History of the steam engine

Encyclopedia

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

being the aeolipile

Aeolipile

An aeolipile , also known as a Hero engine, is a rocket style jet engine which spins when heated. In the 1st century AD, Hero of Alexandria described the device, and many sources give him the credit for its invention.The aeolipile Hero described is considered to be the first recorded steam engine...

described by Hero of Alexandria

Hero of Alexandria

Hero of Alexandria was an ancient Greek mathematician and engineerEnc. Britannica 2007, "Heron of Alexandria" who was active in his native city of Alexandria, Roman Egypt...

. Over a millennium after Hero's (or "Heron's") experiments, a number of steam-powered devices were experimented with or proposed, but it was not until 1712 that a commercially successful steam engine

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

was finally developed, Thomas Newcomen's

Thomas Newcomen

Thomas Newcomen was an ironmonger by trade and a Baptist lay preacher by calling. He was born in Dartmouth, Devon, England, near a part of the country noted for its tin mines. Flooding was a major problem, limiting the depth at which the mineral could be mined...

atmospheric engine. During the industrial revolution, steam engines became the dominant source of power and remained so into the early decades of the 20th century, when advances in the design of the electric motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

and the internal combustion engine

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

resulted in the rapid replacement of the steam engine by these technologies. However, the steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

, an alternative form of steam engine, has become the most common method by which electrical power generators are driven. Investigations are being made into the practicalities of reviving the reciprocating steam engine as the basis for a new wave of 'advanced steam technology

Advanced steam technology

Advanced steam technology reflects an approach to the technical development of the steam engine intended for a wider variety of applications than has recently been the case...

' .

Early uses of steam power

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

, the aeolipile

Aeolipile

An aeolipile , also known as a Hero engine, is a rocket style jet engine which spins when heated. In the 1st century AD, Hero of Alexandria described the device, and many sources give him the credit for its invention.The aeolipile Hero described is considered to be the first recorded steam engine...

, is described by a Greek mathematician and engineer named Hero of Alexandria

Hero of Alexandria

Hero of Alexandria was an ancient Greek mathematician and engineerEnc. Britannica 2007, "Heron of Alexandria" who was active in his native city of Alexandria, Roman Egypt...

(Heron) in 1st century Roman Egypt, as recorded in his manuscript Spiritalia seu Pneumatica. Steam ejected tangentially from nozzles caused a pivoted ball to rotate. Its thermal efficiency was low. This suggests that the conversion of steam pressure into mechanical movement was known in Roman Egypt in the 1st century. Hero also devised a machine that used air heated in an altar fire to displace a quantity of water from a closed vessel. The weight of the water was made to pull a hidden rope to operate temple doors. Some historians have conflated the two inventions to assert, incorrectly, that the aeolipile was capable of useful work.

According to William of Malmesbury

William of Malmesbury

William of Malmesbury was the foremost English historian of the 12th century. C. Warren Hollister so ranks him among the most talented generation of writers of history since Bede, "a gifted historical scholar and an omnivorous reader, impressively well versed in the literature of classical,...

, in 1125, Reims

Reims

Reims , a city in the Champagne-Ardenne region of France, lies east-northeast of Paris. Founded by the Gauls, it became a major city during the period of the Roman Empire....

was home to a church that had an organ

Organ (music)

The organ , is a keyboard instrument of one or more divisions, each played with its own keyboard operated either with the hands or with the feet. The organ is a relatively old musical instrument in the Western musical tradition, dating from the time of Ctesibius of Alexandria who is credited with...

powered by air escaping from compression "by heated water", apparently designed and constructed by professor Gerbertus.

Among the papers of Leonardo da Vinci

Leonardo da Vinci

Leonardo di ser Piero da Vinci was an Italian Renaissance polymath: painter, sculptor, architect, musician, scientist, mathematician, engineer, inventor, anatomist, geologist, cartographer, botanist and writer whose genius, perhaps more than that of any other figure, epitomized the Renaissance...

dating to the late 15th century is the design for a steam-powered cannon called the Architonnerre

Architonnerre

The Architonnerre was a steam-powered cannon, a description of which is found in the papers of Leonardo da Vinci dating to the late 15th century, although he attributes its invention to Archimedes in the 3rd century BC....

which works by the sudden influx of hot water into a sealed red hot cannon.

A rudimentary impact steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

was described in 1551 by Taqi al-Din, a philosopher

Islamic philosophy

Islamic philosophy is a branch of Islamic studies. It is the continuous search for Hekma in the light of Islamic view of life, universe, ethics, society, and so on...

