Leadscrew

Encyclopedia

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

designed to translate turning motion into linear motion

Linear motion

Linear motion is motion along a straight line, and can therefore be described mathematically using only one spatial dimension. The linear motion can be of two types: uniform linear motion, with constant velocity or zero acceleration; non uniform linear motion, with variable velocity or non-zero...

. Common applications are machine slides (such as in machine tool

Machine tool

A machine tool is a machine, typically powered other than by human muscle , used to make manufactured parts in various ways that include cutting or certain other kinds of deformation...

s), vises

Vise (tool)

A vise or vice is a mechanical screw apparatus used for holding or clamping a work piece to allow work to be performed on it with tools such as saws, planes, drills, mills, screwdrivers, sandpaper, etc. Vises usually have one fixed jaw and another, parallel, jaw which is moved towards or away from...

, presses, and jacks.

Leadscrews are manufactured in the same way as other thread forms.

A lead screw can be used in conjunction with split nut

Split nut

A split nut is a nut that consists of two pieces which can be clamped together to engage the thread of the nut with the bolt, or released, to allow the nut to move along the bolt without turning the bolt. The two pieces have chamfered ends . The nut is split lengthwise so that it may be opened for...

.

Types

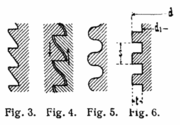

Power screws are classified by the geometry of their threadScrew thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread...

. V-threads are less suitable for leadscrews than others such as Acme because they have more friction between the threads. Their threads are designed to induce this friction to keep the fastener from loosening. Leadscrews, on the other hand, are designed to minimize friction. Therefore, in most commercial and industrial use, V-threads are avoided for leadscrew use. Nevertheless, V-threads are sometimes successfully used as leadscrews, for example on microlathes and micromills.

Square thread

Square threads are named after their square geometry. They are the most efficientMechanical efficiency

Mechanical efficiency measures the effectiveness of a machine in transforming the energy and power that is input to the device into an output force and movement...

, having the least friction

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

, so they are often used for screws that carry high power. But they are also the most difficult to machine, and are thus the most expensive.

Acme thread

Thread angle

The thread angle of a screw is the angle between the threads. This is a defining factor for the shape of a screw thread. Standard values include:...

, which is easier to machine than square threads. They are not as efficient as square threads, due to the increased friction induced by the thread angle.

Buttress thread

Buttress threads are of a triangular shape. These are used where the load force on the screw is only applied in one direction. They are as efficient as square threads in these applications, but are easier to manufacture.Characteristics

A leadscrew nutNut (hardware)

A nut is a type of hardware fastener with a threaded hole. Nuts are almost always used opposite a mating bolt to fasten a stack of parts together. The two partners are kept together by a combination of their threads' friction, a slight stretch of the bolt, and compression of the parts...

and screw mate with rubbing surfaces, and consequently they have a relatively high friction

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

and stiction

Stiction

Stiction is the static friction that needs to be overcome to enable relative motion of stationary objects in contact. The term is a portmanteau of the term "static friction", perhaps also influenced by the verb "stick"....

compared to mechanical parts which mate with rolling surfaces and bearings. Leadscrew efficiency is typically between 25 and 70%, with higher pitch screws tending to be more efficient. A higher performing but more expensive alternative is the ball screw

Ball screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with...

.

The high internal friction means that leadscrew systems are not usually capable of continuous operation at high speed, as they will overheat. Due to inherently high stiction, the typical screw is self-locking (i.e. when stopped, a linear force on the nut will not apply a torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

to the screw) and are often used in applications where backdriving is unacceptable, like holding vertical loads or in hand cranked machine tools.

Leadscrews are typically used well greased, but, with an appropriate nut, they may be run dry with somewhat higher friction. There is often a choice of nuts, and manufacturers will specify screw and nut combination as a set.

The mechanical advantage

Mechanical advantage

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. Ideally, the device preserves the input power and simply trades off forces against movement to obtain a desired amplification in the output force...

of a leadscrew is determined by the screw pitch and lead

Lead (engineering)

Lead is the axial advance of a helix or screw during one complete turn The lead for a screw thread is the axial travel for a single revolution....

