Vise (tool)

Encyclopedia

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

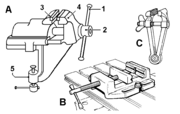

apparatus used for holding or clamping a work piece to allow work to be performed on it with tools such as saw

Saw

A saw is a tool that uses a hard blade or wire with an abrasive edge to cut through softer materials. The cutting edge of a saw is either a serrated blade or an abrasive...

s, plane

Plane (tool)

A hand plane is a tool for shaping wood. When powered by electricity, the tool may be called a planer. Planes are used to flatten, reduce the thickness of, and impart a smooth surface to a rough piece of lumber or timber. Planing is used to produce horizontal, vertical, or inclined flat surfaces on...

s, drill

Drill

A drill or drill motor is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for drilling holes in various materials or fastening various materials together with the use of fasteners. The attachment is gripped by a chuck at one end of...

s, mill

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

s, screwdriver

Screwdriver

A screwdriver is a tool for driving screws and often rotating other machine elements with the mating drive system. The screwdriver is made up of a head or tip, which engages with a screw, a mechanism to apply torque by rotating the tip, and some way to position and support the screwdriver...

s, sandpaper

Sandpaper

Sandpaper, also known as glasspaper, is a heavy paper with abrasive material attached to its surface.Sandpaper is part of the "coated abrasives" family of abrasive products. It is used to remove small amounts of material from surfaces, either to make them smoother , to remove a layer of material...

, etc. Vises usually have one fixed jaw and another, parallel, jaw which is moved towards or away from the fixed jaw by the screw.

Types

Without qualification, "vise" usually refers to a bench vise with flat, parallel jaws, attached to a workbenchWorkbench

A workbench is sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewelers benches to the huge benches used by staircase makers...

. There are two main types: a woodworking vise and engineer's vise. The woodworker's bench vise main characteristic is its integration into the bench. An engineer's bench vise is usually clamped or bolted onto the top of the bench.

Woodworking vises

Woodworking

Woodworking is the process of building, making or carving something using wood.-History:Along with stone, mud, and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood...

, the jaws are made of wood, plastic or from metal, in the latter case they are usually faced with wood to avoid marring the work piece. The top edges of the jaws are typically brought flush with the bench top by the extension of the wooden face above the top of the iron moveable jaw. This jaw may include a dog hole to hold a bench dog

Bench dog

A bench dog is an accessory used on a woodworking workbench to allow clamping of wooden items whilst being worked.At its most basic a bench dog is simply a peg which is installed in a corresponding dog hole in the top of a bench...

. In modern metal woodworkers' vises, a split nut

Nut (hardware)

A nut is a type of hardware fastener with a threaded hole. Nuts are almost always used opposite a mating bolt to fasten a stack of parts together. The two partners are kept together by a combination of their threads' friction, a slight stretch of the bolt, and compression of the parts...

is often used. The nut in which the screw turns is in two parts so that, by means of a lever, it can be removed from the screw and the moveable jaw can be quickly slid into a suitable position at which point the nut is again closed onto the screw so that the vise may be closed firmly onto the work.

Engineer's vises

Fitter

Fitter may refer to:* Fitter , a Soviet attack aircraft* Fitter , a person who uses machine tools to make or modify parts* Comparative of the adjective "fit"-People named Fitter:* Alastair Fitter, British ecologist...

's vise, is used in metalworking

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

applications. The jaws are made of soft or hard metal. The vise is bolted onto the top surface of the bench with the face of the fixed jaws just forward of the front edge of the bench. The bench height should be such that the top of the vise jaws is at or just below the elbow height of the user when standing upright. The vise may include other features such as a small anvil

Anvil

An anvil is a basic tool, a block with a hard surface on which another object is struck. The inertia of the anvil allows the energy of the striking tool to be transferred to the work piece. In most cases the anvil is used as a forging tool...

on the back of its body.

