Gold parting

Encyclopedia

Gold parting is the separating of gold

from silver

. Gold and silver are often extracted from the same ore

s and are chemically similar and therefore hard to separate. Over the centuries special means of separation have been invented. The very earliest precious metals had mixes of gold and silver; gold and silver alloy is called electrum

; gold with small impurities of silver (5% and less) is called bullion. With the advent of coinage, methods had to be invented to remove impurities from the gold so that gold of specific purities could be made. Cupellation

was able to remove gold and silver from mixtures containing lead

and other metals, but silver could not be removed. Gold parting as a process was specifically invented to remove the silver. The main ancient process of gold parting was by salt cementation and there is archaeological evidence of that process from the 6th century BC in Sardis

, Lydia

. In the post-medieval period parting using antimony

, sulphates

and mineral acids was also used. In the modern period chlorination

using the Miller process

, and electrolysis

using the Wohlwill process

are the most widely used methods of refining gold by removing silver and platinum

.

that had a surface of high gold (83%), low silver (9%) and copper

(8%) compared with an interior of 45% gold, 10% silver and 45% copper

. The surface was compacted and heavily burnished and indicates early use of depletion gilding

to enhance the surface.

Separation of gold from silver was not practised in antiquity prior to the Lydian Period

Separation of gold from silver was not practised in antiquity prior to the Lydian Period

(12th century BC to 546BC). Material from Sardis

(in modern Turkey

) is evidence of the earliest use of gold and silver parting in the 6th century. Literary sources and the lack of physical evidence suggest that gold-silver parting was not practised before the mid first millennium BC. Gold parting came with the invention of coinage and there is no evidence for the use of a true refining processes before the introduction of coinage. As refining gold (as opposed to surface enhancement) results in a noticeable loss in material, there would have been little reason to do this before the advent of coinage and the need to have a standard grade of material.

The first possible literary reference to the salt cementation parting process is in the Arthasastra, a 4th century BC treatise from India

, that mentions heating of gold with Indus earth. Indus earth is taken to mean soils high in salt

, nitre and ammonium salts and therefore ideal for the cementation parting process. A better known and more detailed early description is given by Diodorus Siculus

in the 1st century BC quoting an earlier lost book, ‘’On the Erythraean Sea’’ from the 2nd century BC by Agatharchides of Cnidus. An experiment recreating the process as described by Diodorus Siculus by heating a mixture of the gold and salt

in a sealed pot for 5 days was done by Notton and was found to be successful.

Pliny

in this Naturalis Historia

mentions the purification of gold a number of times and makes reference to the salt cementation process of gold parting. He says that the gold is "roasted with a double weight of salt and three times the weight of misy (ferric sulphates) and again with two portions of salt and one of the stone which is called schiston." Here he is describing the heating of gold with salt and iron sulphates which act to dissolve the copper and silver in the gold. Parting vessels used for refining gold with the cementation process have been found in London

, Lincoln

, York

and Winchester

. The London vessels, dating from the Flavian period

(c.70–85AD), were sealed using luting clay

; XRF

analysis detected gold and silver, with highest concentration around the sealed region showing possible escape of silver as the volatile silver chloride.

Gold parting had been well used throughout the ancient times but only in the Medieval period were clear and detailed descriptions of the processes written. All the archaeological finds of Roman and early medieval parting point to a solid state process using common salt as the active ingredient. The only large group of medieval parting vessels so far discovered were found at Coppergate and Picadilly sites in York. The pinkish-purple discolouration of the vessels showed them to have been used with the salt cementation process which removes iron from the clay as ferric chloride. Other vessel fragments are known from Carlisle and Winchester. Theophilus

was a 12th century German monk and in his book ‘’De Diversus Artibus’’ gives the clearest description of the salt cementation process.

This mixture is then added to an earthenware pot and layered with thin sheets of gold fold. The pot is then sealed and heated in a furnace.

