Hot bulb engine

Encyclopedia

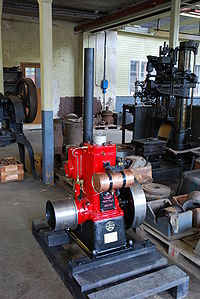

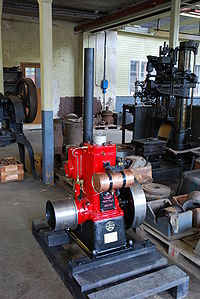

The hot bulb engine, or hotbulb or heavy oil engine is a type of internal combustion engine

. It is an engine in which fuel

is ignited

by being brought into contact with a red-hot metal surface inside a bulb.

Most hot bulb engines were produced as one-cylinder low-speed two-stroke crankcase

scavenging

units.

at the end of the 19th century. The first prototypes were built in 1886 and production started in 1891 by Richard Hornsby & Sons

of Grantham, Lincolnshire, England under the title Hornsby Akroyd Patent Oil Engine under licence. It was later developed in the USA by the German emigrants Mietz and Weiss by combining it with the two-stroke

engine developed by Joseph Day

. Similar engines, for agricultural and marine use, were built by Bolinder

and Pythagoras engine factory in Sweden. Bolinder is now part of the Volvo

group.

Akroyd-Stuart's heavy oil engine (compared to spark-ignition

Akroyd-Stuart's heavy oil engine (compared to spark-ignition

) is distinctly different from Rudolf Diesel's

better-known engine where ignition is initiated through the heat of compression. An oil engine will have a compression ratio

of about 3:1, where a typical Diesel engine

will have a compression ratio ranging between 15:1 and 20:1. Furthermore fuel is injected

during the intake stroke and not at the end of the compression stroke as in a diesel.

s, in that it has a piston

, inside a cylinder

, connected to a flywheel

via a connecting rod and crankshaft

. Akroyd-Stuart's original engine operated on the four-stroke cycle (Induction, Compression, Power, Exhaust) and Hornsby

continued to build engines to this design, as did several other British manufacturers such as Blackstone

and Crossley

. Manufacturers in Europe

, Scandinavia

and in the USA built engines working on the two-stroke cycle with crankcase scavenging. The latter type formed the majority of hot-bulb engine production. The flow of gases through the engine is controlled by valves in four-stroke engines, and by the piston covering and uncovering ports in the cylinder wall in two-strokes.

In the hot-bulb engine combustion takes place in a separated combustion chamber, the "vaporizer" (also called the "hot bulb"), usually mounted on the cylinder head, into which fuel is sprayed. It is connected to the cylinder by a narrow passage and is heated by the combustion while running; an external flame such as a blow-lamp

In the hot-bulb engine combustion takes place in a separated combustion chamber, the "vaporizer" (also called the "hot bulb"), usually mounted on the cylinder head, into which fuel is sprayed. It is connected to the cylinder by a narrow passage and is heated by the combustion while running; an external flame such as a blow-lamp

or slow-burning wick is used for starting (on later models sometimes electric heating or pyrotechnics was used). Another method is the inclusion of a spark plug and vibrator coil ignition. The engine could be started on petrol and switched over to oil after it had warmed to running temperature.

The pre-heating time depends on the engine design, the type of heating used and the ambient temperature, but generally ranges from 2–5 minutes (for most engines in a temperate climate) to as much as half an hour (if operating in extreme cold or the engine is especially large). The engine is then turned over, usually by hand but sometimes by compressed air or an electric motor.

Once the engine is running, the heat of compression and ignition maintains the hot-bulb at the necessary temperature and the blow-lamp or other heat source can be removed. From this point the engine requires no external heat and requires only a supply of air, fuel oil and lubricating oil to run. However, under low power the bulb could cool off too much, and a throttle can cut down the cold fresh air supply. Also, as the engine's load increased, so does the temperature of the bulb, causing the ignition period to advance; to counteract pre-ignition, water is dripped into the air intake. Equally, if the load on the engine is low, combustion temperatures may not be sufficient to maintain the temperature of the hot-bulb. Many hot-bulb engines cannot be run off-load without auxiliary heating for this reason.

The fact that the engine can be left unattended for long periods while running made hot bulb engines a popular choice for applications requiring a steady power output such as farm tractors, generator

s, pump

s and canal

boat propulsion.

A supply of lubricating oil must be fed to the crankcase to supply the crankshaft

bearings

. Since the crankcase is also used to supply air to the engine, the engine's lubricating oil is carried into the cylinder with the air charge, burnt during combustion and carried out of the exhaust. The oil carried from the crankcase to the cylinder is used to lubricate the piston

. This means that a two-stroke hot-bulb engine will gradually burn its supply of lubricating oil – a design known as a 'total loss' lubricating system. There were also designs that employed a scavenge pump or similar to remove oil from the crankcase and return it to the lubricating oil reservoir. Lanz hot-bulb tractors and their many imitators had this feature. This reduces oil consumption considerably.

In addition, if excess crankcase oil is present on start up, there is a danger of the engine starting and accelerating uncontrollably to well past the RPM limits of the rotating and reciprocating components. This can result in destruction of the engine. There is normally a bung or stopcock that allows draining of the crankcase before starting.

The lack of valves and the doubled-up working cycle also means that a two-stroke hot bulb engine can run equally well in both directions. A common starting technique for smaller two-stroke engines is to turn the engine over against the normal direction of rotation. The piston will 'bounce' off the compression phase with sufficient force to spin the engine the correct way and start it. This bi-directional running was an advantage in marine applications as the engine could, like the steam engine

, drive a vessel forward or backwards without the need for a gearbox. The direction could be reversed either by stopping the engine and starting it again in the other direction or, with sufficient skill and timing on the part of the operator, slowing the engine until it carried just enough momentum to bounce against its own compression and run the other way. This was an undesirable quality in hot-bulb powered tractors equipped with gearboxes. At very low engine speeds the engine could reverse itself almost without any change in sound or running quality and without the driver noticing until the tractor drove in the opposite direction to that intended. Lanz Bulldog

tractors featured a dial, mechanically driven by the engine, that showed a spinning arrow. The arrow pointed in the direction of normal engine rotation – if the dial spun the other way the engine had reversed itself.

, which was then the dominant source of power in industry. Condenserless steam engines achieved an average thermal efficiency (the percent of heat generated that is actually turned into useful work) of around 6%.

Hot-bulb engines could easily achieve 12% thermal efficiency.

During the 1910s–1950s, hot-bulb engines were more economical to manufacture with their low pressure crude fuel injection and lower compression ratio than diesel engines.

The hot-bulb engine is much simpler to construct and operate than the steam engine. Boilers require at least one person to add water and fuel as needed and monitor pressure to prevent overpressure and a resulting explosion. If fitted with automatic lubrication systems and a governor

to control engine speed, a hot-bulb engine could be left running, unattended for hours at a time.

