Drawing (manufacturing)

Encyclopedia

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

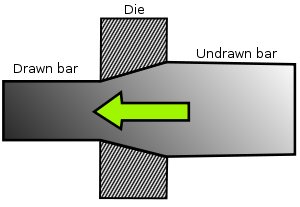

process which uses tensile forces to stretch metal. It is broken up into two types: sheet metal drawing and wire, bar, and tube drawing. The specific definition for sheet metal drawing is that it involves plastic deformation over a curved axis. For wire, bar, and tube drawing the starting stock is drawn through a die

Die (manufacturing)

A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Like molds, dies are generally customized to the item they are used to create...

to reduce its diameter and increase its length. Drawing is usually done at room temperature, thus classified a cold working process, however it may be performed at elevated temperatures to hot work

Hot working

Hot working refers to processes where metals are plastically deformed above their recrystallization temperature. Being above the recrystallization temperature allows the material to recrystallize during deformation. This is important because recrystallization keeps the materials from strain...

large wires, rods or hollow sections in order to reduce forces.

Sheet metal

The success of forming is in relation to two things, the flow and stretch of material. As a die forms a shape from a flat sheet of metal, there is a need for the material to move into the shape of the die. The flow of material is controlled through pressure applied to the blank and lubrication applied to the die or the blank. If the form moves too easily, wrinkles will occur in the part. To correct this, more pressure or less lubrication is applied to the blank to limit the flow of material and cause the material to stretch or thin. If too much pressure is applied, the part will become too thin and break. Drawing metal is the science of finding the correct balance between wrinkles and breaking to achieve a successful part.Deep drawing

Sheet metal drawing becomes deep drawing when the workpiece is drawing longer than its diameter. It is common that the workpiece is also processed using other forming processes, such as piercing, ironingIroning (metalworking)

Ironing is a sheet metal forming process that uniformly thins the workpiece in a specific area.This is a very useful process when employed in combination with deep drawing to produce a uniform wall thickness part with greater height-to-diameter ratio...

, necking

Necking (engineering)

Necking, in engineering or materials science, is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck"...

, rolling

Rolling (metalworking)

In metalworking, rolling is a metal forming process in which metal stock is passed through a pair of rolls. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is termed as hot rolling...

, and beading

Tube beading

Tube beading is a metal forming process that forms a bead on the end of a tube. Tube beads can be used to help hold a hose on the end of a tube or to strengthen the end of the tube. There are two forming processes: internal roll forming and ram forming....

.

Bar, tube & wire

Bar, tube, and wire drawing all work upon the same principle: the starting stock drawn through a die to reduce the diameter and increase the length. Usually the die is mounted on a draw benchDraw bench

A Draw bench is a machine used to do cold work on a metal, such as changing the shape of the metal without applying heat and applying only pressure.- Machine Construction :...

. The end of the workpiece is reduced or pointed to get the end through the die. The end is then placed in grips and the rest of the workpiece is pulled through the die. Steels, copper alloys, and aluminium alloy

Aluminium alloy

Aluminium alloys are alloys in which aluminium is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories...

s are common materials that are drawn.

Drawing can also be used to produce a cold formed shaped cross-section. Cold drawn cross-sections are more precise and have a better surface finish than hot extruded parts. Inexpensive materials can be used instead of expensive alloys for strength requirements, due to work hardening

Work hardening

Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements within the crystal structure of the material. Any material with a reasonably high melting point such as metals and...

.

Bar drawing

Bars or rods that are drawn cannot be coiled therefore straight-pull draw benches are used. Chain drives are used to draw workpieces up to 30 m (98.4 ft). Hydraulic cylinders are used for shorter length workpieces.The reduction in area is usually restricted to 20 to 50%, because greater reductions would exceed the tensile strength of the material, depending on its ductility

Ductility

In materials science, ductility is a solid material's ability to deform under tensile stress; this is often characterized by the material's ability to be stretched into a wire. Malleability, a similar property, is a material's ability to deform under compressive stress; this is often characterized...

. To achieve a certain size or shape multiple passes through progressively smaller dies or intermediate anneals

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

may be required.