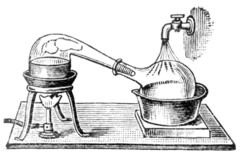

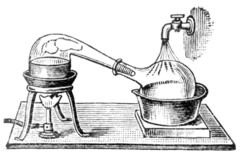

It was during the medieval period that distillation

was discovered and the first description of nitric acid production was given by Geber

in the Summa perfectionis, 1330. Nitric acid

is able to dissolve silver. The addition of sal ammoniac

to nitric acid creates Aqua regia

and this acid is able to dissolve gold. Both acids are used in the acid method of parting but the acids were expensive so were not used until the post medieval period.

Comprehensive accounts of the salt cementation processes is given by; Biringuccio in his The Method of cementing gold and of Bringing it to its Ultimate Fineness.; in the Probierbuchlein – Little Books on Assaying; by Georgius Agricola in book 10 of De Re Metallica

Comprehensive accounts of the salt cementation processes is given by; Biringuccio in his The Method of cementing gold and of Bringing it to its Ultimate Fineness.; in the Probierbuchlein – Little Books on Assaying; by Georgius Agricola in book 10 of De Re Metallica

; and by Ercker in his Treatise on ores and assaying. This was a period where new techniques began to be explored. Granulation of the gold instead of gold foil increased surface area and therefore the efficiency of the reaction. Salt cementation continued to be the main method of parting until the 16th century but in later Middle Ages processes using sulphur, antimony and mineral acids began to be used. There are archaeological finds at sites in London of distillation vessels for making acids in Britain from the 15th century which include fragments of ceramic cucurbits (vessels for heating reacting chemicals) which were used with alembics for distillation. By the 18th century cementation was rarely used and had been replaced by acid treatment. Into modern times the acid parting method continued to be used but other methods were discovered. In 1860’s Australia the Miller process

was developed, this removed silver by bubbling chlorine

gas through the molten gold mixture. Soon after, in the 1870’s, Electrolytic refining

of gold was developed, the Wohlwill process

, to deal with the problem of removing platinum

from the gold. This technique is the most commonly used today.

to post medieval times. It is a solid state process relying on common salt

as the active ingredient but it is possible to use a mixture of saltpetre

(KNO3) and green vitriol (FeSO4). The basic process involved the mixing of argentiferous gold foil (in later periods granules were used), common salt and brick dust or burnt clay in a closed and sealed container. Theophilus mentions the addition of urine to the mix. With heating, the silver reacts with the salt to form silver chloride which is removed leaving a purified gold behind. Conditions needed for this process are below 1000°C as the gold should not melt. Silver can be recovered by smelting the debris. Heating can take 24 hours. Hoover and Hoover explains the process thus; under heating salt (sodium chloride, NaCl) decomposes in the presence of silica and alumina (from the brick dust or clay) to produce hydrochloric acid and also some chlorine. This reacts with the silver to produce silver chloride (AgCl). The urine is acidic and aids decomposition. Silver chloride is volatile and would be removed from the metal. And the container is sealed to stop the escape of the silver which can be recovered later. Notton in experiments found that with one heating the gold content could be taken from 37.5% to 93%

(Sb2S3) instead of sulphur because stibnite is stable at a higher temperature than sulphur. This is much quicker than the salt process and gave a purer gold, but it could dissolve some of the gold as well. This process is first described in the Probierbuchlein.

2KNO3 + H2O + FeSO4 → FeO + K2SO4 + 2HNO3

Nitric acid, after distillation to increase the acid strength, was capable of dissolving the silver from a finely divided mixture of silver and gold, leaving the gold. Aqua regia

was also used for parting. It was made by adding sal ammoniac

to nitric acid

which produced a mixture of hydrochloric acid

and nitric acid. This acid dissolved the gold to a soluble chloride

and the silver was attacked and precipitated as an insoluble chloride. Silver was removed by filtering and gold was then recovered by evaporating the liquid and heating the residue. Nitric acid was suitable for separating small quantities of gold from silver and ‘’Aqua regia’’ used to separate small quantities of silver from gold.

process was invented by Francis Bowyer Miller in 1860’s Australia

. It is able to refine gold to 99.95% purity. The process involves blowing a stream of chlorine gas over and through a crucible filled with molten impure gold. Impurities in the gold form chlorides before the gold does and these insoluble salts are removed from the melt by skimming the surface.

