Connecting rod

Encyclopedia

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

to the crank

Crank (mechanism)

A crank is an arm attached at right angles to a rotating shaft by which reciprocating motion is imparted to or received from the shaft. It is used to change circular into reciprocating motion, or reciprocating into circular motion. The arm may be a bent portion of the shaft, or a separate arm...

or crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion.

Connecting rods may also convert rotating motion into linear motion. Historically, before the development of engines, they were first used in this way.

As a connecting rod is rigid, it may transmit either a push or a pull and so the rod may rotate the crank through both halves of a revolution, i.e. piston pushing and piston pulling. Earlier mechanisms, such as chains, could only pull. In a few two-stroke engines, the connecting rod is only required to push.

Today, connecting rods are best known through their use in internal combustion piston engines, such as car engines. These are of a distinctly different design from earlier forms of connecting rods, used in steam engines and steam locomotives.

History

The earliest evidence for a connecting rod appears in the late 3rd century AD RomanRoman Empire

The Roman Empire was the post-Republican period of the ancient Roman civilization, characterised by an autocratic form of government and large territorial holdings in Europe and around the Mediterranean....

Hierapolis sawmill

Hierapolis sawmill

The Hierapolis sawmill was a Roman water-powered stone sawmill at Hierapolis, Asia Minor . Dating to the second half of the 3rd century AD, the sawmill is the earliest known machine to combine a crank with a connecting rod....

. It also appears in two 6th century Eastern Roman

Byzantine Empire

The Byzantine Empire was the Eastern Roman Empire during the periods of Late Antiquity and the Middle Ages, centred on the capital of Constantinople. Known simply as the Roman Empire or Romania to its inhabitants and neighbours, the Empire was the direct continuation of the Ancient Roman State...

saw mills excavated at Ephesus

Ephesus

Ephesus was an ancient Greek city, and later a major Roman city, on the west coast of Asia Minor, near present-day Selçuk, Izmir Province, Turkey. It was one of the twelve cities of the Ionian League during the Classical Greek era...

respectively Gerasa. The crank

Crank (mechanism)

A crank is an arm attached at right angles to a rotating shaft by which reciprocating motion is imparted to or received from the shaft. It is used to change circular into reciprocating motion, or reciprocating into circular motion. The arm may be a bent portion of the shaft, or a separate arm...

and connecting rod mechanism of these Roman watermills converted the rotary motion of the waterwheel into the linear movement of the saw blades.

Sometime between 1174 and 1206, the Arab inventor and engineer Al-Jazari

Al-Jazari

Abū al-'Iz Ibn Ismā'īl ibn al-Razāz al-Jazarī was a Muslim polymath: a scholar, inventor, mechanical engineer, craftsman, artist, mathematician and astronomer from Al-Jazira, Mesopotamia, who lived during the Islamic Golden Age...

described a machine which incorporated the connecting rod with a crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

to pump water as part of a water-raising machine, but the device was unnecessarily complex indicating that he still did not fully understand the concept of power conversion.

In Renaissance Italy, the earliest evidence of a − albeit mechanically misunderstood − compound crank and connecting-rod is found in the sketch books of Taccola

Taccola

Mariano di Jacopo detto il Taccola , called Taccola , was an Italian administrator, artist and engineer of the early Renaissance. Taccola is known for his technological treatises De ingeneis and De machinis, which feature annotated drawings of a wide array of innovative machines and devices...

. A sound understanding of the motion involved displays the painter Pisanello

Pisanello

Pisanello , known professionally as Antonio di Puccio Pisano or Antonio di Puccio da Cereto, also erroneously called Vittore Pisano by Giorgio Vasari, was one of the most distinguished painters of the early Italian Renaissance and Quattrocento...

(d. 1455) who showed a piston-pump driven

by a water-wheel and operated by two simple cranks and two connecting-rods.

By the 16th century, evidence of cranks and connecting rods in the technological treatises and artwork of Renaissance

Renaissance

The Renaissance was a cultural movement that spanned roughly the 14th to the 17th century, beginning in Italy in the Late Middle Ages and later spreading to the rest of Europe. The term is also used more loosely to refer to the historical era, but since the changes of the Renaissance were not...

Europe becomes abundant; Agostino Ramelli

Agostino Ramelli

Agostino Ramelli was an engineer who designed the "book wheel" or "reading wheel".During the Siege of La Rochelle , Agostino successfully engineered a mine under a bastion and breached the fortification, making him popular with his commander, Henri d'Anjou, who later became Henri III of France.In...

