Productivity improving technologies (historical)

Encyclopedia

Productivity improving technologies date back to antiquity, with rather slow progress until the late Middle Ages. Technological progress was aided by literacy and the diffusion of knowledge that accelerated after the spinning wheel

spread to Western Europe in the 13th century. The spinning wheel increased the supply of rags used for pulp in paper

making, whose technology reached Sicily sometime in the 12th century. Cheap paper was a factor in the development of the moveable type printing press

, ca. 1440, which lead to a large increase in the number of books and titles published. Books on science and technology eventually began to appear, such as the mining technical manual De Re Metallica

.

Later, near the beginning of the Industrial Revolution, came publication of the Encyclopédie

, written by numerous contributors and edited by Denis Diderot

and Jean le Rond d'Alembert

(1751-72). It contained many articles on science and was the first general encyclopedia provide in depth coverage on the mechanical arts, but far more celebrated for it's presentation of thoughts of the Enlightenment

.

An important mechanism for the transfer of technical knowledge were scientific societies, such as The Royal Society of London for Improving Natural Knowledge, better known as the Royal Society

and technical colleges, such as the École Polytechnique

.

Technological and economic progress did not proceed at a significant rate until the English Industrial Revolution in late 18th century and even then productivity grew about 0.5% annually. High productivity growth began during late 19th century in what is sometimes call the Second Industrial Revolution

. Most major innovations of the Second Industrial Revolution were based on the modern scientific understanding of chemistry

, electromagnetic theory

and thermodynamics

.

Productivity gains were not just the result of inventions, but also of continuous improvements to those inventions which greatly increased output in relation both capital and labor compared to the original inventions.

Since the beginning of the Industrial Revolution, some of the major contributors to productivity have been as follows:

1. Replacing human and animal power with water and wind power, steam, electricity and internal combustion and

greatly increasing the use of energy

2. Energy efficiency in the conversion of energy to: useful work, process heat or chemical energy in the manufacture of materials

2. Energy efficiency in the conversion of energy to: useful work, process heat or chemical energy in the manufacture of materials

3. Infrastructures: canals, railroads, highways and pipelines

4. Mechanization, both production machinery and agricultural machines

5. Work practices and processes: The American system of manufacturing, Taylorism or scientific management, mass production, assembly line, modern business enterprise

6. Materials handling: bulk materials, palletization and containerization

7. Scientific agriculture: fertilizers and the green revolution, livestock and poultry management

8. New materials, new process for their production and dematerialization.

9. Communications: Telegraph, telephone, radio, satellites, fiber optic network and the Internet

10. Home economics: Public water supply, household gas, appliances

11. Automation and process control

12. Computers and software, data processing

In recent decades there here have been a number of excellent books and papers published on the history of technology, the role of energy in economics and related issues such as resource depletion, some of which are referenced herein.

(1891).

, the "father of civil engineering," significantly improved the efficiency of the water wheel by applying scientific principles, thereby adding badly needed power for the Industrial Revolution.

In 1711 a Newcomen steam engine

was installed for pumping water from a mine, a job that typically was done by large teams of horses, of which some mines used as many as 500. Fossil fuel energy first exceeded all animal and water power in 1870. The role energy and machines replacing physical work is discussed in Ayres-Warr (2004).

By about 1870 steam power

first exceeded all water, wind and muscle power. While steamboats were used in some areas, as recently as the late 19th Century thousands of workers pulled barges. Until the late 19th century most coal and other minerals were mined with picks and shovels and crops were harvested and grain threshed using animal power or by hand. Heavy loads like 382 pound bales of cotton were handled on hand trucks until the early 20th century.

Excavation was done with shovels until the late 19th century when steam shovels came into use. It was reported that a laborer on the western division of the Erie Canal was expected to dig 5 cubic yards per day in 1860; however, by 1890 only 3-1/2 yards per day were expected. Today's large electric shovels have buckets that can hold 168 cubic meters and consume the power of a city of 100,000.

Excavation was done with shovels until the late 19th century when steam shovels came into use. It was reported that a laborer on the western division of the Erie Canal was expected to dig 5 cubic yards per day in 1860; however, by 1890 only 3-1/2 yards per day were expected. Today's large electric shovels have buckets that can hold 168 cubic meters and consume the power of a city of 100,000.

Dynamite

, a safe to handle blend of nitroglycerin and diatomaceous earth

was patented in 1867 by Alfred Nobel

. Dynamite increased productivity of mining, tunneling, road building, construction and demolition and made projects such as the Panama Canal possible.

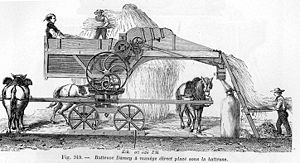

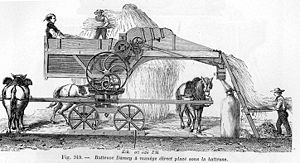

Steam power was applied to threshing machine

s in the late 19th century. There were steam engines that moved around on wheels under their own power that were used for supplying temporary power to stationary farm equipment such as threshing machines. These were called road engines, and Henry Ford seeing one as a boy was inspired to build an automobile. Steam tractors were used but never became popular.

With internal combustion came the first mass produced tractors (Fordson

ca. 1917). Tractors replaced horses and mules for pulling reapers and combine harvesters, but in the 1930s self powered combines were developed. Output per man hour in growing wheat rose by a factor of about 10 from the end of World War II until about 1985, largely because of powered machinery, but also because of increased crop yields. Corn manpower showed a similar but higher productivity increase.

See section 4: Mechanization in agriculture

One of the greatest periods of productivity growth coincided with the electrification

of factories which took place between 1900 and 1930 in the U.S. See: Mass production: Factory electrification

2. Energy efficiency and productivity: The Useful work growth theory

Energy efficiency has played a significant role in increasing productivity in the past; however, most industrial processes have exhausted the easy efficiency gains. The early Newcomen steam engine

was about than 0.5% efficient and was improved to slightly over 1% by John Smeaton

before Watt's improvements. Watt's

improvements increased thermal efficiency

to 2%, and today's steam turbine

s have efficiencies in the 40% range. See: Engine efficiency#Steam and Timeline of steam power

More efficient steam and internal combustion engines have higher power-to-weight ratios. The Newcomen and Watt engines operated near atmospheric pressure and used atmospheric pressure, or actually a vacuum caused by condensing steam, to do work. Higher pressure engines were light enough, and efficient enough to be used for powering ships and locomotives. Multiple expansion (multi-stage) engines were developed in the 1870s and were efficient enough for the first time to allow ships to carry more freight than coal, leading to great increases in international trade. The most efficient prime mover is the two stroke marine diesel engine

developed in the 1920s, now ranging in size to over 100,000 horsepower with a thermal efficiency

of 50%. Steam locomotives that used up to 20% of the U.S. coal production were replaced by diesel locomotives after World War II, saving a great deal of energy and reducing manpower for handling coal, boiler water and mechanical maintenance.

Improvements in steam engine efficiency caused a large increase in the number of steam engines and the amount of coal used, as noted by William Stanley Jevons

in The Coal Question

. This is called the Jevons paradox

.

Electric lights were far more efficient than oil or gas lighting and did not generate heat, smoke and fumes. Electric light extended the work day, making factories, businesses and homes more productive. Electric light was not a great fire hazard like oil and gas light.

When anti-friction bearings were introduced in locomotives three female office workers demonstrated their efficiency by manually pulling the Timken 1111

locomotive.