Gold

Gold is a chemical element with the symbol Au and an atomic number of 79. Gold is a dense, soft, shiny, malleable and ductile metal. Pure gold has a bright yellow color and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is a...

from silver

Silver

Silver is a metallic chemical element with the chemical symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metal...

. Gold and silver are often extracted from the same ore

Ore

An ore is a type of rock that contains minerals with important elements including metals. The ores are extracted through mining; these are then refined to extract the valuable element....

s and are chemically similar and therefore hard to separate. Over the centuries special means of separation have been invented. The very earliest precious metals had mixes of gold and silver; gold and silver alloy is called electrum

Electrum

Electrum is a naturally occurring alloy of gold and silver, with trace amounts of copper and other metals. It has also been produced artificially. The ancient Greeks called it 'gold' or 'white gold', as opposed to 'refined gold'. Its color ranges from pale to bright yellow, depending on the...

; gold with small impurities of silver (5% and less) is called bullion. With the advent of coinage, methods had to be invented to remove impurities from the gold so that gold of specific purities could be made. Cupellation

Cupellation

Cupellation is a metallurgical process in which ores or alloyed metals are treated under high temperatures and carefully controlled operations in order to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, that might be present in...

was able to remove gold and silver from mixtures containing lead

Lead

Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed...

and other metals, but silver could not be removed. Gold parting as a process was specifically invented to remove the silver. The main ancient process of gold parting was by salt cementation and there is archaeological evidence of that process from the 6th century BC in Sardis

Sardis

Sardis or Sardes was an ancient city at the location of modern Sart in Turkey's Manisa Province...

, Lydia

Lydia

Lydia was an Iron Age kingdom of western Asia Minor located generally east of ancient Ionia in the modern Turkish provinces of Manisa and inland İzmir. Its population spoke an Anatolian language known as Lydian....

. In the post-medieval period parting using antimony

Antimony

Antimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite...

, sulphates

Sulfate

In inorganic chemistry, a sulfate is a salt of sulfuric acid.-Chemical properties:...

and mineral acids was also used. In the modern period chlorination

Chlorination

Chlorination is the process of adding the element chlorine to water as a method of water purification to make it fit for human consumption as drinking water...

using the Miller process

Miller process

The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity . It was invented by Francis Bowyer Miller. This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold...

, and electrolysis

Electrolysis

In chemistry and manufacturing, electrolysis is a method of using a direct electric current to drive an otherwise non-spontaneous chemical reaction...

using the Wohlwill process

Wohlwill process

The Wohlwill process is an industrial-scale chemical procedure used to refine gold to the highest degree of purity . The process was invented in 1874 by Emil Wohlwill. This electrochemical process involves using a cast dore ingot, often called a Doré bar, of 95%+ gold to serve as an anode...

are the most widely used methods of refining gold by removing silver and platinum

Platinum

Platinum is a chemical element with the chemical symbol Pt and an atomic number of 78. Its name is derived from the Spanish term platina del Pinto, which is literally translated into "little silver of the Pinto River." It is a dense, malleable, ductile, precious, gray-white transition metal...

.

Early history

The very earliest attempts at refining gold can be shown by the surface enhancement of gold rings. Gold quality was enhanced at the surface by 80–95% gold compared to 64–75% gold at the interior found in Nahal Qanah Cave dated to the 4th millennium BC. Further evidence is from three gold chisels from the 3rd Millennium BC royal cemetery at UrUr

Ur was an important city-state in ancient Sumer located at the site of modern Tell el-Muqayyar in Iraq's Dhi Qar Governorate...

that had a surface of high gold (83%), low silver (9%) and copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

(8%) compared with an interior of 45% gold, 10% silver and 45% copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

. The surface was compacted and heavily burnished and indicates early use of depletion gilding

Depletion gilding

Depletion gilding is a method for producing a layer of nearly pure gold on an object made of gold alloy by removing the other metals from its surface. It is sometimes referred to as a "surface enrichment" process.-Process:...

to enhance the surface.

Gold parting in ancient and medieval world

Lydia

Lydia was an Iron Age kingdom of western Asia Minor located generally east of ancient Ionia in the modern Turkish provinces of Manisa and inland İzmir. Its population spoke an Anatolian language known as Lydian....