. For multi-start screws the mechanical advantage is lower, but the traveling speed is higher.

Backlash

Backlash (engineering)

In mechanical engineering, backlash, sometimes called lash or play, is clearance between mating components, sometimes described as the amount of lost motion due to clearance or slackness when movement is reversed and contact is re-established...

can be reduced with the use of a second nut, or a tensioning spring, to create a static loading force known as preload

Preload

In cardiac physiology, preload is the end volumetric pressure that stretches the right or left ventricle of the heart to its greatest geometric dimensions under variable physiologic demand...

; alternately, the nut can be cut across its diameter and preloaded by clamping that cut back together.

A leadscrew with a sufficiently high helix angle can back drive: forces on the nut applied parallel to such a leadscrew will cause the leadscrew, if it is not otherwise held in place, to rotate. Such a tendency to backdrive depends on the thread helix angle

Helix angle

In mechanical engineering, a helix angle is the angle between any helix and an axial line on its right, circular cylinder or cone. Common applications are screws, helical gears, and worm gears....

, coefficient of friction of the interface of the components (screw/nut) and the included angle of the thread form. In general, a steel acme thread and bronze nut will back drive when the helix angle of the thread is greater than 20°.

Advantages & disadvantages

The advantages of a leadscrew are:- Large load carrying capability

- Compact

- Simple to design

- Easy to manufacture; no specialized machinery is required

- Large mechanical advantage

- Precise and accurate linear motion

- Smooth, quiet, and low maintenance

- Minimal number of parts

- Most are self-locking

The disadvantages are that most are not very efficient. Due to the low efficiency they cannot be used in continuous power transmission applications. They also have a high degree for friction on the threads, which can wear the threads out quickly. For square threads, the nut must be replaced; for trapezoidal threads, a split nut

Split nut

A split nut is a nut that consists of two pieces which can be clamped together to engage the thread of the nut with the bolt, or released, to allow the nut to move along the bolt without turning the bolt. The two pieces have chamfered ends . The nut is split lengthwise so that it may be opened for...

may be used to compensate for the wear.

Alternatives

Alternatives to actuation by leadscrew include:- Ball screwBall screwA ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with...

s and roller screwRoller screwA roller screw, also known as a planetary roller screw or satellite roller screw, is a low-friction precision mechanical device for converting rotational motion to linear motion, or vice versa. Planetary roller screws are most commonly used as the actuator mechanism in electro-mechanical linear...

s (sometimes categorized as types of leadscrew rather than in contradistinction) - Fluid powerFluid powerFluid power is the use of fluids under pressure to generate, control, and transmit power. Fluid power is subdivided into hydraulics using a liquid such as mineral oil or water, and pneumatics using a gas such as air or other gases...

(i.e., hydraulicsHydraulicsHydraulics is a topic in applied science and engineering dealing with the mechanical properties of liquids. Fluid mechanics provides the theoretical foundation for hydraulics, which focuses on the engineering uses of fluid properties. In fluid power, hydraulics is used for the generation, control,...

and pneumaticsPneumaticsPneumatics is a branch of technology, which deals with the study and application of use of pressurized gas to effect mechanical motion.Pneumatic systems are extensively used in industry, where factories are commonly plumbed with compressed air or compressed inert gases...

) - GearGearA gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

trains (e.g., worm driveWorm driveA worm drive is a gear arrangement in which a worm meshes with a worm gear...

s, rack-and-pinionRack and pinionA rack and pinion is a type of linear actuator that comprises a pair of gears which convert rotational motion into linear motion. A circular gear called "the pinion" engages teeth on a linear "gear" bar called "the rack"; rotational motion applied to the pinion causes the rack to move, thereby...

drives) - ElectromagneticElectromagnetismElectromagnetism is one of the four fundamental interactions in nature. The other three are the strong interaction, the weak interaction and gravitation...

actuation (e.g., solenoidSolenoidA solenoid is a coil wound into a tightly packed helix. In physics, the term solenoid refers to a long, thin loop of wire, often wrapped around a metallic core, which produces a magnetic field when an electric current is passed through it. Solenoids are important because they can create...