, astronomer

Islamic astronomy

Islamic astronomy or Arabic astronomy comprises the astronomical developments made in the Islamic world, particularly during the Islamic Golden Age , and mostly written in the Arabic language. These developments mostly took place in the Middle East, Central Asia, Al-Andalus, and North Africa, and...

and engineer

Inventions in the Islamic world

A number of inventions were developed in the medieval Islamic world, a geopolitical region that has at various times extended from Spain and Africa in the west to the Indian subcontinent in the east. The inventions listed here were developed during the medieval Islamic world, which covers the...

in 16th century Ottoman Egypt

Ottoman Egypt

Ottoman Egypt covers two main periods:* Egypt Eyalet 1517–1867 under direct rule of the Ottoman Empire.* Khedivate of Egypt 1867–1914 as autonomous tributary state of the Ottoman Empire....

, who described a method for rotating a spit

Rotisserie

Rotisserie is a style of roasting where meat is skewered on a spit - a long solid rod used to hold food while it is being cooked over a fire in a fireplace or over a campfire, or roasted in an oven. This method is generally used for cooking large joints of meat or entire animals, such as pigs,...

by means of a jet of steam playing on rotary vanes around the periphery of a wheel. A similar device for rotating a spit was also later described by John Wilkins

John Wilkins

John Wilkins FRS was an English clergyman, natural philosopher and author, as well as a founder of the Invisible College and one of the founders of the Royal Society, and Bishop of Chester from 1668 until his death....

in 1648. These devices were then called "mills" but are now known as steam jacks. Another similar rudimentary steam turbine is shown by Giovanni Branca

Giovanni Branca

Giovanni Branca was an Italian engineer and architect, chiefly remembered today for what some commentators have taken to be an early steam engine.-Life:...

, an Italian

Italy

Italy , officially the Italian Republic languages]] under the European Charter for Regional or Minority Languages. In each of these, Italy's official name is as follows:;;;;;;;;), is a unitary parliamentary republic in South-Central Europe. To the north it borders France, Switzerland, Austria and...

engineer, in 1629 for turning a cylindrical escapement

Escapement

In mechanical watches and clocks, an escapement is a device that transfers energy to the timekeeping element and enables counting the number of oscillations of the timekeeping element...

device that alternately lifted and let fall a pair of pestles working in mortars. The steam flow of these early steam turbines, however, was not concentrated and most of its energy was dissipated in all directions. This would have led to a great waste of energy and so they were never seriously considered for industrial use.

In 1605 French mathematician Florence Rivault

Florence Rivault

Florence Rivault was a French mathematician and royal servant. He was born probably at La Cropte, near Laval, France....

in his treatise on artillery wrote on his discovery that water, if confined in a bombshell and heated, would explode the shells.

In 1606, Jerónimo de Ayanz y Beaumont

Jerónimo de Ayanz y Beaumont

Jerónimo de Ayanz y Beaumont . Spanish soldier, painter, musician and inventor. He is best remembered for the invention of a steam-powered water pump for draining mines, for which he was granted a patent by the Spanish monarchy in 1606.-References:*García Tapia, Nicolás, Un inventor navarro:...

demonstrated and was granted a patent for a steam powered water pump.

In 1663 Edward Somerset, 2nd Marquess of Worcester

Edward Somerset, 2nd Marquess of Worcester

Edward Somerset, 2nd Marquess of Worcester , styled Lord Herbert of Ragland from 1628–1644, was an English nobleman involved in royalist politics and an inventor...

published designs for raising water between floors employing a similar principle to that of a coffee percolator

Coffee percolator

A coffee percolator is a type of pot used to brew coffee. The name stems from the word "percolate" which means to cause to pass through a permeable substance especially for extracting a soluble constituent....

. His system was the first to separate the boiler from the pumping action. Water was admitted into a reinforced barrel from a cistern, and then a valve was opened to admit steam from a separate boiler. The pressure built over the top of the water, driving it up a pipe. He installed his steam-powered device on the wall of the Great Tower at Raglan Castle

Raglan Castle

Raglan Castle is a late medieval castle located just north of the village of Raglan in the county of Monmouthshire in south east Wales. The modern castle dates from between the 15th and early 17th-centuries, when the successive ruling families of the Herberts and the Somersets created a luxurious,...

to supply water through the tower. The grooves in the wall where the engine was installed were still to be seen in the 19th century. However, no one was prepared to risk money for such a revolutionary concept, and without backers the machine remained undeveloped.

