Parts cleaning

Encyclopedia

Parts cleaning is essential to many industrial processes, as a prelude to surface finishing

or to protect sensitive components. Electroplating

is particularly sensitive to part cleanliness, since molecular layers of oil

can prevent adhesion

of the coating

. ASTM B322 is a standard guide for cleaning metal

s prior to electroplating. Cleaning processes include solvent

cleaning, hot alkali

ne detergent

cleaning, electrocleaning, and acid etch. The most common industrial test for cleanliness is the waterbreak test, in which the surface is thoroughly rinsed and held vertical. Hydrophobic

contaminants such as oils cause the water

to bead and break up, allowing the water to drain rapidly. Perfectly clean metal surfaces are hydrophilic

and will retain an unbroken sheet of water that does not bead up or drain off. ASTM F22 describes a version of this test. This test does not detect hydrophilic contaminants, but the electroplating process can displace these easily since the solutions are water-based. Surfactant

s such as soap

reduce the sensitivity of the test, so these must be thoroughly rinsed off.

s and composite material

s in this sector. The term component cleaning leaves out the cleaning of steel

sections and sheets and finally degreasing only describes a part of the topic as in most cases also chips, fines, particles, salts etc. have to be removed.

The terms 'commercial and industrial parts cleaning', 'parts cleaning in craft and industry' or 'commercial parts cleaning' probably best describe this field of activity. There are some specialists who prefer the term 'industrial parts cleaning', because they want to exclude maintenance of buildings, rooms, areas, windows, floors, tanks, machinery, hygiene

, hands washing, showers etc.

Cleaning activities in this sector can only be characterised sufficiently by a description of a number of different factors. These are outlined in illustration 1.

Cleaning activities in this sector can only be characterised sufficiently by a description of a number of different factors. These are outlined in illustration 1.

s can frequently be found and indeed are on the increase because e.g. the automobile

industry as well as others uses more and more lighter materials.

Mass

and size can be very important for the selection of cleaning methods, for example big shafts for ship

s are usually cleaned manually, whereas tiny shafts for electrical appliances are often cleaned in bulk in highly automated plants.

Similarly important is the geometry of the parts. Long, thin, branching, threaded holes, which could contain jammed chips, feature among the greatest challenges in this technical field. high pressure and the power wash process

are one way to remove these chips as well as robot

s, which are programmed to exactly flush the drilled holes under high pressure.

layer but only the material on top. In another case, where crack proofing is necessary one has to remove the paint layer and it is regarded as an unwanted substance.

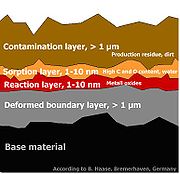

The classification of soiling follows the layer structure starting from the base material:

See illustration 2: Structure of a metallic surface

The nearer the layers are to the substrate surface, the more energy

is needed to remove them. Correspondingly the cleaning itself can be structured according to the type of energy input :

The contamination layer may then be further classified according to:

The American Society for Testing and Materials (ASTM

) presents six groups of contaminations in their manual "Choosing a cleaning process" and relates them to the most common cleaning methods, thereby the suitability of cleaning methods for the removal of a given contaminate is discussed in detail . In addition they list exemplary cleaning processes for different typical applications. Since one has to consider very many different aspects when choosing a process, this can only serve as a first orientation. The groups of contaminants are stated as follows:

Usually the cleaning takes place in a workshop. Several common methods are solvent degreasing

, vapor degreasing

and using an aqueous parts washer

. Companies often want the charging, loading and unloading to be integrated into the production line, which is much more demanding as regards size and throughput ability of the cleaning system.

Such cleaning systems often exactly match the requirements regarding parts, contaminants and charging methods (special production). Nonetheless central cleaning equipment, often built as multi task systems, are commonly used. These systems can suit different cleaning requirements. Typical examples are the wash stands or the small cleaning machines

which are found in many insdustrial plants.

The process may be performed in one step, which is especially true for the manual cleaning, but typically it requires several steps. Therefore, it is not uncommon to find 10 to 20 steps in large plants e.g. for the medical and optical industry. This can be especially complex because non-cleaning steps may be integrated in such plants like application of corrosion

protection layers or phosphating

. Cleaning can also be simple, the cleaning processes are integrated into other processes as it is the case with electroplating

or galvanising, where it usually serves as a pre-treatment step.

The following procedure is quite common:

Each of these steps may take place in its own bath or chamber or in case of spray cleaning in its own zone (line or multi-chamber equipment). But quite often these steps may have a single chamber into which the respective media are pumped in (single chamber plant).

Besides equipment and procedure, cleaning media plays an important role as it removes the contaminants from the substrate.

For liquid media the following cleaners are in use: aqueous agents, semi-aqueous agents (an emulsion of solvents and water), hydrocarbon based solvents and halogenated solvents. Usually the latter are referred to as chlorinated agents, but there are also brominated and fluorated substances in (limited) use, that is why we have chosen the higher level classification. The hazardous traditionally used chlorinated agents TCI

and PCE

are nowadays only applied in airtight plants and the modern volume shift systems limits any emissions.In the group of hydrocarbon based solvents, there are some newly developed agents like fatty acid esters made of natural fats and oils, modified alcohols and dibasic esters.

