Rawmill

Encyclopedia

Cement

In the most general sense of the word, a cement is a binder, a substance that sets and hardens independently, and can bind other materials together. The word "cement" traces to the Romans, who used the term opus caementicium to describe masonry resembling modern concrete that was made from crushed...

. Rawmix is then fed to a cement kiln

Cement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates...

, which transforms it into clinker

Clinker (cement)

thumb|200px|right|Typical clinker nodulesthumb|200px|right|Hot clinkerIn the manufacture of Portland cement, clinker is lumps or nodules, usually 3-25 mm in diameter, produced by sintering limestone and alumino-silicate during the cement kiln stage.-Uses:...

, which is then ground to make cement in the cement mill

Cement mill

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement...

. The rawmilling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process.

History

The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture used existing technology in the early days. Early hydraulic materials such as hydraulic limeHydraulic lime

Hydraulic lime is a variety of lime, a slaked lime used to make lime mortar. Hydraulicity is the ability of lime to set under water. Hydraulic lime is produced by heating calcining limestone that contains clay and other impurities. Calcium reacts in the kiln with the clay minerals to produce...

s, natural cements

Cement

In the most general sense of the word, a cement is a binder, a substance that sets and hardens independently, and can bind other materials together. The word "cement" traces to the Romans, who used the term opus caementicium to describe masonry resembling modern concrete that was made from crushed...

and Parker's

James Parker (cement maker)

James Parker was a British clergyman and cement manufacturer who invented one of the pioneering new cements of the late eighteenth century.In 1791, he was granted a patent "Method of Burning bricks, Tiles, Chalk"...

Roman cement

Roman cement

For the architectural material actually used by the ancient Romans, see Roman concrete."Roman cement" is a substance developed by James Parker in the 1780s, and finally patented in 1796...

were all based on "natural" raw materials, burned "as-dug". Because these natural blends of minerals occur only rarely, manufacturers were interested in making a fine-grained artificial mixture of readily available minerals such as limestone and clay that could be used in the same way. A typical problem would be to make an intimate mixture of 75% chalk and 25% clay, and burn this to produce an ”artificial cement". The development of the "wet" method of producing fine-grained clay in the ceramics

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

industry afforded a means of doing this. For this reason, the early cement industry used the "wet process", in which the raw materials are ground together with water, to produce a slurry, containing 20–50% water. Both Louis Vicat

Louis Vicat

Louis Vicat French engineer.He graduated from École Polytechnique 1804 and École des Ponts et Chaussées 1806....

and James Frost

James Frost (cement maker)

James Frost was a British cement manufacturer who invented processes that led to the eventual development of Portland cement.- Biography :...

used this technique in the early 19th century, and it remained the only way of making rawmix for Portland cement

Portland cement

Portland cement is the most common type of cement in general use around the world because it is a basic ingredient of concrete, mortar, stucco and most non-specialty grout...

until 1890. A modification of the technique used by the early industry was "double-burning", in which a hard limestone would be burned and slaked before combining with clay slurry. This technique avoided the grinding of hard stone, and was employed by, among others, Joseph Aspdin

Joseph Aspdin

Joseph Aspdin was a British cement manufacturer who obtained the patent for Portland cement on 21 October 1824....

. Early grinding technology was poor, and early slurries were made thin, with a high water content. The slurry was then allowed to stand in large reservoirs ("slurry-backs") for several weeks. Large, un-ground particles would drop to the bottom, and excess water rose to the top. The water was periodically decanted until a stiff cake, of the consistency of pottery clay, was left. This was sliced up, discarding the coarse material at the bottom, and burned in the kiln. Wet grinding is comparatively energy-efficient, and so when good dry-grinding equipment became available, the wet process continued in use throughout the 20th century, often employing equipment that Josiah Wedgewood would have recognized.

