quartz inversion is accompanied by a linear expansion of 0.45 %. This inversion can lead to cracking of...

, transforms reversibly to β-quartz. The reverse process however is not entirely homogeneous and crystal twinning

Crystal twinning

Crystal twinning occurs when two separate crystals share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals in a variety of specific configurations. A twin boundary or composition surface separates the two crystals....

occurs. Care has to be taken during manufacture and processing to avoid the phase transformation. Other phases, e.g. the higher-temperature phases tridymite

Tridymite

Tridymite is a high-temperature polymorph of quartz and usually occurs as minute tabular white or colorless pseudo-hexagonal triclinic crystals, or scales, in cavities in acidic volcanic rocks. Its chemical formula is SiO2. Tridymite was first described in 1868 and the type location is in Hidalgo,...

and cristobalite

Cristobalite

The mineral cristobalite is a high-temperature polymorph of silica, meaning that it has the same chemical formula, SiO2, but a distinct crystal structure. Both quartz and cristobalite are polymorphs with all the members of the quartz group which also include coesite, tridymite and stishovite...

, are not significant for oscillators. All quartz oscillator crystals are the α-quartz type.

Infrared spectrophotometry is used as one of the methods for measuring the quality of the grown crystals. The wavenumber

Wavenumber

In the physical sciences, the wavenumber is a property of a wave, its spatial frequency, that is proportional to the reciprocal of the wavelength. It is also the magnitude of the wave vector...

s 3585, 3500, and 3410 cm−1 are commonly used. The measured value is based on the absorption band

Absorption band

An absorption band is a range of wavelengths, frequencies or energies in the electromagnetic spectrum which are able to excite a particular transition in a substance...

s of the OH radical and the infrared Q value is calculated. The electronic grade crystals, grade C, have Q of 1.8 million or above; the premium grade B crystals have Q of 2.2 million, and special premium grade A crystals have Q of 3.0 million. The Q value is calculated only for the z region; crystals containing other regions can be adversely affected. Another quality indicator is the etch channel density; when the crystal is etched

Etching

Etching is the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio in the metal...

, tubular channels are created along linear defects. For processing involving etching, e.g. the wristwatch tuning fork crystals, low etch channel density is desirable. The etch channel density for swept quartz is about 10–100 and significantly more for unswept quartz. Presence of etch channels and etch pits degrades the resonator's Q and introduces nonlinearities.

Quartz crystals can be grown for specific purposes.

Crystals for AT-cut are the most common in mass production of oscillator materials; the shape and dimensions are optimized for high yield of the required wafers. High-purity quartz crystals are grown with especially low content of aluminium, alkali metal and other impurities and minimal defects; the low amount of alkali metals provides increased resistance to ionizing radiation. Crystals for wrist watches, for cutting the tuning fork 32768 Hz crystals, are grown with very low etch channel density.

Crystals for SAW devices are grown as flat, with large X-size seed with low etch channel density.

Special high-Q crystals, for use in highly stable oscillators, are grown at constant slow speed and have constant low infrared absorption along the entire Z axis. Crystals can be grown as Y-bar, with a seed crystal

Seed crystal

A seed crystal is a small piece of single crystal/polycrystal material from which a large crystal of the same material typically is to be grown...

in bar shape and elongated along the Y axis, or as Z-plate, grown from a plate seed with Y-axis direction length and X-axis width. The region around the seed crystal contains a large number of crystal defects and should not be used for the wafers.

Crystals grow anisotropically; the growth along the Z axis is up to 3 times faster than along the X axis. The growth direction and rate also influences the rate of uptake of impurities. Y-bar crystals, or Z-plate crystals with long Y axis, have four growth regions usually called +X, -X, Z, and S. The distribution of impurities during growth is uneven; different growth areas contain different level of contaminants. The z regions are the purest, the small occasionally present s regions are less pure, the +x region is yet less pure, and the -x region has the highest level of impurities. The impurities have negative impact on radiation hardness, susceptibility to twinning

Crystal twinning

Crystal twinning occurs when two separate crystals share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals in a variety of specific configurations. A twin boundary or composition surface separates the two crystals....