Cylinders

Denis Papin

Denis Papin was a French physicist, mathematician and inventor, best known for his pioneering invention of the steam digester, the forerunner of the steam engine and of the pressure cooker.-Life in France:...

collaborated with the Dutch physicist Christiaan Huygens on an engine which drove out the air from a cylinder by exploding gunpowder

Gunpowder

Gunpowder, also known since in the late 19th century as black powder, was the first chemical explosive and the only one known until the mid 1800s. It is a mixture of sulfur, charcoal, and potassium nitrate - with the sulfur and charcoal acting as fuels, while the saltpeter works as an oxidizer...

inside it. Realising the incompleteness of the vacuum produced by this means and on moving to England in 1680, Papin devised a version of the same cylinder that obtained a more complete vacuum from boiling water and then allowing the steam to condense; in this way he was able to raise weights by attaching the end of the piston to a rope passing over a pulley. As a demonstration model the system worked, but in order to repeat the process the whole apparatus had to be dismantled and reassembled. Papin quickly saw that to make an automatic cycle the steam would have to be generated separately in a boiler; however as he did not take the project further all we can say is that he invented the reciprocating steam engine conceptually and thus paved the way to Newcomen's engine. Papin also designed a paddle boat driven by a jet playing on a mill-wheel in a combination of Taqi al Din and Savery's conceptions and he is also credited with a number of significant devices such as the safety valve

Safety valve

A safety valve is a valve mechanism for the automatic release of a substance from a boiler, pressure vessel, or other system when the pressure or temperature exceeds preset limits....

. Papin's years of research into the problems of harnessing steam was to be play a key part in the development of the first successful industrial engines that soon followed his death.

The first industrial engines

The first steam engine to be applied industrially was the "fire-engine" or "Miner's Friend", designed by Thomas SaveryThomas Savery

Thomas Savery was an English inventor, born at Shilstone, a manor house near Modbury, Devon, England.-Career:Savery became a military engineer, rising to the rank of Captain by 1702, and spent his free time performing experiments in mechanics...

in 1698. This was a pistonless steam pump, similar to the one developed by Worcester. Savery made two key contributions that greatly improved the practicality of the design. First, in order to allow the water supply to be placed below the engine, he used condensed steam to produce a partial vacuum in the pumping reservoir (the barrel in Worcester's example), and using that to pull the water upward. Secondly, in order to rapidly cool the steam to produce the vacuum, he ran cold water over the reservoir.

Operation required several valves; when the reservoir was empty at the start of a cycle a valve was opened to admit steam. The valve was closed to seal the reservoir and the cooling water valve turned on to condense the steam and create a partial vacuum. A supply valve was opened, pulling water upward into the reservoir, and the typical engine could pull water up to 20 feet. This was closed and the steam valve reopened, building pressure over the water and pumping it upward, as in the Worcester design. The cycle essentially doubled the distance that water could be pumped for any given pressure of steam, and production examples raised water about 40 feet.

Savery's engine solved a problem that had only recently become a serious one; raising water out of the mines in southern England as they reached greater depths. But the engine was expensive and apparently not very efficient; nor was it very safe because part of its cycle required steam under pressure supplied by a boiler, and given the technology of the period the pressure vessel

Pressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

could not be made strong enough and so was prone to explosion. The explosion of one of his pumps at Broad Waters (near Wednesbury

Wednesbury

Wednesbury is a market town in England's Black Country, part of the Sandwell metropolitan borough in West Midlands, near the source of the River Tame. Similarly to the word Wednesday, it is pronounced .-Pre-Medieval and Medieval times:...

), about 1705, probably marks the end of attempts to exploit his invention.

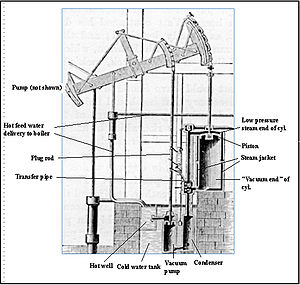

Newcomen "atmospheric" engine

Thomas Newcomen

Thomas Newcomen was an ironmonger by trade and a Baptist lay preacher by calling. He was born in Dartmouth, Devon, England, near a part of the country noted for its tin mines. Flooding was a major problem, limiting the depth at which the mineral could be mined...

with his "atmospheric-engine

Newcomen steam engine

The atmospheric engine invented by Thomas Newcomen in 1712, today referred to as a Newcomen steam engine , was the first practical device to harness the power of steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines,...

