Intergranular corrosion

Encyclopedia

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

where the boundaries of crystallite

Crystallite

Crystallites are small, often microscopic crystals that, held together through highly defective boundaries, constitute a polycrystalline solid. Metallurgists often refer to crystallites as grains.- Details :...

s of the material are more susceptible to corrosion than their insides. (Cf. transgranular corrosion.)

This situation can happen in otherwise corrosion-resistant alloys, when the grain boundaries are depleted, known as , of the corrosion-inhibiting elements such as chromium by some mechanism. In nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

alloys and austenitic stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

s, where chromium

Chromium

Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

is added for corrosion resistance, the mechanism involved is precipitation of chromium carbide

Chromium carbide

Chromium carbide is an extremely hard refractory ceramic material. It is usually processed by sintering. It has the appearance of a gray powder with orthorhombic crystal structure. The orthorhombic Cr3C2 occurs extremely rarely as mineral tongbaite....

at the grain boundaries, resulting in the formation chromium-depleted zones adjacent to the grain boundaries (this process is called sensitization). Around 12% chromium is minimally required to ensure passivation, mechanism by which an ultra thin invisible film, known as passive film, forms on the surface of stainless steels. This passive film protects the metal from corrosive environments. The self-healing property of the passive film make the steel stainless. Selective leaching

Selective leaching

Selective leaching, also called dealloying, demetalification, parting and selective corrosion, is a corrosion type in some solid solution alloys, when in suitable conditions a component of the alloys is preferentially leached from the material. The less noble metal is removed from the alloy by...

often involve grain boundary depletion mechanisms.

These zones also act as local galvanic couples, causing local galvanic corrosion. This condition happens when the material is heated to temperature around 700 °C for too long time, and often happens during welding

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

or an improper heat treatment

Heat treatment

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass...

. When zones of such material form due to welding, the resulting corrosion is termed weld decay. Stainless steels can be stabilized against this behavior by addition of titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

, niobium

Niobium

Niobium or columbium , is a chemical element with the symbol Nb and atomic number 41. It's a soft, grey, ductile transition metal, which is often found in the pyrochlore mineral, the main commercial source for niobium, and columbite...

, or tantalum

Tantalum

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as tantalium, the name comes from Tantalus, a character in Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion resistant. It is part of the refractory...

, which form titanium carbide

Titanium carbide

Titanium carbide, TiC, is an extremely hard refractory ceramic material, similar to tungsten carbide.It is commercially used in tool bits. It has the appearance of black powder with NaCl-type face centered cubic crystal structure...

, niobium carbide

Niobium carbide

Niobium carbide is an extremely hard refractory ceramic material, commercially used in tool bits for cutting tools. It is usually processed by sintering and is a frequent additive in cemented carbides. It has the appearance of a brown-gray metallic powder with purple lustre...

and tantalum carbide

Tantalum carbide

Tantalum carbides form a family of binary chemical compounds of tantalum and carbon with the empirical formula TaCx, where x usually varies between 0.4 and 1. They are extremely hard, brittle, refractory ceramic materials with metallic electrical conductivity. They appear as brown-gray powders...

preferentially to chromium carbide, by lowering the content of carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

in the steel and in case of welding also in the filler metal under 0.02%, or by heating the entire part above 1000 °C and quenching it in water, leading to dissolution of the chromium carbide in the grains and then preventing its precipitation. Another possibility is to keep the welded parts thin enough so that, upon cooling, the metal dissipates heat too quickly for chromium carbide to precipitate.

Other related kind of intergranular corrosion is termed knifeline attack (KLA). Knifeline attack impacts steels stabilized by niobium, such as 347 stainless steel. Titanium, niobium, and their carbide

Carbide

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by chemical bonding type as follows: salt-like, covalent compounds, interstitial compounds, and "intermediate" transition metal carbides...

s dissolve in steel at very high temperatures. At some cooling regimes, niobium carbide does not precipitate, and the steel then behaves like unstabilized steel, forming chromium carbide instead. This affects only a thin zone several millimeters wide in the very vicinity of the weld, making it difficult to spot and increasing the corrosion speed. Structures made of such steels have to be heated in a whole to about 1950 °F, when the chromium carbide dissolves and niobium carbide forms. The cooling rate after this treatment is not important, as the carbon that would otherwise pose risk of formation of chromium carbide is already sequestered as niobium carbide.

http://httd.njuct.edu.cn/MatWeb/corrosie/c_iga.htm

Aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

-based alloys may be sensitive to intergranular corrosion if there are layers of materials acting as anode

Anode

An anode is an electrode through which electric current flows into a polarized electrical device. Mnemonic: ACID ....

s between the aluminium-rich crystals. High strength aluminium alloys, especially when extruded or otherwise subjected to high degree of working, can undergo exfoliation corrosion

Exfoliation corrosion

In metallurgy, exfoliation corrosion is a form of intergranular corrosion that manifests itself by lifting up the surface grains of a metal by the force of expanding corrosion products occurring at the grain boundaries just below the surface. It is visible evidence of intergranular corrosion. It...