Industrial process have been continuously improved to reduce the energy consumption per unit of production. See: Section 8: New materials, processes and de-materialization

The Ayres-Warr Model(2004) analyzed the production function

and explained part of the Solow residual

by electrical generation efficiency.

, which opened in 1761, bringing coal from Worsley to Manchester. The Bridgewater Canal’s success started a frenzy of canal building that lasted until the appearance of railroads in the 1830s.

Railroads greatly reduced the cost of overland transportation. It is estimated that by 1890 the cost of wagon freight was U.S. 24.5 cents/ton-mile versus 0.875 cents/ton-mile by railroad. Also see: History of rail transport

Electric street railways (tram

s, trolleys or streetcars) were the final phase of railroad building from the late 1890s and first two decades of the 20th century. Street railways were soon displaced by motor buses and automobiles after WW I.

Highways with internal combustion powered vehicles completed the mechanization of overland transportation. When trucks appeared ca. 1920 the price transporting farm goods to market or to rail stations was greatly reduced. Motorized highway transport also reduced inventories.

Before iron and steel

were in widespread use, wooden pipelines were used, such as those once supplying water to London from springs located away from the city. Iron and steel pipelines came into use during latter part of the 19th century, but only became a major infrastructure during the 20th century. Centrifugal pump

s and centrifugal compressor

s are efficient means of pumping liquids and natural gas.

The relative energy required for transport of a tonne-km for various modes of transport are: pipelines=1(basis), water 2, rail 3, road 10, air 100.

s for pounding rags into pulp for making paper and for crushing ore. Just before the Industrial revolution water power was applied to bellows for iron smelting. Wind and water power were also used in sawmills.

The technology of building mills and mechanical clocks was important to the development of the machines of the Industrial Revolution.

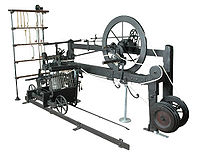

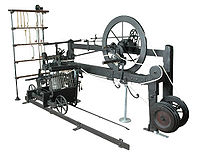

The spinning wheel

was a medieval invention that increased thread making productivity by a factor greater than ten. One of the early developments that preceded the Industrial Revolution

was the stocking frame

(loom) of ca. 1589. Later in the Industrial Revolution came the flying shuttle

, a simple device that doubled the productivity of weaving. Spinning thread had been a limiting factor in cloth making requiring 10 spinners using the spinning wheel

to supply one weaver. With the spinning jenny

a spinner could spin eight threads at once. The water frame

(Ptd. 1768) adapted water power to spinning, but it could only spin one thread at a time. The water frame was easy to operate and many could be located in a single building. The spinning mule

(1779) allowed a large number of threads to be spun by a single machine using water power. A change in consumer preference for cotton at the time of increased cloth production resulted in the invention of the cotton gin

(Ptd. 1794). Steam power eventually was used as a supplement to water during the Industrial Revolution, and both were used until electrification. A graph of productivity of spinning technologies can be found in Ayres (1989), along with much other data related this article.

With a cotton gin (1792) in one day a man could remove seed from as much upland cotton as would have previously taken a woman working two months to process at one pound per day.

The sewing machine

, invented and improved during the early 19th century and produced in large numbers by the 1870s, increased productivity by more than 500%.

Machine tools, which cut, grind and shape parts, were another important mechanical innovation of the Industrial Revolution. Perhaps the best early example of a productivity increase by machine tools and special purpose machines is the ca. 1803 Portsmouth Block Mills. With these machines 10 men could produce as many blocks as 110 skilled craftsmen. However, around 1900, it was the combination of small electric motors, specialty steels and new cutting and grinding materials that allowed machine tools to mass produce steel parts. Production of the Ford Model T

required 32,000 machine tools.

Modern manufacturing began around 1900 when machines, aided by electric, hydraulic and pneumatic power, began to replace hand methods in industry. An early example is the Owens'es

automatic glass bottle blowing machine, which reduced labor in making bottles by over 80%. See also: Mass production#Factory electrification

Mechanical stokers for feeding coal to locomotives were in use in the 1920s. A completely mechanized and automated coal handling and stoking system was first used to feed pulverized coal to an electric utility boiler in 1921.

Coal seam undercutting machines appeared around 1890 and were used for 75% of coal production by 1934. Coal loading was still being done manually with shovels around 1930, but mechanical pick up and loading machines were coming into use. The use of the coal boring machine improved productivity of sub-surface coal mining by a factor of three between 1949 and 1969.

Jethro Tull

's seed drill

(ca. 1701) was a mechanical seed spacing and depth placing device that increased crop yields and saved seed, which was important when yields were measured in terms of seeds harvested per seed planted, which was typically between 3 and 6. The seed drill was an important factor in the British Agricultural Revolution

.

Since the beginning of agriculture threshing was done by hand with a flail

, requiring a great deal of labor. The threshing machine

(ca. 1794) simplified the operation and allowed it to use animal power. Threshing machines displaced thousands of workers in Europe, many of who were driven to the brink of starvation.

Before ca. 1790 a worker could harvest 1/4 acre per day with a scythe

Before ca. 1790 a worker could harvest 1/4 acre per day with a scythe

. It was estimated that for each of Cyrus McCormick's

horse pulled reaper

s (Ptd. 1834) freed up five men for military service in the U.S. Civil War. By 1890 two men and two horses could cut, rake and bind 20 acres of wheat per day.

In the 1880s the reaper and threshing machine

were combined into the combine harvester

. These machines required large teams of horses or mules to pull. Over the entire 19th century the output per man hour for producing wheat rose by about 500% and for corn about 250%.

Farm machinery and higher crop yields reduced the labor to produce 100 bushels of corn from 35 to 40 hours in 1900 to 2 hours 45 minutes in 1999. The conversion of agricultural mechanization to internal combustion power began after 1915. The horse population began to decline in the 1920s after the conversion of agriculture and transportation to internal combustion. In addition to saving labor, this freed up much land previously used for supporting draft animals.

The peak years for tractor sales in the U.S. were the 1950s. There was a large surge in horsepower of farm machinery in the 1950s.

which used special purpose machines and machine tools that made parts with precision so as to be interchangeable

. The process took decades to perfect at great expense because interchangeable parts were more costly at first. Interchangeable parts

were achieved by using fixtures to hold and precisely align parts being machined, jigs to guide the machine tools and gauges to measure critical dimensions of finished parts.

Other work processes involved minimizing the amount of steps in doing individual tasks, such as bricklaying, by performing time and motion studies

to determine the one best method, the system becoming known as Taylorism after Fredrick Winslow Taylor who is the best known developer of this method, which is also known as scientific management

after his work The Principles of Scientific Management

.

Electrification allowed the placement of machinery such as machine tools in a systematic arrangement along the flow of the work. The assembly line

, which used motorized conveyors to transfer parts and assemblies to workers, was a key step leading to mass production

.

Business administration, which includes management practices and accounting systems is another important form of work practices. Business administration as we know it arose from the mass production era.

Work processes are well described at the following links:

Modern business enterprize (MBE) is the organization and management of businesses, particularly large ones. MBE's employ professionals who use knowledge based techniques such areas as engineering, research and development, information technology, business administration, finance and accounting. MBE's typically benefit from economies of scale.

Dry bulk materials handling systems use a variety of stationary equipment such as conveyors, stackers, reclaimers and mobile equipment such as loaders to handle high volumes of ores, coal, grains, sand, gravel, crushed stone, etc. Bulk materials are systems are used at mines, for loading and unloading ships and at factories that process bulk materials into finished goods, such as steel and paper mills.

