Camshaft

Encyclopedia

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

is fastened or of which a cam forms an integral part.

History

An early cam was built into HellenisticHellenistic civilization

Hellenistic civilization represents the zenith of Greek influence in the ancient world from 323 BCE to about 146 BCE...

water-driven automata

Automaton

An automaton is a self-operating machine. The word is sometimes used to describe a robot, more specifically an autonomous robot. An alternative spelling, now obsolete, is automation.-Etymology:...

from the 3rd century BC. The camshaft was later described in Iraq

Iraq

Iraq ; officially the Republic of Iraq is a country in Western Asia spanning most of the northwestern end of the Zagros mountain range, the eastern part of the Syrian Desert and the northern part of the Arabian Desert....

(Mesopotamia

Mesopotamia

Mesopotamia is a toponym for the area of the Tigris–Euphrates river system, largely corresponding to modern-day Iraq, northeastern Syria, southeastern Turkey and southwestern Iran.Widely considered to be the cradle of civilization, Bronze Age Mesopotamia included Sumer and the...

) by Al-Jazari

Al-Jazari

Abū al-'Iz Ibn Ismā'īl ibn al-Razāz al-Jazarī was a Muslim polymath: a scholar, inventor, mechanical engineer, craftsman, artist, mathematician and astronomer from Al-Jazira, Mesopotamia, who lived during the Islamic Golden Age...

in 1206. He employed it as part of his automata, water-raising machines, and water clock

Water clock

A water clock or clepsydra is any timepiece in which time is measured by the regulated flow of liquid into or out from a vessel where the amount is then measured.Water clocks, along with sundials, are likely to be the oldest time-measuring instruments, with the only exceptions...

s such as the castle clock

Castle clock

A castle clock is a clock whose face is mounted outside a castle or perhaps a church tower. They may be elaborate or simple.Al-Jazari constructed an elaborate clock and described it in his Book of Knowledge of Ingenious Mechanical Devices in 1206. It was about 3,3 metres high , and had multiple...

. The cam and camshaft later appeared in European mechanisms from at least the 14th century, or possibly earlier.

Uses

In internal combustion engines with pistons, the camshaft is used to operate poppet valvePoppet valve

A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

s. It then consists of a cylindrical rod running the length of the cylinder bank

Cylinder bank

Internal combustion piston engines are usually arranged so that the cylinders are in lines parallel to the crankshaft. Where they are in a single line, this is referred to as an inline or straight engine....

with a number of oblong lobes protruding from it, one for each valve. The cams force the valves open by pressing on the valve, or on some intermediate mechanism as they rotate.

Material

Camshafts can be made out of several different types of material. These include:Chilled iron castings: this is a good choice for high volume production. A chilled iron camshaft has a resistance against wear because the camshaft lobes have been chilled, generally making them harder. When making chilled iron castings, other elements are added to the iron before casting to make the material more suitable for its application.

Billet Steel: When a high quality camshaft is required, engine builders and camshaft manufacturers choose to make the camshaft from steel billet. This method is also used for low volume production. This is a much more time consuming process, and is generally more expensive than other methods. However the finished product is far superior. When making the camshaft, CNC

Numerical control

Numerical control refers to the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone...

lathes

Lathe (metal)

A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of...

, CNC milling machine

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

s and CNC camshaft grinders will be used. Different types of steel bar can be used, one example being EN40b. When manufacturing a camshaft from EN40b, the camshaft will also be heat treated

Heat treatment

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass...

via gas nitriding, which changes the micro-structure of the material. It gives a surface hardness of 55-60 HRC

Rockwell scale

The Rockwell scale is a hardness scale based on the indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single...

. These types of camshafts can be used in high-performance engines.