(12th century BC to 546BC). Material from Sardis

Sardis

Sardis or Sardes was an ancient city at the location of modern Sart in Turkey's Manisa Province...

(in modern Turkey

Turkey

Turkey , known officially as the Republic of Turkey , is a Eurasian country located in Western Asia and in East Thrace in Southeastern Europe...

) is evidence of the earliest use of gold and silver parting in the 6th century. Literary sources and the lack of physical evidence suggest that gold-silver parting was not practised before the mid first millennium BC. Gold parting came with the invention of coinage and there is no evidence for the use of a true refining processes before the introduction of coinage. As refining gold (as opposed to surface enhancement) results in a noticeable loss in material, there would have been little reason to do this before the advent of coinage and the need to have a standard grade of material.

The first possible literary reference to the salt cementation parting process is in the Arthasastra, a 4th century BC treatise from India

India

India , officially the Republic of India , is a country in South Asia. It is the seventh-largest country by geographical area, the second-most populous country with over 1.2 billion people, and the most populous democracy in the world...

, that mentions heating of gold with Indus earth. Indus earth is taken to mean soils high in salt

Salt

In chemistry, salts are ionic compounds that result from the neutralization reaction of an acid and a base. They are composed of cations and anions so that the product is electrically neutral...

, nitre and ammonium salts and therefore ideal for the cementation parting process. A better known and more detailed early description is given by Diodorus Siculus

Diodorus Siculus

Diodorus Siculus was a Greek historian who flourished between 60 and 30 BC. According to Diodorus' own work, he was born at Agyrium in Sicily . With one exception, antiquity affords no further information about Diodorus' life and doings beyond what is to be found in his own work, Bibliotheca...

in the 1st century BC quoting an earlier lost book, ‘’On the Erythraean Sea’’ from the 2nd century BC by Agatharchides of Cnidus. An experiment recreating the process as described by Diodorus Siculus by heating a mixture of the gold and salt

Salt

In chemistry, salts are ionic compounds that result from the neutralization reaction of an acid and a base. They are composed of cations and anions so that the product is electrically neutral...

in a sealed pot for 5 days was done by Notton and was found to be successful.

Pliny

Pliny the Elder

Gaius Plinius Secundus , better known as Pliny the Elder, was a Roman author, naturalist, and natural philosopher, as well as naval and army commander of the early Roman Empire, and personal friend of the emperor Vespasian...

in this Naturalis Historia

Naturalis Historia

The Natural History is an encyclopedia published circa AD 77–79 by Pliny the Elder. It is one of the largest single works to have survived from the Roman Empire to the modern day and purports to cover the entire field of ancient knowledge, based on the best authorities available to Pliny...

mentions the purification of gold a number of times and makes reference to the salt cementation process of gold parting. He says that the gold is "roasted with a double weight of salt and three times the weight of misy (ferric sulphates) and again with two portions of salt and one of the stone which is called schiston." Here he is describing the heating of gold with salt and iron sulphates which act to dissolve the copper and silver in the gold. Parting vessels used for refining gold with the cementation process have been found in London

London

London is the capital city of :England and the :United Kingdom, the largest metropolitan area in the United Kingdom, and the largest urban zone in the European Union by most measures. Located on the River Thames, London has been a major settlement for two millennia, its history going back to its...

, Lincoln

Lincoln, Lincolnshire

Lincoln is a cathedral city and county town of Lincolnshire, England.The non-metropolitan district of Lincoln has a population of 85,595; the 2001 census gave the entire area of Lincoln a population of 120,779....

, York

York

York is a walled city, situated at the confluence of the Rivers Ouse and Foss in North Yorkshire, England. The city has a rich heritage and has provided the backdrop to major political events throughout much of its two millennia of existence...

and Winchester

Winchester

Winchester is a historic cathedral city and former capital city of England. It is the county town of Hampshire, in South East England. The city lies at the heart of the wider City of Winchester, a local government district, and is located at the western end of the South Downs, along the course of...