The nut in which the screw turns may be split so that, by means of a lever, it can be removed from the screw and the screw and moveable jaw quickly slid into a suitable position at which point the nut is again closed onto the screw. The disadvantage to this system is lower precision, as compared to a solid screw system. Vise screws are usually either of an Acme thread form or a buttress thread

Buttress thread

The buttress thread form, also known as the breech-lock thread form, refers to two different thread profiles. One is a type of leadscrew and the other is a type of hydraulic sealing thread form...

. Those with a quick-release nut use a buttress thread. Some vises have a hydraulic or pneumatic screw, making setup not only faster, but more accurate as human error is reduced.

For large parts, an array of regular machine vises may be set up to hold a part that is too long for one vise to hold. The vises' fixed jaws are aligned by means of a dial indicator

Dial indicator

Dial indicators, also known as dial gauges and probe indicators, are instruments used to accurately measure small linear distances, and are frequently used in industrial and mechanical processes...

so that there is a common reference plane.

For multiple parts, several options exist, and all machine vise manufacturers have lines of vises available for high production work:

- The first step is a two clamp vise, where the fixed jaw is in the center of the vise and movable jaws ride on the same screw to the outside.

- The next step up is the modular vise. Modular vises can be arranged and bolted together in a grid, with no space between them. This allows the greatest density of vises on a given work surface. This style vise also comes in a two clamp variety.

- Tower vises are vertical vises used in horizontal machining centers. They have one vise per side, and come in single or dual clamping station varieties. A dual clamping tower vise, for example, will hold eight relatively large parts without the need for a tool change.

- Tombstone fixtures follow the same theory as a tower vise. Tombstones allow four surfaces of vises to be worked on one rotary table pallet. A tombstone is a large, accurate, hardened block of metal that is bolted to the CNC pallet. The surface of the tombstone has holes to accommodate modular vises across all four faces on a pallet that can rotate to expose those faces to the machine spindle.

- New work holding fixtures are becoming available for five-axis machining centers. These specialty vises allow the machine to work on surfaces that would normally be obscured when mounted in a traditional or tombstone vise setup.

Jaws

Grinding (abrasive cutting)

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.A wide variety of machines are used for grinding:* Hand-cranked knife-sharpening stones * Handheld power tools such as angle grinders and die grinders...

flat and smooth to increase accuracy. The latter relies on pressure for gripping, instead of a rough surface. An unskilled operator has the tendency to over-tighten jaws, leading to part deformation and error in the finished workpiece.

Soft jaws are usually made from a soft metal (usually aluminum), plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

, or wood

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

. They are used to either hold delicate workpieces or cut to hold specifically shaped workpieces. These specifically cut jaws are often used in place of fixture

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. What makes a fixture unique is that each one is built to fit a particular part or shape. The main purpose of a fixture is to locate and in some cases hold a workpiece during either a machining operation or some...

s and most commonly used in gang operations. They are also used for rapid change-over type set-ups since they can be easily engraved with the part number, the job number, or other information relevant to the job being run. Soft jaws are considered a consumable item, because they are discarded or recycled after multiple uses.

Others

Other kinds of vise include:- hand vises

- machine vises - drill vises (lie flat on a drill press bed). Vises of the same general form are used also on milling machines and grinding machines.

- compound slide vises are more complex machine vises. They allow speed and precision in the placement of the work.

- cross vises, which can be adjusted using leadscrewLeadscrewA leadscrew , also known as a power screw or translation screw, is a screw designed to translate turning motion into linear motion...

s in the X and Y axes; these are useful if many holes need to be drilled in the same workpiece using a drill press. Compare router tableRouter tableRouter table may refer to* Routing table - a concept in computer networking* Router Table - a power tool used in woodworking...

. - off-center vises

- angle vises

- sine vises, which use gauge blocks to set up a highly accurate angle

- rotary vises

- diemakers' vises

- table vises

- pin vises (for holding thin, long cylindrical objects by one end)

- jewellers' vises and by contrast

- leg vises, which are attached to a bench but also supported from the ground so as to be stable under the very heavy use imposed by a blacksmith's work.