, filter loss, and long and short term stability of the crystals. Different-cut seeds in different orientations may provide other kinds of growth regions. The growth speed of the -x direction is slowest due to the effect of adsorption of water molecules on the crystal surface; aluminium impurities suppress growth in two other directions. The content of aluminium is lowest in z region, higher in +x, yet higher in -x, and highest in s; the size of s regions also grows with increased amount of aluminium present. The content of hydrogen is lowest in z region, higher in +x region, yet higher in s region, and highest in -x. Aluminium inclusions transform to color centers with a gamma ray irradiation, causing darkening of the crystal proportional to the dose and level of impurities; presence of regions with different darkness reveals the different growth regions.

The dominant type of defect

Crystallographic defect

Crystalline solids exhibit a periodic crystal structure. The positions of atoms or molecules occur on repeating fixed distances, determined by the unit cell parameters. However, the arrangement of atom or molecules in most crystalline materials is not perfect...

of concern in quartz crystals is the substitution of Al(III)

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

for Si(IV)

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

atom in the crystal lattice. The aluminium ion has an associated interstitial charge compensator present nearby, which can be a H+

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

ion (attached to the nearby oxygen and forming a hydroxyl group, called Al-OH defect), Li+

Lithium

Lithium is a soft, silver-white metal that belongs to the alkali metal group of chemical elements. It is represented by the symbol Li, and it has the atomic number 3. Under standard conditions it is the lightest metal and the least dense solid element. Like all alkali metals, lithium is highly...

ion, Na+

Sodium

Sodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

ion, K+

Potassium

Potassium is the chemical element with the symbol K and atomic number 19. Elemental potassium is a soft silvery-white alkali metal that oxidizes rapidly in air and is very reactive with water, generating sufficient heat to ignite the hydrogen emitted in the reaction.Potassium and sodium are...

ion (less common), or an electron hole

Electron hole

An electron hole is the conceptual and mathematical opposite of an electron, useful in the study of physics, chemistry, and electrical engineering. The concept describes the lack of an electron at a position where one could exist in an atom or atomic lattice...

trapped in a nearby oxygen atom orbital. The composition of the growth solution, whether it is based on lithium or sodium alkali compounds, determines the charge compensating ions for the aluminium defects. The ion impurities are of concern as they are not firmly bound and can migrate through the crystal, altering the local lattice elasticity and the resonant frequency of the crystal. Other common impurities of concern are e.g. iron(III) (interstitial), fluorine, boron(III), phosphorus(V) (substitution), titanium(IV) (substitution, universally present in magmatic quartz, less common in hydrothermal quartz), and germanium(IV) (substitution). Sodium and iron ions can cause inclusions

Inclusion (mineral)

In mineralogy, an inclusion is any material that is trapped inside a mineral during its formation.In gemology, an inclusion is a characteristic enclosed within a gemstone, or reaching its surface from the interior....

of acnite and elemeusite crystals. Inclusions of water may be present in fast-grown crystals; interstitial water molecules are abundant near the crystal seed. Another defect of importance is the hydrogen containing growth defect, when instead of a Si-O-Si structure a pair of Si-OH HO-Si groups is formed; essentially a hydrolyzed bond. Fast-grown crystals contain more hydrogen defects than slow-grown ones. These growth defects source as supply of hydrogen ions for radiation-induced processes and forming Al-OH defects. Germanium impurities tend to trap electrons created during irradiation; the alkali metal cations then migrate towards the negatively charged center and form a stabilizing complex. Matrix defects can be also present; oxygen vacancies, silicon vacancies (usually compensated by 4 hydrogens or 3 hydrogens and a hole), peroxy groups, etc. Some of the defects produce localized levels in the forbidden band, serving as charge traps; Al(III) and B(III) typically serve as hole traps while electron vacancies, titanium, germanium, and phosphorus atoms serve as electron traps. The trapped charge carriers can be released by heating; their recombination is the cause of thermoluminescence

Thermoluminescence

Thermoluminescence is a form of luminescence that is exhibited by certain crystalline materials, such as some minerals, when previously absorbed energy from electromagnetic radiation or other ionizing radiation is re-emitted as light upon heating of the material...