. The London vessels, dating from the Flavian period

Flavian dynasty

The Flavian dynasty was a Roman Imperial Dynasty, which ruled the Roman Empire between 69 and 96 AD, encompassing the reigns of Vespasian , and his two sons Titus and Domitian . The Flavians rose to power during the civil war of 69, known as the Year of the Four Emperors...

(c.70–85AD), were sealed using luting clay

Clay

Clay is a general term including many combinations of one or more clay minerals with traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.- Formation :Clay minerals...

; XRF

X-ray fluorescence

X-ray fluorescence is the emission of characteristic "secondary" X-rays from a material that has been excited by bombarding with high-energy X-rays or gamma rays...

analysis detected gold and silver, with highest concentration around the sealed region showing possible escape of silver as the volatile silver chloride.

Gold parting had been well used throughout the ancient times but only in the Medieval period were clear and detailed descriptions of the processes written. All the archaeological finds of Roman and early medieval parting point to a solid state process using common salt as the active ingredient. The only large group of medieval parting vessels so far discovered were found at Coppergate and Picadilly sites in York. The pinkish-purple discolouration of the vessels showed them to have been used with the salt cementation process which removes iron from the clay as ferric chloride. Other vessel fragments are known from Carlisle and Winchester. Theophilus

Theophilus Presbyter

Theophilus Presbyter is the pseudonymous author or compiler ofa Latin text containing detailed descriptions of various medieval arts, a text commonly known as the Schedula diversarum artium or De diversis artibus , probably first compiled between 1100 and 1120...

was a 12th century German monk and in his book ‘’De Diversus Artibus’’ gives the clearest description of the salt cementation process.

This mixture is then added to an earthenware pot and layered with thin sheets of gold fold. The pot is then sealed and heated in a furnace.

It was during the medieval period that distillation

Distillation

Distillation is a method of separating mixtures based on differences in volatilities of components in a boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction....

was discovered and the first description of nitric acid production was given by Geber

Geber

Abu Musa Jābir ibn Hayyān, often known simply as Geber, was a prominent polymath: a chemist and alchemist, astronomer and astrologer, engineer, geologist, philosopher, physicist, and pharmacist and physician. Born and educated in Tus, he later traveled to Kufa...

in the Summa perfectionis, 1330. Nitric acid

Nitric acid

Nitric acid , also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming...

is able to dissolve silver. The addition of sal ammoniac

Sal ammoniac

Sal ammoniac is a rare mineral composed of ammonium chloride, NH4Cl. It forms colorless to white to yellow-brown crystals in the isometric-hexoctahedral class. It has very poor cleavage and a brittle to conchoidal fracture. It is quite soft, with a Mohs hardness of 1.5 to 2, and has a low specific...

to nitric acid creates Aqua regia

Aqua regia

Aqua regia or aqua regis is a highly corrosive mixture of acids, fuming yellow or red solution, also called nitro-hydrochloric acid. The mixture is formed by freshly mixing concentrated nitric acid and hydrochloric acid, usually in a volume ratio of 1:3, respectively...

and this acid is able to dissolve gold. Both acids are used in the acid method of parting but the acids were expensive so were not used until the post medieval period.

Post medieval to Modern Period

De re metallica

De re metallica is a book cataloguing the state of the art of mining, refining, and smelting metals, published in 1556. The author was Georg Bauer, whose pen name was the Latinized Georgius Agricola...

; and by Ercker in his Treatise on ores and assaying. This was a period where new techniques began to be explored. Granulation of the gold instead of gold foil increased surface area and therefore the efficiency of the reaction. Salt cementation continued to be the main method of parting until the 16th century but in later Middle Ages processes using sulphur, antimony and mineral acids began to be used. There are archaeological finds at sites in London of distillation vessels for making acids in Britain from the 15th century which include fragments of ceramic cucurbits (vessels for heating reacting chemicals) which were used with alembics for distillation. By the 18th century cementation was rarely used and had been replaced by acid treatment. Into modern times the acid parting method continued to be used but other methods were discovered. In 1860’s Australia the Miller process

Miller process

The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity . It was invented by Francis Bowyer Miller. This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold...