" of 1712 who can be said to have brought together most of the essential elements established by Papin in order to develop the first practical steam engine for which there could be a commercial demand. This took the shape of a reciprocating beam engine installed at surface level driving a succession of pumps at one end of the beam. The engine, attached by chains from other end of the beam, worked on the atmospheric, or vacuum principle.

Newcomen's design used some elements of earlier concepts. Like the Savery design, Newcomen's engine used steam, cooled with water, to create a vacuum. Unlike Savery's pump, however, Newcomen used the vacuum to pull on a piston instead of pulling on water directly. The upper end of the cylinder was open to the atmospheric pressure, and when the vacuum formed, the atmospheric pressure above the piston pushes it down into the cylinder. The piston was lubricated by a trickle of water from the same cistern that supplied the cooling water. Further, to improve the cooling effect, he sprayed water directly into the cylinder.

The piston was attached by a chain to a large pivoted beam. When the piston pulled the beam, the other side of the beam was pulled upward. This end was attached to a rod that pulled on a series of conventional pump handles in the mine. At the end of this power stroke, the steam valve was reopened, and the weight of the pump rods pulled the beam down, lifting the piston and drawing steam into the cylinder again.

Using the piston and beam allowed the Newcomen engine to power pumps at different levels throughout the mine, as well as eliminating the need for any high pressure steam. The entire system was isolated to a single building on the surface. Although inefficient and extremely heavy on coal (compared to later engines), these engines raised far greater volumes of water and from greater depths than had previously been possible. Over 100 Newcomen engines were installed around England by 1735, and it is estimated that as many as 2,000 were in operation by 1800 (including Watt versions).

John Smeaton

John Smeaton

John Smeaton, FRS, was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist...

made numerous improvements to the Newcomen engine, notably the seals, and by improving these was able to almost triple their efficiency. He also preferred to use wheels instead of beams for transferring power off of the cylinder, which made his engines more compact. Smeaton was the first to develop a rigorous theory of steam engine design of operation. He worked backward from the intended role to calculate the amount of power

Power (physics)

In physics, power is the rate at which energy is transferred, used, or transformed. For example, the rate at which a light bulb transforms electrical energy into heat and light is measured in watts—the more wattage, the more power, or equivalently the more electrical energy is used per unit...

that would be needed for the task, the size and speed of a cylinder that would provide it, the size of boiler needed to feed it, and the amount of fuel it would consume. These were developed empirically after studying dozens of Newcomen engines in Cornwall and Newcastle, and building an experimental engine of his own at his home in Austhorpe

Austhorpe

Austhorpe is a civil parish in east Leeds, West Yorkshire, England that is situated between Pendas Fields to the north, Whitkirk to the west, Cross Gates to the north-west and Colton to the south-west....

in 1770. By the time the Watt engine was introduced only a few years later, Smeaton had built dozens of ever-larger engines into the 100 hp range.

Watt's separate condenser

University of Glasgow

The University of Glasgow is the fourth-oldest university in the English-speaking world and one of Scotland's four ancient universities. Located in Glasgow, the university was founded in 1451 and is presently one of seventeen British higher education institutions ranked amongst the top 100 of the...

as an instrument maker and repairman in 1759, James Watt

James Watt

James Watt, FRS, FRSE was a Scottish inventor and mechanical engineer whose improvements to the Newcomen steam engine were fundamental to the changes brought by the Industrial Revolution in both his native Great Britain and the rest of the world.While working as an instrument maker at the...

was introduced to the power of steam by Professor John Robison

John Robison (physicist)

John Robison FRSE was a Scottish physicist and mathematician. He was a professor of philosophy at the University of Edinburgh....

. Fascinated, Watt took to reading everything he could on the subject, and independently developed the concept of latent heat

Latent heat

Latent heat is the heat released or absorbed by a chemical substance or a thermodynamic system during a process that occurs without a change in temperature. A typical example is a change of state of matter, meaning a phase transition such as the melting of ice or the boiling of water. The term was...