Another attraction was their safety. A steam engine, with its exposed fire and hot boiler, steam pipes and working cylinder could not be used in flammable conditions such as munitions factories or fuel refineries. Hot-bulb engines also produced cleaner exhaust fumes. A big danger with the steam engine was that if the boiler pressure grew too high and the safety valve failed, a highly dangerous explosion could occur (although this was a relatively rare occurrence by the time the hot-bulb engine was invented). A more common problem was that if the water level in the boiler of a steam engine dropped too low the lead plug in the crown of the furnace would melt, extinguishing the fire. If a hot bulb engine ran out of fuel, it would simply stop and could be immediately restarted with more fuel. The cooling water was usually a closed circuit, so no water loss would occur unless there was a leak. If the cooling water ran low, the engine would seize through overheating – a major problem, but it carried no danger of explosion.

Compared with steam, gasoline (petrol), and diesel engines, hot-bulb engines are simpler and therefore have fewer potential problems. There is no electrical system as found on a petrol engine, and no external boiler and steam system as on a steam engine.

A big attraction with the hot-bulb engine was its ability to run on a wide range of fuels. Even poor-burning fuels could be used since a combination of vaporiser- and compression-ignition meant that such fuels could be made to combust. The usual fuel used was fuel oil, similar to modern-day diesel, but natural gas

, kerosene

, paraffin

, crude oil, vegetable oil or creosote

could also be used. This made the hot-bulb engine very cheap to run, since it could be run on cheaply available fuels. Some operators even ran engines on used engine oil, thus providing almost free power. Recently, this multi-fuel ability has led to an interest in using hot bulb engines in developing nations where they can be run on locally produced biofuel.http://energy.saving.nu/biofuels/biofueldev.shtml

Due to the lengthy pre-heating time, hot-bulb engines were nearly always guaranteed to start quickly, even in extremely cold conditions. This made them popular choices in cold regions such as Canada

and Scandinavia

, where steam engines were not viable and early gasoline and diesel engine

s could not be relied on to operate.

The reliability of the hot-bulb engine, their ability to run on many fuels and the fact that they can be left running for hours or days at a time made them extremely popular with agricultural, forestry and marine users, where they were used for pumping and for powering milling, sawing and threshing machinery. Hot-bulb engines were also used on road roller

The reliability of the hot-bulb engine, their ability to run on many fuels and the fact that they can be left running for hours or days at a time made them extremely popular with agricultural, forestry and marine users, where they were used for pumping and for powering milling, sawing and threshing machinery. Hot-bulb engines were also used on road roller

s and tractor

s.

J.V. Svensons Motorfabrik, i Augustendal in Stockholm

Sweden

used hot bulb engines in their Typ 1 motor plough, produced from 1912 to 1925. Munktells Mekaniska Verkstads AB, in Eskilstuna

, Sweden

, produced agricultural tractors with hot bulb engines from 1913 onwards.

Heinrich Lanz Mannheim AG, in Mannheim

, Germany

, started to use hot bulb engines in 1921, in the Lanz Bulldog

HL. Other well known tractor manufacturers that used bulb engines were Bubba, Gambino, Landini

and Orsi

in Italy

, HSCS in Hungary

, SFV in France

Ursus

in Poland

, and Marshall

in England

.

At the start of the 20th century there were several hundreds of Europe

At the start of the 20th century there were several hundreds of Europe

an manufacturers of hot bulb engines for marine use. In Sweden alone there were over 70 manufacturers, of which Bolinder

is the best known (in the 1920s they had about 80% of the world market). The Norwegian

SABB was a very popular hot bulb engine for small fishing boats and many of them are still in working order. In America Standard, Weber, Reid, Stickney, Oil City, and Fairbanks Morse built hotbulb engines.

A limitation of the design of the engine was that it could only run over quite a narrow (and slow) speed band, typically 50-300 R.P.M.. This made the hot-bulb engine difficult to adapt to automotive uses other than vehicles such as tractors, where speed was not a major requirement. This limitation was of little consequence for stationary applications, where the hot-bulb engine was very popular.

A limitation of the design of the engine was that it could only run over quite a narrow (and slow) speed band, typically 50-300 R.P.M.. This made the hot-bulb engine difficult to adapt to automotive uses other than vehicles such as tractors, where speed was not a major requirement. This limitation was of little consequence for stationary applications, where the hot-bulb engine was very popular.

Owing to the lengthy pre-heating time, hot-bulb engines only found favour with users who needed to run engines for long periods of time, where the pre-heating process only represented a small percentage of the overall running period. This included marine use (especially in fishing boats) and pumping/drainage duties.

The hot-bulb engine was invented at the same time that dynamo

s and electric light

systems were perfected, and electricity generation was one of the hot-bulb engines main uses. The engine could achieve higher R.P.M. than a standard reciprocating steam engine (although high-speed steam engines were developed during the 1890s), and its low fuel and maintenance requirements (including the ability to be operated and maintained by only one person) made it ideal for small-scale power supply. Generator sets driven by hot-bulb engines were installed in numerous large houses (especially in rural areas) in Europe

, as well as in factories, theatres, lighthouse

s, radio stations and many other locations where a centralised electricity grid was not available. Usually the dynamo

or alternator

would be driven off the engine's flywheel by a flat belt, to allow the necessary 'gearing up'- making the generator turn at a faster speed than the engine. Companies such as Armstrong Whitworth

and Boulton Paul manufactured and supplied complete generating sets (both the engine and generator) from the 1900s to the late 1920s, when the formation of national grid systems throughout the world and the replacement of the hot-bulb engine by the diesel engine

caused a drop in demand.

The engines were also used in areas where the fire of a steam engine would be an unacceptable fire risk. Akroyd-Stuart developed the world's first oil-engined locomotive (the 'Lachesis') for the Royal Arsenal

, Woolwich

, where the use of locomotives had previously been impossible due to the risk. Hot-bulb engines proved very popular for industrial engines in the early 20th century, but lacked the power to be used in anything larger.

to increase the engine's thermal efficiency. However, above ratios of around 8:1 the fuel oil in the vapouriser would ignite before the piston reached the limit of its travel. This pre-detonation caused rough running, power loss and ultimately engine damage (see engine knocking

for more information). Working with engineers at Hornsby's

, Akroyd Stuart developed a system whereby the compression ratio was increased to as much as 18:1 and fuel oil was delivered to the cylinder only when the piston reached top dead centre, thus preventing pre-ignition.

This system was patented in October 1890 and development continued. In 1892 (5 years before Rudolf Diesel's

first prototype), engineers at Hornsby's built an experimental engine. The vapouriser was replaced with a standard cylinder head

and used a high-pressure fuel nozzle system. The engine could be started from cold and ran for 6 hours, making it the world's first internal combustion engine to run on purely compression ignition. However, to build a fully practical fuel injection system required using machining

techniques and building to tolerances that were not possible to mass produce

at the time. Hornsby's was also working at full capacity building and selling hot-bulb engines, so these developments were not pursued.

was improved dramatically, with more power being available at greater efficiencies than the hot-bulb engine could manage (Diesel engines can achieve over 50% efficiency if designed with maximum economy in mind). Diesel engines offered greater power for a given engine size due to the more efficient combustion method (they had no hot-bulb, relying purely on compression-ignition) and greater ease of use as they required no pre-heating.