Timing

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

is of critical importance. Since the valves control the flow of the air/fuel mixture intake and exhaust gases, they must be opened and closed at the appropriate time during the stroke of the piston. For this reason, the camshaft is connected to the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

either directly, via a gear

Gear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

mechanism, or indirectly via a belt or chain called a timing belt

Timing belt

A timing belt, or cam belt , is a part of an internal combustion engine that controls the timing of the engine's valves. Some engines, such as the flat-4 Volkswagen air-cooled engine, and the straight-6 Toyota F engine use timing gears...

or timing chain

Roller chain

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire and tube drawing machines, printing presses, cars, motorcycles, and simple machines like...

. Direct drive using gears is unusual because the frequently reversing torque caused by the slope of the cams tends to quickly wear out gear teeth. Where gears are used, they tend to be made from resilient fibre rather than metal, except in racing engines that have a high maintenance routine. Fibre gears have a short life span and must be replaced regularly, much like a cam belt. In some designs the camshaft also drives the distributor

Distributor

A distributor is a device in the ignition system of an internal combustion engine that routes high voltage from the ignition coil to the spark plugs in the correct firing order. The first reliable battery operated ignition was developed by Dayton Engineering Laboratories Co. and introduced in the...

and the oil

Lubricant

A lubricant is a substance introduced to reduce friction between moving surfaces. It may also have the function of transporting foreign particles and of distributing heat...

and fuel pump

Fuel pump

A fuel pump is a frequently essential component on a car or other internal combustion engined device. Many engines do not require any fuel pump at all, requiring only gravity to feed fuel from the fuel tank through a line or hose to the engine...

s. Some vehicles may have the power steering pump driven by the camshaft. With some early fuel injection

Fuel injection

Fuel injection is a system for admitting fuel into an internal combustion engine. It has become the primary fuel delivery system used in automotive petrol engines, having almost completely replaced carburetors in the late 1980s....

systems, cams on the camshaft would operate the fuel injectors.

An alternative used in the early days of OHC engines was to drive the camshaft(s) via a vertical shaft with bevel gears at each end. This system was, for example, used on the pre-WW1 Peugeot and Mercedes

Mercedes-Benz in motorsport

Throughout its long history, Mercedes-Benz has been involved in a range of motorsport activities, including sportscar racing and rallying, and is currently active in Formula Three, DTM and Formula One.-Early history:...

Grand Prix cars. Another option was to use a triple eccentric with connecting rods; these were used on certain W.O. Bentley-designed engines and also on the Leyland Eight

Leyland Eight

The Leyland Eight was a luxury car produced by Leyland Motors from 1920 to 1923. The car was designed by the chief engineer of Leyland Motors, J.G. Parry-Thomas and his assistant Reid Railton, and was intended to be the finest car available...

.

In a two-stroke engine that uses a camshaft, each valve is opened once for each rotation of the crankshaft; in these engines, the camshaft rotates at the same speed as the crankshaft. In a four-stroke engine, the valves are opened only half as often; thus, two full rotations of the crankshaft occur for each rotation of the camshaft.

The timing of the camshaft can be advanced to produce better low RPM torque, or retarded for better high RPM power. Either of these moves the overall power produced by the engine down or up the RPM scale respectively. The amount of change is very little (usually < 5 deg), and affects valve to piston clearances.

Duration

Duration is the number of crankshaft degrees of engine rotation during which the valve is off the seat. As a generality, greater duration results in more horsepower. The RPM at which peak horsepower occurs is typically increased as duration increases at the expense of lower rpm efficiency (torque).Duration can often be confusing because manufacturers may select any lift point to advertise a camshaft's duration and sometimes will manipulate these numbers. The power and idle characteristics of a camshaft rated at .006" will be much different than one rated the same at .002".

Many performance engine builders gauge a race profile's aggressiveness by looking at the duration at .020", .050" and .200". The .020" number determines how responsive the motor will be and how much low end torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

the motor will make. The .050" number is used to estimate where peak power will occur, and the .200" number gives an estimate of the power potential.