Dry bulk materials handling systems use a variety of stationary equipment such as conveyors, stackers, reclaimers and mobile equipment such as loaders to handle high volumes of ores, coal, grains, sand, gravel, crushed stone, etc. Bulk materials are systems are used at mines, for loading and unloading ships and at factories that process bulk materials into finished goods, such as steel and paper mills.

Around 1900 various types of conveyors (belt, slat, bucket, screw or auger), overhead crane

s and industrial trucks began being used for handling materials and goods in various stages of production in factories. A well known application of conveyors is Ford. Motor Co.'s assembly line

(ca. 1913), although Ford used various industrial trucks, overhead cranes, slides and whatever devices necessary to minimize labor in handling parts in various stages of production. See: Mass production

.

Liquids and gases are handled with centrifugal pump

Liquids and gases are handled with centrifugal pump

s and compressors, respectively.

Conversion to powered material handling increased during WW 1 as shortages of unskilled labor developed and unskilled wages rose relative to skilled labor.

Handling goods on pallet

s was a significant improvement over using hand trucks or carrying sacks or boxes by hand and greatly speeded up loading and unloading of trucks, rail cars and ships. Pallets can be handled with pallet jack

s or forklift truck

s. Loading dock

s built to architectural standards allow trucks or rail cars to load and unload at the same elevation as the warehouse floor.

Containerization

was used in both world wars, particularly WW II, but became commercial in the 1960s. Containerization left large numbers of warehouses at wharves in port cities vacant, freeing up land for other development. See also: Intermodal freight transport

Keeping livestock indoors in winter reduces the amount of feed needed. Also, feeding chopped hay and ground grains, particularly corn (maize), was found to improve digestibility. The amount of feed required to produce a kg of live weight chicken fell from 5 in 1930 to 2 by the late 1990s and the time required fell from three months to six weeks.

The Green Revolution

increased crop yields by a factor of 3 for soybeans and between 4 and 5 for corn (maize), wheat, rice and some other crops. Using data for corn (maize) in the U.S., yields increased about 1.7 bushels per acre from the early 1940s until the first decade of the 21st century when concern was being expressed about reaching limits of photosynthesis. Because of the constant nature of the yield increase, the annual percentage increase has declined from over 5% in the 1940s to 1% today, so while yields for a while outpaced population growth, yield growth now lags population growth.

High yields would not be possible without significant applications of fertilizer, particularly nitrogen fertilizer which was made affordable by the Haber-Bosch

ammonia process. Nitrogen fertilizer is applied in many parts of Asia in amounts subject to diminishing returns, which however does still give a slight increase in yield. Crops in Africa are in general starved for NPK and much of the world's soils are deficient in zinc, which leads to deficiencies in humans.

The greatest period of agricultural productivity growth in the U.S. occurred from World War 2 until the 1970s.

Land is considered a form of capital, but otherwise has received little attention relative to its importance as a factor of productivity by modern economist, although it was important in classical economics. However, higher crop yields effectively multiplied the amount of land.

The Bessemer

(Ptd.1855) and the Siemens-Martin

(ca. 1865) processes greatly reduced the cost of steel

. Steel has much higher strength than wrought iron

and allowed long span bridges, high rise buildings, automobiles and other items. Steel also made superior threaded fasteners (screws, nuts, bolts), nails, wire and other hardware items. Steel rails lasted 17 times longer than wrought iron

rails. The cheapness and superiority of steel to wrought iron

led to cessation of practically all iron production by WW II.

Today a variety of alloy steels are available that have superior properties for special applications like automobiles, pipelines and drill bits. High speed or tool steels, whose development began in the late 19th century, allowed machine tools to cut steel at much higher speeds. High speed steel and even harder materials were an essential component of mass production

of automobiles.

Some of the most important specialty materials are steam turbine

and gas turbine

blades, which have to withstand extreme mechanical stress and high temperatures.

The size of blast furnaces grew greatly over the 20th century and innovations like additional heat recovery and pulverized coal, which displaced coke and increased energy efficiency.

By the end of the 19th century the Bessemer process was displaced by the open hearth furnace (OHF). After World War II the OHF was displaced by the basic oxygen furnace (BOF), which used oxygen instead of air and required about 35–40 minutes to produce a batch of steel compared to 8 to 9 hours for the OHF. The BOF also was more energy efficient.

By 1913, 80% of steel was being made from molten pig iron directly from the blast furnace, eliminating the step of casting the "pigs" (ingots) and remelting.

After 1950 continuous casting contributed to productivity of converting steel to structural shapes by eliminating the intermittent step of making slabs, billets (square cross-section)) or blooms (rectangular) which then usually have to be reheated before rolling into shapes.

As a result of these innovations, between 1920 and 2000 labor requirements in the steel industry decreased by a factor of 1,000, from more than 3 worker-hours per tonne to just 0.003.

Paper was made one sheet at a time by hand until development of the Fourdrinier paper machine (ca. 1801) which made a continuous sheet. Paper making was severely limited by the supply of cotton and linen rags from the time of the invention of the printing press until the development of wood pulp (ca. 1840s). The sulfite process

for making wood pulp was developed in the 1860s and 1870s. Paper made from sulfite pulp had superior strength properties than the previously used ground wood pulp (ca. 1840). The kraft

(Swedish for strong) pulping process was commercialized in the 1930s. Pulping chemicals are recovered and internally recycled in the kraft process, also saving energy and reducing pollution. Kraft paperboard

is the material that the outer layers of corrugated boxes are made of. Until Kraft corrugated boxes were available, and even for some decades after, packaging consisted largely of wooden crates and boxes. Corrugated boxes required much less labor to manufacture and offered good protection to their contents.

Plastics can be inexpensively made into everyday items and have significantly lowered the cost of a variety of goods including packaging, containers, parts and household piping.

Seismic exploration

, beginning in the 1920s, uses reflected sound waves to map subsurface geology to help locate potential oil reservoirs. This was a great improvement over previous methods, which involved mostly luck and good knowledge of geology, although luck continued to be important in several major discoveries. Rotary drilling was a faster and more efficient way of drilling oil and water wells. It became popular after being used for the initial discovery of the East Texas field in 1930.

Dematerialization

is the reduction of use of materials in manufacturing, construction, packaging or other uses. It is made possible by substitution with better materials and by engineering to reduce weight while maintaining function. Modern examples are plastic beverage containers replacing glass and paperboard, plastic shrink wrap

used in shipping and light weight plastic packing materials. Dematerialization

has been occurring in the U. S. steel industry where the peak in consumption occurred in 1973 on both an absolute and per capita basis.

Optical fiber

began to replace copper wire in the telephone network during the 1980s.

Teleprinter

s appeared in 1910 and had replaced between 80 and 90% of Morse code operators by 1929. It is estimated that one teletypist replaced 15 Morse code operators.

The early use of telephones was primarily for business. Monthly service cost about one third of the average worker's earnings. The telephone along with trucks and the new road networks allowed businesses to reduce inventory sharply during the 1920s.

Telephone calls were handled by operators using switchboard

s until the 1920s when the automatic (dial) telephone and automatic switchboard came into use, and by 1929, 31.9% of the Bell system was automatic.

After WWII microwave transmission

began being used for long distance telephony and television.

The diffusion of telephony to households was mature by the arrival of fiber optic communications in the late 1970s. Fiber optics greatly increased the transmission capacity of information over previous copper wires and further lowered the cost of long distance communication.

