Glass-reinforced plastic

Encyclopedia

Fiberglass is a fiber reinforced polymer made of a plastic

matrix reinforced by fine fibers of glass. It is also known as GFK (for ).

Fiberglass is a lightweight, extremely strong, and robust material. Although strength properties are somewhat lower than carbon fiber

and it is less stiff, the material is typically far less brittle, and the raw materials are much less expensive. Its bulk strength and weight properties are also very favorable when compared to metals, and it can be easily formed using molding processes.

The plastic matrix may be epoxy

, a thermosetting plastic

(most often polyester

or vinylester

) or thermoplastic

.

Common uses of fiber glass include boats, automobiles, baths, hot tubs, water tanks, roofing, pipes, cladding and external door skins.

s. If a bulk piece of glass were to be defect free, then it would be equally as strong as glass fibers; however, it's generally impractical to produce bulk material in a defect-free state outside of laboratory conditions.

. The diameter of the filaments, as well as the number of filaments in the roving determine its weight. This is typically expressed in yield-yards per pound (how many yards of fiber in one pound of material, thus a smaller number means a heavier roving, example of standard yields are 225yield, 450yield, 675yield) or in tex-grams per km (how many grams 1 km of roving weighs, this is inverted from yield, thus a smaller number means a lighter roving, examples of standard tex are 750tex, 1100tex, 2200tex).

These rovings are then either used directly in a composite application such as pultrusion

, filament winding

(pipe), gun roving (automated gun chops the glass into short lengths and drops it into a jet of resin, projected onto the surface of a mold), or used in an intermediary step, to manufacture fabrics such as chopped strand mat (CSM) (made of randomly oriented small cut lengths of fiber all bonded together), woven fabrics, knit fabrics or uni-directional fabrics.

and compression—that is, along its axis. Although it might be assumed that the fiber is weak in compression, it is actually only the long aspect ratio

of the fiber which makes it seem so; i.e., because a typical fiber is long and narrow, it buckles easily. On the other hand, the glass fiber is weak in shear—that is, across its axis. Therefore if a collection of fibers can be arranged permanently in a preferred direction within a material, and if the fibers can be prevented from buckling in compression, then that material will become preferentially strong in that direction.

Furthermore, by laying multiple layers of fiber on top of one another, with each layer oriented in various preferred directions, the stiffness and strength properties of the overall material can be controlled in an efficient manner. In the case of fiberglass, it is the plastic matrix which permanently constrains the structural glass fibers to directions chosen by the designer. With chopped strand mat, this directionality is essentially an entire two dimensional plane; with woven fabrics or unidirectional layers, directionality of stiffness and strength can be more precisely controlled within the plane.

A fiberglass component is typically of a thin "shell" construction, sometimes filled on the inside with structural foam, as in the case of surfboards. The component may be of nearly arbitrary shape, limited only by the complexity and tolerances of the mold used for manufacturing the shell.

Fiberglass was developed in the UK

during the Second World War as a replacement for the molded plywood used in aircraft radome

s (fiberglass being transparent

to microwaves). Its first main civilian application was for building of boat

s, where it gained acceptance in the 1950s. Its use has broadened to the automotive and sport equipment sectors as well as model aircraft, although its use there is now partly being taken over by carbon fiber

which weighs less per given volume and is stronger both by volume and by weight. Fiberglass uses also include hot tub

s, pipes for drinking water and sewers, office plant display containers and flat roof systems.

Advanced manufacturing techniques such as pre-preg

s and fiber

roving

s extend the applications and the tensile strength possible with fiber-reinforced plastics.

Fiberglass is also used in the telecommunications industry for shroud

ing the visual appearance of antennas

, due to its RF

permeability and low signal attenuation properties. It may also be used to shroud the visual appearance of other equipment where no signal permeability is required, such as equipment cabinets and steel

support structures, due to the ease with which it can be molded, manufactured and painted to custom designs, to blend in with existing structures or brickwork. Other uses include sheet form made electrical insulators and other structural components commonly found in the power industries.