Aqueous cleaners are mostly a combination of various substances like alkaline builders, surfactants, sequestering agents, etc. In the case of ferrous metal cleaning, rust inibitors are built into the aqueous cleaner to prevent flash rusting after washing. Their use is on the rise as their results have proven to be in many cases as good or better than hydrocarbon cleaners. Additionally, the wastes generated are less hazardous resulting in less costly disposal.

Aqueous cleaners have advantages as regards to particle and polar contaminants and only require higher inputs of mechanical and thermal energy to be effective, whereas solvents more easily remove oils and greases but have health and environmental risks. In addition most solvents are flammable and create fire and explosion hazards. Now days, with the proper industrial parts washer

equipment, it is generally accepted that aqueous cleaners remove oil and grease as easily as solvents.

Another approach is with solid cleaning media (blasting) which constitutes of the CO2 dry ice process

: For tougher requirements pellets are used while for more sensitive materials or components CO2 in form of snow is applied. One draw back is the high energy consumption required to make dry ice.

Last but not least there are processes without any media like vibration, laser, brushing and blow/exhaust systems.

All cleaning steps are characterised by media and applied temperatures and their individual agitation/application (mechanical impact). There is a wide range of different methods and combinations of these methods:

Finally, every cleaning step is described by the time which the parts to be cleaned spends in the respective zone, bath or chamber and thus medium, temperature and agitation can impact on the contamination.

Every cleaning equipment needs a so-called periphery. This term describes measures and equipment on the one hand side to maintain and control baths and on the other hand side to protect human beings and the environment.

In most plants the cleaning agents are circulated until their cleaning power has eventually decreased and reached the maximum tolerable contaminant level. In order to delay the necessary bath exchange as much as possible there are sophisticated treatment attachments in use, removing contaminants and the used up agents from the system. At the same time fresh cleaning agents or parts thereof have to be supplemented, which requires a bath control. The latter is more and more facilitated online and thus allows a computer aided adjustment of the bath. With the help of oil separators, demulsifying agents and evaporators aqueous processes can be conducted 'waste water free'. Complete exchange of baths becomes only necessary every 3 to 12 months.

When using organic solvents the preferred method to achieve a long operating bath life is distillation, an especially effective method to separate contaminants and agents.

The periphery also includes measures to protect the workers like encapsulation, automatic shut off of power supply, automatic refill and sharpening of media (e.g. gas shuttle technique), explosion prevention measures, exhaust ventilation etc., and also measures to protect the environment, e.g. capturing of volatile solvents, impounding basins, extraction, treatment and disposal of resulting wastes. Solvents based cleaning processes have the advantage that the dirt and the cleaning agent can be more easily separated, whereas in aqueous processes is more complex.

In processes without cleaning media like laser ablation

and vibration cleaning, only the removed dirt has to be disposed of as there is no cleaning agent. Quite little waste is generated in processes like CO2 blasting and automatic brush cleaning at the expense of higher energy costs.

The rather general rules includes the classification in intermediate cleaning, final cleaning, precision cleaning and critical cleaning (s. table), in practice seen only as a general guideline.

Related to the total dirt; (2) Only related to Carbon

Thus in practice the rule of thumb is still followed, stating that the quality requirements are met, if the subsequent process (see below) does not cause any problems, for example a paint coating does not flake off before the guarantee period ends.

Where this is not sufficient, especially in case of external orders, because of missing standards there are often specific customer requirements regarding remaining contamination, corrosion protection, spots and gloss level etc.

Measuring methods to ensure quality therefore do not play a bigger role in the workshops, although there exist a broad scale of different methods, from visual control over simple testing methods (among other things water break test, wipe test, measurement of contact angle, test inks, tape test) to complex analysis methods (among others gravimetric

test, particle counting, infrared spectroscopy

, glow discharge spectroscopy, energy dispersive X-ray

analysis, scanning electron microscopy and electrochemical methods). Nevertheless there are only few methods, which can be applied directly in the line and which offer reproducible and comparable results. It was not until recently that bigger advancements in this area have been made

The general situation has changed meanwhile, because of dramatically rising cleanliness requirements for certain components in the automotive industry. For example brake

systems and fuel-injection systems need to be fitted with increasingly smaller diameters and they have to withstand increasingly higher pressures. Therefore, a very minor particle contamination may lead to big problems. Due to the rising innovation speed, the industry cannot afford to identify possible failures at a relatively late stage. Therefore, the standard VDA 19/ISO 16232 'Road Vehicles – Cleanliness of Components of Fluid Circuits' was developed which describes methods that can control the compliance with the cleanliness requirements.

The classification follows basically the metal work theory:

In the course of time empirical values were established, how efficient the cleaning has to be, to assure the processes for the particular guarantee period and beyond. Choosing the cleaning method often starts from here.

SAGE:

Unfortunately no longer in operation the comprehensive expert system for parts cleaning and degreasing provided a graded list with relatively general processes of possible solvent and process alternatives. Developed by the Surface Cleaning Programme at the Research Triangle Institute, Raleigh, North Carolina

, USA, in cooperation with the U.S. EPA

(used to be available under: http://clean.rti.org/).