The hot-bulb engine was limited in its scope in terms of speed and overall power-to-size ratio. To make a hot-bulb engine capable of powering a ship or locomotive, it would have been prohibitively large and heavy. The hot-bulb engines used in Landini

tractors were as much as 20 litres in capacity for relatively low power outputs. To create even combustion throughout the multiple hot-bulbs in multi-cylinder engines is difficult. The hot-bulb engine's low compression ratio in comparison to diesel engines limited its efficiency, power output and speed. Most hot-bulb engines could run at a maximum speed of around 100 rpm, while by the 1930s diesel engines capable of 2,000 rpm were being built. Also, due to the design of hot bulb and the limitations of current technology in regards to the injector system, most hot-bulb engines were single-speed engines, running at a fixed speed, or in a very narrow speed range. Diesel engines can be designed to operate over a much wider speed range, making them more versatile. This made these medium-sized diesels a very popular choice for use in generator sets, replacing the hot-bulb engine as the engine of choice for small-scale power generation.

The development of small-capacity, high-speed diesel engines in the 1930s and 1940s, led to hot-bulb engines falling dramatically out of favour. The last large-scale manufacturer of hot-bulb engines stopped producing them in the 1950s and they are now virtually extinct in commercial use, except in very remote areas of the developing world. An exception to this is marine use; hot-bulb engines were widely fitted to inland barge

s and narrowboat

s in Europe. The United Kingdom's first two self-powered "motor" narrowboats—Cadbury's Bournville

I and Bournville II in 1911—were powered by 15 horsepower Bolinder single-cylinder hot-bulb engines, and this type became common between the 1920s and the 1950s. With hot-bulb engines being generally long-lived and ideally suited to such a use, it is not uncommon to find vessels still fitted with their original hot-bulb engines today.

Although many people believe that model glow engines

are a variation of the hot-bulb engine, this is not the case. Model glow engines are catalytic ignition engines. They take advantage of a reaction between platinum in the glow plug coil and methyl alcohol vapour whereby at certain temperatures and pressures platinum will glow in contact with the vapour.

There is also a crucial difference in the timing of the fuel injection process:

There is another, detailed difference in the method of fuel injection:

During this period technology had not advanced to the point that oil engines could run faster than 150 rpm. The structure of these engines were basically the same as steam engines and without pressured lubrication.

In hot-bulb engines, fuel is injected at low pressure, using a more economical and more reliable, and simpler configuration. However, by not using compressed air injection it is less efficient.

In this period diesel and hot bulb engines were four stroke. In 1902 F. Rundlof invented the two-stroke crankcase scavenged engine that went on to become the prevalent hot bulb type engine.

s to be used for starting. With technology developed by Robert Bosch GmbH

pump and injector systems could be built to run at a much higher pressure. Combined with high precision injectors, high speed diesels were produced from 1927.

The hot bulbs started to develop cracks and breakups and were gradually replaced by water cooled cylinder heads with a flat hot spot. Over time the compression ratios were increased from 3:1 to 14:1. Fuel injection started from 135 degrees before top dead center with low compression down to 20 degrees before top dead center with later higher compression engines increasing the hot air factor for ignition and increasing the fuel efficiency. Glowplugs finally replaced the preheating with a blowtorch methods and engine speeds were increased, resulting in what is now classified as an indirect injection diesel.

Hot bulb or prechambered engines were always easier to produce, more reliable and could handle smaller amounts of fuel in smaller engines than the direct injected "pure" diesels could.

Hot bulb engines were built by a large number of manufacturers, usually in modest series.These engines were slow running (300-400 RPM) and mostly with cast iron parts including pistons. The fuel pump was usually made with a brass housing and steel plunger operating with a variable stroke length. This resulted in a simple, rugged heavy engine. Therefore they could be machined in an average machine shop without special tools.

Hot bulb engines were built by a large number of manufacturers, usually in modest series.These engines were slow running (300-400 RPM) and mostly with cast iron parts including pistons. The fuel pump was usually made with a brass housing and steel plunger operating with a variable stroke length. This resulted in a simple, rugged heavy engine. Therefore they could be machined in an average machine shop without special tools.

The Pythagoras Engine Factory in Norrtälje in Sweden is kept as a museum (the Pythagoras Mechanical Workshop Museum

), and has a functioning production line and extensive factory archives.

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

. It is an engine in which fuel

Fuel

Fuel is any material that stores energy that can later be extracted to perform mechanical work in a controlled manner. Most fuels used by humans undergo combustion, a redox reaction in which a combustible substance releases energy after it ignites and reacts with the oxygen in the air...

is ignited

Combustion

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

by being brought into contact with a red-hot metal surface inside a bulb.

Most hot bulb engines were produced as one-cylinder low-speed two-stroke crankcase

Crankcase

In an internal combustion engine of the reciprocating type, the crankcase is the housing for the crankshaft. The enclosure forms the largest cavity in the engine and is located below the cylinder, which in a multicylinder engine are usually integrated into one or several cylinder blocks...

scavenging

Scavenging (automotive)

In automotive usage, scavenging is the process of pushing exhausted gas-charge out of the cylinder and drawing in a fresh draught of air ready for the next cycle....

units.

History

The concept of this engine was established by Herbert Akroyd StuartHerbert Akroyd Stuart

Herbert Akroyd-Stuart was an English inventor who is noted for his invention of the hot bulb engine, or heavy oil engine.-Life:...

at the end of the 19th century. The first prototypes were built in 1886 and production started in 1891 by Richard Hornsby & Sons

Richard Hornsby & Sons

Richard Hornsby & Sons was an engine and machinery manufacturer in Lincolnshire, England from 1828 until 1918. The company was a pioneer in the manufacture of the oil engine developed by Herbert Akroyd Stuart and marketed under the Hornsby-Akroyd name. The company developed an early track system...

of Grantham, Lincolnshire, England under the title Hornsby Akroyd Patent Oil Engine under licence. It was later developed in the USA by the German emigrants Mietz and Weiss by combining it with the two-stroke

Two-stroke cycle

A two-stroke engine is an internal combustion engine that completes the process cycle in one revolution of the crankshaft...

engine developed by Joseph Day

Joseph Day

Joseph Day trained as an engineer at the School of Practical Engineering at Crystal Palace in London, began work at Stothert & Pitt in Bath, and in 1889 designed the two-stroke engine as it is widely-known today , the Valve-less Two-Stroke Engine...

. Similar engines, for agricultural and marine use, were built by Bolinder

Bolinder-Munktell

AB Bolinder-Munktell was a tractor and machines manufacturer founded in Eskilstuna, Sweden in 1932 through the merger of the mechanical companies Bolinder and Munktell...

and Pythagoras engine factory in Sweden. Bolinder is now part of the Volvo

Volvo

AB Volvo is a Swedish builder of commercial vehicles, including trucks, buses and construction equipment. Volvo also supplies marine and industrial drive systems, aerospace components and financial services...

group.