Storage tank

Storage tank

s can be made of fiberglass with capacities up to about 300 tonne

s. The smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fibre with the fibre orientation at right angles to the hoop stress

imposed in the side wall by the contents. They tend to be used for chemical storage because the plastic liner (often polypropylene

) is resistant to a wide range of strong chemicals. Fiberglass tanks are also used for septic tank

s.

is similar to the hand lay-up process but the difference comes from the application of the fiber and resin material to the mold. Spray-up is an open-molding composites fabrication process where resin and reinforcements are sprayed onto a mold. The resin and glass may be applied separately or simultaneously "chopped" in a combined stream from a chopper gun. Workers roll out the spray-up to compact the laminate. Wood, foam or other core material may then be added, and a secondary spray-up layer imbeds the core between the laminates. The part is then cured, cooled and removed from the reusable mold.

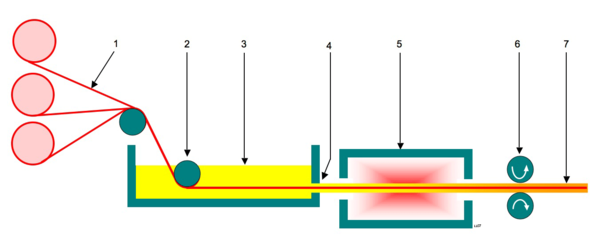

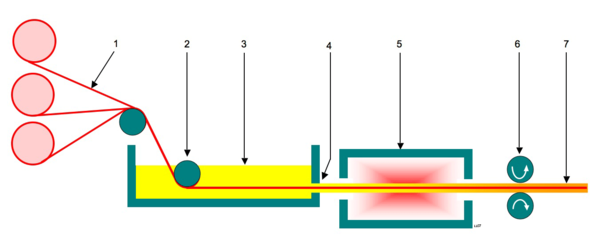

Pultrusion is a manufacturing method used to make strong light weight composite materials, in this case fiberglass. Fibers (the glass material) are pulled from spools through a device that coats them with a resin. They are then typically heat treated and cut to length. Pultrusions can be made in a variety of shapes or cross-sections such as a W or S cross-section. The word pultrusion describes the method of moving the fibers through the machinery. It is pulled through using either a hand over hand method or a continuous roller method. This is opposed to an extrusion

Pultrusion is a manufacturing method used to make strong light weight composite materials, in this case fiberglass. Fibers (the glass material) are pulled from spools through a device that coats them with a resin. They are then typically heat treated and cut to length. Pultrusions can be made in a variety of shapes or cross-sections such as a W or S cross-section. The word pultrusion describes the method of moving the fibers through the machinery. It is pulled through using either a hand over hand method or a continuous roller method. This is opposed to an extrusion

, which would push the material through dies.

It is typically processed using the hand lay-up technique, where sheets of material are placed in a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished.

Using chopped strand mat gives a fiberglass with isotropic in-plane material properties.

Further manufacture of GRP components (grinding, cutting, sawing) goes along with the emission of fine dusts and chips containing glass filaments as well as of tacky dust in substantial quantities. These affect people's health and functionality of machines and equipment.

To ensure safety regulations are adhered to and efficiency can be sustained, the installation of effective extraction and filtration equipment is needed.

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

matrix reinforced by fine fibers of glass. It is also known as GFK (for ).

Fiberglass is a lightweight, extremely strong, and robust material. Although strength properties are somewhat lower than carbon fiber

Carbon fiber

Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber...

and it is less stiff, the material is typically far less brittle, and the raw materials are much less expensive. Its bulk strength and weight properties are also very favorable when compared to metals, and it can be easily formed using molding processes.

The plastic matrix may be epoxy

Epoxy

Epoxy, also known as polyepoxide, is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives....

, a thermosetting plastic

Thermosetting plastic

A thermosetting plastic, also known as a thermoset, is polymer material that irreversibly cures. The cure may be done through heat , through a chemical reaction , or irradiation such as electron beam processing.Thermoset materials are usually liquid or malleable prior to curing and designed to be...

(most often polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

or vinylester

Vinylester

Vinyl Ester, or Vinylester, is a resin produced by the esterification of an epoxy resin with an unsaturated monocarboxylic acid. The reaction product is then dissolved in a reactive solvent, such as styrene, to a 35 - 45 percent content by weight....

) or thermoplastic

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

.

Common uses of fiber glass include boats, automobiles, baths, hot tubs, water tanks, roofing, pipes, cladding and external door skins.

Fiber

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strengthTensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

s. If a bulk piece of glass were to be defect free, then it would be equally as strong as glass fibers; however, it's generally impractical to produce bulk material in a defect-free state outside of laboratory conditions.