Cleantool:

A ‘Best Practice’ database in seven languages with comprehensive and specific processes, directly recorded in companies. It contains furthermore an integrated evaluation tool, which covers the areas technology, quality, health and safety at work, environmental protection as well as costs. Also included is a comprehensive glossary (seven languages, link see below).

Bauteilreinigung:

A selection system for component cleaning developed by the University of Dortmund, assisting the users to analyse their cleaning tasks with regard to the suitable cleaning processes and cleaning agents (German only, link see below).

TURI, Toxic Use Reduction Institute:

A department of the University of Lowell, Massachusetts

(USA). TURI's laboratory has been conducting evaluations on alternative cleaning products since 1993. A majority of these products were designed for metal surface cleaning. The results of these tests are available on-line through the Institute’s laboratory database (English only, link see below).

Surface finishing

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property. Finishing processes may be employed to: improve appearance, adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance,...

or to protect sensitive components. Electroplating

Electroplating

Electroplating is a plating process in which metal ions in a solution are moved by an electric field to coat an electrode. The process uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal...

is particularly sensitive to part cleanliness, since molecular layers of oil

Oil

An oil is any substance that is liquid at ambient temperatures and does not mix with water but may mix with other oils and organic solvents. This general definition includes vegetable oils, volatile essential oils, petrochemical oils, and synthetic oils....

can prevent adhesion

Adhesion

Adhesion is any attraction process between dissimilar molecular species that can potentially bring them in close contact. By contrast, cohesion takes place between similar molecules....

of the coating

Coating

Coating is a covering that is applied to the surface of an object, usually referred to as the substrate. In many cases coatings are applied to improve surface properties of the substrate, such as appearance, adhesion, wetability, corrosion resistance, wear resistance, and scratch resistance...

. ASTM B322 is a standard guide for cleaning metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

s prior to electroplating. Cleaning processes include solvent

Solvent

A solvent is a liquid, solid, or gas that dissolves another solid, liquid, or gaseous solute, resulting in a solution that is soluble in a certain volume of solvent at a specified temperature...

cleaning, hot alkali

Alkali

In chemistry, an alkali is a basic, ionic salt of an alkali metal or alkaline earth metal element. Some authors also define an alkali as a base that dissolves in water. A solution of a soluble base has a pH greater than 7. The adjective alkaline is commonly used in English as a synonym for base,...

ne detergent

Detergent

A detergent is a surfactant or a mixture of surfactants with "cleaning properties in dilute solutions." In common usage, "detergent" refers to alkylbenzenesulfonates, a family of compounds that are similar to soap but are less affected by hard water...

cleaning, electrocleaning, and acid etch. The most common industrial test for cleanliness is the waterbreak test, in which the surface is thoroughly rinsed and held vertical. Hydrophobic

Hydrophobe

In chemistry, hydrophobicity is the physical property of a molecule that is repelled from a mass of water....

contaminants such as oils cause the water

Water

Water is a chemical substance with the chemical formula H2O. A water molecule contains one oxygen and two hydrogen atoms connected by covalent bonds. Water is a liquid at ambient conditions, but it often co-exists on Earth with its solid state, ice, and gaseous state . Water also exists in a...

to bead and break up, allowing the water to drain rapidly. Perfectly clean metal surfaces are hydrophilic

Hydrophile

A hydrophile, from the Greek "water" and φιλια "love," is a molecule or other molecular entity that is attracted to, and tends to be dissolved by water. A hydrophilic molecule or portion of a molecule is one that has a tendency to interact with or be dissolved by, water and other polar substances...

and will retain an unbroken sheet of water that does not bead up or drain off. ASTM F22 describes a version of this test. This test does not detect hydrophilic contaminants, but the electroplating process can displace these easily since the solutions are water-based. Surfactant

Surfactant

Surfactants are compounds that lower the surface tension of a liquid, the interfacial tension between two liquids, or that between a liquid and a solid...

s such as soap

Soap

In chemistry, soap is a salt of a fatty acid.IUPAC. "" Compendium of Chemical Terminology, 2nd ed. . Compiled by A. D. McNaught and A. Wilkinson. Blackwell Scientific Publications, Oxford . XML on-line corrected version: created by M. Nic, J. Jirat, B. Kosata; updates compiled by A. Jenkins. ISBN...

reduce the sensitivity of the test, so these must be thoroughly rinsed off.

Definitions and classifications

For the activities described here the following terms are often found: metal cleaning, metal surface cleaning, component cleaning, degreasing, parts washing, parts cleaning. These are well established in technical language usage but they have their shortcomings. Metal cleaning can easily be mixed up with refinement of unpurified metals. Metal surface cleaning and metal cleaning do not consider the increasing usage of plasticPlastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

s and composite material

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

s in this sector. The term component cleaning leaves out the cleaning of steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

sections and sheets and finally degreasing only describes a part of the topic as in most cases also chips, fines, particles, salts etc. have to be removed.

