Case hardening

Encyclopedia

Hardening (metallurgy)

Hardening is a metallurgical and metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain...

the surface of a metal, often a low carbon steel, by infusing elements into the material's surface, forming a thin layer of a harder alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

. Case hardening is usually done after the part in question has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding

Pattern welding

Pattern welding is the practice in sword and knife making of forming a blade of several metal pieces of differing composition that are forge-welded together and twisted and manipulated to form a pattern. Often called Damascus steel, blades forged in this manner often display bands of slightly...

or similar process. The term face hardening is also used to describe this technique, when discussing modern armour

Armour

Armour or armor is protective covering used to prevent damage from being inflicted to an object, individual or a vehicle through use of direct contact weapons or projectiles, usually during combat, or from damage caused by a potentially dangerous environment or action...

.

History

Early ironIron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

melting made use of bloomeries

Bloomery

A bloomery is a type of furnace once widely used for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. A bloomery's product is a porous mass of iron and slag called a bloom. This mix of slag and iron in the bloom is termed sponge iron, which...

, which produced two layers of metal: one with a very low carbon content that is worked into wrought iron

Wrought iron

thumb|The [[Eiffel tower]] is constructed from [[puddle iron]], a form of wrought ironWrought iron is an iron alloy with a very low carbon...

, and the rest a high carbon cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

. Since the high carbon iron is hot short, meaning it fractures and crumbles when forge

Forge

A forge is a hearth used for forging. The term "forge" can also refer to the workplace of a smith or a blacksmith, although the term smithy is then more commonly used.The basic smithy contains a forge, also known as a hearth, for heating metals...

d, it was not useful without more smelting. The wrought iron, with nearly no carbon in it, was very malleable and ductile, but not very hard.

Case hardening involves packing the low-carbon iron within a substance high in carbon, then heating this pack to encourage carbon migration into the surface of the iron. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. The resulting product combines much of the toughness of a low-carbon steel core, with the hardness and wear resistance of the outer high-carbon steel.

The traditional method of applying the carbon to the surface of the iron involved packing the iron in a mixture of ground bone

Bone

Bones are rigid organs that constitute part of the endoskeleton of vertebrates. They support, and protect the various organs of the body, produce red and white blood cells and store minerals. Bone tissue is a type of dense connective tissue...

and charcoal

Charcoal

Charcoal is the dark grey residue consisting of carbon, and any remaining ash, obtained by removing water and other volatile constituents from animal and vegetation substances. Charcoal is usually produced by slow pyrolysis, the heating of wood or other substances in the absence of oxygen...

, or a combination of leather

Leather

Leather is a durable and flexible material created via the tanning of putrescible animal rawhide and skin, primarily cattlehide. It can be produced through different manufacturing processes, ranging from cottage industry to heavy industry.-Forms:...

, hooves

Hoof

A hoof , plural hooves or hoofs , is the tip of a toe of an ungulate mammal, strengthened by a thick horny covering. The hoof consists of a hard or rubbery sole, and a hard wall formed by a thick nail rolled around the tip of the toe. The weight of the animal is normally borne by both the sole...

, salt

Salt

In chemistry, salts are ionic compounds that result from the neutralization reaction of an acid and a base. They are composed of cations and anions so that the product is electrically neutral...

and urine

Urine

Urine is a typically sterile liquid by-product of the body that is secreted by the kidneys through a process called urination and excreted through the urethra. Cellular metabolism generates numerous by-products, many rich in nitrogen, that require elimination from the bloodstream...

, all inside a well-sealed box. This carburizing package is then heated to a high temperature, but still under the melting point of the iron, and left at that temperature for a length of time. The longer the package is held at the high temperature, the deeper the carbon will diffuse into the surface. Different depths of hardening is desirable for different purposes: sharp tools need deep hardening to allow grinding and resharpening without exposing the soft core, while machine parts like gears might need only shallow hardening for increased wear resistance.

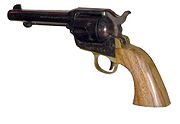

The resulting case hardened part may show distinct surface discoloration. The steel darkens significantly, and shows a mottled pattern of black, blue and purple, caused by the various compounds formed from impurities in the bone and charcoal. This oxide surface works similarly to bluing

Bluing (steel)

Bluing is a passivation process in which steel is partially protected against rust, and is named after the blue-black appearance of the resulting protective finish. True gun bluing is an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface...