Production

The manufacturing process for glass fibers suitable for reinforcement uses large furnaces to gradually melt the silica sand, limestone, kaolin clay, fluorspar, colemanite, dolomite and other minerals to liquid form. Then it is extruded through bushings, which are bundles of very small orifices (typically 5–25 micrometres in diameter for E-Glass, 9 micrometres for S-Glass). These filaments are then sized (coated) with a chemical solution. The individual filaments are now bundled together in large numbers to provide a rovingRoving

A roving is a long and narrow bundle of fibre. It is usually used to spin woollen yarn. A roving can be created by carding the fibre, and it is then drawn into long strips. Because it is carded, the fibres are not parallel, though drawing it into strips may line the fibres up a bit...

. The diameter of the filaments, as well as the number of filaments in the roving determine its weight. This is typically expressed in yield-yards per pound (how many yards of fiber in one pound of material, thus a smaller number means a heavier roving, example of standard yields are 225yield, 450yield, 675yield) or in tex-grams per km (how many grams 1 km of roving weighs, this is inverted from yield, thus a smaller number means a lighter roving, examples of standard tex are 750tex, 1100tex, 2200tex).

These rovings are then either used directly in a composite application such as pultrusion

Pultrusion

Pultrusion is a continuous process for manufacture of composite materials with constant cross-section. Reinforced fibers are pulled through a resin, possibly followed by a separate preforming system, and into a heated die, where the resin undergoes polymerization...

, filament winding

Filament winding

Filament winding is a fabrication technique for manufacturing composite material, usually in the form of cylindrical structures. The process involves winding filaments under varying amounts of tension over a male mould or mandrel. The mandrel rotates while a carriage moves horizontally, laying...

(pipe), gun roving (automated gun chops the glass into short lengths and drops it into a jet of resin, projected onto the surface of a mold), or used in an intermediary step, to manufacture fabrics such as chopped strand mat (CSM) (made of randomly oriented small cut lengths of fiber all bonded together), woven fabrics, knit fabrics or uni-directional fabrics.

Sizing

A sort of coating, or primer, is used which both helps protect the glass filaments for processing/manipulation as well as ensure proper bonding to the resin matrix, thus allowing for transfer of shear loads from the glass fibers to the thermoset plastic. Without this bonding, the fibers can 'slip' in the matrix and localised failure would ensue. .Properties

An individual structural glass fiber is both stiff and strong in tensionTension

Tension may refer to:* The Void , also known as Tension in some regions* Tension , a factor that affects knitting gauge...

and compression—that is, along its axis. Although it might be assumed that the fiber is weak in compression, it is actually only the long aspect ratio

Aspect ratio

The aspect ratio of a shape is the ratio of its longer dimension to its shorter dimension. It may be applied to two characteristic dimensions of a three-dimensional shape, such as the ratio of the longest and shortest axis, or for symmetrical objects that are described by just two measurements,...

of the fiber which makes it seem so; i.e., because a typical fiber is long and narrow, it buckles easily. On the other hand, the glass fiber is weak in shear—that is, across its axis. Therefore if a collection of fibers can be arranged permanently in a preferred direction within a material, and if the fibers can be prevented from buckling in compression, then that material will become preferentially strong in that direction.

Furthermore, by laying multiple layers of fiber on top of one another, with each layer oriented in various preferred directions, the stiffness and strength properties of the overall material can be controlled in an efficient manner. In the case of fiberglass, it is the plastic matrix which permanently constrains the structural glass fibers to directions chosen by the designer. With chopped strand mat, this directionality is essentially an entire two dimensional plane; with woven fabrics or unidirectional layers, directionality of stiffness and strength can be more precisely controlled within the plane.