's The Diverse and Artifactitious Machines of 1588 alone depicts eighteen examples, a number which rises in the Theatrum Machinarum Novum by Georg Andreas Böckler

Georg Andreas Böckler

Georg Andreas Böckler was a German architect and engineer who wrote Architectura Curiosa Nova and Theatrum Machinarum Novum ....

to 45 different machines.

Steam engines

The first steam engines, Newcomen's atmospheric engine, was single-acting: its piston only did work in one direction, and so these used a chain rather than a connecting rod. Their output rocked back and forth, rather than rotating continuously.Steam engines after this are usually double-acting: their internal pressure works on each side of the piston in turn. This requires a seal around the piston rod and so the hinge between the piston and connecting rod is placed outside the cylinder, in a large sliding bearing block called a crosshead.

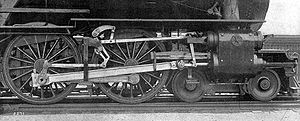

Steam locomotive

A steam locomotive is a railway locomotive that produces its power through a steam engine. These locomotives are fueled by burning some combustible material, usually coal, wood or oil, to produce steam in a boiler, which drives the steam engine...

, the crank pin

Crank pin

In a reciprocating engine, the crankpins, also known as crank journals are the journals of the big end bearings, at the ends of the connecting rods opposite to the pistons....

s are usually mounted directly on one or more pairs of driving wheel

Driving wheel

On a steam locomotive, a driving wheel is a powered wheel which is driven by the locomotive's pistons...

s, and the axle of these wheels serves as the crankshaft. The connecting rods, also called the main rods (in US practice), run between the crank pins and crossheads, where they connect to the piston rod

Piston rod

In a piston engine, a piston rod joins a piston to a connecting rod.Many internal combustion engines, and in particular all current automobile engines, do not have true piston rods, and the term piston rod is often used as a synonym for connecting rod in the context of these engines.All engines...

s. Crossheads or trunk guides are also used on large diesel engines manufactured for marine service. The similar rods between driving wheels are called coupling rods (in British practice).

The connecting rods of smaller steam locomotives are usually of rectangular cross-section but, on small locomotives, marine-type rods of circular cross-section have occasionally been used. Stephen Lewin

Stephen Lewin

Stephen Lewin of Poole, Dorset, England was a builder of steamboats and steam locomotives.-Locomotives:Only a small number of locomotives were built, including:* 0-4-0 Ant and Bee, for 20 inch gauge Great Laxey Mine Railway, Isle of Man...

, who built both locomotive and marine engines, was a frequent user of round rods. Gresley

Nigel Gresley

Sir Herbert Nigel Gresley was one of Britain's most famous steam locomotive engineers, who rose to become Chief Mechanical Engineer of the London and North Eastern Railway . He was the designer of some of the most famous steam locomotives in Britain, including the LNER Class A1 and LNER Class A4...

's A4 Pacifics, such as Mallard

LNER Class A4 4468 Mallard

Number 4468 Mallard is a London and North Eastern Railway Class A4 4-6-2 Pacific steam locomotive built at Doncaster, England in 1938. While in other respects a relatively typical member of its class, it is historically significant for being the holder of the official world speed record for steam...

, had an alloy steel connecting rod with a web that was only 0.375 in (0.9525 cm) thick.

On Western Rivers steamboats

Paddle steamer

A paddle steamer is a steamship or riverboat, powered by a steam engine, using paddle wheels to propel it through the water. In antiquity, Paddle wheelers followed the development of poles, oars and sails, where the first uses were wheelers driven by animals or humans...

, the connecting rods are properly called pitmans, and are sometimes incorrectly referred to as pitman arm

Pitman arm

The Pitman arm is a steering component in an automobile or truck.The Pitman arm is a linkage attached to the steering gear sector shaft, that converts the angular motion of the sector shaft into the linear motion needed to steer the wheels. The Pitman arm is supported by the sector shaft and...

s.

Internal combustion engines

Automobile

An automobile, autocar, motor car or car is a wheeled motor vehicle used for transporting passengers, which also carries its own engine or motor...

internal combustion engine

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

s, the connecting rods are most usually made of steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

for production engines, but can be made of T6-2024 and T651-7075 aluminum alloys (for lightness and the ability to absorb high impact at the expense of durability) or titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

(for a combination of lightness with strength, at higher cost) for high performance engines, or of cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

for applications such as motor scooters. They are not rigidly fixed at either end, so that the angle between the connecting rod and the piston can change as the rod moves up and down and rotates around the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. Connecting rods, especially in racing engines, may be called "billet" rods, if they are machined out of a solid billet

Billet (manufacturing)

Semi-finished casting products are intermediate castings produced in a foundry that need further processing before being a finished good. There are four types: ingots, billets, blooms, and slabs.-Ingot:...

of metal, rather than being cast

Casting

In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process...

.