Communications satellitess came into use in the 1960s and today carry a variety of information including credit card transaction data, radio, television and telephone calls. The Global Positioning System

(GPS) operates on signals from satellites.

Fax

(short for facsimile) machines of various types had been in existence since the early 1900s but became widespread beginning in the mid 1970s.

Gas utilities first supplied synthetic gas, mainly for lighting. In the late 19th century natural gas began being supplied to households. This saved many hours of feeding wood fires for heating and cooking.

Household appliances followed household electrification in the 1920s', with consumers buying electric ranges, toasters, refrigerators and washing machines. As a result of appliances and convenience foods, time spent on meal preparation and clean up, laundry and cleaning decreased from 58 hours/week in 1900 to 18 hours/week by 1975. Less time spent on housework allowed more women to enter the labor force.

11. Automation

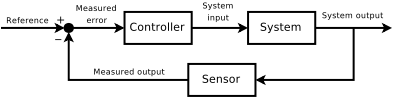

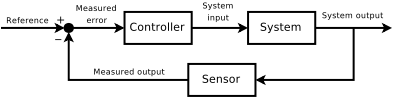

Automation

Automation

in the original sense means automatic control, meaning a process is run with minimum operator intervention. An simple analogy is cruise control on a car, which applies continuous correction when a sensor on the controlled variable (Speed in this example) deviates from a set-point and can respond in a corrective manner to hold the setting. Process control

is the usual form of automation that allows industrial operations like oil refineries, steam plants generating electricity or paper mills to be run with a minimum of manpower, usually from a number of control rooms.

The earliest applications of process control were mechanisms that adjusted the gap between mill stones for grinding grain and for keeping windmills facing into the wind. The centrifugal governor

used for adjusting the mill stones was copied by James Watt for controlling speed of steam engines; however, it took much development work to achieve the degree of steadiness necessary to operate textile machinery. Mathematical analysis of control theory was first developed by James Clerk Maxwell

.

Automation of the telephone system allowed dialing local numbers instead of having calls placed through an operator. Further automation allowed callers to place long distance calls by direct dial. Eventually almost all operators were replaced with automation.

Machine tools were automated with Numerical control

(NC) in the 1950s. This soon evolved into computerized numerical control (CNC).

Industrial robot

s were used on a limited scale from the 1960s but began their rapid growth phase in the mid 1980s after the widespread availability of microprocessors used for their control. The diffusion curve of robots went through the build out phase over the next decade with the saturation approach inflection point in the early 1990s. By 2000 there were over 700,000 robots world-wide.

The ultimate objective of automation is autonomous machines, that is, machines that run themselves, without operator attention. While this has been achieved to some extent in some industries, in many industries it is necessary to have operators because of the large amount of defective product than can be produced in a short time when things go wrong. Also, operators are necessary for safety and protection of valuable equipment.

Early electric data processing was done by running punched cards through tabulating machine

Early electric data processing was done by running punched cards through tabulating machine

s, the holes in the cards allowing electrical contact to increment electronic counters. Tabulating machines were in a category called unit record equipment

, through which the flow of punched cards was arranged in a program-like sequence to allow sophisticated data processing. They were widely used before the introduction of computers.

The usefulness of tabulating machines was demonstrated by compiling the 1890 U.S. census, allowing the census to be processed in less than a year and with great labor savings compared to the estimated 13 years by the previous manual method.

The first digital computers were more productive than tabulating machines, but not by a great amount. Early computers used thousands of vacuum tube

s (thermionic valves) which used a lot of electricity and constantly needed replacing. By the 1950s the vacuum tubes were replaced by transistor

s which were much more reliable and used relatively little electricity. By the 1960s thousands of transistors and other electronic components could were being manufactured on silicon semiconductor

wafers as integrated circuits, which are universally used in today's computers.

Computers used paper tape and punched cards for data and programming input until the 1980s when it was still common to receive monthly utility bills printed on a punched card that was returned with the customer’s payment.

In 1973 IBM introduced point of sale

(POS) terminals in which electronic cash registers were networked to the store mainframe computer. By the 1980s bar code readers were added. These technologies automated inventory management. Wal-Mart

was an early adopter of POS.

Data storage became better organized after the development of relational database

software that allowed data to be stored in different tables. For example, a theoretical airline may have numerous tables such as: airplanes, employees, maintenance contractors, caterers, flights, airports, payments, tickets, etc. each containing a narrower set of more specific information than would a flat file, such as a spreadsheet. These tables are related by common data fields called keys. Data can be retrieved in various specific configurations by posing a query without having to pull up a whole table. This, for example, makes it easy to find a passenger's seat assignment by a variety of means such as ticket number or name.

Since the mid 1990s, interactive web pages have allowed users to access various servers

over Internet to engage in e-commerce such as online shopping, paying bills, trading stocks, managing bank accounts and renewing auto registrations. This is the ultimate form of back office automation because the transaction information is transferred directly to the database.

Computers also greatly increased productivity of the communications sector, especially in areas like the elimination of telephone operators. In engineering, computers replaced manual drafting with CAD, with a 500% average increase in a draftsman's output. Software was developed for calculations used in designing electronic circuits, stress analysis, heat and material balances. Process simulation

software has been developed for both steady state and dynamic simulation, the latter able to give the user a very similar experience to operating a real process like a refinery or paper mill, allowing the user to optimize the process or experiment with process modifications.

Automated teller machines (ATM's) became popular in recent decades and self checkout at retailers appeared in the 1990s.

The Airline Reservations System

and banking are areas where computers are practically essential. Modern military systems also rely on computers.

Computers did not revolutionize manufacturing because automation, in the form of control system

s, had already been in existence for decades, although they did allow more sophisticated control, which led to improved product quality and process optimization. See: Productivity paradox

U.S. productivity growth has been in long term decline since the early 1970s. Part of the early decline was attributed to increased governmental regulation since the 1960s, including stricter environmental regulations. However, most of the decline in productivity growth is due to exhaustion of opportunities. Robert J. Gordon

considered productivity to be "One big wave" that crested and is now receding to a lower level, while M. King Hubbert

called the phenomenon of the great productivity gains preceding the Great Depression a "one time event."

Because of reduced population growth in the U.S. and a peaking of productivity growth, U.S. GDP growth has never returned to the 4% plus rates of the pre-World War 1 decades.

The computer and computer like semiconductor devices used in automation are the most significant productivity improving technologies developed in the final decades of the twentieth century; however, their contribution was disappointing. Economist Robert J. Gordon

is among those who questioned whether computers lived up to the great innovations of the past, such as electrification. This issue is known as the Productivity paradox

. Gordon's analysis of productivity in the U.S. gives two possible high points, one between World War 1 and World War 2 and the other between the 1920s and the early post World War 2 decades, depending on how government capital is treated.

Whereas lack of knowledge of scientific principles and efficient work methods was the norm before the mid-19th century, today we have trained professionals in civil, structural, mechanical, chemical, electrical, industrial and other fields of engineering, computer science, information technology, medicine and medical technology and management and business. Opportunities to improve productivity are no longer overlooked and incremental improvements are made wherever possible, but rarely do they create dramatic savings that can be widely applied throughout the economy.