A fiberglass component is typically of a thin "shell" construction, sometimes filled on the inside with structural foam, as in the case of surfboards. The component may be of nearly arbitrary shape, limited only by the complexity and tolerances of the mold used for manufacturing the shell.

| Material | Specific gravity | Tensile strength MPa (ksi) | Compressive strength MPa (ksi) |

|---|---|---|---|

| Polyester resin (unreinforced) | 1.28 | 55 megapascal | 140 megapascal |

| Polyester and Chopped Strand Mat Laminate 30% E-glass | 1.4 | 100 megapascal | 150 megapascal |

| Polyester and Woven Rovings Laminate 45% E-glass | 1.6 | 250 megapascal | 150 megapascal |

| Polyester and Satin Weave Cloth Laminate 55% E-glass | 1.7 | 300 megapascal | 250 megapascal |

| Polyester and Continuous Rovings Laminate 70% E-glass | 1.9 | 800 megapascal | 350 megapascal |

| E-Glass Epoxy composite | 1.99 | 1770 megapascal | |

| S-Glass Epoxy composite | 1.95 | 2358 megapascal |

Applications

Fiberglass is an immensely versatile material which combines its light weight with an inherent strength to provide a weather resistant finish, with a variety of surface textures.Fiberglass was developed in the UK

United Kingdom

The United Kingdom of Great Britain and Northern IrelandIn the United Kingdom and Dependencies, other languages have been officially recognised as legitimate autochthonous languages under the European Charter for Regional or Minority Languages...

during the Second World War as a replacement for the molded plywood used in aircraft radome

Radome

A radome is a structural, weatherproof enclosure that protects a microwave or radar antenna. The radome is constructed of material that minimally attenuates the electromagnetic signal transmitted or received by the antenna. In other words, the radome is transparent to radar or radio waves...

s (fiberglass being transparent

Transparency (telecommunication)

In telecommunications, transparency can refer to:#The property of an entity that allows another entity to pass through it without altering either of the entities....

to microwaves). Its first main civilian application was for building of boat

Boat

A boat is a watercraft of any size designed to float or plane, to provide passage across water. Usually this water will be inland or in protected coastal areas. However, boats such as the whaleboat were designed to be operated from a ship in an offshore environment. In naval terms, a boat is a...

s, where it gained acceptance in the 1950s. Its use has broadened to the automotive and sport equipment sectors as well as model aircraft, although its use there is now partly being taken over by carbon fiber

Carbon fiber

Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. The carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber...

which weighs less per given volume and is stronger both by volume and by weight. Fiberglass uses also include hot tub

Hot tub

A hot tub is a large tub or small pool full of heated water and used for soaking, relaxation, massage, or hydrotherapy. In most cases, they have jets for massage purposes. Hot tubs are usually located outdoors, and are often sheltered for protection from the elements, as well as for privacy....

s, pipes for drinking water and sewers, office plant display containers and flat roof systems.

Advanced manufacturing techniques such as pre-preg

Pre-preg

Pre-preg is a term for "pre-impregnated" composite fibres. These usually take the form of a weave or are uni-directional. They already contain an amount of the matrix material used to bond them together and to other components during manufacture. The pre-preg are mostly stored in cooled areas since...

s and fiber

Fiber

Fiber is a class of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together....

roving

Roving

A roving is a long and narrow bundle of fibre. It is usually used to spin woollen yarn. A roving can be created by carding the fibre, and it is then drawn into long strips. Because it is carded, the fibres are not parallel, though drawing it into strips may line the fibres up a bit...

s extend the applications and the tensile strength possible with fiber-reinforced plastics.

Fiberglass is also used in the telecommunications industry for shroud

Shroud

Shroud usually refers to an item, such as a cloth, that covers or protects some other object. The term is most often used in reference to burial sheets, winding-cloths or winding-sheets, such as the famous Shroud of Turin or Tachrichim that Jews are dressed in for burial...

ing the visual appearance of antennas

Antenna (radio)

An antenna is an electrical device which converts electric currents into radio waves, and vice versa. It is usually used with a radio transmitter or radio receiver...

, due to its RF

Radio frequency

Radio frequency is a rate of oscillation in the range of about 3 kHz to 300 GHz, which corresponds to the frequency of radio waves, and the alternating currents which carry radio signals...

permeability and low signal attenuation properties. It may also be used to shroud the visual appearance of other equipment where no signal permeability is required, such as equipment cabinets and steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

support structures, due to the ease with which it can be molded, manufactured and painted to custom designs, to blend in with existing structures or brickwork. Other uses include sheet form made electrical insulators and other structural components commonly found in the power industries.