Spark-ignition

The term spark-ignition engine refers to internal combustion engines, usually petrol engines, where the combustion process of the air-fuel mixture is ignited by a spark from a spark plug...

) is distinctly different from Rudolf Diesel's

Rudolf Diesel

Rudolf Christian Karl Diesel was a German inventor and mechanical engineer, famous for the invention of the diesel engine.-Early life:Diesel was born in Paris, France in 1858 the second of three children of Theodor and Elise Diesel. His parents were Bavarian immigrants living in Paris. Theodor...

better-known engine where ignition is initiated through the heat of compression. An oil engine will have a compression ratio

Compression ratio

The 'compression ratio' of an internal-combustion engine or external combustion engine is a value that represents the ratio of the volume of its combustion chamber from its largest capacity to its smallest capacity...

of about 3:1, where a typical Diesel engine

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

will have a compression ratio ranging between 15:1 and 20:1. Furthermore fuel is injected

during the intake stroke and not at the end of the compression stroke as in a diesel.

Operation and working cycle

The hot-bulb engine shares its basic layout with nearly all other internal combustion engineInternal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

s, in that it has a piston

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

, inside a cylinder

Cylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

, connected to a flywheel

Flywheel

A flywheel is a rotating mechanical device that is used to store rotational energy. Flywheels have a significant moment of inertia, and thus resist changes in rotational speed. The amount of energy stored in a flywheel is proportional to the square of its rotational speed...

via a connecting rod and crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. Akroyd-Stuart's original engine operated on the four-stroke cycle (Induction, Compression, Power, Exhaust) and Hornsby

Richard Hornsby & Sons

Richard Hornsby & Sons was an engine and machinery manufacturer in Lincolnshire, England from 1828 until 1918. The company was a pioneer in the manufacture of the oil engine developed by Herbert Akroyd Stuart and marketed under the Hornsby-Akroyd name. The company developed an early track system...

continued to build engines to this design, as did several other British manufacturers such as Blackstone

Blackstone

-Businesses:*Blackstone Group, U.S. private equity and asset management firm*Blackstone Career Institute, online training institute*Blackstone & Co, a farm implement and engine manufacturer in Stamford, Lincolnshire until absorbed by Lister in 1937-People:...

and Crossley

Crossley

Crossley, based in Manchester, United Kingdom, was a pioneering company in the production of internal combustion engines. Since 1988 it has been part of the Rolls-Royce Power Engineering group.More than 100,000 Crossley oil and gas engines have been built....

. Manufacturers in Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

, Scandinavia

Scandinavia

Scandinavia is a cultural, historical and ethno-linguistic region in northern Europe that includes the three kingdoms of Denmark, Norway and Sweden, characterized by their common ethno-cultural heritage and language. Modern Norway and Sweden proper are situated on the Scandinavian Peninsula,...

and in the USA built engines working on the two-stroke cycle with crankcase scavenging. The latter type formed the majority of hot-bulb engine production. The flow of gases through the engine is controlled by valves in four-stroke engines, and by the piston covering and uncovering ports in the cylinder wall in two-strokes.

Blow torch

A blowtorch , blow torch , or blowlamp is a tool for applying lower-intensity and more diffuse flame and heat for various applications, than the oxyacetylene torch. Before aerosol cans and pressurized gas cylinders, fuel was pressurized by a syringe or pump...

or slow-burning wick is used for starting (on later models sometimes electric heating or pyrotechnics was used). Another method is the inclusion of a spark plug and vibrator coil ignition. The engine could be started on petrol and switched over to oil after it had warmed to running temperature.

The pre-heating time depends on the engine design, the type of heating used and the ambient temperature, but generally ranges from 2–5 minutes (for most engines in a temperate climate) to as much as half an hour (if operating in extreme cold or the engine is especially large). The engine is then turned over, usually by hand but sometimes by compressed air or an electric motor.

Once the engine is running, the heat of compression and ignition maintains the hot-bulb at the necessary temperature and the blow-lamp or other heat source can be removed. From this point the engine requires no external heat and requires only a supply of air, fuel oil and lubricating oil to run. However, under low power the bulb could cool off too much, and a throttle can cut down the cold fresh air supply. Also, as the engine's load increased, so does the temperature of the bulb, causing the ignition period to advance; to counteract pre-ignition, water is dripped into the air intake. Equally, if the load on the engine is low, combustion temperatures may not be sufficient to maintain the temperature of the hot-bulb. Many hot-bulb engines cannot be run off-load without auxiliary heating for this reason.

The fact that the engine can be left unattended for long periods while running made hot bulb engines a popular choice for applications requiring a steady power output such as farm tractors, generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

s, pump

Pump

A pump is a device used to move fluids, such as liquids, gases or slurries.A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps...

s and canal

Canal

Canals are man-made channels for water. There are two types of canal:#Waterways: navigable transportation canals used for carrying ships and boats shipping goods and conveying people, further subdivided into two kinds:...

boat propulsion.

Four-stroke engines

Air is drawn into the cylinder through the intake valve as the piston descends (the induction stroke). During the same stroke, fuel is sprayed into the vaporizer by a mechanical (jerk-type) fuel pump through a nozzle. The air in the cylinder is then forced through the top of the cylinder as the piston rises (the compression stroke), through the opening into the vaporizer, where it is compressed and its temperature rises. The vaporized fuel mixes with the compressed air and ignites primarily due to the heat of the hot bulb generated while running, or heat applied to the hot-bulb prior to starting. By contracting the bulb to a very narrow neck where it attaches to the cylinder, a high degree of turbulence is set up as the ignited gases flash through the neck into the cylinder, where combustion is completed. The resulting pressure drives the piston down (the power stroke). The piston's action is converted to a rotary motion by the crankshaft-flywheel assembly, to which equipment can be attached for work to be performed. The flywheel stores momentum, some of which is used to turn the engine when power is not being produced. The piston rises, expelling exhaust gases through the exhaust valve (the exhaust stroke). The cycle then starts again.Two-stroke engines

The cycle starts with the piston at the bottom of its stroke. As it rises, it draws air into the crankcase through the Inlet Port. At the same time fuel is sprayed into the vapouriser. The charge of air on top of the piston is compressed into the vapouriser where it is mixed with the atomised fuel and ignites. The piston is driven down the cylinder. As it descends the piston first uncovers the Exhaust Port. The pressurised exhaust gases flow out of the cylinder. A fraction after the Exhaust Port is uncovered, the descending piston uncovers the Transfer Port. The piston is now pressurising the air in the crankcase, which is forced through the Transfer Port and into the space above the piston. Part of the incoming air charge is lost out of the still-open Exhaust Port to ensure all the exhaust gases are cleared from the cylinder (a process known as 'scavenging'). The piston then reaches the bottom of its stroke and begins to rise again, drawing a fresh charge of air into the crankcase and completing the cycle. Induction and Compression are carried out on the upward stroke and Power and Exhaust on the downward stroke.A supply of lubricating oil must be fed to the crankcase to supply the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

bearings

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

. Since the crankcase is also used to supply air to the engine, the engine's lubricating oil is carried into the cylinder with the air charge, burnt during combustion and carried out of the exhaust. The oil carried from the crankcase to the cylinder is used to lubricate the piston

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

. This means that a two-stroke hot-bulb engine will gradually burn its supply of lubricating oil – a design known as a 'total loss' lubricating system. There were also designs that employed a scavenge pump or similar to remove oil from the crankcase and return it to the lubricating oil reservoir. Lanz hot-bulb tractors and their many imitators had this feature. This reduces oil consumption considerably.