The terms 'commercial and industrial parts cleaning', 'parts cleaning in craft and industry' or 'commercial parts cleaning' probably best describe this field of activity. There are some specialists who prefer the term 'industrial parts cleaning', because they want to exclude maintenance of buildings, rooms, areas, windows, floors, tanks, machinery, hygiene

Hygiene

Hygiene refers to the set of practices perceived by a community to be associated with the preservation of health and healthy living. While in modern medical sciences there is a set of standards of hygiene recommended for different situations, what is considered hygienic or not can vary between...

, hands washing, showers etc.

Elements and their interactions

Parts and materials to be cleaned

First, consider the parts to be cleaned. They may consist of non- or hardly-processed sections, sheets and wires. But also machined parts or assembled components needing cleaning. Therefore, they may be composed of different metals or different combinations of metals. Plastics and composite materialComposite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

s can frequently be found and indeed are on the increase because e.g. the automobile

Automobile

An automobile, autocar, motor car or car is a wheeled motor vehicle used for transporting passengers, which also carries its own engine or motor...

industry as well as others uses more and more lighter materials.

Mass

Mass

Mass can be defined as a quantitive measure of the resistance an object has to change in its velocity.In physics, mass commonly refers to any of the following three properties of matter, which have been shown experimentally to be equivalent:...

and size can be very important for the selection of cleaning methods, for example big shafts for ship

Ship

Since the end of the age of sail a ship has been any large buoyant marine vessel. Ships are generally distinguished from boats based on size and cargo or passenger capacity. Ships are used on lakes, seas, and rivers for a variety of activities, such as the transport of people or goods, fishing,...

s are usually cleaned manually, whereas tiny shafts for electrical appliances are often cleaned in bulk in highly automated plants.

Similarly important is the geometry of the parts. Long, thin, branching, threaded holes, which could contain jammed chips, feature among the greatest challenges in this technical field. high pressure and the power wash process

Parts washer

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces...

are one way to remove these chips as well as robot

Robot

A robot is a mechanical or virtual intelligent agent that can perform tasks automatically or with guidance, typically by remote control. In practice a robot is usually an electro-mechanical machine that is guided by computer and electronic programming. Robots can be autonomous, semi-autonomous or...

s, which are programmed to exactly flush the drilled holes under high pressure.

Contaminations

The parts are usually covered by unwanted substances, the contaminations or soiling. The definition used is quite varied. In certain cases these coverings may be desired: e.g. one may not wish to remove a paintPaint

Paint is any liquid, liquefiable, or mastic composition which after application to a substrate in a thin layer is converted to an opaque solid film. One may also consider the digital mimicry thereof...

layer but only the material on top. In another case, where crack proofing is necessary one has to remove the paint layer and it is regarded as an unwanted substance.

The classification of soiling follows the layer structure starting from the base material:

- Deformed boundary layer, > 1 µm

- Reaction layer, 1 - 10 nm

- Sorption layer, 1 - 10 nm

- Contamination layer, > 1 µm

See illustration 2: Structure of a metallic surface

The nearer the layers are to the substrate surface, the more energy

Energy

In physics, energy is an indirectly observed quantity. It is often understood as the ability a physical system has to do work on other physical systems...

is needed to remove them. Correspondingly the cleaning itself can be structured according to the type of energy input :

- mechanical - abrasive: blasting, grinding

- mechanical - non-abrasive: stirring, mixing, ultrasound, spraying

- thermal - reactive: heat treatment much above 100°C in reactive gases

- thermal - non-reactive: temperature below 100°C, increased bath temperature, vapour degreasing

- chemical - abrasive/reactive: pickling in liquids, plasma-assistedPlasma cleaningPlasma cleaning involves the removal of impurities and contaminants from surfaces through the use of an energetic plasma created from gaseous species. Gases such as argon and oxygen, as well as mixtures such as air and hydrogen/nitrogen are used...

, sputter-cleaning, elektropolishing - chemical - non-reactive: organic solvents, aqueous solutions, supercritical CO2

The contamination layer may then be further classified according to:

- Origin

- Composition: e.g. cooling lubricantLubricantA lubricant is a substance introduced to reduce friction between moving surfaces. It may also have the function of transporting foreign particles and of distributing heat...

s may be composed very differently, thereby single components may account for big problems especially for job shop cleaners, who have no control over prior processes and thus don't know the contaminants. For example silicateSilicateA silicate is a compound containing a silicon bearing anion. The great majority of silicates are oxides, but hexafluorosilicate and other anions are also included. This article focuses mainly on the Si-O anions. Silicates comprise the majority of the earth's crust, as well as the other...

s may obstruct nitriding. - State of aggregation

- Chemical and physical properties

The American Society for Testing and Materials (ASTM

ASTM International

ASTM International, known until 2001 as the American Society for Testing and Materials , is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services...