Storage tanks

Storage tank

A storage tank is a container, usually for holding liquids, sometimes for compressed gases . The term can be used for reservoirs , and for manufactured containers. The usage of the word tank for reservoirs is common or universal in Indian English, American English and moderately common in British...

s can be made of fiberglass with capacities up to about 300 tonne

Tonne

The tonne, known as the metric ton in the US , often put pleonastically as "metric tonne" to avoid confusion with ton, is a metric system unit of mass equal to 1000 kilograms. The tonne is not an International System of Units unit, but is accepted for use with the SI...

s. The smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fibre with the fibre orientation at right angles to the hoop stress

Hoop stress

Circumferential stress is a type of mechanical stress of a cylindrically shaped part as a result of internal or external pressure.The classic example of circumferential stress is the tension applied to the iron bands, or hoops, of a wooden barrel...

imposed in the side wall by the contents. They tend to be used for chemical storage because the plastic liner (often polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

) is resistant to a wide range of strong chemicals. Fiberglass tanks are also used for septic tank

Septic tank

A septic tank is a key component of the septic system, a small-scale sewage treatment system common in areas with no connection to main sewage pipes provided by local governments or private corporations...

s.

House building

Glass reinforced plastics are also used in the house building market for the production of roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, heads with keystones and sills. The use of fiberglass for these applications provides for a much faster installation and due to the reduced weight manual handling issues are reduced. With the advent of high volume manufacturing processes it is possible to construct fiberglass brick effect panels which can be used in the construction of composite housing. These panels can be constructed with the appropriate insulation which reduces heat loss.Piping

GRP and GRE pipe systems can be used for a variety of applications, above and under the ground.- Firewater systems

- Cooling water systems

- Drinking water systems

- Waste water systems/Sewage systems

- Gas systems

Fiberglass hand lay-up operation

Resin is mixed with a catalyst or hardener if working with epoxy, otherwise it will not cure (harden) for days/weeks. Next, the mold is wetted out with the mixture. The sheets of fiberglass are placed over the mold and rolled down into the mold using steel rollers. The material must be securely attached to the mold, air must not be trapped in between the fiberglass and the mold. Additional resin is applied and possibly additional sheets of fiberglass. Rollers are used to make sure the resin is between all the layers, the glass is wetted throughout the entire thickness of the laminate, and any air pockets are removed. The work must be done quickly enough to complete the job before the resin starts to cure. Various curing times can be achieved by altering the amount of catalyst employed. It is important to use the correct ratio of catalyst to resin to ensure the correct curing time. 1% catalyst is a slow cure, 2% is the recommended ratio, and 3% will give a fast cure. Adding more than 4% may result in the resin failing to cure at all. To finish the process, a weight is applied from the top to press out any excess resin and trapped air. Stops (like coins) are used to maintain the thickness which the weight could otherwise compress beyond the desired limit.Fiberglass spray lay-up operation

The fiberglass spray lay-up processFiberglass spray lay-up process

Fibreglass spray lay-up process is very different to the hand lay-up process. The difference comes from the application of the fibre and resin material to the mould. Spray-up is an open-moulding composites fabrication process where resin and reinforcements are sprayed onto a reusable mould...

is similar to the hand lay-up process but the difference comes from the application of the fiber and resin material to the mold. Spray-up is an open-molding composites fabrication process where resin and reinforcements are sprayed onto a mold. The resin and glass may be applied separately or simultaneously "chopped" in a combined stream from a chopper gun. Workers roll out the spray-up to compact the laminate. Wood, foam or other core material may then be added, and a secondary spray-up layer imbeds the core between the laminates. The part is then cured, cooled and removed from the reusable mold.

Pultrusion operation

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

, which would push the material through dies.

Chopped strand mat

Chopped strand mat or CSM is a form of reinforcement used in fiberglass. It consists of glass-fibers laid randomly across each other and held together by a binder.It is typically processed using the hand lay-up technique, where sheets of material are placed in a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished.

Using chopped strand mat gives a fiberglass with isotropic in-plane material properties.

Examples of fiberglass use

- GlidersGlider (sailplane)A glider or sailplane is a type of glider aircraft used in the sport of gliding. Some gliders, known as motor gliders are used for gliding and soaring as well, but have engines which can, in some cases, be used for take-off or for extending a flight...