, only recently published by Joseph Black

Joseph Black

Joseph Black FRSE FRCPE FPSG was a Scottish physician and chemist, known for his discoveries of latent heat, specific heat, and carbon dioxide. He was professor of Medicine at University of Glasgow . James Watt, who was appointed as philosophical instrument maker at the same university...

at the same university. When Watt learned that the University owned a small working model of Newcomen engine, he pressed to have it returned from London

London

London is the capital city of :England and the :United Kingdom, the largest metropolitan area in the United Kingdom, and the largest urban zone in the European Union by most measures. Located on the River Thames, London has been a major settlement for two millennia, its history going back to its...

where it was being unsuccessfully repaired. Watt repaired the machine, but found it was barely functional even when fully repaired.

After working with the design, Watt concluded that 80% of the steam used by the engine was wasted. Instead of providing motive force, it was instead being used to heat the cylinder. In the Newcomen design, every power stroke was started with a spray of cold water, which not only condensed the steam, but also cooled the walls of the cylinder. This heat had to be replaced before the cylinder would accept steam again. In the Newcomen engine the heat was supplied only by the steam, so when the steam valve was opened again the vast majority condensed on the cold walls as soon as it was admitted to the cylinder. It took a considerable amount of time and steam before the cylinder warmed back up and the steam started to fill it up.

Watt solved the problem of the water spray by removing the cold water to a different cylinder, placed beside the power cylinder. Once the power stroke was complete a valve was opened between the two, and any steam that entered the cylinder would condense inside this cold cylinder. This would create a vacuum that would pull more of the steam into the cylinder, and so on until the steam was mostly condensed. The valve was then closed, and operation of the main cylinder continued as it would on a conventional Newcomen engine. As the power cylinder remained at operational temperature throughout, the system was ready for another stroke as soon as the piston was pulled back to the top. Maintaining the temperature was a jacket around the cylinder where steam was admitted. Watt produced a working model in 1765.

Convinced that this was a great advance, Watt entered into partnerships to provide venture capital

Venture capital

Venture capital is financial capital provided to early-stage, high-potential, high risk, growth startup companies. The venture capital fund makes money by owning equity in the companies it invests in, which usually have a novel technology or business model in high technology industries, such as...

while he worked on the design. Not content with this single improvement, Watt worked tirelessly on a series of other improvements to practically every part of the engine. Watt further improved the system by adding a small vacuum pump to pull the steam out of the cylinder into the condenser, further improving cycle times. A more radical change from the Newcomen design was closing off the top of the cylinder and introducing low pressure steam above the piston. Now the power was not due to the difference of atmospheric pressure and the vacuum, but the pressure of the steam and the vacuum, a somewhat higher value. On the upward return stroke, the steam on top was transferred through a pipe to the underside of the piston ready to be condensed for the downward stroke. Sealing of the piston on a Newcomen engine had been achieved by maintaining a small quantity of water on its upper side. This was no longer possible in Watt's engine due to the presence of the steam. Watt spent considerable effort to find a seal that worked, eventually obtained by using a mixture of tallow and oil. The piston rod also passed through a gland

Gland (engineering)

A gland is a general type of stuffing box, used to seal a rotating or reciprocating shaft against a fluid. The most common example is in the head of a tap where the gland is usually packed with string which has been soaked in tallow or similar grease...

on the top cylinder cover sealed in a similar way.

The piston sealing problem was due to having no way to produce a sufficiently round cylinder. Watt tried having cylinders bored from cast iron, but they were too out of round. Watt was forced to use a hammered iron cylinder. The following quotation is from Roe (1916):

"When [John] SmeatonJohn SmeatonJohn Smeaton, FRS, was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist...

saw the first engine he reported to the Society of Engineers that 'neither the tools nor the workmen existed who could manufacture such a complex machine with sufficient precision' "

Watt finally considered the design good enough to release in 1774, and the Watt engine was released to the market. As portions of the design could be easily fitted to existing Newcomen engines, there was no need to build an entirely new engine at the mines. Instead, Watt and Boulton licensed the improvements to engine operators, charging them a portion of the money they would save in reduced fuel costs. The design was wildly successful, and the Boulton and Watt

Boulton and Watt

The firm of Boulton & Watt was initially a partnership between Matthew Boulton and James Watt.-The engine partnership:The partnership was formed in 1775 to exploit Watt's patent for a steam engine with a separate condenser. This made much more efficient use of its fuel than the older Newcomen engine...

company was formed to license the design and help new manufacturers build the engines. The two would later open the Soho Foundry

Soho Foundry

Soho Foundry was a factory created in 1795 by Matthew Boulton and James Watt at Smethwick, West Midlands, England , for the manufacture of steam engines.-History:...

to produce engines of their own.