s) - Piezoelectric actuation

Mechanics

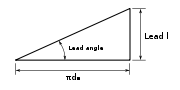

long and the height is the lead (pictured to the right). The force of the load is directed downward, the normal force is perpendicular to the hypotenuse of the triangle, the frictional force is directed in the opposite direction of the direction of motion (perpendicular to the normal force or along the hypotenuse), and an imaginary "effort" force is acting horizontally in the direction opposite the direction of the frictional force. Using this free-body diagram the torque required to lift or lower a load can be calculated:

long and the height is the lead (pictured to the right). The force of the load is directed downward, the normal force is perpendicular to the hypotenuse of the triangle, the frictional force is directed in the opposite direction of the direction of motion (perpendicular to the normal force or along the hypotenuse), and an imaginary "effort" force is acting horizontally in the direction opposite the direction of the frictional force. Using this free-body diagram the torque required to lift or lower a load can be calculated:

| Screw material | | Nut material | |||

|---|---|---|---|---|

| Steel | Bronze | Brass | Cast iron | |

| Steel, dry | 0.15–0.25 | 0.15–0.23 | 0.15–0.19 | 0.15–0.25 |

| Steel, machine oil | 0.11–0.17 | 0.10–0.16 | 0.10–0.15 | 0.11–0.17 |

| Bronze | 0.08–0.12 | 0.04–0.06 | - | 0.06–0.09 |

where

- T = torque

- F = load on the screw

- dm = mean diameter

= coefficient of friction (common values are found in the table to the right)

= coefficient of friction (common values are found in the table to the right)- l = lead

= friction angle

= friction angle = lead angle

= lead angle

Based on the Tlower equation it can be found that the screw is self-locking when the coefficient of friction is greater than the tangent of the lead angle. An equivalent comparison is when the friction angle is greater than the lead angle (

). When this is not true the screw will back-drive, or lower under the weight of the load.

). When this is not true the screw will back-drive, or lower under the weight of the load.The efficiency, calculated using the torque equations above, is:

For screws that have a thread angle other than zero, such as a trapezoidal thread, this must be compensated as it increases the frictional forces. The equations below takes this into account:

where

is one half the thread angle.

is one half the thread angle.If the leadscrew has a collar in which the load rides on then the frictional forces between the interface must be accounted for in the torque calculations as well. For the following equation the load is assumed to be concentrated at the mean collar diameter (dc):

where

is the coefficient of friction between the collar on the load and dc is the mean collar diameter. For collars that use thrust bearings the frictional loss is negligible and the above equation can be ignored.

is the coefficient of friction between the collar on the load and dc is the mean collar diameter. For collars that use thrust bearings the frictional loss is negligible and the above equation can be ignored.| Material combination | Starting  | Running  |

|---|---|---|

| Soft steel / cast iron | 0.17 | 0.12 |

| Hardened steel / cast iron | 0.15 | 0.09 |

| Soft steel / bronze | 0.10 | 0.08 |

| Hardened steel / bronze | 0.08 | 0.06 |

Running speed

| Nut material | | Safe loads [psi] | | Speed |

|---|---|---|

| Bronze | 2500–3500 | Low speed |

| Bronze | 1600–2500 | 10 fpm |

| Cast iron | 1800–2500 | 8 fpm |

| Bronze | 800–1400 | 20–40 fpm |

| Cast iron | 600–1000 | 20–40 fpm |

| Bronze | 150–240 | 50 fpm |

The running speed for a leadscrew (or ball screw) is typically limited to, at most, 80% of the calculated critical speed

Critical speed

In solid mechanics, in the field of rotordynamics, the critical speed is the theoretical angular velocity which excites the natural frequency of a rotating object, such as a shaft, propeller, leadscrew, or gear. As the speed of rotation approaches the object's natural frequency, the object begins...

.

The critical speed is the speed that excites the natural frequency of the screw.

For a steel leadscrew or steel ballscrew, the critical speed is approximately

where

- N = critical speed in RPM

- dc = smallest (root) diameter of the leadscrew in inches

- L = length between bearing supports in inches

- C = .36 for one end fixed, one end free

- C = 1.00 for both ends simple

- C = 1.47 for one end fixed, one end simple

- C = 2.23 for both ends fixed