, providing a degree of corrosion resistance, as well as an attractive finish. Case coloring refers to this pattern and is commonly encountered as a decorative finish on replica

Replica

A replica is a copy closely resembling the original concerning its shape and appearance. An inverted replica complements the original by filling its gaps. It can be a copy used for historical purposes, such as being placed in a museum. Sometimes the original never existed. For example, Difference...

historic firearm

Firearm

A firearm is a weapon that launches one, or many, projectile at high velocity through confined burning of a propellant. This subsonic burning process is technically known as deflagration, as opposed to supersonic combustion known as a detonation. In older firearms, the propellant was typically...

s.

With modern steelworking techniques, it is possible to make homogeneous steels of low to high carbon content, removing much of the original motivation for case hardening. However, the heterogeneous nature of case hardened steel may still be desirable, as it can combine both extreme hardness and extreme toughness, something which is not readily matched by homogeneous alloys.

Chemistry

Carbon itself is solid at case-hardening temperatures and so is immobile. Transport to the surface of the steel was as gaseous carbon monoxideCarbon monoxide

Carbon monoxide , also called carbonous oxide, is a colorless, odorless, and tasteless gas that is slightly lighter than air. It is highly toxic to humans and animals in higher quantities, although it is also produced in normal animal metabolism in low quantities, and is thought to have some normal...

, generated by the breakdown of the carburising compound and the oxygen packed into the sealed box. This takes place with pure carbon, but unworkably slowly. Although oxygen is required for this process it's re-circulated through the CO cycle and so can be carried out inside a sealed box. The sealing is necessary to stop the CO either leaking out, or being oxidised to CO2 by excess outside air.

Adding an easily decomposed carbonate "energiser" such as barium carbonate

Barium carbonate

Barium carbonate , also known as witherite, is a chemical compound used in rat poison, bricks, ceramic glazes and cement.Witherite crystallizes in the orthorhombic system...

breaks down to BaO + CO2 and this encourages the reaction

- C (from the donor) + CO2 <—> 2 CO

increasing the overall abundance of CO and the activity of the carburising compound.

It's 'common knowledge

Common knowledge

Common knowledge is knowledge that is known by everyone or nearly everyone, usually with reference to the community in which the term is used. Common knowledge need not concern one specific subject, e.g., science or history. Rather, common knowledge can be about a broad range of subjects, including...

' that case-hardening was done with bone, but this is misleading. Although bone was used, the main carbon donor was hoof and horn. Bone contains some carbonates, but is mainly calcium phosphate (as hydroxylapatite

Hydroxylapatite

Hydroxylapatite, also called hydroxyapatite , is a naturally occurring mineral form of calcium apatite with the formula Ca53, but is usually written Ca1062 to denote that the crystal unit cell comprises two entities. Hydroxylapatite is the hydroxyl endmember of the complex apatite group...

). This doesn't have the beneficial effect on encouraging CO production and it can also supply phosphorus

Phosphorus

Phosphorus is the chemical element that has the symbol P and atomic number 15. A multivalent nonmetal of the nitrogen group, phosphorus as a mineral is almost always present in its maximally oxidized state, as inorganic phosphate rocks...

as an impurity into the steel alloy.

Modern use

Both carbon and alloy steels are suitable for case-hardening; typically mild steels are used, with low carbonCarbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

content, usually less than 0.3% (see plain-carbon steel

Plain-carbon steel

Carbon steel, also called plain-carbon steel, is steel where the main interstitial alloying constituent is carbon. The American Iron and Steel Institute defines carbon steel as: "Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt,...

for more information). These mild steels are not normally hardenable due to the low quantity of carbon, so the surface of the steel is chemically altered to increase the hardenability. Case hardened steel is formed by diffusing carbon (carburization

Carburization

Carburizing, spelled carburising in the UK, is a heat treatment process in which iron or steel is heated in the presence of another material which liberates carbon as it decomposes. Depending on the amount of time and temperature, the affected area can vary in carbon content...

), nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

(nitriding) and/or boron

Boron

Boron is the chemical element with atomic number 5 and the chemical symbol B. Boron is a metalloid. Because boron is not produced by stellar nucleosynthesis, it is a low-abundance element in both the solar system and the Earth's crust. However, boron is concentrated on Earth by the...

(boriding) into the outer layer of the steel at high temperature, and then heat treating the surface layer to the desired hardness.

The term case hardening is derived from the practicalities of the carburization process itself, which is essentially the same as the ancient process. The steel work piece is placed inside a case packed tight with a carbon-based case hardening compound. This is collectively known as a carburizing pack. The pack is put inside a hot furnace for a variable length of time. Time and temperature determines how deep into the surface the hardening extends. However, the depth of hardening is ultimately limited by the inability of carbon to diffuse deeply into solid steel, and a typical depth of surface hardening with this method is up to 1.5 mm. Other techniques are also used in modern carburizing, such as heating in a carbon-rich atmosphere. Small items may be case hardened by repeated heating with a torch and quenching in a carbon rich medium, such as the commercial products Kasenit / Casenite or "Cherry Red". Older formulations of these compounds contain potentially toxic cyanide

Cyanide

A cyanide is a chemical compound that contains the cyano group, -C≡N, which consists of a carbon atom triple-bonded to a nitrogen atom. Cyanides most commonly refer to salts of the anion CN−. Most cyanides are highly toxic....

compounds, such as ferrocyanide

Ferrocyanide

Ferrocyanide is the name of the anion Fe64−. In aqueous solutions, this coordination complex is relatively unreactive. It is usually available as the salt potassium ferrocyanide, which has the formula K4Fe6....

compounds, while the more recent types such as Cherry Red do not.

Flame and induction hardening

Flame or induction hardening are processes in which the surface of the steel is heated to high temperatures (by direct application of a flame, or by induction heatingInduction heating

Induction heating is the process of heating an electrically conducting object by electromagnetic induction, where eddy currents are generated within the metal and resistance leads to Joule heating of the metal...

) then cooled rapidly, generally using water; this creates a "case" of martensite

Martensite

Martensite, named after the German metallurgist Adolf Martens , most commonly refers to a very hard form of steel crystalline structure, but it can also refer to any crystal structure that is formed by displacive transformation. It includes a class of hard minerals occurring as lath- or...

on the surface. A carbon content of 0.3–0.6 wt% C is needed for this type of hardening.

Typical uses are for the shackle of a lock, where the outer layer is hardened to be file resistant, and mechanical gears, where hard gear mesh surfaces are needed to maintain a long service life while toughness is required to maintain durability and resistance to catastrophic failure.

Carburizing

Carburizing is a process used to case harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process steel is introduced to a carbon rich environment and elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil.Carburization is a diffusion-controlled process, so the longer the steel is held in the carbon-rich environment the greater the carbon penetration will be and the higher the carbon content. The carburized section will have a carbon content high enough that it can be hardened again through flame or induction hardening.

It's possible to carburize only a portion of a part, either by protecting the rest by a process such as copper plating, or by applying a carburizing medium to only a section of the part.

The carbon can come from a solid, liquid or gaseous source; if it comes from a solid source the process is called pack carburizing. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. A heating period of a few hours might form a high-carbon layer about one millimeter thick.

Liquid carburizing involves placing parts in a bath of a molten carbon-containing material, often a metal cyanide; gas carburizing involves placing the parts in a furnace maintained with a methane-rich interior.

Nitriding

Nitriding heats the steel part to 482 – in an atmosphere of ammonia gas and dissociated ammonia. The time the part spends in this environment dictates the depth of the case. The hardness is achieved by the formation of nitrides. Nitride forming elements must be present for this method to work; these elements include chromiumChromium

Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

, molybdenum

Molybdenum

Molybdenum , is a Group 6 chemical element with the symbol Mo and atomic number 42. The name is from Neo-Latin Molybdaenum, from Ancient Greek , meaning lead, itself proposed as a loanword from Anatolian Luvian and Lydian languages, since its ores were confused with lead ores...

, and aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

. The advantage of this process is it causes little distortion, so the part can be case hardened after being quenched, tempered and machined.