Typically productivity gains are highest in the early years of a new technology or product. The development of the steam engine is rather unique because there was no knowledge of thermodynamics until after Watt's

improvements, so it took over 50 years from the time of the Newcomen engine (1712) until Watt's condenser and other improvements increased efficiency by 400% ca. 1765. The study of the steam engine and the simultaneous development of thermodynamics

led to continued improvements, at a decelerating rate, until efficiency approached theoretical limits in the 1960s with high pressure steam turbine

s. See: Engine efficiency#Steam

Another example of productivity increases with a new process is a new, mechanized factory producing light bulbs that started operating in 1925. After six years of operation output per worker hour increased fivefold.

The early automobile industry struggled with producing enough automobiles to achieve economies of scale that were thought to be necessary to bring costs down so as to be affordable. Ford Motor Co. solved the problem with a totally new manufacturing concept which became known as mass production

. The amount of labor, and consequently the price of the Ford Model T

did fall dramatically after the development of the assembly line

in 1914, and further with the factory designed for mass production

, but after those new processes productivity gains were much slower.

The recent example of high productivity in a new industry occurred in the computer and related industries in the late 1990s, during which time computer related industries were responsible for most of the overall productivity growth.

, discussed in the International Institute for Applied Systems Analysis (IIASA

) work of Cesare Marchetti, and by Carlota Prez and others. Most basic materials, agricultural commodities, automobiles and appliances are like the steel example in that by far the greatest amount of labor has already been saved so that removing the remaining labor would result infinitely high output per hour in terms of physical product but would only slightly lower cost.

The largest productivity gains in absolute and relative terms typically occurred soon after the introduction of a new technology or product. Examples include the assembly line, which came a decade and a half after the manufacturing of automobiles and in the manufacture of electric light bulbs. A modern example is the performance of semiconductors, and in fact, most of the productivity gains of the last decades were in in semiconductor, computer and Internet related industries.

Robert Ayres, Benjamin Warr and Vaclav Smil have all written that the processes for making many basic materials such as steel, aluminum and various chemicals and electricity generation have reduced energy consumption to where it is approaching theoretical minimums.

Resource depletion decreases productivity as more effort in the form of labor, materials and energy are required for extraction and processing. For example, early U.S. onshore oil production yield has shown a consistent decline in the number of barrels of oil produced per foot drilled. Ore grades of copper and other important minerals have significantly declined in concentration, requiring much higher volumes of low grade ore to be handled and processed.

Based on the exhaustion of opportunities and resource depletion, Ayres-Warr (2009) are forecasting that economic growth in developed countries will end sometime after 2030. See: Useful work growth theory

Economic theory that deals with historical long term business cycles and their relationship to technology refers to these cycles as Kondratiev waves.

Resource depletion is in the field of ecological economics

.

The gains in standards of living have been accomplished largely through increases in productivity. In the U.S. the amount of personal consumption that could be bought with one hour of work was about $3.00 in 1900 and increased to about $22 by 1990, measured in 2010 dollars. For comparison, a U. S. worker today earns more (in terms of buying power) working for ten minutes than subsistence workers, such as the English mill workers that Fredrick Engels wrote about in 1844, earned in a 12 hour day.

As a result of productivity the work week declined considerably over the 19th century. By the 1920s the average work week was 49 hours, but the work week was reduced to 40 hours (after which overtime premium was applied) as part of the National Industrial Recovery Act

of 1933. At the time of the Great Depression of the 1930s it was understood that with the enormous productivity gains due to electrification

, mass production

and agricultural mechanization, there was no need for a large number of previously employed workers. M. King Hubbert

, the namesake of peak the oil curve, advocated a four work day in his prescient paper Man Hours and Distribution.

One of the earlier sources of 20th century productivity data is the 1940 study by the Brookings Institution which gives productivity by major U.S. industries from 1919 to 1939.

John W. Kendrick of the National Bureau of Economic Research

published data series on output, labor, inputs and capital for major industry divisions over the period between 1870 to 1953.

Spinning wheel

A spinning wheel is a device for spinning thread or yarn from natural or synthetic fibers. Spinning wheels appeared in Asia, probably in the 11th century, and very gradually replaced hand spinning with spindle and distaff...

spread to Western Europe in the 13th century. The spinning wheel increased the supply of rags used for pulp in paper

Paper

Paper is a thin material mainly used for writing upon, printing upon, drawing or for packaging. It is produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets....

making, whose technology reached Sicily sometime in the 12th century. Cheap paper was a factor in the development of the moveable type printing press

Printing press

A printing press is a device for applying pressure to an inked surface resting upon a print medium , thereby transferring the ink...

, ca. 1440, which lead to a large increase in the number of books and titles published. Books on science and technology eventually began to appear, such as the mining technical manual De Re Metallica

De re metallica

De re metallica is a book cataloguing the state of the art of mining, refining, and smelting metals, published in 1556. The author was Georg Bauer, whose pen name was the Latinized Georgius Agricola...

.

Later, near the beginning of the Industrial Revolution, came publication of the Encyclopédie

Encyclopédie

Encyclopédie, ou dictionnaire raisonné des sciences, des arts et des métiers was a general encyclopedia published in France between 1751 and 1772, with later supplements, revised editions, and translations. It was edited by Denis Diderot and Jean le Rond d'Alembert...

, written by numerous contributors and edited by Denis Diderot

Denis Diderot

Denis Diderot was a French philosopher, art critic, and writer. He was a prominent person during the Enlightenment and is best known for serving as co-founder and chief editor of and contributor to the Encyclopédie....

and Jean le Rond d'Alembert

Jean le Rond d'Alembert

Jean-Baptiste le Rond d'Alembert was a French mathematician, mechanician, physicist, philosopher, and music theorist. He was also co-editor with Denis Diderot of the Encyclopédie...

(1751-72). It contained many articles on science and was the first general encyclopedia provide in depth coverage on the mechanical arts, but far more celebrated for it's presentation of thoughts of the Enlightenment

Age of Enlightenment

The Age of Enlightenment was an elite cultural movement of intellectuals in 18th century Europe that sought to mobilize the power of reason in order to reform society and advance knowledge. It promoted intellectual interchange and opposed intolerance and abuses in church and state...

.

An important mechanism for the transfer of technical knowledge were scientific societies, such as The Royal Society of London for Improving Natural Knowledge, better known as the Royal Society

Royal Society

The Royal Society of London for Improving Natural Knowledge, known simply as the Royal Society, is a learned society for science, and is possibly the oldest such society in existence. Founded in November 1660, it was granted a Royal Charter by King Charles II as the "Royal Society of London"...

and technical colleges, such as the École Polytechnique

École Polytechnique

The École Polytechnique is a state-run institution of higher education and research in Palaiseau, Essonne, France, near Paris. Polytechnique is renowned for its four year undergraduate/graduate Master's program...

.

Technological and economic progress did not proceed at a significant rate until the English Industrial Revolution in late 18th century and even then productivity grew about 0.5% annually. High productivity growth began during late 19th century in what is sometimes call the Second Industrial Revolution

Second Industrial Revolution

The Second Industrial Revolution, also known as the Technological Revolution, was a phase of the larger Industrial Revolution corresponding to the latter half of the 19th century until World War I...

. Most major innovations of the Second Industrial Revolution were based on the modern scientific understanding of chemistry

Chemistry

Chemistry is the science of matter, especially its chemical reactions, but also its composition, structure and properties. Chemistry is concerned with atoms and their interactions with other atoms, and particularly with the properties of chemical bonds....