In 1774 John Wilkinson

John Wilkinson

John Wilkinson may refer to:* John Wilkinson * John Wilkinson , British industrialist who suggested the use of iron for many roles where other materials had previously been used...

invented a boring machine with the shaft holding the boring tool supported on both ends, extending through the cylinder, unlike the then used cantilevered borers. With this machine he was able to successfully bore the 50 inch diameter (1.27 meter) cylinder for Boulton & Watt

Boulton and Watt

The firm of Boulton & Watt was initially a partnership between Matthew Boulton and James Watt.-The engine partnership:The partnership was formed in 1775 to exploit Watt's patent for a steam engine with a separate condenser. This made much more efficient use of its fuel than the older Newcomen engine...

's first commercial engine in 1776.

Watt never ceased improving his designs. This further improved the operating cycle speed, introduced governors, automatic valves, double-acting pistons, a variety of rotary power takeoffs and many other improvements. Watt's technology enabled the widespread commercial use of stationary steam engines.

Humphrey Gainsborough

Humphrey Gainsborough

Humphrey Gainsborough was a non-conformist minister, engineer and inventor.Humphrey Gainsborough was pastor to the Independent Church in Henley-on-Thames, England. He was the brother of the artist Thomas Gainsborough. He invented the drill plough , winning a prize of £60 from the Royal Society for...

produced a model condensing

Condensation

Condensation is the change of the physical state of matter from gaseous phase into liquid phase, and is the reverse of vaporization. When the transition happens from the gaseous phase into the solid phase directly, the change is called deposition....

steam engine in the 1760s, which he showed to Richard Lovell Edgeworth

Richard Lovell Edgeworth

Richard Lovell Edgeworth was an Anglo-Irish politician, writer and inventor.-Biography:Edgeworth was born in Pierrepont Street, Bath, England, grandson of Sir Salathiel Lovell through his daughter, Jane Lovell....

, a member of the Lunar Society

Lunar Society

The Lunar Society of Birmingham was a dinner club and informal learned society of prominent figures in the Midlands Enlightenment, including industrialists, natural philosophers and intellectuals, who met regularly between 1765 and 1813 in Birmingham, England. At first called the Lunar Circle,...

. Gainsborough believed that Watt had used his ideas for the invention; however James Watt was not a member of the Lunar Society at this period and his many accounts explaining the succession of thought processes leading to the final design would tend to belie this story.

Power was still limited by the low pressure, the displacement of the cylinder, combustion and evaporation rates and condenser capacity. Maximum theoretical efficiency was limited by the relatively low temperature differential on either side of the piston; this meant that for a Watt engine to provide a usable amount of power, the first production engines had to be very large, and were thus expensive to build and install.

Watt double-acting and rotative engines

Boulton & Watt developed the reciprocating engine into the rotative type. Unlike the Newcomen engine, the Watt engine could operate smoothly enough to be connected to a drive shaft – via sun and planet gearSun and planet gear

The sun and planet gear was a method of converting reciprocal motion to rotary motion and was utilised in a reciprocating steam engine....

s – to provide rotary power along with double-acting condensing cylinders. The earliest example was built as a demonstrator and was installed in Boulton's factory to work machines for lapping (polishing) buttons or similar. For this reason it was always known as the "Lap engine". In early steam engines the piston is usually connected by a rod to a balanced beam, rather than directly to a flywheel, and these engines are therefore known as beam engine

Beam engine

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall...

s. This was in all essentials the steam engine that we know today.

High-pressure engines

As the 18th century advanced, the call was for higher pressures; this was strongly resisted by Watt who used the monopoly his patent gave him to prevent others from building high-pressure engines and using them in vehicles. He mistrusted the materials' resistance and the boiler technology of the day.The main difference between how high-pressure and low-pressure steam engines work is the source of the force that moves the piston. In Newcomen's and Watt's engines, it is the condensation of the steam that creates most of the pressure difference, causing atmospheric pressure (Newcomen) or low-pressure steam (Watt) to push the piston; the internal pressures never greatly exceed atmospheric pressure. In a high-pressure engine, most of the pressure difference is provided by the high pressure steam from the boiler; the low pressure side of the piston may be at atmospheric pressure or, if it is connected to a condenser, this only provides a small proportion of the pressure difference.