Cyaniding

Cyaniding is a case hardening process that is fast and efficient; it is mainly used on low carbon steels. The part is heated to 871-954 °C (1600-1750 °F) in a bath of sodium cyanideSodium cyanide

Sodium cyanide is an inorganic compound with the formula NaCN. This highly toxic colorless salt is used mainly in gold mining but has other niche applications...

and then is quenched and rinsed, in water or oil, to remove any residual cyanide.

- 2NaCN + O2 → 2NaCNO

- 2NaCNO + O2 → NaCO3 +CO + 2N

- 2CO → CO2 + C

This process produces a thin, hard shell (between 0.254 - 0.762 mm [0.010 and 0.030 inches]) that is harder than the one produced by carburizing, and can be completed in 20 to 30 minutes compared to several hours so the parts have less opportunity to become distorted. It is typically used on small parts such as bolts, nuts, screws and small gears. The major drawback of cyaniding is that cyanide salts are poisonous.

Carbonitriding

Carbonitriding is similar to cyaniding except a gaseous atmosphere of ammonia and hydrocarbons is used instead of sodium cyanide. If the part is to be quenched then the part is heated to 775 –; if not then the part is heated to 649 –.Ferritic nitrocarburizing

Ferritic nitrocarburizing diffuses mostly nitrogen and some carbon into the case of a workpiece below the critical temperature, approximately 650 °C (1,202 °F). Under the critical temperature the workpiece's microstructure does not convert to an austenitic phase, but stays in the ferritic phase, which is why it is called ferritic nitrocarburization.Applications

Parts that are subject to high pressures and sharp impacts are still commonly case hardened. Examples include firing pinFiring pin

A firing pin or striker is part of the firing mechanism used in a firearm or explosive device e.g. an M14 landmine or bomb fuze. Firing pins may take many forms, though the types used in landmines, bombs, grenade fuzes or other single-use devices generally have a sharpened point...

s and rifle bolt

Bolt (firearm)

A bolt is a mechanical part of a firearm that blocks the rear of the chamber while the propellant burns.In manually-operated firearms, such as bolt-action, lever-action, and pump-action rifles and shotguns, the bolt is held fixed by its locking lugs during firing, forcing all the expanding gas...

faces, or engine camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

s. In these cases, the surfaces requiring the hardness may be hardened selectively, leaving the bulk of the part in its original tough state.

Firearms were a common item case hardened in the past, as they required precision machining best done on low carbon alloys, yet needed the hardness and wear resistance of a higher carbon alloy. Many modern replicas of older firearms, particularly single action revolvers, are still made with case hardened frames, or with case coloring, which simulates the mottled pattern left by traditional charcoal and bone case hardening.

Another common application of case hardening is on screws, particularly self-drilling screws. In order for the screws to be able to drill, cut and tap into other materials like steel, the drill point and the forming threads must be harder than the material(s) that it is drilling into. However, if the whole screw is uniformly hard, it will become very brittle and it will break easily. This is overcome by ensuring that only the case is hardened and the core remains relatively soft. For screws and fasteners, case hardening is less complicated as it is achieved by heating and quenching in the form of heat treatment

For theft prevention, lock shackles and chains are often case hardened to resist cutting, whilst remaining less brittle inside to resist impacts. As case hardened components are difficult to machine, they are generally shaped before hardening.

See also

- Differential hardeningDifferential hardeningDifferential hardening is a method used in forging swords and knives to increase the hardness of the edge without making the whole blade brittle. To achieve this, the edge is cooled more rapidly than the spine by adding a heat insulator to the spine before quenching. Clay or another material is...

- Diffusion hardeningDiffusion hardeningDiffusion hardening is a process used in manufacturing that increases the hardness of steels. In diffusion hardening, diffusion occurs between a steel with a low carbon content and a carbon-rich environment to increase the carbon content of the steel and ultimately harden the workpiece...

- Quench polish quenchQuench Polish QuenchQuench polish quench is a specialized type of nitrocarburizing case hardening that increases corrosion resistance, originally developed by the Kolene Company...

- Shot peeningShot peeningShot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals. It entails impacting a surface with shot with force sufficient to create plastic deformation...

- Surface engineeringSurface engineeringSurface engineering is the sub-discipline of materials science which deals with the surface of solid matter. It has applications to chemistry, mechanical engineering, and electrical engineering ....