, electromagnetic theory

Maxwell's equations

Maxwell's equations are a set of partial differential equations that, together with the Lorentz force law, form the foundation of classical electrodynamics, classical optics, and electric circuits. These fields in turn underlie modern electrical and communications technologies.Maxwell's equations...

and thermodynamics

Thermodynamics

Thermodynamics is a physical science that studies the effects on material bodies, and on radiation in regions of space, of transfer of heat and of work done on or by the bodies or radiation...

.

Productivity gains were not just the result of inventions, but also of continuous improvements to those inventions which greatly increased output in relation both capital and labor compared to the original inventions.

Since the beginning of the Industrial Revolution, some of the major contributors to productivity have been as follows:

1. Replacing human and animal power with water and wind power, steam, electricity and internal combustion and

greatly increasing the use of energy

3. Infrastructures: canals, railroads, highways and pipelines

4. Mechanization, both production machinery and agricultural machines

5. Work practices and processes: The American system of manufacturing, Taylorism or scientific management, mass production, assembly line, modern business enterprise

6. Materials handling: bulk materials, palletization and containerization

7. Scientific agriculture: fertilizers and the green revolution, livestock and poultry management

8. New materials, new process for their production and dematerialization.

9. Communications: Telegraph, telephone, radio, satellites, fiber optic network and the Internet

10. Home economics: Public water supply, household gas, appliances

11. Automation and process control

12. Computers and software, data processing

In recent decades there here have been a number of excellent books and papers published on the history of technology, the role of energy in economics and related issues such as resource depletion, some of which are referenced herein.

Details of productivity improving technologies

A description of economic events and technologies that created the great productivity growth that began in the period from 1870-90 is given by David Ames WellsDavid Ames Wells

David Ames Wells was an American engineer, textbook author, economist and advocate of low tariffs.-Biography:...

(1891).

“The economic changes that have occurred during the last quarter of a century -or during the present generation of living men- have unquestionably been more important and more varied than during any period of the world’s history”. David Ames WellsDavid Ames WellsDavid Ames Wells was an American engineer, textbook author, economist and advocate of low tariffs.-Biography:...

, 1889

1. Replacing human and animal power and greatly increasing overall power

Before the industrial revolution the only sources of power were water, wind and muscle. Most good water power sites (those not requiring massive modern dams) in Europe were developed during medieval period. In the 1750s John SmeatonJohn Smeaton

John Smeaton, FRS, was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist...

, the "father of civil engineering," significantly improved the efficiency of the water wheel by applying scientific principles, thereby adding badly needed power for the Industrial Revolution.

In 1711 a Newcomen steam engine

Newcomen steam engine

The atmospheric engine invented by Thomas Newcomen in 1712, today referred to as a Newcomen steam engine , was the first practical device to harness the power of steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines,...

was installed for pumping water from a mine, a job that typically was done by large teams of horses, of which some mines used as many as 500. Fossil fuel energy first exceeded all animal and water power in 1870. The role energy and machines replacing physical work is discussed in Ayres-Warr (2004).

By about 1870 steam power

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

first exceeded all water, wind and muscle power. While steamboats were used in some areas, as recently as the late 19th Century thousands of workers pulled barges. Until the late 19th century most coal and other minerals were mined with picks and shovels and crops were harvested and grain threshed using animal power or by hand. Heavy loads like 382 pound bales of cotton were handled on hand trucks until the early 20th century.

Dynamite

Dynamite

Dynamite is an explosive material based on nitroglycerin, initially using diatomaceous earth , or another absorbent substance such as powdered shells, clay, sawdust, or wood pulp. Dynamites using organic materials such as sawdust are less stable and such use has been generally discontinued...

, a safe to handle blend of nitroglycerin and diatomaceous earth

Diatomaceous earth

Diatomaceous earth also known as diatomite or kieselgur/kieselguhr, is a naturally occurring, soft, siliceous sedimentary rock that is easily crumbled into a fine white to off-white powder. It has a particle size ranging from less than 1 micrometre to more than 1 millimetre, but typically 10 to...

was patented in 1867 by Alfred Nobel

Alfred Nobel

Alfred Bernhard Nobel was a Swedish chemist, engineer, innovator, and armaments manufacturer. He is the inventor of dynamite. Nobel also owned Bofors, which he had redirected from its previous role as primarily an iron and steel producer to a major manufacturer of cannon and other armaments...

. Dynamite increased productivity of mining, tunneling, road building, construction and demolition and made projects such as the Panama Canal possible.

Steam power was applied to threshing machine

Threshing machine

The thrashing machine, or, in modern spelling, threshing machine , was a machine first invented by Scottish mechanical engineer Andrew Meikle for use in agriculture. It was invented for the separation of grain from stalks and husks. For thousands of years, grain was separated by hand with flails,...

s in the late 19th century. There were steam engines that moved around on wheels under their own power that were used for supplying temporary power to stationary farm equipment such as threshing machines. These were called road engines, and Henry Ford seeing one as a boy was inspired to build an automobile. Steam tractors were used but never became popular.

With internal combustion came the first mass produced tractors (Fordson

Fordson tractor

Fordson was a brand name used on a range of mass produced general-purpose tractors manufactured by Henry Ford & Son, Inc, from 1917 until 1920 when it was merged into the Ford Motor Company, which used the name until 1964...

ca. 1917). Tractors replaced horses and mules for pulling reapers and combine harvesters, but in the 1930s self powered combines were developed. Output per man hour in growing wheat rose by a factor of about 10 from the end of World War II until about 1985, largely because of powered machinery, but also because of increased crop yields. Corn manpower showed a similar but higher productivity increase.

See section 4: Mechanization in agriculture

One of the greatest periods of productivity growth coincided with the electrification

Electrification

Electrification originally referred to the build out of the electrical generating and distribution systems which occurred in the United States, England and other countries from the mid 1880's until around 1940 and is in progress in developing countries. This also included the change over from line...

of factories which took place between 1900 and 1930 in the U.S. See: Mass production: Factory electrification

2. Energy efficiency and productivity: The Useful work growth theoryUseful work growth theoryThe Useful work growth theory, also called the Ayres-Warr model, states that physical and chemical work performed by energy, or more correctly exergy, has historically been the most important driver of economic growth...

Energy efficiency has played a significant role in increasing productivity in the past; however, most industrial processes have exhausted the easy efficiency gains. The early Newcomen steam engineNewcomen steam engine

The atmospheric engine invented by Thomas Newcomen in 1712, today referred to as a Newcomen steam engine , was the first practical device to harness the power of steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines,...

was about than 0.5% efficient and was improved to slightly over 1% by John Smeaton

John Smeaton

John Smeaton, FRS, was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist...

before Watt's improvements. Watt's

Watt steam engine

The Watt steam engine was the first type of steam engine to make use of steam at a pressure just above atmospheric to drive the piston helped by a partial vacuum...

improvements increased thermal efficiency

Thermal efficiency

In thermodynamics, the thermal efficiency is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, a boiler, a furnace, or a refrigerator for example.-Overview:...

to 2%, and today's steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

s have efficiencies in the 40% range. See: Engine efficiency#Steam and Timeline of steam power

Timeline of steam power

Steam power developed slowly over a period of several hundred years, progressing through expensive and fairly limited devices in the early 17th century, to useful pumps for mining in 1700, and then to Watt's improved steam engine designs in the late 18th century...