Materials ground

Rawmixes are formulated to contain a correctly balanced chemistry for the production of calcium silicates (aliteAlite

Alite is a name for tricalcium silicate, Ca3SiO5, sometimes formulated as 3CaO·SiO2 . It is the major, and characteristic, mineral phase in Portland cement. The name was given by Törneborn in 1897 to a crystal identified in microscopic investigation of Portland cement...

and belite

Belite

Belite is an industrial mineral important in Portland cement manufacture, a name for dicalcium silicate, Ca2SiO4, sometimes formulated as 2 CaO · SiO2 ....

) and fluxes (aluminate

Tricalcium aluminate

Tricalcium aluminate Ca3Al2O6, often formulated as 3CaO·Al2O3 to highlight the proportions of the oxides from which it is made, is the most basic of the calcium aluminates...

and ferrite

Calcium aluminoferrite

Calcium aluminoferrite is a dark brown crystalline phase commonly found in cements. In the cement industry it is termed ferrite...

) in the kiln. Chemical analysis data in cement manufacture are expressed in terms of oxides, and the most important of these in rawmix design are SiO2, Al2O3, Fe2O3 and CaO. In principle, any material that can contribute any of these oxides can be used as a rawmix component. Because the major oxide required is CaO, the most prevalent rawmix component is limestone

Limestone

Limestone is a sedimentary rock composed largely of the minerals calcite and aragonite, which are different crystal forms of calcium carbonate . Many limestones are composed from skeletal fragments of marine organisms such as coral or foraminifera....

, while the others are mostly contributed by clay

Clay

Clay is a general term including many combinations of one or more clay minerals with traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.- Formation :Clay minerals...

or shale

Shale

Shale is a fine-grained, clastic sedimentary rock composed of mud that is a mix of flakes of clay minerals and tiny fragments of other minerals, especially quartz and calcite. The ratio of clay to other minerals is variable. Shale is characterized by breaks along thin laminae or parallel layering...

. Minor adjustments to the chemistry are made by smaller additions of materials such as those shown below.

Typical rawmix component chemical analyses:

| Oxide | Gray Limestone | White Limestone | Marl Marl Marl or marlstone is a calcium carbonate or lime-rich mud or mudstone which contains variable amounts of clays and aragonite. Marl was originally an old term loosely applied to a variety of materials, most of which occur as loose, earthy deposits consisting chiefly of an intimate mixture of clay... |

Clay | Sand | Millscale | Kaolin | Bauxite Bauxite Bauxite is an aluminium ore and is the main source of aluminium. This form of rock consists mostly of the minerals gibbsite Al3, boehmite γ-AlO, and diaspore α-AlO, in a mixture with the two iron oxides goethite and hematite, the clay mineral kaolinite, and small amounts of anatase TiO2... |

Fly ash Fly ash Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal... |

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | 6.6 | 2.1 | 14.1 | 61.6 | 98.0 | 1.3 | 46.1 | 11.1 | 48.1 |

| Al2O3 | 1.5 | 0.3 | 3.3 | 17.5 | 0.9 | 1.2 | 38.5 | 54.4 | 26.5 |

| Fe2O3 | 0.7 | 0.13 | 1.3 | 7.5 | 0.13 | 96.8 | 0.35 | 9.7 | 6.3 |

| CaO | 48.4 | 53.7 | 43.8 | 1.1 | 0.1 | 0.3 | 0.3 | 0.6 | 4.7 |

| MgO | 2.0 | 0.8 | 0.7 | 1.1 | 0.0 | 0.6 | 0.1 | 0.1 | 1.2 |

| Na2O | 0.07 | 0.02 | 0.07 | 0.5 | 0.02 | 0.11 | 0.01 | 0.05 | 0.3 |

| K2O | 0.27 | 0.08 | 0.43 | 1.9 | 0.37 | 0.05 | 0.09 | 0.05 | 1.3 |

| TiO2 | 0.06 | 0.02 | 0.15 | 0.8 | 0.06 | 0.30 | 0.9 | 2.1 | 1.5 |

| Mn2O3 | 0.03 | 0.01 | 0.02 | 0.12 | 0 | 0.63 | 0 | 0.09 | 0.07 |

| LoI950 | 40.0 | 42.7 | 35.8 | 6.8 | 0.3 | 0 | 13.7 | 20.8 | 9.1 |

Note: LoI950 is the Loss on ignition

Loss on ignition

Loss on Ignition is a test used in inorganic analytical chemistry, particularly in the analysis of minerals. It consists of strongly heating a sample of the material at a specified temperature, allowing volatile substances to escape, until its mass ceases to change. This may be done in air, or...

at 950 °C, and represents (approximately) the components lost during kiln processing. It consists mainly of CO2 from carbonates, H2O from clay hydrates, and organic carbon.