In addition, if excess crankcase oil is present on start up, there is a danger of the engine starting and accelerating uncontrollably to well past the RPM limits of the rotating and reciprocating components. This can result in destruction of the engine. There is normally a bung or stopcock that allows draining of the crankcase before starting.

The lack of valves and the doubled-up working cycle also means that a two-stroke hot bulb engine can run equally well in both directions. A common starting technique for smaller two-stroke engines is to turn the engine over against the normal direction of rotation. The piston will 'bounce' off the compression phase with sufficient force to spin the engine the correct way and start it. This bi-directional running was an advantage in marine applications as the engine could, like the steam engine

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

, drive a vessel forward or backwards without the need for a gearbox. The direction could be reversed either by stopping the engine and starting it again in the other direction or, with sufficient skill and timing on the part of the operator, slowing the engine until it carried just enough momentum to bounce against its own compression and run the other way. This was an undesirable quality in hot-bulb powered tractors equipped with gearboxes. At very low engine speeds the engine could reverse itself almost without any change in sound or running quality and without the driver noticing until the tractor drove in the opposite direction to that intended. Lanz Bulldog

Lanz Bulldog

The Lanz Bulldog was a tractor manufactured by Heinrich Lanz AG in Mannheim, Baden-Württemberg, Germany. Production started in 1921 and various versions of the Bulldog were produced up to 1960. John Deere purchased Lanz in 1956 and started using the name "John Deere-Lanz" for the Lanz product line....

tractors featured a dial, mechanically driven by the engine, that showed a spinning arrow. The arrow pointed in the direction of normal engine rotation – if the dial spun the other way the engine had reversed itself.

Advantages

At the time the hot-bulb engine was invented, its great attractions were its economy, simplicity, and ease of operation in comparison to the steam engineSteam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

, which was then the dominant source of power in industry. Condenserless steam engines achieved an average thermal efficiency (the percent of heat generated that is actually turned into useful work) of around 6%.

Hot-bulb engines could easily achieve 12% thermal efficiency.

During the 1910s–1950s, hot-bulb engines were more economical to manufacture with their low pressure crude fuel injection and lower compression ratio than diesel engines.

The hot-bulb engine is much simpler to construct and operate than the steam engine. Boilers require at least one person to add water and fuel as needed and monitor pressure to prevent overpressure and a resulting explosion. If fitted with automatic lubrication systems and a governor

Governor (device)

A governor, or speed limiter, is a device used to measure and regulate the speed of a machine, such as an engine. A classic example is the centrifugal governor, also known as the Watt or fly-ball governor, which uses a rotating assembly of weights mounted on arms to determine how fast the engine...

to control engine speed, a hot-bulb engine could be left running, unattended for hours at a time.

Another attraction was their safety. A steam engine, with its exposed fire and hot boiler, steam pipes and working cylinder could not be used in flammable conditions such as munitions factories or fuel refineries. Hot-bulb engines also produced cleaner exhaust fumes. A big danger with the steam engine was that if the boiler pressure grew too high and the safety valve failed, a highly dangerous explosion could occur (although this was a relatively rare occurrence by the time the hot-bulb engine was invented). A more common problem was that if the water level in the boiler of a steam engine dropped too low the lead plug in the crown of the furnace would melt, extinguishing the fire. If a hot bulb engine ran out of fuel, it would simply stop and could be immediately restarted with more fuel. The cooling water was usually a closed circuit, so no water loss would occur unless there was a leak. If the cooling water ran low, the engine would seize through overheating – a major problem, but it carried no danger of explosion.

Compared with steam, gasoline (petrol), and diesel engines, hot-bulb engines are simpler and therefore have fewer potential problems. There is no electrical system as found on a petrol engine, and no external boiler and steam system as on a steam engine.

A big attraction with the hot-bulb engine was its ability to run on a wide range of fuels. Even poor-burning fuels could be used since a combination of vaporiser- and compression-ignition meant that such fuels could be made to combust. The usual fuel used was fuel oil, similar to modern-day diesel, but natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

, kerosene

Kerosene

Kerosene, sometimes spelled kerosine in scientific and industrial usage, also known as paraffin or paraffin oil in the United Kingdom, Hong Kong, Ireland and South Africa, is a combustible hydrocarbon liquid. The name is derived from Greek keros...

, paraffin

Paraffin

In chemistry, paraffin is a term that can be used synonymously with "alkane", indicating hydrocarbons with the general formula CnH2n+2. Paraffin wax refers to a mixture of alkanes that falls within the 20 ≤ n ≤ 40 range; they are found in the solid state at room temperature and begin to enter the...

, crude oil, vegetable oil or creosote

Creosote

Creosote is the portion of chemical products obtained by the distillation of a tar that remains heavier than water, notably useful for its anti-septic and preservative properties...

could also be used. This made the hot-bulb engine very cheap to run, since it could be run on cheaply available fuels. Some operators even ran engines on used engine oil, thus providing almost free power. Recently, this multi-fuel ability has led to an interest in using hot bulb engines in developing nations where they can be run on locally produced biofuel.http://energy.saving.nu/biofuels/biofueldev.shtml

Due to the lengthy pre-heating time, hot-bulb engines were nearly always guaranteed to start quickly, even in extremely cold conditions. This made them popular choices in cold regions such as Canada

Canada

Canada is a North American country consisting of ten provinces and three territories. Located in the northern part of the continent, it extends from the Atlantic Ocean in the east to the Pacific Ocean in the west, and northward into the Arctic Ocean...

and Scandinavia

Scandinavia

Scandinavia is a cultural, historical and ethno-linguistic region in northern Europe that includes the three kingdoms of Denmark, Norway and Sweden, characterized by their common ethno-cultural heritage and language. Modern Norway and Sweden proper are situated on the Scandinavian Peninsula,...

, where steam engines were not viable and early gasoline and diesel engine

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

s could not be relied on to operate.

Uses

Road roller

A road roller is a compactor type engineering vehicle used to compact soil, gravel, concrete, or asphalt in the construction of roads and foundations, similar rollers are used also at landfills or in agriculture.In some parts of the world, road rollers are still known colloquially as steam...

s and tractor

Tractor

A tractor is a vehicle specifically designed to deliver a high tractive effort at slow speeds, for the purposes of hauling a trailer or machinery used in agriculture or construction...

s.

J.V. Svensons Motorfabrik, i Augustendal in Stockholm

Stockholm

Stockholm is the capital and the largest city of Sweden and constitutes the most populated urban area in Scandinavia. Stockholm is the most populous city in Sweden, with a population of 851,155 in the municipality , 1.37 million in the urban area , and around 2.1 million in the metropolitan area...