More efficient steam and internal combustion engines have higher power-to-weight ratios. The Newcomen and Watt engines operated near atmospheric pressure and used atmospheric pressure, or actually a vacuum caused by condensing steam, to do work. Higher pressure engines were light enough, and efficient enough to be used for powering ships and locomotives. Multiple expansion (multi-stage) engines were developed in the 1870s and were efficient enough for the first time to allow ships to carry more freight than coal, leading to great increases in international trade. The most efficient prime mover is the two stroke marine diesel engine

Wärtsilä-Sulzer RTA96-C

The Wärtsilä RT-flex96C is a two-stroke turbocharged low-speed diesel engine designed by the Finnish manufacturer Wärtsilä. It is currently considered the largest reciprocating engine in the world, designed for large container ships, running on heavy fuel oil...

developed in the 1920s, now ranging in size to over 100,000 horsepower with a thermal efficiency

Thermal efficiency

In thermodynamics, the thermal efficiency is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, a boiler, a furnace, or a refrigerator for example.-Overview:...

of 50%. Steam locomotives that used up to 20% of the U.S. coal production were replaced by diesel locomotives after World War II, saving a great deal of energy and reducing manpower for handling coal, boiler water and mechanical maintenance.

Improvements in steam engine efficiency caused a large increase in the number of steam engines and the amount of coal used, as noted by William Stanley Jevons

William Stanley Jevons

William Stanley Jevons was a British economist and logician.Irving Fisher described his book The Theory of Political Economy as beginning the mathematical method in economics. It made the case that economics as a science concerned with quantities is necessarily mathematical...

in The Coal Question

The Coal Question

The Coal Question; An Inquiry Concerning the Progress of the Nation, and the Probable Exhaustion of Our Coal Mines was a book by economist William Stanley Jevons that explored the implications of Britain's reliance on coal. Given that coal was a finite, non-renewable energy resource, Jevons raised...

. This is called the Jevons paradox

Jevons paradox

In economics, the Jevons paradox is the proposition that technological progress that increases the efficiency with which a resource is used, tends to increase the rate of consumption of that resource...

.

Electric lights were far more efficient than oil or gas lighting and did not generate heat, smoke and fumes. Electric light extended the work day, making factories, businesses and homes more productive. Electric light was not a great fire hazard like oil and gas light.

When anti-friction bearings were introduced in locomotives three female office workers demonstrated their efficiency by manually pulling the Timken 1111

Timken 1111

Timken 1111, also called the Timken Four Aces, was a 4-8-4 steam locomotive built in 1930 by American Locomotive Company to serve as a demonstration unit for new roller bearings produced by the Timken Roller Bearing Company...

locomotive.

Industrial process have been continuously improved to reduce the energy consumption per unit of production. See: Section 8: New materials, processes and de-materialization

The Ayres-Warr Model(2004) analyzed the production function

Production function

In microeconomics and macroeconomics, a production function is a function that specifies the output of a firm, an industry, or an entire economy for all combinations of inputs...

and explained part of the Solow residual

Solow residual

The Solow residual is a number describing empirical productivity growth in an economy from year to year and decade to decade. Robert Solow defined rising productivity as rising output with constant capital and labor input...

by electrical generation efficiency.

3. Infrastructures

Sailing ships could transport goods for over a thousand miles for the cost of 30 miles by wagon. A horse that could pull a one ton wagon could pull a 30 ton barge. During the English or First Industrial Revolution, supplying coal to the furnaces at Manchester was difficult because there were few roads and because of the high cost of using wagons. However, canal barges were known to be workable, and this was demonstrated by building the Bridgewater CanalBridgewater Canal

The Bridgewater Canal connects Runcorn, Manchester and Leigh, in North West England. It was commissioned by Francis Egerton, 3rd Duke of Bridgewater, to transport coal from his mines in Worsley to Manchester...

, which opened in 1761, bringing coal from Worsley to Manchester. The Bridgewater Canal’s success started a frenzy of canal building that lasted until the appearance of railroads in the 1830s.

Railroads greatly reduced the cost of overland transportation. It is estimated that by 1890 the cost of wagon freight was U.S. 24.5 cents/ton-mile versus 0.875 cents/ton-mile by railroad. Also see: History of rail transport

History of rail transport

The history of rail transport dates back nearly 500 years and includes systems with man or horse power and rails of wood or stone. Modern rail transport systems first appeared in England in the 1820s...

Electric street railways (tram

Tram

A tram is a passenger rail vehicle which runs on tracks along public urban streets and also sometimes on separate rights of way. It may also run between cities and/or towns , and/or partially grade separated even in the cities...

s, trolleys or streetcars) were the final phase of railroad building from the late 1890s and first two decades of the 20th century. Street railways were soon displaced by motor buses and automobiles after WW I.

Highways with internal combustion powered vehicles completed the mechanization of overland transportation. When trucks appeared ca. 1920 the price transporting farm goods to market or to rail stations was greatly reduced. Motorized highway transport also reduced inventories.

Before iron and steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

were in widespread use, wooden pipelines were used, such as those once supplying water to London from springs located away from the city. Iron and steel pipelines came into use during latter part of the 19th century, but only became a major infrastructure during the 20th century. Centrifugal pump

Centrifugal pump

A centrifugal pump is a rotodynamic pump that uses a rotating impeller to create flow by the addition of energy to a fluid. Centrifugal pumps are commonly used to move liquids through piping...

s and centrifugal compressor

Centrifugal compressor

Centrifugal compressors, sometimes termed radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.The idealized compressive dynamic turbo-machine achieves a pressure rise by adding kinetic energy/velocity to a continuous flow of fluid through the rotor or impeller...

s are efficient means of pumping liquids and natural gas.

The relative energy required for transport of a tonne-km for various modes of transport are: pipelines=1(basis), water 2, rail 3, road 10, air 100.

4. Mechanization (general) and in agriculture

The most important mechanical devices before the Industrial Revolution were water and wind mills. Water wheels date to Roman times and windmills somewhat later. Water and wind power were first used for grinding grain into flour, but were later adapted to power trip hammerTrip hammer

A trip hammer, also known as a helve hammer, is a massive powered hammer used in:* agriculture to facilitate the labor of pounding, decorticating and polishing of grain;...

s for pounding rags into pulp for making paper and for crushing ore. Just before the Industrial revolution water power was applied to bellows for iron smelting. Wind and water power were also used in sawmills.

The technology of building mills and mechanical clocks was important to the development of the machines of the Industrial Revolution.

The spinning wheel

Spinning wheel

A spinning wheel is a device for spinning thread or yarn from natural or synthetic fibers. Spinning wheels appeared in Asia, probably in the 11th century, and very gradually replaced hand spinning with spindle and distaff...

was a medieval invention that increased thread making productivity by a factor greater than ten. One of the early developments that preceded the Industrial Revolution

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

was the stocking frame

Stocking frame

A stocking frame was a mechanical knitting machine used in the textiles industry. It was invented by William Lee of Calverton near Nottingham in 1589...

(loom) of ca. 1589. Later in the Industrial Revolution came the flying shuttle

Flying shuttle

The flying shuttle was one of the key developments in weaving that helped fuel the Industrial Revolution. It was patented by John Kay in 1733. Only one weaver was needed to control its lever-driven motion. Before the shuttle, a single weaver could not weave a fabric wider than arms length. Beyond...