.

The mobility of interstitial ions depends strongly on temperature. Hydrogen ions are mobile down to 10 K, but alkali metal ions become mobile only at temperatures around and above 200 K.

The hydroxyl defects can be measured by near-infrared spectroscopy. The trapped holes can be measured by electron spin resonance. The Al-Na+ defects show as an acoustic loss peak due to their stress-induced motion; the Al-Li+ defects do not form a potential well so are not detectable this way. Some of the radiation induced defects during their thermal annealing produce thermoluminescence

Thermoluminescence

Thermoluminescence is a form of luminescence that is exhibited by certain crystalline materials, such as some minerals, when previously absorbed energy from electromagnetic radiation or other ionizing radiation is re-emitted as light upon heating of the material...

; defects related to aluminium, titanium, and germanium can be distinguished.

Swept crystals are crystals that undergone a solid-state electrodiffusion purification process. Sweeping involves heating the crystal above 500 °C in a hydrogen-free atmosphere, and the voltage gradient of at least 1 kilovolt/cm, for several (usually over 12) hours. The migration of impurities and the gradual replacement of alkali metal ions with hydrogen (when swept in air) or electron holes (when swept in vacuum) causes a weak electric current through the crystal; decay of this current to a constant value signals end of the process. The crystal is then left to cool, while the electric field is maintained. The impurities are concentrated at the cathode region of the crystal, which is cut off afterwards and discarded. Swept crystals have increased resistance to radiation, as the dose effects are dependent on the level of alkali metal impurities; they are suitable for use in devices exposed to ionizing radiation, e.g. for nuclear and space technology. Sweeping under vacuum at higher temperatures and higher field strengths yields yet more radiation-hard crystals. The level and character of impurities can be measured by infrared spectroscopy. Quartz can be swept in both α and β phase; sweeping in β phase is faster, but the phase transition may induce twinning. Twinning can be mitigated by subjecting the crystal to compression stress in the X direction, or an AC or DC electric field along the X axis while the crystal cools through the phase transformation temperature region.

Sweeping can be also used to introduce one kind of an impurity into the crystal. Lithium, sodium, and hydrogen swept crystals are used for e.g. studying quartz behavior.

Very small crystals for high fundamental mode frequencies can be manufactured by photolithography.

Crystals can be adjusted to exact frequency by laser trimming

Laser trimming

Laser trimming is the manufacturing process of using a laser to adjust the operating parameters of an electronic circuit.One of the most common applications uses a laser to burn away small portions of resistors, raising their resistance value...

. A technique used in the world of amateur radio

Amateur radio

Amateur radio is the use of designated radio frequency spectrum for purposes of private recreation, non-commercial exchange of messages, wireless experimentation, self-training, and emergency communication...

for slight decrease of the crystal frequency may be achieved by exposing crystals with silver electrodes to vapors of iodine

Iodine

Iodine is a chemical element with the symbol I and atomic number 53. The name is pronounced , , or . The name is from the , meaning violet or purple, due to the color of elemental iodine vapor....

, which causes a slight mass increase on the surface by forming a thin layer of silver iodide

Silver iodide

Silver iodide is a yellow, inorganic, photosensitive iodide of silver used in photography, in medicine as an antiseptic, and in rainmaking for cloud seeding.-Crystal structure:...

; such crystals however had problematic long-term stability.

Another method commonly used is electrochemical increase or decrease of silver electrode thickness by submerging resonator in lapis solved in water, citric acid in water, or water with salt, and using resonator as one electrode, and small silver electrode as another.

By choosing direction of current, one can either increase, or decrease mass of electrodes.

Details were published in "Radio" magazine (3/1978) by UB5LEV.