The first known advocate of "strong steam" was Jacob Leupold

Jacob Leupold

Jacob Leupold was a German physicist, scientist, mathematician, instrument maker, mining commissioner and an engineer. He wrote the important and popular book Theatrum Machinarum Generale, which was published in 1727.- Early life :Jacob Leupold was born on July 22, 1674 as a son of a craftsman...

in his scheme for an engine that appeared in encyclopaedic works from around 1725. Various projects for steam propelled boats and vehicles also appeared throughout the century one of the most promising being Nicolas-Joseph Cugnot

Nicolas-Joseph Cugnot

Nicolas-Joseph Cugnot was a French inventor. He is believed to have built the first self-propelled mechanical vehicle...

's who demonstrated his "fardier" (steam wagon), in 1769. Whilst the working pressure used for this vehicle is unknown, the small size of the boiler gave insufficient steam production rate to allow the fardier to advance more than a few hundred metres at a time before having to stop to raise steam. Other projects and models were proposed, but as with William Murdoch

William Murdoch

William Murdoch was a Scottish engineer and long-term inventor.Murdoch was employed by the firm of Boulton and Watt and worked for them in Cornwall, as a steam engine erector for ten years, spending most of the rest of his life in Birmingham, England.He was the inventor of the oscillating steam...

's model of 1784, many were blocked by Boulton and Watt.

This did not apply in the USA, and in 1788 a steamboat built by John Fitch

John Fitch (inventor)

John Fitch was an American inventor, clockmaker, and silversmith who, in 1787, built the first recorded steam-powered boat in the United States...

operated in regular commercial service along the Delaware river

Delaware River

The Delaware River is a major river on the Atlantic coast of the United States.A Dutch expedition led by Henry Hudson in 1609 first mapped the river. The river was christened the South River in the New Netherland colony that followed, in contrast to the North River, as the Hudson River was then...

between Philadelphia PA and Burlington NJ, carrying as many as 30 passengers. This boat could typically make 7 to 8 miles per hour, and traveled more than 2000 miles (3,218.7 km) during its short length of service. The Fitch steamboat was not a commercial success, as this route was adequately covered by relatively good wagon roads. In 1802 William Symington

William Symington

William Symington was a Scottish engineer and inventor, and the builder of the first practical steamboat, the Charlotte Dundas.-Early life:...

built a practical steamboat, and in 1807 Robert Fulton

Robert Fulton

Robert Fulton was an American engineer and inventor who is widely credited with developing the first commercially successful steamboat...

used a Watt steam engine to power the first commercially successful steamboat

Steamboat

A steamboat or steamship, sometimes called a steamer, is a ship in which the primary method of propulsion is steam power, typically driving propellers or paddlewheels...

.

Oliver Evans

Oliver Evans

Oliver Evans was an American inventor. Evans was born in Newport, Delaware to a family of Welsh settlers. At the age of 14 he was apprenticed to a wheelwright....

in his turn was in favour of "strong steam" which he applied to boat engines and to stationary uses. He was a pioneer of cylindrical boilers; however Evans' boilers did suffer several serious boiler explosions, which tended to lend weight to Watt's qualms. He founded the Pittsburgh Steam Engine Company

Pittsburgh Steam Engine Company

The Pittsburgh Steam Engine Company, originally the Pittsburgh Engine Company was a company founded in 1811 by Oliver Evans to manufacture high-pressure steam engines. It opened for business soon after Fulton's low-pressure New Orleans left Pittsburgh on her maiden voyage as the first steamboat...

in 1811 in Pittsburgh, Pennsylvania.

The company introduced high-pressure steam engines to the riverboat trade in the Mississippi watershed

Mississippi River

The Mississippi River is the largest river system in North America. Flowing entirely in the United States, this river rises in western Minnesota and meanders slowly southwards for to the Mississippi River Delta at the Gulf of Mexico. With its many tributaries, the Mississippi's watershed drains...

.

The importance of raising steam under pressure (from a thermodynamic

Thermodynamics

Thermodynamics is a physical science that studies the effects on material bodies, and on radiation in regions of space, of transfer of heat and of work done on or by the bodies or radiation...

standpoint) is that it attains a higher temperature. Thus, any engine using high pressure steam operates at a higher temperature and pressure differential than is possible with a low pressure vacuum engine. The high pressure engine thus became the basis for most further development of reciprocating steam technology. Even so, around the year 1800, "high pressure" amounted to what today would be considered very low pressure, i.e. 40-50 psi (276-345 kPa), the point being that the high pressure engine in question was non-condensing, driven solely by the expansive power of the steam, and once that steam had performed work it was usually exhausted at higher-than-atmospheric pressure. The blast of the exhausting steam into the chimney could be exploited to create induced draught through the fire grate and thus increase the rate of burning, hence creating more heat in a smaller furnace, at the expense of creating back pressure on the exhaust side of the piston. The most important outcome was that engines could be made much smaller than previously for a given power output. There was thus the potential for steam engines to be developed that were small and powerful enough to propel themselves and other objects. As a result, steam power for transportation now became a practicality in the form of ships and land vehicles, which revolutionised cargo businesses, travel, military strategy, and essentially every aspect of society.