) presents six groups of contaminations in their manual "Choosing a cleaning process" and relates them to the most common cleaning methods, thereby the suitability of cleaning methods for the removal of a given contaminate is discussed in detail . In addition they list exemplary cleaning processes for different typical applications. Since one has to consider very many different aspects when choosing a process, this can only serve as a first orientation. The groups of contaminants are stated as follows:

- Pigmented drawing compounds

- Unpigmented oil and grease

- Chips and cutting fluids

- Polishing and buffing compounds

- RustRustRust is a general term for a series of iron oxides. In colloquial usage, the term is applied to red oxides, formed by the reaction of iron and oxygen in the presence of water or air moisture...

and scale - Others

Charging

In order to select suitable equipment and media it should be known also which amount and which throughput has to be handled. Small amounts can hardly be cleaned economically in larger plants. Also the type of charging has to be ascertained. Sensitive parts sometimes need to be fixed in boxes. Very economically when dealing with large amounts is bulk charging, but it is quite difficult to achieve a sufficient level of cleanliness with flat pieces clinging together. Also drying can be difficult in these cases.Place of cleaning

Another consideration is the place of cleaning. E.g. is the cleaning to be done on site, which can be the case with repair and maintenance work.Usually the cleaning takes place in a workshop. Several common methods are solvent degreasing

Solvent degreasing

Solvent degreasing is a process used to prepare a part for further operations such as electroplating or painting. Typically it uses petroleum, chlorine, or alcohol based solvents to dissolve the machining fluids and other contaminants that might be on the part.- Process :Solvent degreasing is a...

, vapor degreasing

Vapor Degreasing

Vapor degreasing is a surface finishing process. It involves solvents in vapor form to cleanse the workpiece in preparation for further finishing operations.-Process:...

and using an aqueous parts washer

Parts washer

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces...

. Companies often want the charging, loading and unloading to be integrated into the production line, which is much more demanding as regards size and throughput ability of the cleaning system.

Such cleaning systems often exactly match the requirements regarding parts, contaminants and charging methods (special production). Nonetheless central cleaning equipment, often built as multi task systems, are commonly used. These systems can suit different cleaning requirements. Typical examples are the wash stands or the small cleaning machines

Parts washer

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces...

which are found in many insdustrial plants.

Cleaning equipment and procedure

First, one can differentiate between the following techniques:- Manual

- Mechanical

- Automatic

- Robot supported

The process may be performed in one step, which is especially true for the manual cleaning, but typically it requires several steps. Therefore, it is not uncommon to find 10 to 20 steps in large plants e.g. for the medical and optical industry. This can be especially complex because non-cleaning steps may be integrated in such plants like application of corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

protection layers or phosphating

Parkerizing

Parkerizing is a method of protecting a steel surface from corrosion and increasing its resistance to wear through the application of an electrochemical phosphate conversion coating...

. Cleaning can also be simple, the cleaning processes are integrated into other processes as it is the case with electroplating

Electroplating

Electroplating is a plating process in which metal ions in a solution are moved by an electric field to coat an electrode. The process uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal...

or galvanising, where it usually serves as a pre-treatment step.

The following procedure is quite common:

- Pre cleaning

- Main cleaning

- Rinsing

- Rinsing with deionised water

- Rinsing with corrosion protection

- Drying

Each of these steps may take place in its own bath or chamber or in case of spray cleaning in its own zone (line or multi-chamber equipment). But quite often these steps may have a single chamber into which the respective media are pumped in (single chamber plant).

Besides equipment and procedure, cleaning media plays an important role as it removes the contaminants from the substrate.

For liquid media the following cleaners are in use: aqueous agents, semi-aqueous agents (an emulsion of solvents and water), hydrocarbon based solvents and halogenated solvents. Usually the latter are referred to as chlorinated agents, but there are also brominated and fluorated substances in (limited) use, that is why we have chosen the higher level classification. The hazardous traditionally used chlorinated agents TCI

Trichloroethylene

The chemical compound trichloroethylene is a chlorinated hydrocarbon commonly used as an industrial solvent. It is a clear non-flammable liquid with a sweet smell. It should not be confused with the similar 1,1,1-trichloroethane, which is commonly known as chlorothene.The IUPAC name is...

and PCE

Tetrachloroethylene

Tetrachloroethylene, also known under its systematic name tetrachloroethene and many other names, is a chlorocarbon with the formula Cl2C=CCl2. It is a colourless liquid widely used for dry cleaning of fabrics, hence it is sometimes called "dry-cleaning fluid." It has a sweet odor detectable by...

are nowadays only applied in airtight plants and the modern volume shift systems limits any emissions.In the group of hydrocarbon based solvents, there are some newly developed agents like fatty acid esters made of natural fats and oils, modified alcohols and dibasic esters.

Aqueous cleaners are mostly a combination of various substances like alkaline builders, surfactants, sequestering agents, etc. In the case of ferrous metal cleaning, rust inibitors are built into the aqueous cleaner to prevent flash rusting after washing. Their use is on the rise as their results have proven to be in many cases as good or better than hydrocarbon cleaners. Additionally, the wastes generated are less hazardous resulting in less costly disposal.

Aqueous cleaners have advantages as regards to particle and polar contaminants and only require higher inputs of mechanical and thermal energy to be effective, whereas solvents more easily remove oils and greases but have health and environmental risks. In addition most solvents are flammable and create fire and explosion hazards. Now days, with the proper industrial parts washer

Parts washer

A parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces...

equipment, it is generally accepted that aqueous cleaners remove oil and grease as easily as solvents.