Tube drawing

Tube drawing is very similar to bar drawing, except the beginning stock is a tube. It is used to decrease the diameter, improve surface finish and improve dimensional accuracy. A mandrelMandrel

A mandrel is one of the following:* an object used to shape machined work.* a tool component that grips or clamps materials to be machined.* a tool component that can be used to grip other moving tool components.- Variants :...

may or may not be used depending on the specific process used.

Wire drawing

This technique has long been used to produce flexible metalMetal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

wire

Wire

A wire is a single, usually cylindrical, flexible strand or rod of metal. Wires are used to bear mechanical loads and to carry electricity and telecommunications signals. Wire is commonly formed by drawing the metal through a hole in a die or draw plate. Standard sizes are determined by various...

by drawing the material through a series of dies of decreasing size. These dies are manufactured from a number of materials, the most common being tungsten carbide

Tungsten carbide

Tungsten carbide is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. Colloquially, tungsten carbide is often simply called carbide. In its most basic form, it is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery,...

and diamond

Diamond

In mineralogy, diamond is an allotrope of carbon, where the carbon atoms are arranged in a variation of the face-centered cubic crystal structure called a diamond lattice. Diamond is less stable than graphite, but the conversion rate from diamond to graphite is negligible at ambient conditions...

.

Plastic drawing

Plastic drawing, sometimes referred to as cold drawing, is the same process as used on metal bars, but applied to plastics.Cold drawing is primarily used in manufacturing plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

fiber

Fiber

Fiber is a class of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together....

s. The process was discovered by Julian Hill

Julian Hill

Julian Hill was the tenth head college football coach for the University of Richmond Spiders located in Richmond, Virginia and he held that position for the 1899 season. His career coaching record at Richmond was 2 wins, 2 losses, and 0 ties. This ranks him 22nd at Richmond in total wins and...

in 1930 while trying to make fibers from an early polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

. It is performed after the material has been "spun" into filaments; by extruding the polymer melt

Melt

Melt can refer to:* Melting, in physics, the process of heating a solid substance to a liquid*Melt , the semi-liquid material used in steelmaking and glassblowing*Melt inclusions, a feature of igneous rock...

through pores of a spinneret

Spinneret (polymers)

Spinneret refers to a multi-pored device through which a plastic polymer melt is extruded to form fibers. Streams of viscous polymer usually exit into cool air or liquid to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber...

. During this process, the individual polymer chains tend to somewhat align because of viscous

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

flow

Rheology

Rheology is the study of the flow of matter, primarily in the liquid state, but also as 'soft solids' or solids under conditions in which they respond with plastic flow rather than deforming elastically in response to an applied force....

. These filaments still have an amorphous structure, so they are drawn to align the fibers further, thus increasing crystallinity

Crystallinity

Crystallinity refers to the degree of structural order in a solid. In a crystal, the atoms or molecules are arranged in a regular, periodic manner. The degree of crystallinity has a big influence on hardness, density, transparency and diffusion. In a gas, the relative positions of the atoms or...

, tensile strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

and stiffness

Stiffness

Stiffness is the resistance of an elastic body to deformation by an applied force along a given degree of freedom when a set of loading points and boundary conditions are prescribed on the elastic body.-Calculations:...

. This is done on a draw twister

Draw twister

A draw twister is a machine used to draw and twist large quantities of polymer fibers. It uses two sets of rollers, where the second set rotates faster than the first, thus drawing the fiber between them. While the fibers are being drawn they are also twisted into thread....

machine.

For nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

, the fiber is stretched four times its spun length. The crystals formed during drawing are held together by hydrogen bonds between the amide

Amide

In chemistry, an amide is an organic compound that contains the functional group consisting of a carbonyl group linked to a nitrogen atom . The term refers both to a class of compounds and a functional group within those compounds. The term amide also refers to deprotonated form of ammonia or an...

hydrogens of one chain and the carbonyl

Carbonyl

In organic chemistry, a carbonyl group is a functional group composed of a carbon atom double-bonded to an oxygen atom: C=O. It is common to several classes of organic compounds, as part of many larger functional groups....

oxygens of another chain.