The small end attaches to the piston pin, gudgeon pin or wrist pin, which is currently most often press fit into the connecting rod but can swivel in the piston, a "floating wrist pin" design. The big end connects to the bearing journal on the crank throw

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

, in most engines running on replaceable bearing

Plain bearing

A plain bearing, also known as a plane bearing or a friction bearing is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore the journal slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole...

shells accessible via the connecting rod bolts which hold the bearing "cap" onto the big end. Typically there is a pinhole bored through the bearing and the big end of the connecting rod so that pressurized lubricating

Lubricant

A lubricant is a substance introduced to reduce friction between moving surfaces. It may also have the function of transporting foreign particles and of distributing heat...

motor oil

Motor oil

Motor oil or engine oil is an oil used for lubrication of various internal combustion engines. The main function is to lubricate moving parts; it also cleans, inhibits corrosion, improves sealing, and cools the engine by carrying heat away from moving parts.Motor oils are derived from...

squirts out onto the thrust

Thrust

Thrust is a reaction force described quantitatively by Newton's second and third laws. When a system expels or accelerates mass in one direction the accelerated mass will cause a force of equal magnitude but opposite direction on that system....

side of the cylinder

Cylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

wall to lubricate the travel of the pistons and piston ring

Piston ring

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.The three main functions of piston rings in reciprocating engines are:...

s. Most small two-stroke engines and some single cylinder four-stroke engines avoid the need for a pumped lubrication system by using a rolling-element bearing

Rolling-element bearing

A rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing round elements between the two pieces...

instead, however this requires the crankshaft to be pressed apart and then back together in order to replace a connecting rod.

The connecting rod is under tremendous stress from the reciprocating load represented by the piston, actually stretching and being compressed with every rotation, and the load increases to the square of the engine speed increase. Failure of a connecting rod, usually called "throwing a rod" is one of the most common causes of catastrophic engine failure in cars, frequently putting the broken rod through the side of the crankcase

Crankcase

In an internal combustion engine of the reciprocating type, the crankcase is the housing for the crankshaft. The enclosure forms the largest cavity in the engine and is located below the cylinder, which in a multicylinder engine are usually integrated into one or several cylinder blocks...

and thereby rendering the engine irreparable; it can result from fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

near a physical defect in the rod, lubrication failure in a bearing due to faulty maintenance, or from failure of the rod bolts from a defect, improper tightening. Re-use of rod bolts is a common practice as long as the bolts meet manufacturer specifications. Despite their frequent occurrence on televised competitive automobile events, such failures are quite rare on production cars during normal daily driving. This is because production auto parts have a much larger factor of safety

Factor of safety

Factor of safety , also known as safety factor , is a term describing the structural capacity of a system beyond the expected loads or actual loads. Essentially, how much stronger the system is than it usually needs to be for an intended load...

, and often more systematic quality control

Quality control

Quality control, or QC for short, is a process by which entities review the quality of all factors involved in production. This approach places an emphasis on three aspects:...

.

When building a high performance engine, great attention is paid to the connecting rods, eliminating stress risers by such techniques as grinding the edges of the rod to a smooth radius, shot peening

Shot peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals. It entails impacting a surface with shot with force sufficient to create plastic deformation...

to induce compressive surface stresses (to prevent crack initiation), balancing all connecting rod/piston assemblies to the same weight and Magnaflux

Magnaflux

Magnetic Particle Inspection , developed originally by Alfred Victor de Forest and Foster Baird Doane, and developed further with the assistance of Carl E. Betz, is a method of testing ferrous metals for surface and subsurface flaws. The component being tested must be made of a ferromagnetic...

ing to reveal otherwise invisible small cracks which would cause the rod to fail under stress. In addition, great care is taken to torque the connecting rod bolts to the exact value specified; often these bolts must be replaced rather than reused. The big end of the rod is fabricated as a unit and cut or cracked in two to establish precision fit around the big end bearing shell. Therefore, the big end "caps" are not interchangeable between connecting rods, and when rebuilding an engine, care must be taken to ensure that the caps of the different connecting rods are not mixed up. Both the connecting rod and its bearing cap are usually embossed with the corresponding position number in the engine block.

Recent engines such as the Ford 4.6 liter engine and the Chrysler 2.0 liter engine, have connecting rods made using powder metallurgy

Powder metallurgy

Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape , and then heating the compressed material in a controlled atmosphere to bond the material . The powder metallurgy process generally consists of four basic steps: powder manufacture, powder...

, which allows more precise control of size and weight with less machining and less excess mass to be machined off for balancing. The cap is then separated from the rod by a fracturing process, which results in an uneven mating surface due to the grain of the powdered metal. This ensures that upon reassembly, the cap will be perfectly positioned with respect to the rod, compared to the minor misalignments which can occur if the mating surfaces are both flat.