Sweden

Sweden

Sweden , officially the Kingdom of Sweden , is a Nordic country on the Scandinavian Peninsula in Northern Europe. Sweden borders with Norway and Finland and is connected to Denmark by a bridge-tunnel across the Öresund....

used hot bulb engines in their Typ 1 motor plough, produced from 1912 to 1925. Munktells Mekaniska Verkstads AB, in Eskilstuna

Eskilstuna

Eskilstuna is a city and the seat of Eskilstuna Municipality, Södermanland County, Sweden with 60,185 inhabitants in 2005. Eskilstuna has a large Sweden Finn population....

, Sweden

Sweden

Sweden , officially the Kingdom of Sweden , is a Nordic country on the Scandinavian Peninsula in Northern Europe. Sweden borders with Norway and Finland and is connected to Denmark by a bridge-tunnel across the Öresund....

, produced agricultural tractors with hot bulb engines from 1913 onwards.

Heinrich Lanz Mannheim AG, in Mannheim

Mannheim

Mannheim is a city in southwestern Germany. With about 315,000 inhabitants, Mannheim is the second-largest city in the Bundesland of Baden-Württemberg, following the capital city of Stuttgart....

, Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

, started to use hot bulb engines in 1921, in the Lanz Bulldog

Lanz Bulldog

The Lanz Bulldog was a tractor manufactured by Heinrich Lanz AG in Mannheim, Baden-Württemberg, Germany. Production started in 1921 and various versions of the Bulldog were produced up to 1960. John Deere purchased Lanz in 1956 and started using the name "John Deere-Lanz" for the Lanz product line....

HL. Other well known tractor manufacturers that used bulb engines were Bubba, Gambino, Landini

Landini (tractor)

Landini SpA, headquartered in Fabbrico, Italy, was founded by Giovanni Landini in 1884 to produce agricultural equipment. Landini had just started making tractors in 1925 when Giovanni died preventing the completion of the first prototype tractor...

and Orsi

Orsi

Orsi is a surname, and may refer to:* Adolfo Orsi - Italian industrialist* Clodomil Orsi - Brazilian football executive* Fernando Orsi - Italian football manager and former player...

in Italy

Italy

Italy , officially the Italian Republic languages]] under the European Charter for Regional or Minority Languages. In each of these, Italy's official name is as follows:;;;;;;;;), is a unitary parliamentary republic in South-Central Europe. To the north it borders France, Switzerland, Austria and...

, HSCS in Hungary

Hungary

Hungary , officially the Republic of Hungary , is a landlocked country in Central Europe. It is situated in the Carpathian Basin and is bordered by Slovakia to the north, Ukraine and Romania to the east, Serbia and Croatia to the south, Slovenia to the southwest and Austria to the west. The...

, SFV in France

France

The French Republic , The French Republic , The French Republic , (commonly known as France , is a unitary semi-presidential republic in Western Europe with several overseas territories and islands located on other continents and in the Indian, Pacific, and Atlantic oceans. Metropolitan France...

Ursus

Ursus Tractor Factory

The Ursus Factory is a Polish producer of agricultural machinery located in Warsaw.- Early History :The Ursus Factory was founded in Poland in 1893 on 15 Siennej Street, Warsaw, by three engineers and four businessmen...

in Poland

Poland

Poland , officially the Republic of Poland , is a country in Central Europe bordered by Germany to the west; the Czech Republic and Slovakia to the south; Ukraine, Belarus and Lithuania to the east; and the Baltic Sea and Kaliningrad Oblast, a Russian exclave, to the north...

, and Marshall

Field Marshall

The Field-Marshalls were a range of British farm tractors manufactured by Marshall, Sons & Co. of Gainsborough, Lincolnshire.Field-Marshalls were in production from 1945 to 1957. However, the first single-cylinder Marshall came into production in 1930....

in England

England

England is a country that is part of the United Kingdom. It shares land borders with Scotland to the north and Wales to the west; the Irish Sea is to the north west, the Celtic Sea to the south west, with the North Sea to the east and the English Channel to the south separating it from continental...

.

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

an manufacturers of hot bulb engines for marine use. In Sweden alone there were over 70 manufacturers, of which Bolinder

Bolinder-Munktell

AB Bolinder-Munktell was a tractor and machines manufacturer founded in Eskilstuna, Sweden in 1932 through the merger of the mechanical companies Bolinder and Munktell...

is the best known (in the 1920s they had about 80% of the world market). The Norwegian

Norway

Norway , officially the Kingdom of Norway, is a Nordic unitary constitutional monarchy whose territory comprises the western portion of the Scandinavian Peninsula, Jan Mayen, and the Arctic archipelago of Svalbard and Bouvet Island. Norway has a total area of and a population of about 4.9 million...

SABB was a very popular hot bulb engine for small fishing boats and many of them are still in working order. In America Standard, Weber, Reid, Stickney, Oil City, and Fairbanks Morse built hotbulb engines.

Owing to the lengthy pre-heating time, hot-bulb engines only found favour with users who needed to run engines for long periods of time, where the pre-heating process only represented a small percentage of the overall running period. This included marine use (especially in fishing boats) and pumping/drainage duties.

The hot-bulb engine was invented at the same time that dynamo

Dynamo

- Engineering :* Dynamo, a magnetic device originally used as an electric generator* Dynamo theory, a theory relating to magnetic fields of celestial bodies* Solar dynamo, the physical process that generates the Sun's magnetic field- Software :...

s and electric light

Electric light

Electric lights are a convenient and economic form of artificial lighting which provide increased comfort, safety and efficiency. Most electric lighting is powered by centrally-generated electric power, but lighting may also be powered by mobile or standby electric generators or battery systems...

systems were perfected, and electricity generation was one of the hot-bulb engines main uses. The engine could achieve higher R.P.M. than a standard reciprocating steam engine (although high-speed steam engines were developed during the 1890s), and its low fuel and maintenance requirements (including the ability to be operated and maintained by only one person) made it ideal for small-scale power supply. Generator sets driven by hot-bulb engines were installed in numerous large houses (especially in rural areas) in Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

, as well as in factories, theatres, lighthouse

Lighthouse

A lighthouse is a tower, building, or other type of structure designed to emit light from a system of lamps and lenses or, in older times, from a fire, and used as an aid to navigation for maritime pilots at sea or on inland waterways....

s, radio stations and many other locations where a centralised electricity grid was not available. Usually the dynamo

Dynamo

- Engineering :* Dynamo, a magnetic device originally used as an electric generator* Dynamo theory, a theory relating to magnetic fields of celestial bodies* Solar dynamo, the physical process that generates the Sun's magnetic field- Software :...

or alternator

Alternator

An alternator is an electromechanical device that converts mechanical energy to electrical energy in the form of alternating current.Most alternators use a rotating magnetic field but linear alternators are occasionally used...

would be driven off the engine's flywheel by a flat belt, to allow the necessary 'gearing up'- making the generator turn at a faster speed than the engine. Companies such as Armstrong Whitworth

Armstrong Whitworth

Sir W G Armstrong Whitworth & Co Ltd was a major British manufacturing company of the early years of the 20th century. Headquartered in Elswick, Newcastle upon Tyne, Armstrong Whitworth engaged in the construction of armaments, ships, locomotives, automobiles, and aircraft.-History:In 1847,...

and Boulton Paul manufactured and supplied complete generating sets (both the engine and generator) from the 1900s to the late 1920s, when the formation of national grid systems throughout the world and the replacement of the hot-bulb engine by the diesel engine

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

caused a drop in demand.