A secondary effect of increase duration is increasing overlap, which is the number of crankshaft degrees during which both intake and exhaust valves are off their seats. It is overlap which most affects idle quality, inasmuch as the "blow-through" of the intake charge which occurs during overlap reduces engine efficiency, and is greatest during low RPM operation. In reality, increasing a camshaft's duration typically increases the overlap event, unless one spreads lobe centers between intake and exhaust valve lobe profiles.

Lift

The camshaft "lift" is the resultant net rise of the valve from its seat. The further the valve rises from its seat the more airflow can be realised, which is generally more beneficial. Greater lift has some limitations. Firstly, the lift is limited by the increased proximity of the valve head to the piston crown and secondly greater effort is required to move the valve's springs to higher state of compression. Increased lift can also be limited by lobe clearance in the cylinder head construction, so higher lobes may not necessarily clear the framework of the cylinder head casing. Higher valve lift can have the same effect as increased duration where valve overlap is less desirable.Higher lift allows accurate timing of airflow; although even by allowing a larger volume of air to pass in the relatively larger opening, the brevity of the typical duration with a higher lift cam results in less airflow than with a cam with lower lift but more duration, all else being equal. On forced induction motors this higher lift could yield better results than longer duration, particularly on the intake side. Notably though, higher lift has more potential problems than increased duration, in particular as valve train rpm rises which can result in more inefficient running or loss of torque.

Cams that have too high a resultant valve lift, and at high rpm, can result in what is called "valve bounce", where the valve spring tension is insufficient to keep the valve following the cam at its apex. This could also be as a result of a very steep rise of the lobe and short duration, where the valve is effectively shot off the end of the cam rather than have the valve follow the cams’ profile. This is typically what happens on a motor over rev. This is an occasion where the engine rpm exceeds the engine maximum design speed. The valve train is typically the limiting factor in determining the maximum rpm the engine can maintain either for a prolonged period or temporarily. Sometimes an over rev can cause engine failure where the valve stems become bent as a result of colliding with the piston crowns.

Position

Depending on the location of the camshaft, the cams operate the valves either directly or through a linkage of pushrods and rockers. Direct operation involves a simpler mechanism and leads to fewer failures, but requires the camshaft to be positioned at the top of the cylinders. In the past when engines were not as reliable as today this was seen as too much bother, but in modern gasoline engines the overhead cam system, where the camshaft is on top of the cylinder headCylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

, is quite common.

Number of camshafts

While today some cheaper engines rely on a single camshaft per cylinder bank, which is known as a single overhead camshaft (SOHC), most modern engine designs (the overhead-valve or OHVOverhead valve

An overhead valve engine, also informally called pushrod engine or I-head engine, is a type of piston engine that places the camshaft within the cylinder block , and uses pushrods or rods to actuate rocker arms above the cylinder...

engine being largely obsolete on passenger vehicles), are driven by a two camshafts per cylinder bank arrangement (one camshaft for the intake valves and another for the exhaust valves); such camshaft arrangement is known as a double or dual overhead cam (DOHC), thus, a V engine

V engine

A V engine, or Vee engine is a common configuration for an internal combustion engine. The cylinders and pistons are aligned, in two separate planes or 'banks', so that they appear to be in a "V" when viewed along the axis of the crankshaft...

, which has two separate cylinder banks, may have four camshafts (colloquially known as a quad-cam engine).

More unusual is the modern W engine

W engine

A W engine is a type of reciprocating engine arranged with its cylinders in a configuration in which the cylinder banks resemble the letter W, in the same way those of a V engine resemble the letter V....

(also known as a 'VV' engine to distinguish itself from the pre-war

Pre-war

The term pre-war or prewar is usually applied to the most recent or significant war in a culture's history.Antebellum is most often used to denote the period before the American Civil War while pre-war typically refers to the period before WWII.In real estate the term refers to buildings from the...