Using these materials, typical rawmixes could be composed:

- Mix 1: General-purpose cement: 88.0% gray limestone, 8.9% clay, 2.2% sand and 0.9% millscale.

- Mix 2: Sulfate-resisting cement: 87.6% gray limestone, 5.2% clay, 5.0% sand and 2.2% millscale.

- Mix 3: White cementWhite Portland cementWhite Portland cement or white ordinary Portland cement is similar to ordinary, gray Portland cement in all respects except for its high degree of whiteness...

: 82.3% white limestone, 6.8% kaolin and 10.9% sand.

The chemical analyses of these rawmixes would be:

| Oxide | Mix 1 | Mix 2 | Mix 3 |

|---|---|---|---|

| SiO2 | 13.46 | 13.91 | 15.55 |

| Al2O3 | 2.91 | 2.30 | 2.96 |

| Fe2O3 | 2.16 | 3.14 | 0.14 |

| CaO | 42.69 | 42.47 | 44.23 |

| MgO | 1.86 | 1.82 | 0.67 |

| Na2O | 0.11 | 0.09 | 0.02 |

| K2O | 0.41 | 0.35 | 0.11 |

| TiO2 | 0.13 | 0.10 | 0.09 |

| Mn2O3 | 0.04 | 0.05 | 0.01 |

| LoI950 | 35.8 | 35.4 | 36.1 |

The raw materials and mixes shown are only "typical": considerable variations are possible depending on the raw materials available.

Control of minor elements

Apart from the major oxides (CaO, SiO2, Al2O3 and Fe2O3) the minor oxides are, at best, diluents of the clinker, and may be deleterious. However, cement raw materials are for the most part dug from the Earth's crust and contain most of the elements in the periodic tablePeriodic table

The periodic table of the chemical elements is a tabular display of the 118 known chemical elements organized by selected properties of their atomic structures. Elements are presented by increasing atomic number, the number of protons in an atom's atomic nucleus...

in some amount. The manufacturer therefore selects materials so that the deleterious effects of minor elements are minimized or kept under control. Minor elements that are frequently encountered are as follows:

- FluorineFluorineFluorine is the chemical element with atomic number 9, represented by the symbol F. It is the lightest element of the halogen column of the periodic table and has a single stable isotope, fluorine-19. At standard pressure and temperature, fluorine is a pale yellow gas composed of diatomic...

is beneficial to the kiln process in that it allows alite to form at lower temperature. However, at levels above 0.25% in the clinker, delayed and erratic cement setting time results.

- Alkali metals (primarily sodiumSodiumSodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

and potassiumPotassiumPotassium is the chemical element with the symbol K and atomic number 19. Elemental potassium is a soft silvery-white alkali metal that oxidizes rapidly in air and is very reactive with water, generating sufficient heat to ignite the hydrogen emitted in the reaction.Potassium and sodium are...

) cause processing problems because they form volatile salts in the kiln system. These evaporate in the kiln burning zone and re-condense in the cooler regions of the preheater, causing blockages. Alkalis are also deleterious to concrete, potentially causing alkali silica reactionAlkali Silica ReactionThe alkali–silica reaction is a reaction which occurs over time in concrete between the highly alkaline cement paste and reactive non-crystalline silica, which is found in many common aggregates....

. For this reason, many standards limit alkalis (typically expressed as "total equivalent soda" which is Na2O + 0.658 K2O). Typical specification limits are in the range 0.5–0.8%.