On February 21, 1804 at the Penydarren

Penydarren

Penydarren Ironworks was the fourth of the great ironworks established at Merthyr Tydfil in South Wales.Built in 1784 by the brothers Samuel Homfray, Jeremiah Homfray, and Thomas Homfray, all sons of Francis Homfray of Stourbridge. Their father, Francis, for a time managed a nail warehouse there...

ironworks at Merthyr Tydfil

Merthyr Tydfil

Merthyr Tydfil is a town in Wales, with a population of about 30,000. Although once the largest town in Wales, it is now ranked as the 15th largest urban area in Wales. It also gives its name to a county borough, which has a population of around 55,000. It is located in the historic county of...

in South Wales

Wales

Wales is a country that is part of the United Kingdom and the island of Great Britain, bordered by England to its east and the Atlantic Ocean and Irish Sea to its west. It has a population of three million, and a total area of 20,779 km²...

, the first self-propelled railway steam engine or steam locomotive, built by Richard Trevithick, was demonstrated.

The Cornish engine and compounding

Around 1811 Richard TrevithickRichard Trevithick

Richard Trevithick was a British inventor and mining engineer from Cornwall. His most significant success was the high pressure steam engine and he also built the first full-scale working railway steam locomotive...

was required to update a Watt pumping engine in order to adapt it to one of his new large cylindrical Cornish boilers. When Trevithick left for South America in 1816, his improvements were continued by William Sims. In a parallel, Arthur Woolf

Arthur Woolf

Arthur Woolf was a Cornish engineer, most famous for inventing a high-pressure compound steam engine. As such he made an outstanding contribution to the development and perfection of the Cornish engine.Woolf left Cornwall in 1785 to work for Joseph Bramah's engineering works in London...

developed a compound engine with two cylinders, so that steam expanded in a high pressure cylinder before being released into a low pressure one. Efficiency was further improved by Samuel Groase, who insulated the boiler, engine, and pipes.

Steam pressure above the piston was increased eventually reaching 40 psi (0.27579029172 MPa) or even 50 psi (0.34473786465 MPa) and now provided much of the power for the downward stroke; at the same time condensing was improved. This considerably raised efficiency and further pumping engines on the Cornish system (often known as Cornish engine

Cornish engine

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt...

s) continued to be built new throughout the 19th century. Older Watt engines were updated to conform.

The take-up of these Cornish improvements was slow in textile manufacturing areas where coal was cheap, due to the higher capital cost of the engines and the greater wear that they suffered. The change only began in the 1830s, usually by compounding through adding an additional (high pressure) cylinder.

Another limitation of early steam engines was speed variability, which made them unsuitable for many textile applications, especially spinning. In order to obtain steady speeds, early steam powered textile mills used the steam engine to pump water to a water wheel, which drove the machinery.

Many of these engines were supplied worldwide and gave reliable and efficient service over a great many years with greatly reduced coal consumption. Some of them were very large and the type continued to be built right down to the 1890s.

Triple expansion engines allowed ships to carry more freight than coal, greatly increasing international trade in the last quarter of the 19th century.

Corliss engine

The Corliss steam engineCorliss Steam Engine

A Corliss steam engine is a steam engine, fitted with rotary valves and with variable valve timing patented in 1849, invented by and named after the American engineer George Henry Corliss in Providence, Rhode Island....

(patented 1849) was called the greatest improvement since James Watt. The Corliss engine

Corliss Steam Engine

A Corliss steam engine is a steam engine, fitted with rotary valves and with variable valve timing patented in 1849, invented by and named after the American engineer George Henry Corliss in Providence, Rhode Island....

had greatly improved speed control and better efficiency, making it suitable to all sorts of industrial applications, including spinning.

Further reading

- Stuart, Robert, A Descriptive History of the Steam Engine, London: J. Knight and H. Lacey, 1824.