A major source of engine wear is the sideways force exerted on the piston through the connecting rod by the crankshaft, which typically wears the cylinder

Cylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

into an oval

Oval

An oval is any curve resembling an egg or an ellipse, such as a Cassini oval. The term does not have a precise mathematical definition except in one area oval , but it may also refer to:* A sporting arena of oval shape** a cricket field...

cross-section rather than circular, making it impossible for piston ring

Piston ring

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.The three main functions of piston rings in reciprocating engines are:...

s to correctly seal against the cylinder walls. Geometrically, it can be seen that longer connecting rods will reduce the amount of this sideways force, and therefore lead to longer engine life. However, for a given engine block, the sum of the length of the connecting rod plus the piston stroke is a fixed number, determined by the fixed distance between the crankshaft axis and the top of the cylinder block where the cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

fastens; thus, for a given cylinder block longer stroke, giving greater engine displacement

Engine displacement

Engine displacement is the volume swept by all the pistons inside the cylinders of an internal combustion engine in a single movement from top dead centre to bottom dead centre . It is commonly specified in cubic centimeters , litres , or cubic inches...

and power, requires a shorter connecting rod (or a piston with smaller compression height), resulting in accelerated cylinder wear.

Compound rods

V12 engine

A V12 engine is a V engine with 12 cylinders mounted on the crankcase in two banks of six cylinders, usually but not always at a 60° angle to each other, with all 12 pistons driving a common crankshaft....

layout have little space available for many connecting rod journals on a limited length of crankshaft. This is a difficult compromise to solve and its consequence has often led to engines being regarded as failures (Sunbeam Arab

Sunbeam Arab

|-See also:-Bibliography:* Lumsden, Alec. British Piston Engines and their Aircraft. Marlborough, Wiltshire: Airlife Publishing, 2003. ISBN 1-85310-294-6.* Brew, Alec. Sunbeam Aero-Engines. Airlife Publishing. Shrewsbury. ISBN 1 84037 023 8...

, Rolls-Royce Vulture

Rolls-Royce Vulture

|-See also:-Bibliography:* Gunston, Bill. World Encyclopaedia of Aero Engines. Cambridge, England. Patrick Stephens Limited, 1989. ISBN 1-85260-163-9...

).

The simplest solution, almost universal in road car engines, is to use simple rods where cylinders from both banks share a journal. This requires the rod bearings to be narrower, increasing bearing load and the risk of failure in a high-performance engine. This also means the opposing cylinders are not exactly in line with each other.

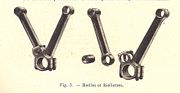

In certain engine types, master/slave rods are used rather than the simple type shown in the picture above. The master rod carries one or more ring pins to which are bolted the much smaller big ends of slave rods on other cylinders. Certain designs of V engine

V engine

A V engine, or Vee engine is a common configuration for an internal combustion engine. The cylinders and pistons are aligned, in two separate planes or 'banks', so that they appear to be in a "V" when viewed along the axis of the crankshaft...

s use a master/slave rod for each pair of opposite cylinders. A drawback of this is that the stroke of the subsidiary rod is slightly shorter than the master, which increases vibration in a vee engine, catastrophically so for the Sunbeam Arab

Sunbeam Arab

|-See also:-Bibliography:* Lumsden, Alec. British Piston Engines and their Aircraft. Marlborough, Wiltshire: Airlife Publishing, 2003. ISBN 1-85310-294-6.* Brew, Alec. Sunbeam Aero-Engines. Airlife Publishing. Shrewsbury. ISBN 1 84037 023 8...

.

Radial engine

Radial engine

The radial engine is a reciprocating type internal combustion engine configuration in which the cylinders point outward from a central crankshaft like the spokes on a wheel...

s typically have a master rod for one cylinder and multiple slave rods for all the other cylinders in the same bank.

The usual solution for high-performance aero-engines is a "forked" connecting rod. One rod is split in two at the big end and the other is thinned to fit into this fork. The journal is still shared between cylinders. The Rolls-Royce Merlin

Rolls-Royce Merlin

The Rolls-Royce Merlin is a British liquid-cooled, V-12, piston aero engine, of 27-litre capacity. Rolls-Royce Limited designed and built the engine which was initially known as the PV-12: the PV-12 became known as the Merlin following the company convention of naming its piston aero engines after...

used this "fork-and-blade" style.

External links

- Kinematic Models for Design Digital Library (KMODDL) - Movies and photos of hundreds of working mechanical-systems models at Cornell University. Also includes an e-book library of classic texts on mechanical design and engineering.