- MgOMagnesiumMagnesium is a chemical element with the symbol Mg, atomic number 12, and common oxidation number +2. It is an alkaline earth metal and the eighth most abundant element in the Earth's crust and ninth in the known universe as a whole...

causes problems at levels over 2.5%. Small amounts are accommodated in solid solution in the clinker minerals, but above 2.5%, "free" MgO exists in the clinker as periclasePericlasePericlase occurs naturally in contact metamorphic rocks and is a major component of most basic refractory bricks. It is a cubic form of magnesium oxide ....

. This can slowly hydrate to Mg(OH)2 with expansion in the hardened concrete, causing cracking. Careful processing of the clinker to keep the periclase in a microcrystalline form allows levels up to 5% to be managed without serious effect. All standards limit MgO, typical limits being in the range 4-6%.

- P2O5PhosphorusPhosphorus is the chemical element that has the symbol P and atomic number 15. A multivalent nonmetal of the nitrogen group, phosphorus as a mineral is almost always present in its maximally oxidized state, as inorganic phosphate rocks...

at levels above 0.5% starts to cause slow setting and low clinker reactivity.

- ChlorineChlorineChlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine...

produces very volatile salts and consequent preheater blockages, and is usually limited to below 0.1% in rawmix.

- TiO2Titanium dioxideTitanium dioxide, also known as titanium oxide or titania, is the naturally occurring oxide of titanium, chemical formula . When used as a pigment, it is called titanium white, Pigment White 6, or CI 77891. Generally it comes in two different forms, rutile and anatase. It has a wide range of...

is ubiquitous, but is rarely present at levels (~1%) that might cause problems.

- ChromiumChromiumChromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

can end up as chromates (Cr[VI]) in cement, particularly when the clinker is high in sulfate. Chromates cause allergic contact dermatitisContact dermatitisContact dermatitis is a term for a skin reaction resulting from exposure to allergens or irritants . Phototoxic dermatitis occurs when the allergen or irritant is activated by sunlight....

in cement users, and for this reason cement Cr[VI] content is limited in many standards to 0.0002%. Typical natural rawmixes contain around 0.01% Cr2O3, and at this level, Cr[VI] formation can be controlled. Chromium present in the cement as Cr[III] is of no consequence.

- Mn2O3ManganeseManganese is a chemical element, designated by the symbol Mn. It has the atomic number 25. It is found as a free element in nature , and in many minerals...

is not deleterious, acting as a substitute for iron. But it contributes more color to the cement than iron, and high-Mn2O3 cements (>1%) are almost black.

- ZnOZincZinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

is encountered in some rawmix additives (as well as tires used as kiln fuel). At levels above 0.2%, it causes slow setting and low clinker reactivity.

- StrontiumStrontiumStrontium is a chemical element with the symbol Sr and the atomic number 38. An alkaline earth metal, strontium is a soft silver-white or yellowish metallic element that is highly reactive chemically. The metal turns yellow when exposed to air. It occurs naturally in the minerals celestine and...

and bariumBariumBarium is a chemical element with the symbol Ba and atomic number 56. It is the fifth element in Group 2, a soft silvery metallic alkaline earth metal. Barium is never found in nature in its pure form due to its reactivity with air. Its oxide is historically known as baryta but it reacts with...

act as calcium replacements, and only start to reduce clinker reactivity at levels of 1.5% and 0.2% respectively.

- Toxic heavy metals: among these, low levels of arsenicArsenicArsenic is a chemical element with the symbol As, atomic number 33 and relative atomic mass 74.92. Arsenic occurs in many minerals, usually in conjunction with sulfur and metals, and also as a pure elemental crystal. It was first documented by Albertus Magnus in 1250.Arsenic is a metalloid...

, seleniumSeleniumSelenium is a chemical element with atomic number 34, chemical symbol Se, and an atomic mass of 78.96. It is a nonmetal, whose properties are intermediate between those of adjacent chalcogen elements sulfur and tellurium...

, cadmiumCadmiumCadmium is a chemical element with the symbol Cd and atomic number 48. This soft, bluish-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Similar to zinc, it prefers oxidation state +2 in most of its compounds and similar to mercury it shows a low...

, antimonyAntimonyAntimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite...

and tungstenTungstenTungsten , also known as wolfram , is a chemical element with the chemical symbol W and atomic number 74.A hard, rare metal under standard conditions when uncombined, tungsten is found naturally on Earth only in chemical compounds. It was identified as a new element in 1781, and first isolated as...

are not a problem, because they are absorbed in the basic clinker structure as anions. On the other hand, mercuryMercury (element)Mercury is a chemical element with the symbol Hg and atomic number 80. It is also known as quicksilver or hydrargyrum...

, thalliumThalliumThallium is a chemical element with the symbol Tl and atomic number 81. This soft gray poor metal resembles tin but discolors when exposed to air. The two chemists William Crookes and Claude-Auguste Lamy discovered thallium independently in 1861 by the newly developed method of flame spectroscopy...

and leadLeadLead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed...

must be carefully controlled because they can be emitted as volatile halides in the kiln exhaust.

Wet rawmills

Wet grinding is more efficient than dry grinding because water coats the newly formed surfaces of broken particles and prevents re-agglomeration. The process of blending and homogenizing the rawmix is also much easier when it is in slurry form. The disadvantage is that the water in the resultant slurry has to be removed subsequently, and this usually requires a lot of energy. While energy was cheap, wet grinding was common, but since 1970 the situation has changed dramatically, and new wet process plant is now rarely installed. Wet grinding is performed by two distinct means: washmills and ballmills.Washmill

This represents the earliest rawmilling technology, and was used to grind soft materials such as chalk and clay. It is rather similar to a food processor. It consists of a large bowl (up to 15 m in diameter) into which the crushed (to less than 250 mm) raw materials are tipped along with a stream of water. The material is stirred by rotating sets of harrowHarrow (tool)

In agriculture, a harrow is an implement for breaking up and smoothing out the surface of the soil. In this way it is distinct in its effect from the plough, which is used for deeper tillage. Harrowing is often carried out on fields to follow the rough finish left by ploughing operations...

s. The outside walls of the bowl consist of gratings or perforated plates through which fine product can pass. Grinding is largely autogenous (i.e. it takes place by collision between lumps of raw material), and is very efficient, producing little waste heat, provided that the materials are soft. Typically two or three washmills are connected in series, these being provided with successively smaller outlet perforations. The entire system can produce slurry with the expenditure of as little as 5 kW·h of electricity per dry tonne. Relatively hard minerals (such as flint) in the mix, are more or less untouched by the grinding process, and settle out in the base of the mill, from where they are periodically dug out.

Ballmills and washdrums

The ballmillBall mill

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics.-Description:...

allows grinding of the harder limestones that are more common than chalk. A ballmill consists of a horizontal cylinder that rotates on its axis. It holds spherical, cylindrical or rod-like grinding media of size 15–100 mm that may be steel or a variety of ceramic materials, and occupy 20–30% of the mill volume. The shell of the mill is lined with steel or rubber plates. Grinding is effected by impact and attrition between the grinding media. The various mineral components of the rawmix are fed to the mill at a constant rate along with water, and the slurry runs from the outlet end. The washdrum has a similar concept, but contains little or no grinding media, grinding being autogenous, by the cascading action of the larger raw material pieces. It is suitable for soft materials, and particularly for flinty chalk, where the unground flint acts as grinding media.

Slurry fineness and moisture content

Bingham plastic

A Bingham plastic is a viscoplastic material that behaves as a rigid body at low stresses but flows as a viscous fluid at high stress. It is named after Eugene C. Bingham who proposed its mathematical form....

s which can also exhibit thixotropic or rheopectic behaviour. The energy needed to pump slurry at a desired rate is controlled mainly by the slurry's yield stress

Yield (engineering)

The yield strength or yield point of a material is defined in engineering and materials science as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed...

