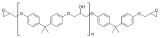

Epoxy

Overview

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

formed from reaction of an epoxide

Epoxide

An epoxide is a cyclic ether with three ring atoms. This ring approximately defines an equilateral triangle, which makes it highly strained. The strained ring makes epoxides more reactive than other ethers. Simple epoxides are named from the parent compound ethylene oxide or oxirane, such as in...

"resin" with polyamine

Polyamine

A polyamine is an organic compound having two or more primary amino groups .This class of compounds includes several synthetic substances that are important feedstocks for the chemical industry, such as ethylene diamine , 1,3-diaminopropane , and hexamethylenediamine...

"hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic

Fibre-reinforced plastic

Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually fibreglass, carbon, or aramid, while the polymer is usually an epoxy, vinylester or polyester thermosetting plastic...

materials and general purpose adhesives.

Epoxy is a copolymer; that is, it is formed from two different chemicals. These are referred to as the "resin" or "compound" and the "hardener" or "activator".

Unanswered Questions