W engines) that has four cylinder banks arranged in a "W" pattern with two pairs narrowly arranged with a 15-degree separation. Even when there are four cylinder banks (that would normally require a total of eight individual camshafts), the narrow-angle design allows the use of just four camshafts in total. For the Bugatti Veyron

Bugatti Veyron

The Bugatti Veyron EB 16.4 is a mid-engined grand touring car. The Super Sport version is the fastest road-legal production car in the world, with a top speed of . The original version has a top speed of...

, which has a 16-cylinder W engine configuration, all the four camshafts are driving a total of 64 valves

Poppet valve

A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

.

The overhead camshaft design adds more valvetrain components that ultimately incur in more complexity and higher manufacturing costs, but this is easily offset by many advantages over the older OHV design: multi-valve design

Multi-valve

In automotive engineering a multi-valve or multivalve engine is one where each cylinder has more than two valves. A multi-valve engine has better breathing and can operate at higher revolutions per minute than a two-valve engine, delivering more power.- Multi-valve rationale :A multi-valve design...

, higher RPM limit and design freedom to better place valves, ignition (Spark-ignition engine) and intake/exhaust ports.

Maintenance

The rockers or cam followerCam follower

A cam follower, also known as a track follower, is a specialized type of roller or needle bearing designed to follow cams. Cam followers come in a vast array of different configurations, however the most defining characteristic is how the cam follower mounts to its mating part; stud style cam...

s sometimes incorporate a mechanism to adjust and set the valve play through manual adjustment, but most modern auto engines have hydraulic lifters

Hydraulic lifters

A Hydraulic Valve Lifter, also known as a hydraulic tappet or a hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. The conventional means of adjusting valve actuation always requires a small clearance to be left between the valve and its...

, eliminating the need to adjust the valve lash at regular intervals as the valvetrain wears, and in particular the valves and valve seat

Valve seat

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed...

s in the combustion chamber

Combustion chamber

A combustion chamber is the part of an engine in which fuel is burned.-Internal combustion engine:The hot gases produced by the combustion occupy a far greater volume than the original fuel, thus creating an increase in pressure within the limited volume of the chamber...

.

Sliding friction between the surface of the cam and the cam follower which rides upon it is considerable. In order to reduce wear at this point, the cam and follower are both surface hardened, and modern lubricant

Lubricant

A lubricant is a substance introduced to reduce friction between moving surfaces. It may also have the function of transporting foreign particles and of distributing heat...

motor oil

Motor oil

Motor oil or engine oil is an oil used for lubrication of various internal combustion engines. The main function is to lubricate moving parts; it also cleans, inhibits corrosion, improves sealing, and cools the engine by carrying heat away from moving parts.Motor oils are derived from...

s contain additives specifically to reduce sliding friction. The lobes of the camshaft are usually slightly tapered, causing the cam followers or valve lifters to rotate slightly with each depression, and helping to distribute wear on the parts. The surfaces of the cam and follower are designed to "wear in" together, and therefore when either is replaced, the other should be as well to prevent excessive rapid wear. In some engines, the flat contact surfaces are replaced with rollers, which eliminate the sliding friction and wear but adds mass to the valvetrain.

Alternatives

In addition to mechanical friction, considerable force is required to overcome the valve springs used to close the engine's valves. This can amount to an estimated 25% of an engine's total output at idle, reducing overall efficiency. Some approaches to reclaiming this "wasted" energy include:- Springless valves, like the desmodromic system employed today by Ducati

- CamlessCamlessMost four-stroke piston engines today employ one or more camshafts to operate poppet valves. The lobes on the camshafts operate cam followers which in turn open the poppet valves. A camless uses electromagnetic, hydraulic, or pneumatic actuators to open the poppet valves instead...

valvetrains using solenoidSolenoidA solenoid is a coil wound into a tightly packed helix. In physics, the term solenoid refers to a long, thin loop of wire, often wrapped around a metallic core, which produces a magnetic field when an electric current is passed through it. Solenoids are important because they can create...

s or magnetic systems have long been investigated by BMWBMWBayerische Motoren Werke AG is a German automobile, motorcycle and engine manufacturing company founded in 1916. It also owns and produces the Mini marque, and is the parent company of Rolls-Royce Motor Cars. BMW produces motorcycles under BMW Motorrad and Husqvarna brands...

and FiatFiatFIAT, an acronym for Fabbrica Italiana Automobili Torino , is an Italian automobile manufacturer, engine manufacturer, financial, and industrial group based in Turin in the Italian region of Piedmont. Fiat was founded in 1899 by a group of investors including Giovanni Agnelli...