The engines were also used in areas where the fire of a steam engine would be an unacceptable fire risk. Akroyd-Stuart developed the world's first oil-engined locomotive (the 'Lachesis') for the Royal Arsenal

Royal Arsenal

The Royal Arsenal, Woolwich, originally known as the Woolwich Warren, carried out armaments manufacture, ammunition proofing and explosives research for the British armed forces. It was sited on the south bank of the River Thames in Woolwich in south-east London, England.-Early history:The Warren...

, Woolwich

Woolwich

Woolwich is a district in south London, England, located in the London Borough of Greenwich. The area is identified in the London Plan as one of 35 major centres in Greater London.Woolwich formed part of Kent until 1889 when the County of London was created...

, where the use of locomotives had previously been impossible due to the risk. Hot-bulb engines proved very popular for industrial engines in the early 20th century, but lacked the power to be used in anything larger.

Compression ignition

Herbert Akroyd Stuart was always keen to improve the efficiency of his engine. The obvious way to do this was to raise the compression ratioCompression ratio

The 'compression ratio' of an internal-combustion engine or external combustion engine is a value that represents the ratio of the volume of its combustion chamber from its largest capacity to its smallest capacity...

to increase the engine's thermal efficiency. However, above ratios of around 8:1 the fuel oil in the vapouriser would ignite before the piston reached the limit of its travel. This pre-detonation caused rough running, power loss and ultimately engine damage (see engine knocking

Engine knocking

Knocking in spark-ignition internal combustion engines occurs when combustion of the air/fuel mixture in the cylinder starts off correctly in response to ignition by the spark plug, but one or more pockets of air/fuel mixture explode outside the envelope of the normal combustion front.The...

for more information). Working with engineers at Hornsby's

Richard Hornsby & Sons

Richard Hornsby & Sons was an engine and machinery manufacturer in Lincolnshire, England from 1828 until 1918. The company was a pioneer in the manufacture of the oil engine developed by Herbert Akroyd Stuart and marketed under the Hornsby-Akroyd name. The company developed an early track system...

, Akroyd Stuart developed a system whereby the compression ratio was increased to as much as 18:1 and fuel oil was delivered to the cylinder only when the piston reached top dead centre, thus preventing pre-ignition.

This system was patented in October 1890 and development continued. In 1892 (5 years before Rudolf Diesel's

Rudolf Diesel

Rudolf Christian Karl Diesel was a German inventor and mechanical engineer, famous for the invention of the diesel engine.-Early life:Diesel was born in Paris, France in 1858 the second of three children of Theodor and Elise Diesel. His parents were Bavarian immigrants living in Paris. Theodor...

first prototype), engineers at Hornsby's built an experimental engine. The vapouriser was replaced with a standard cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

and used a high-pressure fuel nozzle system. The engine could be started from cold and ran for 6 hours, making it the world's first internal combustion engine to run on purely compression ignition. However, to build a fully practical fuel injection system required using machining

Machining

Conventional machining is a form of subtractive manufacturing, in which a collection of material-working processes utilizing power-driven machine tools, such as saws, lathes, milling machines, and drill presses, are used with a sharp cutting tool to physical remove material to achieve a desired...

techniques and building to tolerances that were not possible to mass produce

Mass production

Mass production is the production of large amounts of standardized products, including and especially on assembly lines...

at the time. Hornsby's was also working at full capacity building and selling hot-bulb engines, so these developments were not pursued.

Replacement

From around 1910, the diesel engineDiesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

was improved dramatically, with more power being available at greater efficiencies than the hot-bulb engine could manage (Diesel engines can achieve over 50% efficiency if designed with maximum economy in mind). Diesel engines offered greater power for a given engine size due to the more efficient combustion method (they had no hot-bulb, relying purely on compression-ignition) and greater ease of use as they required no pre-heating.

The hot-bulb engine was limited in its scope in terms of speed and overall power-to-size ratio. To make a hot-bulb engine capable of powering a ship or locomotive, it would have been prohibitively large and heavy. The hot-bulb engines used in Landini

Landini (tractor)

Landini SpA, headquartered in Fabbrico, Italy, was founded by Giovanni Landini in 1884 to produce agricultural equipment. Landini had just started making tractors in 1925 when Giovanni died preventing the completion of the first prototype tractor...

tractors were as much as 20 litres in capacity for relatively low power outputs. To create even combustion throughout the multiple hot-bulbs in multi-cylinder engines is difficult. The hot-bulb engine's low compression ratio in comparison to diesel engines limited its efficiency, power output and speed. Most hot-bulb engines could run at a maximum speed of around 100 rpm, while by the 1930s diesel engines capable of 2,000 rpm were being built. Also, due to the design of hot bulb and the limitations of current technology in regards to the injector system, most hot-bulb engines were single-speed engines, running at a fixed speed, or in a very narrow speed range. Diesel engines can be designed to operate over a much wider speed range, making them more versatile. This made these medium-sized diesels a very popular choice for use in generator sets, replacing the hot-bulb engine as the engine of choice for small-scale power generation.

The development of small-capacity, high-speed diesel engines in the 1930s and 1940s, led to hot-bulb engines falling dramatically out of favour. The last large-scale manufacturer of hot-bulb engines stopped producing them in the 1950s and they are now virtually extinct in commercial use, except in very remote areas of the developing world. An exception to this is marine use; hot-bulb engines were widely fitted to inland barge

Barge

A barge is a flat-bottomed boat, built mainly for river and canal transport of heavy goods. Some barges are not self-propelled and need to be towed by tugboats or pushed by towboats...

s and narrowboat

Narrowboat

A narrowboat or narrow boat is a boat of a distinctive design, made to fit the narrow canals of Great Britain.In the context of British Inland Waterways, "narrow boat" refers to the original working boats built in the 18th, 19th, and 20th centuries for carrying goods on the narrow canals...

s in Europe. The United Kingdom's first two self-powered "motor" narrowboats—Cadbury's Bournville

Bournville

Bournville is a model village on the south side of Birmingham, England, best known for its connections with the Cadbury family and chocolate – including a dark chocolate bar branded "Bournville". It is also a ward within the council constituency of Selly Oak and home to the Bournville Centre...

I and Bournville II in 1911—were powered by 15 horsepower Bolinder single-cylinder hot-bulb engines, and this type became common between the 1920s and the 1950s. With hot-bulb engines being generally long-lived and ideally suited to such a use, it is not uncommon to find vessels still fitted with their original hot-bulb engines today.