Raising frequency by scratching off parts of the electrodes is advised against, as this may damage the crystal and lower its Q factor

Q factor

In physics and engineering the quality factor or Q factor is a dimensionless parameter that describes how under-damped an oscillator or resonator is, or equivalently, characterizes a resonator's bandwidth relative to its center frequency....

. Capacitor trimmer

Trimmer

In light-frame construction, a trimmer is a timber or metal beam used to create an opening around a stairwell, skylight, chimney, and the like...

s can be also used for frequency adjustment of the oscillator circuit.

Some other piezoelectric materials than quartz can be employed; e.g. single crystals of lithium tantalate

Lithium tantalate

Lithium tantalate , is a crystalline solid which possesses unique optical, piezoelectric and pyroelectric properties which make it valuable for nonlinear optics, passive infrared sensors such as motion detectors, terahertz generation and detection, surface acoustic wave applications, cell phones...

, lithium niobate

Lithium niobate

Lithium niobate is a compound of niobium, lithium, and oxygen. Its single crystals are an important material for optical waveguides, mobile phones, optical modulators and various other linear and non-linear optical applications.-Properties:...

, lithium borate, berlinite

Berlinite

Berlinite is a rare phosphate mineral. It has the same crystal structure as quartz with a low temperature polytype isostructural with α–quartz and a high temperature polytype isostructural with β–quartz...

, gallium arsenide, lithium tetraborate, aluminium phosphate

Aluminium phosphate

Aluminium phosphate is a chemical compound. It is used in cake mixes and in some baking powders as a leavening agent to help baked goods rise. Medicinally it is used as adsorbent for toxoid.-Uses:...

, bismuth germanium oxide, polycrystalline zirconium titanate ceramics, high-alumina ceramics, silicon

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

-zinc oxide

Zinc oxide

Zinc oxide is an inorganic compound with the formula ZnO. It is a white powder that is insoluble in water. The powder is widely used as an additive into numerous materials and products including plastics, ceramics, glass, cement, rubber , lubricants, paints, ointments, adhesives, sealants,...

composite, or dipotassium tartrate; some materials may be more suitable for specific applications. An oscillator crystal can be also manufactured by depositing the resonator material on the silicon chip surface. Crystals of gallium phosphate

Gallium phosphate

Gallium phosphate is a colorless trigonal crystal with a hardness of 5.5 on the Mohs scale. GaPO4 is isotypic with quartz, possessing very similar properties, but the silicon atoms are alternately substituted with gallium and phosphorus, thereby doubling the piezoelectric effect...

, langasite, langanite and langanate are about 10 times more pullable than the corresponding quartz crystals, and are used in some VCXO oscillators.

Stability and aging

The frequency stability is determined by the crystal's QQ factor

In physics and engineering the quality factor or Q factor is a dimensionless parameter that describes how under-damped an oscillator or resonator is, or equivalently, characterizes a resonator's bandwidth relative to its center frequency....

. It is inversely dependent on the frequency, and on the constant that is dependent on the particular cut. Other factors influencing Q are the overtone used, the temperature, the level of driving of the crystal, the quality of the surface finish, the mechanical stresses imposed on the crystal by bonding and mounting, the geometry of the crystal and the attached electrodes, the material purity and defects in the crystal, type and pressure of the gas in the enclosure, interfering modes, and presence and absorbed dose of ionizing and neutron radiation.

Temperature influences the operating frequency; various forms of compensation are used, from analog compensation (TCXO) and microcontroller compensation (MCXO) to stabilization of the temperature with a crystal oven

Crystal oven

A crystal oven is a temperature-controlled chamber used to maintain the quartz crystal in electronic crystal oscillators at a constant temperature, in order to prevent changes in the frequency due to variations in ambient temperature...

(OCXO). The crystals possess temperature hysteresis

Hysteresis

Hysteresis is the dependence of a system not just on its current environment but also on its past. This dependence arises because the system can be in more than one internal state. To predict its future evolution, either its internal state or its history must be known. If a given input alternately...