was developed, this removed silver by bubbling chlorine

Chlorine

Chlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine...

gas through the molten gold mixture. Soon after, in the 1870’s, Electrolytic refining

Refining

Refining is the process of purification of a substance or a form. The term is usually used of a natural resource that is almost in a usable form, but which is more useful in its pure form. For instance, most types of natural petroleum will burn straight from the ground, but it will burn poorly...

of gold was developed, the Wohlwill process

Wohlwill process

The Wohlwill process is an industrial-scale chemical procedure used to refine gold to the highest degree of purity . The process was invented in 1874 by Emil Wohlwill. This electrochemical process involves using a cast dore ingot, often called a Doré bar, of 95%+ gold to serve as an anode...

, to deal with the problem of removing platinum

Platinum

Platinum is a chemical element with the chemical symbol Pt and an atomic number of 78. Its name is derived from the Spanish term platina del Pinto, which is literally translated into "little silver of the Pinto River." It is a dense, malleable, ductile, precious, gray-white transition metal...

from the gold. This technique is the most commonly used today.

Salt cementation

This process was used from LydianLydia

Lydia was an Iron Age kingdom of western Asia Minor located generally east of ancient Ionia in the modern Turkish provinces of Manisa and inland İzmir. Its population spoke an Anatolian language known as Lydian....

to post medieval times. It is a solid state process relying on common salt

Salt

In chemistry, salts are ionic compounds that result from the neutralization reaction of an acid and a base. They are composed of cations and anions so that the product is electrically neutral...

as the active ingredient but it is possible to use a mixture of saltpetre

Potassium nitrate

Potassium nitrate is a chemical compound with the formula KNO3. It is an ionic salt of potassium ions K+ and nitrate ions NO3−.It occurs as a mineral niter and is a natural solid source of nitrogen. Its common names include saltpetre , from medieval Latin sal petræ: "stone salt" or possibly "Salt...

(KNO3) and green vitriol (FeSO4). The basic process involved the mixing of argentiferous gold foil (in later periods granules were used), common salt and brick dust or burnt clay in a closed and sealed container. Theophilus mentions the addition of urine to the mix. With heating, the silver reacts with the salt to form silver chloride which is removed leaving a purified gold behind. Conditions needed for this process are below 1000°C as the gold should not melt. Silver can be recovered by smelting the debris. Heating can take 24 hours. Hoover and Hoover explains the process thus; under heating salt (sodium chloride, NaCl) decomposes in the presence of silica and alumina (from the brick dust or clay) to produce hydrochloric acid and also some chlorine. This reacts with the silver to produce silver chloride (AgCl). The urine is acidic and aids decomposition. Silver chloride is volatile and would be removed from the metal. And the container is sealed to stop the escape of the silver which can be recovered later. Notton in experiments found that with one heating the gold content could be taken from 37.5% to 93%

Sulphur and antimony processes

This is similar to the salt cementation process but creates sulphides instead of chlorides. Finely divided impure gold and elemental sulphur are reacted together under moderate heat in a sealed crucible. The impurities form metal sulphides and the gold is left unreacted. The gaseous sulphide condenses on the crucible fabric. The antimony process is the same but uses stibniteStibnite

Stibnite, sometimes called antimonite, is a sulfide mineral with the formula Sb2S3. This soft grey material crystallizes in an orthorhombic space group. It is the most important source for the metalloid antimony...

(Sb2S3) instead of sulphur because stibnite is stable at a higher temperature than sulphur. This is much quicker than the salt process and gave a purer gold, but it could dissolve some of the gold as well. This process is first described in the Probierbuchlein.