Although many people believe that model glow engines

Glow plug (model engine)

A glow plug is a device, similar to a spark plug, used to help ignite the fuel in the very small internal combustion engines typically used in model aircraft, model cars and similar applications...

are a variation of the hot-bulb engine, this is not the case. Model glow engines are catalytic ignition engines. They take advantage of a reaction between platinum in the glow plug coil and methyl alcohol vapour whereby at certain temperatures and pressures platinum will glow in contact with the vapour.

1890s–1910

The hot-bulb engine is often confused with the diesel engine , and it is true that the two engines are very similar. A hot-bulb engine features a prominent hot-bulb vaporiser; a Diesel engine does not. Other significant differences are:- The hot-bulb engine mostly reuses the heat retained in the vaporiser to ignite the fuel with, achieving about 12% efficiency.

- The Diesel engine uses only compression to ignite the fuel. It operates at pressures many times higher than the hot-bulb engine, resulting in over 50% efficiency with large diesels.

- The hot bulb engine required preheating of the hot bulb with a torch for about 15 minutes before starting.

There is also a crucial difference in the timing of the fuel injection process:

- In the hot-bulb engine, before 1910 fuel was injected earlier into the vapouriser (during the intake stroke). This caused the start of combustion to be out of synchronization with the crank angle, meaning that the engine would only run smoothly at one low-speed or load. If the engine's load increased, so would the temperature of the bulb, causing the ignition period to advance, causing pre-ignition. To counteract pre-ignition, water would be dripped into the air intake, providing some flexibility.

- In the diesel engine, fuel is injected into the cylinder, with an adjusted timing relative to the engine speed and load, shortly before the top dead center of the Compression Stroke is reached.

There is another, detailed difference in the method of fuel injection:

- The hot-bulb engine uses a medium-pressure pump to deliver fuel to the cylinder, through a simple nozzle.

- In the original Diesel engine, fuel was sprayed into the cylinder by high pressure compressed air, through an injector. The camshaft lifted a spring-loaded pin to initiate fuel delivery though the nozzle.

During this period technology had not advanced to the point that oil engines could run faster than 150 rpm. The structure of these engines were basically the same as steam engines and without pressured lubrication.

In hot-bulb engines, fuel is injected at low pressure, using a more economical and more reliable, and simpler configuration. However, by not using compressed air injection it is less efficient.

In this period diesel and hot bulb engines were four stroke. In 1902 F. Rundlof invented the two-stroke crankcase scavenged engine that went on to become the prevalent hot bulb type engine.

1910–1950s

Direct injected small diesel engines still were not practical and the prechambered indirect injected engine was invented, along with the requirement of glowplugGlowplug

A glowplug is a heating device used to aid starting diesel engines.-Purpose:Diesel engines, unlike petrol engines, do not use spark plugs to induce combustion...

s to be used for starting. With technology developed by Robert Bosch GmbH

Robert Bosch GmbH

Robert Bosch GmbH is a multinational engineering and electronics company headquartered in Gerlingen, near Stuttgart, Germany. It is the world's largest supplier of automotive components...

pump and injector systems could be built to run at a much higher pressure. Combined with high precision injectors, high speed diesels were produced from 1927.

The hot bulbs started to develop cracks and breakups and were gradually replaced by water cooled cylinder heads with a flat hot spot. Over time the compression ratios were increased from 3:1 to 14:1. Fuel injection started from 135 degrees before top dead center with low compression down to 20 degrees before top dead center with later higher compression engines increasing the hot air factor for ignition and increasing the fuel efficiency. Glowplugs finally replaced the preheating with a blowtorch methods and engine speeds were increased, resulting in what is now classified as an indirect injection diesel.

Hot bulb or prechambered engines were always easier to produce, more reliable and could handle smaller amounts of fuel in smaller engines than the direct injected "pure" diesels could.

Production

The Pythagoras Engine Factory in Norrtälje in Sweden is kept as a museum (the Pythagoras Mechanical Workshop Museum

Pythagoras Mechanical Workshop Museum

Pythagoras Mechanical Workshop Museum is located in the premises of the earlier engine factory Pythagoras at the town of Norrtälje in the province of Uppland in Sweden. At the museum, production facilities and working conditions from the first half of the 20th century are on display...

), and has a functioning production line and extensive factory archives.

See also

- Diesel engineDiesel engineA diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

- GlowplugGlowplugA glowplug is a heating device used to aid starting diesel engines.-Purpose:Diesel engines, unlike petrol engines, do not use spark plugs to induce combustion...

(Diesel starting assist) - Glow plug (model engine)Glow plug (model engine)A glow plug is a device, similar to a spark plug, used to help ignite the fuel in the very small internal combustion engines typically used in model aircraft, model cars and similar applications...

- Hesselman engineHesselman engineThe Hesselman engine is a hybrid between a petrol engine and a Diesel engine introduced by Swedish engineer Jonas Hesselman in 1925. It represented the first use of direct gasoline injection on a spark-ignition engine...

- History of the internal combustion engineHistory of the internal combustion engineAlthough various forms of internal combustion engines were developed before the 19th century, their use was hindered until the commercial drilling and production of petroleum began in the mid-1850s...

- Fairbanks Morse

- Fuel injectionFuel injectionFuel injection is a system for admitting fuel into an internal combustion engine. It has become the primary fuel delivery system used in automotive petrol engines, having almost completely replaced carburetors in the late 1980s....

- Gasoline direct injectionGasoline direct injectionIn internal combustion engines, gasoline direct injection , also known as petrol direct injection or direct petrol injection, is a variant of fuel injection employed in modern two-stroke and four-stroke gasoline engines...

- Indirect injectionIndirect injectionIn an internal combustion engine, the term indirect injection refers to a fuel injection where fuel is not directly injected into the combustion chamber...

- Internal combustion engineInternal combustion engineThe internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

- Lanz BulldogLanz BulldogThe Lanz Bulldog was a tractor manufactured by Heinrich Lanz AG in Mannheim, Baden-Württemberg, Germany. Production started in 1921 and various versions of the Bulldog were produced up to 1960. John Deere purchased Lanz in 1956 and started using the name "John Deere-Lanz" for the Lanz product line....

- Prosper L'OrangeProsper L'OrangeProsper L'Orange was a German engineer and inventor who pioneered the precombustion chamber , which made possible high-speed diesel engines that did not require an air compressor, and enabled them to be built small enough for use in road vehicles.-Career:L'Orange moved to Germany and studied...

Patents

- US Patent 845140 Combustion Engine, dated February 26, 1907.

- US Patent 502837 Engine operated by the explosion of mixtures of gas or hydrocarbon vapor and air, dated August 8, 1893.

- US Patent 439702 Petroleum Engine or Motor, dated November 4, 1890.

External links

- The Stationary Engine Club of Sweden

- A video on the history of the Diesel Engine, which also contains a demonstration and illustration of the hot-bulb engine's working cycle

- An article from Gas Engine Magazine on Mietz & Wiess hot-bulb engines

- Norwegian made semidiesel engines, the last semidiesel Sabb ended in 1969