; the frequency at a given temperature achieved by increasing the temperature is not equal to the frequency on the same temperature achieved by decreasing the temperature. The temperature sensitivity depends primarily on the cut; the temperature compensated cuts are chosen as to minimize frequency/temperature dependence. Special cuts can be made with a linear temperature characteristics; the LC cut is used in quartz thermometers. Other influencing factors are the overtone used, the mounting and electrodes, impurities in the crystal, mechanical strain, crystal geometry, rate of temperature change, thermal history (due to hysteresis), ionizing radiation, and drive level.

Crystals tend to suffer anomalies in their frequency/temperature and resistance/temperature characteristics, known as activity dips. These are small downward (in frequency) or upward (in resistance) excursions localized at certain temperatures, with their temperature position dependent on the value of the load capacitors.

Mechanical stresses also influence the frequency. The stresses can be induced by mounting, bonding, and application of the electrodes, by differential thermal expansion of the mounting, electrodes, and the crystal itself, by differential thermal stresses when there is a temperature gradient present, by expansion or shrinkage of the bonding materials during curing, by the air pressure that is transferred to the ambient pressure within the crystal enclosure, by the stresses of the crystal lattice itself (nonuniform growth, impurities, dislocations), by the surface imperfections and damage caused during manufacture, and by the action of gravity on the mass of the crystal; the frequency can therefore be influenced by position of the crystal. Other dynamic stress inducing factors are shocks, vibrations, and acoustic noise. Some cuts are less sensitive to stresses; the SC (Stress Compensated) cut is an example. Atmospheric pressure changes can also introduce deformations to the housing, influencing the frequency by changing stray capacitances.

Atmospheric humidity influences the thermal transfer properties of air, and can change electrical properties of plastics by diffusion of water molecules into their structure, altering the dielectric constant

Dielectric constant

The relative permittivity of a material under given conditions reflects the extent to which it concentrates electrostatic lines of flux. In technical terms, it is the ratio of the amount of electrical energy stored in a material by an applied voltage, relative to that stored in a vacuum...

s and electrical conductivity.

Other factors influencing the frequency are the power supply voltage, load impedance, magnetic fields, electric fields (in case of cuts that are sensitive to them, e.g. SC), the presence and absorbed dose of γ-particles and ionizing radiation, and the age of the crystal.

Crystals undergo slow gradual change of frequency with time, known as aging. There are many mechanisms involved. The mounting and contacts may undergo relief of the built-in stresses. Molecules of contamination either from the residual atmosphere, outgassed

Outgassing

Outgassing is the release of a gas that was dissolved, trapped, frozen or absorbed in some material. As an example, research has shown how the concentration of carbon dioxide in the Earth's atmosphere has sometimes been linked to ocean outgassing...

from the crystal, electrodes or packaging materials, or introduced during sealing the housing can be adsorbed on the crystal surface, changing its mass; this effect is exploited in quartz crystal microbalance

Quartz crystal microbalance

A quartz crystal microbalance measures a mass per unit area by measuring the change in frequency of a quartz crystal resonator. The resonance is disturbed by the addition or removal of a small mass due to oxide growth/decay or film deposition at the surface of the acoustic resonator...

s. The composition of the crystal can be gradually altered by outgassing, diffusion of atoms of impurities or migrating from the electrodes, or the lattice can be damaged by radiation. Slow chemical reactions may occur on or in the crystal, or on the inner surfaces of the enclosure. Electrode material, e.g. chromium or aluminium, can react with the crystal, creating layers of metal oxide and silicon; these interface layers can undergo changes in time. The pressure in the enclosure can change due to varying atmospheric pressure, temperature, leaks, or outgassing of the materials inside. Factors outside of the crystal itself are e.g. aging of the oscillator circuitry (and e.g. change of capacitances), and drift of parameters of the crystal oven. External atmosphere composition can also influence the aging; hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

can diffuse through nickel housing. Helium can cause similar issues when it diffuses through glass enclosures of rubidium standard

Rubidium standard

A rubidium standard or rubidium atomic clock is a frequency standard in which a specified hyperfine transition of electrons in rubidium-87 atoms is used to control the output frequency...

s.