Acid parting

The distillation was used in the 12th century Europe after its introduction from the East and after that period more powerful acids could be created. Nitric acid (‘’aqua valens’’) could be made by the distillation of saltpetre (KNO3) with alum (KAl(SO4)2) or vitriol (FeSO4) with water.2KNO3 + H2O + FeSO4 → FeO + K2SO4 + 2HNO3

Nitric acid, after distillation to increase the acid strength, was capable of dissolving the silver from a finely divided mixture of silver and gold, leaving the gold. Aqua regia

Aqua regia

Aqua regia or aqua regis is a highly corrosive mixture of acids, fuming yellow or red solution, also called nitro-hydrochloric acid. The mixture is formed by freshly mixing concentrated nitric acid and hydrochloric acid, usually in a volume ratio of 1:3, respectively...

was also used for parting. It was made by adding sal ammoniac

Sal ammoniac

Sal ammoniac is a rare mineral composed of ammonium chloride, NH4Cl. It forms colorless to white to yellow-brown crystals in the isometric-hexoctahedral class. It has very poor cleavage and a brittle to conchoidal fracture. It is quite soft, with a Mohs hardness of 1.5 to 2, and has a low specific...

to nitric acid

Nitric acid

Nitric acid , also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming...

which produced a mixture of hydrochloric acid

Hydrochloric acid

Hydrochloric acid is a solution of hydrogen chloride in water, that is a highly corrosive, strong mineral acid with many industrial uses. It is found naturally in gastric acid....

and nitric acid. This acid dissolved the gold to a soluble chloride

Chloride

The chloride ion is formed when the element chlorine, a halogen, picks up one electron to form an anion Cl−. The salts of hydrochloric acid HCl contain chloride ions and can also be called chlorides. The chloride ion, and its salts such as sodium chloride, are very soluble in water...

and the silver was attacked and precipitated as an insoluble chloride. Silver was removed by filtering and gold was then recovered by evaporating the liquid and heating the residue. Nitric acid was suitable for separating small quantities of gold from silver and ‘’Aqua regia’’ used to separate small quantities of silver from gold.

Miller process

The MillerMiller

A miller usually refers to a person who operates a mill, a machine to grind a cereal crop to make flour. Milling is among the oldest of human occupations. "Miller", "Milne" and other variants are common surnames, as are their equivalents in other languages around the world...

process was invented by Francis Bowyer Miller in 1860’s Australia

Australia

Australia , officially the Commonwealth of Australia, is a country in the Southern Hemisphere comprising the mainland of the Australian continent, the island of Tasmania, and numerous smaller islands in the Indian and Pacific Oceans. It is the world's sixth-largest country by total area...

. It is able to refine gold to 99.95% purity. The process involves blowing a stream of chlorine gas over and through a crucible filled with molten impure gold. Impurities in the gold form chlorides before the gold does and these insoluble salts are removed from the melt by skimming the surface.

Wohlwill process

Invented by Emil Wohlwill in 1874 this produces the highest purity gold (99.999%). It is an electrolytic process using pure gold for the cathode (or titanium as a starter cathode) and chloroauric acid (gold chloride-hydrochloric acid) as the electrolyte; this is made by dissolving gold with chlorine gas in the presence of hydrochloric acid. Gold is dissolved at the anode, and pure gold, traveling through the acid by ion transfer, is plated onto the cathode. Silver forms an insoluble chloride slime and copper and platinum form soluble chlorides that are removed. This procedure is used on a very large industrial scale and has a large set up cost due to the amount of gold that needs to be permanently dissolved in the electrolyte.See also

- Gold extractionGold extractionGold extraction or recovery from its ores may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore....

- Gold miningGold miningGold mining is the removal of gold from the ground. There are several techniques and processes by which gold may be extracted from the earth.-History:...

- GoldGoldGold is a chemical element with the symbol Au and an atomic number of 79. Gold is a dense, soft, shiny, malleable and ductile metal. Pure gold has a bright yellow color and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is a...

- CupellationCupellationCupellation is a metallurgical process in which ores or alloyed metals are treated under high temperatures and carefully controlled operations in order to separate noble metals, like gold and silver, from base metals like lead, copper, zinc, arsenic, antimony or bismuth, that might be present in...

- De Re MetallicaDe re metallicaDe re metallica is a book cataloguing the state of the art of mining, refining, and smelting metals, published in 1556. The author was Georg Bauer, whose pen name was the Latinized Georgius Agricola...

- Metallurgical assayMetallurgical assayA metallurgical assay is a compositional analysis of an ore, metal, or alloy.Some assay methods are suitable for raw materials; others are more appropriate for finished goods. Raw precious metals are assayed by an assay office...