, a simple device that doubled the productivity of weaving. Spinning thread had been a limiting factor in cloth making requiring 10 spinners using the spinning wheel

Spinning wheel

A spinning wheel is a device for spinning thread or yarn from natural or synthetic fibers. Spinning wheels appeared in Asia, probably in the 11th century, and very gradually replaced hand spinning with spindle and distaff...

to supply one weaver. With the spinning jenny

Spinning jenny

The spinning jenny is a multi-spool spinning frame. It was invented c. 1764 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England. The device reduced the amount of work needed to produce yarn, with a worker able to work eight or more spools at once. This grew to 120 as technology...

a spinner could spin eight threads at once. The water frame

Water frame

The water frame is the name given to the spinning frame, when water power is used to drive it. Both are credited to Richard Arkwright who patented the technology in 1768. It was based on an invention by Thomas Highs and the patent was later overturned...

(Ptd. 1768) adapted water power to spinning, but it could only spin one thread at a time. The water frame was easy to operate and many could be located in a single building. The spinning mule

Spinning mule

The spinning mule was a machine used to spin cotton and other fibres in the mills of Lancashire and elsewhere from the late eighteenth to the early twentieth century. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer...

(1779) allowed a large number of threads to be spun by a single machine using water power. A change in consumer preference for cotton at the time of increased cloth production resulted in the invention of the cotton gin

Cotton gin

A cotton gin is a machine that quickly and easily separates cotton fibers from their seeds, a job formerly performed painstakingly by hand...

(Ptd. 1794). Steam power eventually was used as a supplement to water during the Industrial Revolution, and both were used until electrification. A graph of productivity of spinning technologies can be found in Ayres (1989), along with much other data related this article.

With a cotton gin (1792) in one day a man could remove seed from as much upland cotton as would have previously taken a woman working two months to process at one pound per day.

The sewing machine

Sewing machine

A sewing machine is a textile machine used to stitch fabric, cards and other material together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies...

, invented and improved during the early 19th century and produced in large numbers by the 1870s, increased productivity by more than 500%.

Machine tools, which cut, grind and shape parts, were another important mechanical innovation of the Industrial Revolution. Perhaps the best early example of a productivity increase by machine tools and special purpose machines is the ca. 1803 Portsmouth Block Mills. With these machines 10 men could produce as many blocks as 110 skilled craftsmen. However, around 1900, it was the combination of small electric motors, specialty steels and new cutting and grinding materials that allowed machine tools to mass produce steel parts. Production of the Ford Model T

Ford Model T

The Ford Model T is an automobile that was produced by Henry Ford's Ford Motor Company from September 1908 to May 1927...

required 32,000 machine tools.

Modern manufacturing began around 1900 when machines, aided by electric, hydraulic and pneumatic power, began to replace hand methods in industry. An early example is the Owens'es

Michael Joseph Owens

Michael Joseph Owens was an inventor of machines that could automate the production of glass bottles.-Biography:...

automatic glass bottle blowing machine, which reduced labor in making bottles by over 80%. See also: Mass production#Factory electrification

Mechanical stokers for feeding coal to locomotives were in use in the 1920s. A completely mechanized and automated coal handling and stoking system was first used to feed pulverized coal to an electric utility boiler in 1921.

Coal seam undercutting machines appeared around 1890 and were used for 75% of coal production by 1934. Coal loading was still being done manually with shovels around 1930, but mechanical pick up and loading machines were coming into use. The use of the coal boring machine improved productivity of sub-surface coal mining by a factor of three between 1949 and 1969.

Jethro Tull

Jethro Tull (agriculturist)

Jethro Tull was an English agricultural pioneer who helped bring about the British Agricultural Revolution. He perfected a horse-drawn seed drill in 1701 that economically sowed the seeds in neat rows, and later a horse-drawn hoe...

's seed drill

Seed drill

A seed drill is a sowing device that precisely positions seeds in the soil and then covers them. Before the introduction of the seed drill, the common practice was to plant seeds by hand. Besides being wasteful, planting was very imprecise and led to a poor distribution of seeds, leading to low...

(ca. 1701) was a mechanical seed spacing and depth placing device that increased crop yields and saved seed, which was important when yields were measured in terms of seeds harvested per seed planted, which was typically between 3 and 6. The seed drill was an important factor in the British Agricultural Revolution

British Agricultural Revolution

British Agricultural Revolution describes a period of development in Britain between the 17th century and the end of the 19th century, which saw an epoch-making increase in agricultural productivity and net output. This in turn supported unprecedented population growth, freeing up a significant...

.

Since the beginning of agriculture threshing was done by hand with a flail

Flail

A flail is an agricultural implement for threshing.Several tools operate similarly to the agricultural implement and are also called flails:...

, requiring a great deal of labor. The threshing machine

Threshing machine

The thrashing machine, or, in modern spelling, threshing machine , was a machine first invented by Scottish mechanical engineer Andrew Meikle for use in agriculture. It was invented for the separation of grain from stalks and husks. For thousands of years, grain was separated by hand with flails,...

(ca. 1794) simplified the operation and allowed it to use animal power. Threshing machines displaced thousands of workers in Europe, many of who were driven to the brink of starvation.

Scythe

A scythe is an agricultural hand tool for mowing grass, or reaping crops. It was largely replaced by horse-drawn and then tractor machinery, but is still used in some areas of Europe and Asia. The Grim Reaper is often depicted carrying or wielding a scythe...

. It was estimated that for each of Cyrus McCormick's

Cyrus McCormick

Cyrus Hall McCormick, Sr. was an American inventor and founder of the McCormick Harvesting Machine Company, which became part of International Harvester Company in 1902.He and many members of the McCormick family became prominent Chicagoans....

horse pulled reaper

Reaper

A reaper is a person or machine that reaps crops at harvest, when they are ripe.-Hand reaping:Hand reaping is done by various means, including plucking the ears of grains directly by hand, cutting the grain stalks with a sickle, cutting them with a scythe, or with a later type of scythe called a...

s (Ptd. 1834) freed up five men for military service in the U.S. Civil War. By 1890 two men and two horses could cut, rake and bind 20 acres of wheat per day.

In the 1880s the reaper and threshing machine

Threshing machine

The thrashing machine, or, in modern spelling, threshing machine , was a machine first invented by Scottish mechanical engineer Andrew Meikle for use in agriculture. It was invented for the separation of grain from stalks and husks. For thousands of years, grain was separated by hand with flails,...

were combined into the combine harvester

Combine harvester

The combine harvester, or simply combine, is a machine that harvests grain crops. The name derives from the fact that it combines three separate operations, reaping, threshing, and winnowing, into a single process. Among the crops harvested with a combine are wheat, oats, rye, barley, corn ,...

. These machines required large teams of horses or mules to pull. Over the entire 19th century the output per man hour for producing wheat rose by about 500% and for corn about 250%.

Farm machinery and higher crop yields reduced the labor to produce 100 bushels of corn from 35 to 40 hours in 1900 to 2 hours 45 minutes in 1999. The conversion of agricultural mechanization to internal combustion power began after 1915. The horse population began to decline in the 1920s after the conversion of agriculture and transportation to internal combustion. In addition to saving labor, this freed up much land previously used for supporting draft animals.

The peak years for tractor sales in the U.S. were the 1950s. There was a large surge in horsepower of farm machinery in the 1950s.

5. Work practices and processes

Changes to traditional work processes that were done after analyzing the work and making it more systematic greatly increased the productivity of labor and capital. This was the changeover from the European system of craftsmanship, where a crafstman made a whole item, to the American system of manufacturingAmerican system of manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. It involved semi-skilled labor using machine tools and jigs to make standardized, identical, interchangeable parts, manufactured to a tolerance, which could be assembled with a minimum of time...

which used special purpose machines and machine tools that made parts with precision so as to be interchangeable

Interchangeable parts