Gold is a favored electrode material for low-aging resonators; its adhesion to quartz is strong enough to maintain contact even at strong mechanical shocks, but weak enough to not support significant strain gradients (unlike chromium, aluminium, and nickel). Gold also does not form oxides; it adsorbs organic contaminants from the air, but these are easy to remove. However, gold alone can undergo delamination; a layer of chromium is therefore sometimes used for improved binding strength. Silver and aluminium are often used as electrodes; however both form oxide layers with time that increases the crystal mass and lowers frequency. Silver can be passivated by exposition to iodine

Iodine

Iodine is a chemical element with the symbol I and atomic number 53. The name is pronounced , , or . The name is from the , meaning violet or purple, due to the color of elemental iodine vapor....

vapors, forming a layer of silver iodide

Silver iodide

Silver iodide is a yellow, inorganic, photosensitive iodide of silver used in photography, in medicine as an antiseptic, and in rainmaking for cloud seeding.-Crystal structure:...

. Aluminium oxidizes readily but slowly, until about 5 nm thickness is reached; increased temperature during artificial aging does not significantly increase the oxide forming speed; a thick oxide layer can be formed during manufacture by anodizing. Exposition of silver-plated crystal to iodine vapors can be also used in amateur conditions for lowering the crystal frequency slightly; the frequency can be also increased by scratching off parts of the electrodes, but that carries risk of damage to the crystal and loss of Q.

A DC voltage bias between the electrodes can accelerate the initial aging, probably by induced diffusion of impurities through the crystal. Placing a capacitor in series with the crystal and a several-megohm resistor in parallel can minimize such voltages.

Crystals suffer from minor short-term frequency fluctuations as well. The main causes of such noise are e.g. thermal noise (which limits the noise floor), phonon scattering

Phonon scattering

Phonons can scatter through several mechanisms as they travel through the material. These scattering mechanisms are: Umklapp phonon-phonon scattering, phonon-impurity scattering, phonon-electron scattering, and phonon-boundary scattering...

(influenced by lattice defects), adsorption/desorption of molecules on the surface of the crystal, noise of the oscillator circuits, mechanical shocks and vibrations, acceleration and orientation changes, temperature fluctuations, and relief of mechanical stresses. The short-term stability is measured by four main parameters: Allan variance

Allan variance

The Allan variance , also known as two-sample variance, is a measure of frequency stability in clocks, oscillators and amplifiers. It is named after David W. Allan. It is expressed mathematically as\sigma_y^2. \,...

(the most common one specified in oscillator data sheets), phase noise, spectral density of phase deviations, and spectral density of fractional frequency deviations. The effects of acceleration and vibration tend to dominate the other noise sources; surface acoustic wave devices tend to be more sensitive than bulk acoustic wave (BAW) ones, and the stress-compensated cuts are even less sensitive. The relative orientation of the acceleration vector to the crystal dramatically influences the crystal's vibration sensitivity. Mechanical vibration isolation mountings can be used for high-stability crystals.

Crystals are sensitive to shock

Shock (mechanics)

A mechanical or physical shock is a sudden acceleration or deceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation....

. The mechanical stress causes short-time change in the oscillator frequency due to the stress-sensitivity of the crystal, and can introduce a permanent change of frequency due to shock-induced changes of mounting and internal stresses (if the elastic limits of the mechanical parts are exceeded), desorption of contamination from the crystal surfaces, or change in parameters of the oscillator circuit. High magnitudes of shocks may tear the crystals off their mountings (especially the case of large low-frequency crystals suspended on thin wires), or cause cracking of the crystal. Crystals free of surface imperfections are highly shock-resistant; chemical polishing can produce crystals able to survive tens of thousands g

G-force

The g-force associated with an object is its acceleration relative to free-fall. This acceleration experienced by an object is due to the vector sum of non-gravitational forces acting on an object free to move. The accelerations that are not produced by gravity are termed proper accelerations, and...