Another approach is with solid cleaning media (blasting) which constitutes of the CO2 dry ice process

Dry ice blasting

Dry ice-blasting is a form of abrasive blasting, where dry ice, the solid form of carbon dioxide, is accelerated in a pressurized air stream and directed at a surface in order to clean it....

: For tougher requirements pellets are used while for more sensitive materials or components CO2 in form of snow is applied. One draw back is the high energy consumption required to make dry ice.

Last but not least there are processes without any media like vibration, laser, brushing and blow/exhaust systems.

All cleaning steps are characterised by media and applied temperatures and their individual agitation/application (mechanical impact). There is a wide range of different methods and combinations of these methods:

- Sprinkling

- Spraying

- Power Wash ProcessParts washerA parts washer is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces...

- Blasting

- Flooding

- Movement of parts (turning, oscillating, pivoting)

- Circulation of bath

- Gas or air injection into bath

- Boiling under pressure

- Injection flooding

- Pressure flooding

- Hydroson

- Ultrasonic, see ultrasonic cleaningUltrasonic cleaningthumb|300px|Ultrasonic cleaner showing the removable basket in place, and a closeup of the light and timerAn ultrasonic cleaner is a cleaning device that uses ultrasound and an appropriate cleaning solvent to clean delicate items...

- Megasonic, see megasonic cleaningMegasonic cleaningMegasonic Cleaning is a type of acoustic cleaning, related to ultrasonic cleaning. It is a gentler cleaning mechanism, less likely to cause damage, and is used in wafer, medical implant, and industrial part cleaning....

Finally, every cleaning step is described by the time which the parts to be cleaned spends in the respective zone, bath or chamber and thus medium, temperature and agitation can impact on the contamination.

Every cleaning equipment needs a so-called periphery. This term describes measures and equipment on the one hand side to maintain and control baths and on the other hand side to protect human beings and the environment.

In most plants the cleaning agents are circulated until their cleaning power has eventually decreased and reached the maximum tolerable contaminant level. In order to delay the necessary bath exchange as much as possible there are sophisticated treatment attachments in use, removing contaminants and the used up agents from the system. At the same time fresh cleaning agents or parts thereof have to be supplemented, which requires a bath control. The latter is more and more facilitated online and thus allows a computer aided adjustment of the bath. With the help of oil separators, demulsifying agents and evaporators aqueous processes can be conducted 'waste water free'. Complete exchange of baths becomes only necessary every 3 to 12 months.

When using organic solvents the preferred method to achieve a long operating bath life is distillation, an especially effective method to separate contaminants and agents.

The periphery also includes measures to protect the workers like encapsulation, automatic shut off of power supply, automatic refill and sharpening of media (e.g. gas shuttle technique), explosion prevention measures, exhaust ventilation etc., and also measures to protect the environment, e.g. capturing of volatile solvents, impounding basins, extraction, treatment and disposal of resulting wastes. Solvents based cleaning processes have the advantage that the dirt and the cleaning agent can be more easily separated, whereas in aqueous processes is more complex.

In processes without cleaning media like laser ablation

Laser ablation

Laser ablation is the process of removing material from a solid surface by irradiating it with a laser beam. At low laser flux, the material is heated by the absorbed laser energy and evaporates or sublimates. At high laser flux, the material is typically converted to a plasma...

and vibration cleaning, only the removed dirt has to be disposed of as there is no cleaning agent. Quite little waste is generated in processes like CO2 blasting and automatic brush cleaning at the expense of higher energy costs.

Quality requirements

A standardisation of the quality requirements for cleaned surfaces regarding the following process (e.g. coating, heat treatment) or from the point of view of technical functionality is difficult. However it is possible to use general classifications. In Germany it was attempted to define cleaning as a sub category of metal treatment (DIN 8592: Cleaning as sub category of cutting processes), but this does not cope with all the complexities of cleaning.The rather general rules includes the classification in intermediate cleaning, final cleaning, precision cleaning and critical cleaning (s. table), in practice seen only as a general guideline.

| Terms | Max. allowed dirt | Soils removed | Explanations |

|---|---|---|---|

| Intermediate cleaning | E.g. in metal cutting manufacturing | ||

| Final cleaning | ≤ 500 mg / m² (1) | Mil-sized particles and residues thicker than a monolayer | E.g. before assembling or coating |

|

|

||

|

|

|

||

|

|

|

||

| Precision cleaning | ≤ 50 mg / m² (1) | Supermicrometre particles and residues thinner than a monolayer | Controlled environment (Durkee) |

| Critical cleaning | ≤ 5 mg / m² (1) | Sub-micrometre particles and non-volatile residue measured in Angstroms | cleanroom (Durkee) |

Thus in practice the rule of thumb is still followed, stating that the quality requirements are met, if the subsequent process (see below) does not cause any problems, for example a paint coating does not flake off before the guarantee period ends.