, and are currently being prototyped by ValeoValeoValeo is a French automotive components manufacturer.-History:The Société Anonyme Française du Ferodo was founded in 1923 in Saint-Ouen, a suburb of Paris...

and Ricardo - The Wankel engineWankel engineThe Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like epitrochoid-shaped housing and a rotor that...

, a rotary engine which uses neither pistons nor valves, best known for being used by MazdaMazdais a Japanese automotive manufacturer based in Fuchū, Aki District, Hiroshima Prefecture, Japan.In 2007, Mazda produced almost 1.3 million vehicles for global sales...

in the RX-7 and RX-8 sports cars.

Ignition systems

In mechanically timed ignition systems a separate camshaft is geared to the engine and operates a breaker that triggers a spark at the correct points in the combustion cycle.Electrical

Before the advent of solid state electronics, camshaft controllers were used to control the speed of electric motorElectric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

s. A camshaft, driven by an electric motor or a pneumatic motor

Pneumatic motor

A pneumatic motor or compressed air engine is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed air to mechanical work through either linear or rotary motion...

, was used to operate switch

Switch

In electronics, a switch is an electrical component that can break an electrical circuit, interrupting the current or diverting it from one conductor to another....

es in sequence. By this means, resistor

Resistor

A linear resistor is a linear, passive two-terminal electrical component that implements electrical resistance as a circuit element.The current through a resistor is in direct proportion to the voltage across the resistor's terminals. Thus, the ratio of the voltage applied across a resistor's...

s or tap changers

Tap (transformer)

A transformer tap is a connection point along a transformer winding that allows a certain number of turns to be selected. This means, a transformer with a variable turns ratio is produced, enabling voltage regulation of the output...

were switched in or out of the circuit to vary the speed of the main motor. This system was widely used in electric multiple unit

Electric multiple unit

An electric multiple unit or EMU is a multiple unit train consisting of self-propelled carriages, using electricity as the motive power. An EMU requires no separate locomotive, as electric traction motors are incorporated within one or a number of the carriages...

s.

Gallery

|

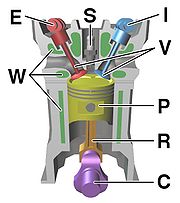

Components of a typical, four-stroke cycle, DOHC piston engine. (E) Exhaust camshaft, (I) Intake camshaft, (S) Spark plug Spark plug A spark plug is an electrical device that fits into the cylinder head of some internal combustion engines and ignites compressed fuels such as aerosol, gasoline, ethanol, and liquefied petroleum gas by means of an electric spark.Spark plugs have an insulated central electrode which is connected by... , (V) Valve Poppet valve A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide... s, (P) Piston Piston A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from... , (R) Connecting rod Connecting rod In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion.... , (C) Crankshaft Crankshaft The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation... , (W) Water jacket for coolant flow. |

Double overhead cams control the opening and closing of a cylinder's valves.

|

|

|

Valve Poppet valve A poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide... timing gear Gear A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine.... s on a Ford Taurus V4 engine — the small gear is on the crankshaft Crankshaft The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation... , the larger gear is on the camshaft. The gear ratio Gear ratio The gear ratio of a gear train is the ratio of the angular velocity of the input gear to the angular velocity of the output gear, also known as the speed ratio of the gear train. The gear ratio can be computed directly from the numbers of teeth of the various gears that engage to form the gear... causes the camshaft to run at half the RPM of the crankshaft. |