.

Phase noise

Phase noise

Phase noise is the frequency domain representation of rapid, short-term, random fluctuations in the phase of a waveform, caused by time domain instabilities...

plays significant role in frequency synthesis systems using frequency multiplication; a multiplication of a frequency by N increases the phase noise power by N2. A frequency multiplication by 10 times multiplies the magnitude of the phase error by 10 times. This can be disastrous for systems employing e.g. PLL or FSK

Frequency-shift keying

Frequency-shift keying is a frequency modulation scheme in which digital information is transmitted through discrete frequency changes of a carrier wave. The simplest FSK is binary FSK . BFSK uses a pair of discrete frequencies to transmit binary information. With this scheme, the "1" is called...

technologies.

Crystals are somewhat sensitive to radiation damage

Radiation damage

Radiation damage is a term associated with ionizing radiation.-Causes:This radiation may take several forms:*Cosmic rays and subsequent energetic particles caused by their collision with the atmosphere and other materials....

. Natural quartz is much more sensitive than artificially grown crystals, and sensitivity can be further reduced by sweeping the crystal – heating the crystal to at least 400 °C in hydrogen-free atmosphere in electric field of at least 500 V/cm for at least 12 hours. Such swept crystals have very low response to steady ionizing radiation. Some Si(IV)

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

atoms are replaced with Al(III)

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

impurities, each having a compensating Li+

Lithium

Lithium is a soft, silver-white metal that belongs to the alkali metal group of chemical elements. It is represented by the symbol Li, and it has the atomic number 3. Under standard conditions it is the lightest metal and the least dense solid element. Like all alkali metals, lithium is highly...

or Na+

Sodium

Sodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

cation nearby. Ionization produces electron-hole pairs; the holes are trapped in the lattice near the Al atom, the resulting Li and Na atoms are loosely trapped along the Z axis; the change of the lattice near the Al atom and the corresponding elastic constant then causes a corresponding change in frequency. Sweeping removes the Li+ and Na+ ions from the lattice, reducing this effect. The Al3+ site can also trap hydrogen atoms. All crystals have transient negative frequency shift after exposition to an X-ray

X-ray

X-radiation is a form of electromagnetic radiation. X-rays have a wavelength in the range of 0.01 to 10 nanometers, corresponding to frequencies in the range 30 petahertz to 30 exahertz and energies in the range 120 eV to 120 keV. They are shorter in wavelength than UV rays and longer than gamma...

pulse; the frequency then shifts gradually back; natural quartz reaches stable frequency after 10–1000 seconds, with negative offset to pre-irradiation frequency, artificial crystals return to frequency slightly lower or higher than pre-irradiation, swept crystals anneal virtually back to original frequency. The annealing is faster at higher temperatures. Sweeping under vacuum at higher temperatures and field strength can further reduce the crystal's response to X-ray pulses. Series resistance of unswept crystals increases after an X-ray dose, and anneals back to a somewhat higher value for a natural quartz (requiring a corresponding gain reserve in the circuit) and back to pre-irradiation value for synthetic crystals. Series resistance of swept crystals is unaffected. Increase of series resistance degrades Q; too high increase can stop the oscillations. Neutron radiation

Neutron radiation

Neutron radiation is a kind of ionizing radiation which consists of free neutrons. A result of nuclear fission or nuclear fusion, it consists of the release of free neutrons from atoms, and these free neutrons react with nuclei of other atoms to form new isotopes, which, in turn, may produce...

induces frequency changes by introducing dislocations into the lattice by knocking out atoms, a single fast neutron can produce many defects; the SC and AT cut frequency increases roughly linearly with absorbed neutron dose, while the frequency of the BT cuts decreases. Neutrons also alter the temperature-frequency characteristics. Frequency change at low ionizing radiation doses is proportionally higher than for higher doses. High-intensity radiation can stop the oscillator by inducing photoconductivity