Where this is not sufficient, especially in case of external orders, because of missing standards there are often specific customer requirements regarding remaining contamination, corrosion protection, spots and gloss level etc.

Measuring methods to ensure quality therefore do not play a bigger role in the workshops, although there exist a broad scale of different methods, from visual control over simple testing methods (among other things water break test, wipe test, measurement of contact angle, test inks, tape test) to complex analysis methods (among others gravimetric

Gravimetry

Gravimetry is the measurement of the strength of a gravitational field. Gravimetry may be used when either the magnitude of gravitational field or the properties of matter responsible for its creation are of interest...

test, particle counting, infrared spectroscopy

Spectroscopy

Spectroscopy is the study of the interaction between matter and radiated energy. Historically, spectroscopy originated through the study of visible light dispersed according to its wavelength, e.g., by a prism. Later the concept was expanded greatly to comprise any interaction with radiative...

, glow discharge spectroscopy, energy dispersive X-ray

X-ray

X-radiation is a form of electromagnetic radiation. X-rays have a wavelength in the range of 0.01 to 10 nanometers, corresponding to frequencies in the range 30 petahertz to 30 exahertz and energies in the range 120 eV to 120 keV. They are shorter in wavelength than UV rays and longer than gamma...

analysis, scanning electron microscopy and electrochemical methods). Nevertheless there are only few methods, which can be applied directly in the line and which offer reproducible and comparable results. It was not until recently that bigger advancements in this area have been made

The general situation has changed meanwhile, because of dramatically rising cleanliness requirements for certain components in the automotive industry. For example brake

Brake

A brake is a mechanical device which inhibits motion. Its opposite component is a clutch. The rest of this article is dedicated to various types of vehicular brakes....

systems and fuel-injection systems need to be fitted with increasingly smaller diameters and they have to withstand increasingly higher pressures. Therefore, a very minor particle contamination may lead to big problems. Due to the rising innovation speed, the industry cannot afford to identify possible failures at a relatively late stage. Therefore, the standard VDA 19/ISO 16232 'Road Vehicles – Cleanliness of Components of Fluid Circuits' was developed which describes methods that can control the compliance with the cleanliness requirements.

Subsequent process

When choosing cleaning techniques, cleaning agents and cleaning processes, the subsequent processes, i.e. the further processing of the cleaned parts is of special interest.The classification follows basically the metal work theory:

- machining

- cutting

- joining

- coating

- heat treatmentHeat treatmentHeat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass...

- assembling

- measuring, testing

- repairing, maintenance.

In the course of time empirical values were established, how efficient the cleaning has to be, to assure the processes for the particular guarantee period and beyond. Choosing the cleaning method often starts from here.

Challenges and trends

The details above illustrate how extremely complex this specific field is. Already small changes in the requirements can necessitate completely different processes. Thus it defies scientific technical determination. On the other hand it becomes more and more important to receive the required degree of cleanliness as cost-effective as possible and with continuously minimised health and environmental risks, because cleaning has become of central importance for the supply chain in manufacturing . Applying companies usually rely on their suppliers, who—due to a big experience base—suggest adequate equipment and processes, which are then adapted to the detailed requirements in tests stations at the supplier’s premises. However they are limited to their scope of technology. To put practitioners in a position to consider all relevant possibilities meeting their requirements, some institutes have developed different tools:SAGE:

Unfortunately no longer in operation the comprehensive expert system for parts cleaning and degreasing provided a graded list with relatively general processes of possible solvent and process alternatives. Developed by the Surface Cleaning Programme at the Research Triangle Institute, Raleigh, North Carolina

Raleigh, North Carolina

Raleigh is the capital and the second largest city in the state of North Carolina as well as the seat of Wake County. Raleigh is known as the "City of Oaks" for its many oak trees. According to the U.S. Census Bureau, the city's 2010 population was 403,892, over an area of , making Raleigh...

, USA, in cooperation with the U.S. EPA

United States Environmental Protection Agency

The U.S. Environmental Protection Agency is an agency of the federal government of the United States charged with protecting human health and the environment, by writing and enforcing regulations based on laws passed by Congress...

(used to be available under: http://clean.rti.org/).

Cleantool:

A ‘Best Practice’ database in seven languages with comprehensive and specific processes, directly recorded in companies. It contains furthermore an integrated evaluation tool, which covers the areas technology, quality, health and safety at work, environmental protection as well as costs. Also included is a comprehensive glossary (seven languages, link see below).

Bauteilreinigung:

A selection system for component cleaning developed by the University of Dortmund, assisting the users to analyse their cleaning tasks with regard to the suitable cleaning processes and cleaning agents (German only, link see below).

TURI, Toxic Use Reduction Institute:

A department of the University of Lowell, Massachusetts

University of Massachusetts Lowell

The University of Massachusetts Lowell is a public university in Lowell, Massachusetts, and part of the University of Massachusetts system...

(USA). TURI's laboratory has been conducting evaluations on alternative cleaning products since 1993. A majority of these products were designed for metal surface cleaning. The results of these tests are available on-line through the Institute’s laboratory database (English only, link see below).