, kit carKit carA kit car, also known as a "component car", is an automobile that is available as a set of parts that a manufacturer sells and the buyer then either assembles into a car themselves, or retains a third party to do part or all of the work on their behalf...

s, sports cars, microcars, karts, bodyshells, boats, kayakKayakA kayak is a small, relatively narrow, human-powered boat primarily designed to be manually propelled by means of a double blade paddle.The traditional kayak has a covered deck and one or more cockpits, each seating one paddler...

s, flat roofs, lorries, wind turbineWind turbineA wind turbine is a device that converts kinetic energy from the wind into mechanical energy. If the mechanical energy is used to produce electricity, the device may be called a wind generator or wind charger. If the mechanical energy is used to drive machinery, such as for grinding grain or...

blades. - MinesweeperMinesweeper (ship)A minesweeper is a small naval warship designed to counter the threat posed by naval mines. Minesweepers generally detect then neutralize mines in advance of other naval operations.-History:...

hullsHull (watercraft)A hull is the watertight body of a ship or boat. Above the hull is the superstructure and/or deckhouse, where present. The line where the hull meets the water surface is called the waterline.The structure of the hull varies depending on the vessel type... - Pods, domes and architectural features where a light weight is necessary.

- Bodies for automobiles, such as the AnadolAnadolAnadol was Turkey's first domestic mass-production passenger vehicle, and the second Turkish car after the ill-fated Devrim sedan of 1961.Anadol cars and pick-ups were manufactured by Otosan Otomobil Sanayii in Istanbul between 1966 and 1991....

, ReliantReliantReliant was a British car manufacturer. The company was traditionally based at Tamworth in Staffordshire, England, but in 2001 it moved to nearby Cannock. It ceased manufacturing cars shortly afterwards.-History:...

, Quantum Coupé, Chevrolet CorvetteChevrolet CorvetteThe Chevrolet Corvette is a sports car by the Chevrolet division of General Motors that has been produced in six generations. The first model, a convertible, was designed by Harley Earl and introduced at the GM Motorama in 1953 as a concept show car. Myron Scott is credited for naming the car after...

and Studebaker AvantiStudebaker AvantiSee also Avanti cars The Studebaker Avanti was a sports coupé built by the Studebaker Corporation at the direction of its president Sherwood Egbert between June 1962 and December 1963...

, and DeLorean DMC-12 under body. - A320Airbus A320 familyThe Airbus A320 family is a family of short- to medium-range, narrow-body, commercial passenger jet airliners manufactured by Airbus Industrie.Airbus was originally a consortium of European aerospace companies, and is now fully owned by EADS. Airbus's name has been Airbus SAS since 2001...

radomeRadomeA radome is a structural, weatherproof enclosure that protects a microwave or radar antenna. The radome is constructed of material that minimally attenuates the electromagnetic signal transmitted or received by the antenna. In other words, the radome is transparent to radar or radio waves...

. - FRP tanks and vesselsFRP tanks and vesselsFRP is a modern composite material of construction for chemical plant equipment like tanks and vessels...

: FRP is used extensively to manufacture chemical equipments and tanks and vessels. BS4994BS4994BS4994 is the "specification for the design and construction of vessels and storage tanks in reinforced plastics"...

is a British standard related to this application. - UHF-broadcasting antennas are often mounted inside a fiberglass cylinder on the pinnacle of a broadcasting tower

- Most commercial VelomobilesVelomobileA velomobile or bicycle car is a human-powered vehicle, enclosed for aerodynamic advantage and protection from weather and collisions. They are virtually always single-passenger vehicles. They are derived from recumbent bicycles and tricycles, with the addition of a full fairing . There are few...

- Most printed circuit boards used in electronics consist of alternating layers of copper and fibreglass FR-4FR-4FR-4 is a grade designation assigned to glass-reinforced epoxy laminate sheets, tubes, rods and printed circuit boards . FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant .FR-4 glass epoxy is a popular and versatile high-pressure...

. - Large Commercial Wind Turbine Blades

- RF coils used in MRI scanners

- Sub sea installation protection covers

Problems in the production and processing

While the resins are cured styrene vapors are released. These are irritating to mucous membranes and respiratory tract. Therefore, the Hazardous Substances Ordinance in Germany dictate a maximum occupational exposure limit of 86 mg/m³. In certain concentrations may even occur a potentially explosive mixture.Further manufacture of GRP components (grinding, cutting, sawing) goes along with the emission of fine dusts and chips containing glass filaments as well as of tacky dust in substantial quantities. These affect people's health and functionality of machines and equipment.

To ensure safety regulations are adhered to and efficiency can be sustained, the installation of effective extraction and filtration equipment is needed.