Photoconductivity

Photoconductivity is an optical and electrical phenomenon in which a material becomes more electrically conductive due to the absorption of electromagnetic radiation such as visible light, ultraviolet light, infrared light, or gamma radiation....

in the crystal and transistors; with a swept crystal and properly designed circuit the oscillations can restart within 15 microseconds after the radiation burst. Quartz crystals with high level of alkali metal impurities lose Q with irradiation; Q of swept artificial crystals is unaffected. Irradiation with higher doses (over 105 rad) lowers sensitivity to subsequent doses. Very low radiation doses (below 300 rad) have disproportionately higher effect, but this nonlinearity saturates at higher doses. At very high doses, the radiation response of the crystal saturates as well, due to finite number of impurity sites that can be affected.

Magnetic field

Magnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

s have low effect on the crystal itself, as quartz is diamagnetic; eddy current

Eddy current

Eddy currents are electric currents induced in conductors when a conductor is exposed to a changing magnetic field; due to relative motion of the field source and conductor or due to variations of the field with time. This can cause a circulating flow of electrons, or current, within the body of...

s or AC voltages can however be induced into the circuits, and magnetic parts of the mounting and housing may be influenced.

After the power-up, the crystals take several seconds to minutes to "warm up" and stabilize their frequency. The oven-controlled OCXOs require usually 3–10 minutes for heating up and reaching thermal equilibrium; the oven-less oscillators stabilize in several seconds as the few milliwatts dissipated in the crystal cause a small but noticeable level of internal heating.

Crystals have no inherent failure mechanisms; some are operating in devices for decades. Failures may be however introduced by faults in bonding, leaky enclosures, corrosion, frequency shift by aging, breaking the crystal by too high mechanical shock, or radiation induced damage when nonswept quartz is used. Crystals can be also damaged by overdriving.

The crystals have to be driven at the appropriate drive level. While AT cuts tend to be fairly forgiving, and only their electrical parameters, stability and aging characteristics are degraded when overdriven, low-frequency crystals, especially flexural-mode ones, may fracture at too high drive levels. The drive level is specified as the amount of power dissipated in the crystal. The appropriate drive levels are about 5 microwatts for flexural modes up to 100 kHz, 1 microwatt for fundamental modes at 1–4 MHz, 0.5 microwatts for fundamental modes 4–20 MHz, and 0.5 microwatts for overtone modes at 20–200 MHz. Too low drive level may cause problems with starting the oscillator. Low drive levels are better for higher stability and lower power consumption of the oscillator. Higher drive levels, in turn, reduce the impact of noise by increasing the signal-to-noise ratio

Signal-to-noise ratio

Signal-to-noise ratio is a measure used in science and engineering that compares the level of a desired signal to the level of background noise. It is defined as the ratio of signal power to the noise power. A ratio higher than 1:1 indicates more signal than noise...

.

The stability of AT cut crystals decreases with increasing frequency. For more accurate higher frequencies it is better to use a crystal with lower fundamental frequency, operating at an overtone.

Aging decreases logarithmically with time, the highest changes occurring shortly after manufacture. Artificially aging the crystal by its prolonged storage at between 85–125 °C can be done for increasing long-term stability.

A badly designed oscillator circuit may suddenly become oscillating on an overtone; in 1972, a train in Fremont, California

Fremont, California

Fremont is a city in Alameda County, California. It was incorporated on January 23, 1956, from the merger of five smaller communities: Centerville, Niles, Irvington, Mission San Jose, and Warm Springs...

crashed. An inappropriate value of the tank capacitor caused the crystal in a control board to be overdriven, jumping to an overtone, and causing the train to speed up instead of slowing down.

Crystal cuts

The resonator plate can be cut from the source crystal in many different ways. The orientation of the cut influences the crystal's aging characteristics, frequency stability, thermal characteristics, and other parameters. These cuts operate at bulk acoustic wave (BAW); for higher frequencies, surface acoustic waveSurface acoustic wave