Literature

- John B. Durkee: "Management of Industrial Cleaning Technology and Processes," 2006, Elsevier, Oxford, United Kingdom, ISBN 0080448887.

- Carole A. LeBlanc: The search for safer and greener chemical solvents in surface cleaning : a proposed tool to support environmental decision-making. 2001, Erasmus University Centre for Environmental Studies, Rotterdam, the Netherlands.

- David S. Peterson: Practical guide to industrial metal cleaning. 1997, Hanser Gardner Publications, Cincinnati, Ohio, USA. ISBN 1-56990-216-X

- Barbara Kanegsberg ed.: Handbook for critical cleaning. 2001, CRC Press, Boca Raton, Florida, USA. ISBN 0-8493-1655-3

- Malcolm C. McLaughlin et al.: The aqueous cleaning handbook : a guide to critical-cleaning procedures, techniques, and validation. 2000, The Morris-Lee Publishing Group, Rosemont, New Jersey, USA. ISBN 0-9645356-7-X

- Karen Thomas, John Laplante, Alan Buckley: Guidebook of part cleaning alternatives : making cleaning greener in Massachusetts. 1997, Toxics Use Reduction Institute, University of Massachusetts, Lowell, Massachusetts, USA

- ASM International: Choosing a cleaning process. 1996, ASM International, Materials Park, Ohio, USA. ISBN 0-87170-572-9

- ASM International: Guide to acid, alkaline, emulsion, and ultrasonic cleaning. 1997, ASM International, Materials Park, Ohio, USA. ISBN 0-87170-577-X

- ASM International: Guide to vapour degreasing and solvent cold cleaning. 1996, ASM International, Materials Park, Ohio, USA. ISBN 0-87170-573-7

- ASM International: Guide to mechanical cleaning systems. 1996, ASM International, Materials Park, Ohio, USA. ISBN 0-87170-574-5

- ASM International: Guide to pickling and descaling, and molten salt bath cleaning. 1996, ASM International, Materials Park, Ohio, USA. ISBN 0-87170-576-1

- Klaus-Peter Müller: Praktische Oberflächentechnik. Edition 2003.XII, vieweg, Braunschweig/Wiesbaden, ISBN 978-3-528-36562-2

- Thomas W. Jelinek: Reinigen und Entfetten in der Metallindustrie. 1. Edition 1999, Leuze Verlag, Saulgau, ISBN 3-87480-155-1

- Brigitte Haase: Wie sauber muß eine Oberfläche sein? in: Journal Oberflächentechnik. Nr. 4, 1997

- Brigitte Haase: Reinigen oder Vorbehandeln? Oberflächenzustand und Nitrierergebnis, Bauteilreinigung, Prozesskontrolle und –analytik. Hochschule Bremerhaven

- Bernd Künne: Online Fachbuch für industrielle Reinigung. in: bauteilreinigung.de. Universität Dortmund, Fachgebiet Maschinenelemente

- Reiner Grün: Reinigen und Vorbehandeln - Stand und Perspektiven. in: Galvanotechnik. 90, 1999, Nr. 7, S. 1836-1844

- Günter Kreisel et al.: Ganzheitliche Bilanzierung/Bewertung von Reinigungs-/Vorbehandlungstechnologien in der Oberflächenbehandlung. 1998, Jena, Institut für Technische Chemie der FSU

Professional journals

- Controlled Environments, USA (formerly A2C2??)

- JOT, Journal Oberflächentechnik, vieweg Verlag, Germany

- mo, metalloberfläche, I.G.T. Informationsgesellschaft Technik mbH, Germany

- Galvanotechnik, Eugen G. Leuze Verlag, Germany

- MM, Maschinenmarkt, Vogel Industrie Medien GmbH & Co.KG, Germany

Fora

In the following fora you can direct your questions to an expert and you can search the questions/answers archives:- Products Finishing online (USA)

- National Metal Finishing Resource Center - Ask the expert (USA)

- PIUS Info Expert Forum (Germany)

Research

- TURI, Toxic Use Reduction Institute of the Lowell University in Massachusetts, USA

- RTI, Research Triangle Institute, Raleigh, N.C., USA

- IWT, Stiftung Institut für Werkstofftechnik, Germany

- AWT, Arbeitsgemeinschaft Wärmebehandlung und Werkstofftechnik e. V., Germany

- Fraunhofer Allianz Reinigungstechnik, Germany

- Conference proceedings, published by PIUS, Germany, partly available in English

Work groups

- AWT Fachausschuss 14, Germany

- Fachausschuss Reinigen der Metall Berufsgenossenschaften, Germany

Federations

- Fachverband Industrielle Teilereinigung e.V., FiT e.V., fit-online.de, Germany

- Industrieverband Hygiene und Oberflächenschutz für industrielle und institutionelle Anwendung e.V., IHO, iho.de, Germany

External links

- Cleantool, best practice database

- Marine tank cleaning information

- Bauteilreinigung, selection system for component cleaning

- Toxic Use Reduction Institute, lab test results database

- CatSub: case studies of substitutions of hazardous chemicals with non- or less hazardous ones

- AWT, work group on cleaning, Germany

- parts2clean German cleaning trade fair