, and this in turn varies more or less exponentially with the slurry solids/liquid ratio. In practice, deflocculants are often added in order to maintain pumpability at low moisture contents. Common deflocculants used (at typical dose rates of 0.005–0.03%) are sodium carbonate

Sodium carbonate

Sodium carbonate , Na2CO3 is a sodium salt of carbonic acid. It most commonly occurs as a crystalline heptahydrate, which readily effloresces to form a white powder, the monohydrate. Sodium carbonate is domestically well-known for its everyday use as a water softener. It can be extracted from the...

, sodium silicate

Sodium silicate

Sodium silicate is the common name for a compound sodium metasilicate, Na2SiO3, also known as water glass or liquid glass. It is available in aqueous solution and in solid form and is used in cements, passive fire protection, refractories, textile and lumber processing, and automobiles...

, sodium polyphosphates

Polyphosphate

Triphosphates are salts or esters of polymeric oxyanions formed from tetrahedral PO4 structural units linked together by sharing oxygen atoms. When two corners are shared the polyphosphate may have a linear chain structure or a cyclic ring structure. In biology the polyphosphate esters AMP, ADP...

and lignosulfonates

Lignosulfonates

Lignosulfonates, or sulfonated lignin, are water-soluble anionic polyelectrolyte polymers: they are byproducts from the production of wood pulp using sulfite pulping....

. Under favourable circumstances, pumpable slurries with less than 25% water can be obtained.

Rawmixes frequently contain minerals of contrasting hardness, such as calcite and quartz. Simultaneous grinding of these in a rawmill is inefficient, because the grinding energy is preferentially used in grinding the softer material. This results in a large amount of excessively fine soft material, which "cushions" the grinding of the harder mineral. For this reason, sand is sometimes ground separately, then fed to the main rawmill as a fine slurry.

Dry rawmills

Ball mills

These are similar to cement millCement mill

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement...

s, but often with a larger gas flow. The gas temperature is controlled by cold-air bleeds to ensure a dry product without overheating the mill. The product passes into an air separator, which returns oversized particles to the mill inlet. Occasionally, the mill is preceded by a hot-air-swept hammer mill which does most of the drying and produces millimetre-sized feed for the mill. Ball mills are rather inefficient, and typically require 10–20 kW·h of electric power to make a tonne of rawmix. The Aerofall mill is sometimes used for pre-grinding large wet feeds. It is a short, large-diameter semi-autogenous mill, typically containing 15% by volume of very large (130 mm) grinding balls. Feed can be up to 250 mm, and the larger chunks produce much of the grinding action. The mill is air-swept, and the fines are carried away in the gas stream. Crushing and drying are efficient, but the product is coarse (around 100 µm), and is usually re-ground in a separate ball mill.

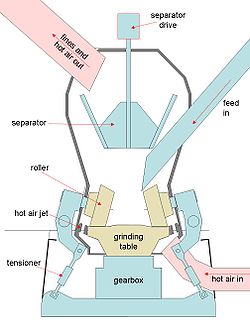

Roller mills

These are the standard form in modern installations, occasionally called vertical spindle mills. In a typical arrangement, the material is fed onto a rotating table, onto which steel rollers press down. A high velocity of hot gas flow is maintained close to the dish so that fine particles are swept away as soon as they are produced. The gas flow carries the fines into an integral air separator, which returns larger particles to the grinding path. The fine material is swept out in the exhaust gas and is captured by a cyclone before being pumped to storage. The remaining dusty gas is usually returned to the main kiln dust control equipment for cleaning. Feed size can be up to 100 mm. Roller mills are efficient, using about half the energy of a ball mill, and there seems to be no limit to the size available. Roller mills with output in excess of 800 tonnes per hour have been installed. Unlike ball mills, feed to the mill must be regular and uninterrupted; otherwise damaging resonant vibration sets in.Hammer mills

Hammer millsHammermill

A hammermill is a machine whose purpose is to shred or crush aggregate material into smaller pieces. These machines have many sorts of applications in many industries, including:*Ethanol plants...

(or "crusher driers") swept with hot kiln exhaust gases have limited application where a soft, wet raw material is being ground. The simple design means that it can be operated at a higher temperature than other mills, giving it high drying capacity. However, the grinding action is poor, and the product is often re-ground in a ball mill.