, where the corrosion products build up between the flat, elongated grains and separate them, resulting in lifting or leafing effect and often propagating from edges of the material through its entire structure. http://www.corrosion-doctors.org/Forms-exfoliation/exfoliation.htm Intergranular corrosion is a concern especially for alloys with high content of copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

.

Other kinds of alloys can undergo exfoliation as well; the sensitivity of cupronickel

Cupronickel

Cupronickel or copper-nickel or "cupernickel" is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. Cupronickel is highly resistant to corrosion in seawater, because its electrode potential is adjusted to be neutral with regard to seawater...

increases together with its nickel content. A broader term for this class of corrosion is lamellar corrosion. Alloys of iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

are susceptible to lamellar corrosion, as the volume of iron oxide

Iron oxide

Iron oxides are chemical compounds composed of iron and oxygen. All together, there are sixteen known iron oxides and oxyhydroxides.Iron oxides and oxide-hydroxides are widespread in nature, play an important role in many geological and biological processes, and are widely utilized by humans, e.g.,...

s is about seven times higher than the volume of original metal, leading to formation of internal tensile stresses tearing the material apart. Similar effect leads to formation of lamellae in stainless steels, due to the difference of thermal expansion of the oxides and the metal. http://www.corrosion-doctors.org/Forms/lamellar.htm

Copper-based alloys become sensitive when depletion of copper content in the grain boundaries occurs.

Anisotropic alloys, where extrusion

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

or heavy working leads to formation of long, flat grains, are especially prone to intergranular corrosion. http://www.corrosion-doctors.org/Forms-intergranular/intergranular.htm

Intergranular corrosion induced by environmental stresses is termed stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

. Intergranular corrosion can be detected by ultrasonic and eddy current methods.

Sensitization effect

Sensitization refers to the precipitation of carbides at grain boundaries in a stainless steel or alloy, causing the steel or alloy to be susceptible to intergranular corrosionIntergranular corrosion

Intergranular corrosion , also known as intergranular attack , is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides...

or intergranular stress corrosion cracking.

Certain alloys when exposed to a temperature characterized as a sensitizing temperature become particularly susceptible to intergranular corrosion

Intergranular corrosion

Intergranular corrosion , also known as intergranular attack , is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides...

. In a corrosive atmosphere, the grain interfaces of these sensitized alloys become very reactive and intergranular corrosion results. This is characterized by a localized attack at an adjacent to grain boundaries

Grain boundary

A grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are defects in the crystal structure, and tend to decrease the electrical and thermal conductivity of the material...

with relatively little corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

of the grains themselves. The alloy disintegrates (grains fall out) and/or loses its strength.

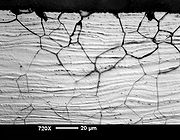

The photos show the typical microstructure of a normalized (unsensitized) type 304 stainless steel and a heavily sensitized steel. The dark lines in the sensitized microstructure are networks of chromium carbides precipitated along the grain boundaries.

Intergranular corrosion

Intergranular corrosion

Intergranular corrosion , also known as intergranular attack , is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides...

is generally considered to be caused by the segregation of impurities at the grain boundaries or by enrichment or depletion of one of the alloying elements in the grain boundary areas. Thus in certain aluminium alloy

Aluminium alloy

Aluminium alloys are alloys in which aluminium is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories...

s, small amounts of iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

have been shown to segregate in the grain boundaries and cause intergranular corrosion. Also, it has been shown that the zinc

Zinc

Zinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

content of a brass

Brass

Brass is an alloy of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties.In comparison, bronze is principally an alloy of copper and tin...

is higher at the grain boundaries and subject to such corrosion. High-strength aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

alloys such as the Duralumin

Duralumin

Duralumin is the trade name of one of the earliest types of age-hardenable aluminium alloys. The main alloying constituents are copper, manganese, and magnesium. A commonly used modern equivalent of this alloy type is AA2024, which contains 4.4% copper, 1.5% magnesium, 0.6% manganese and 93.5%...

-type alloys (Al-Cu) which depend upon precipitated phases for strengthening are susceptible to intergranular corrosion following sensitization at temperatures of about 120°C. Nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

-rich alloys such as Inconel

Inconel

Inconel is a registered trademark of Special Metals Corporation that refers to a family of austenitic nickel-chromium-based superalloys. Inconel alloys are typically used in high temperature applications. It is often referred to in English as "Inco"...

600 and Incoloy 800 show similar susceptibility. Die-cast

Die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process...

zinc

Zinc

Zinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

alloys containing aluminum exhibit intergranular corrosion by steam

Steam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

in a marine atmosphere. Cr-Mn and Cr-Mn-Ni steels are also susceptible to intergranular corrosion following sensitization in the temperature range of 400°-850°C. In the case of the austenitic stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

s, when these steels are sensitized by being heated in the temperature range of about 500° to 800°C, depletion of chromium in the grain boundary region occurs, resulting in susceptibility to intergranular corrosion. Such sensitization of austenitic stainless steels can readily occur because of temperature service requirements, as in steam generator

Steam generator

A steam generator is a device used to boil water to create steam. It may refer to:*Boiler , a closed vessel in which water is heated under pressure...

s, or as a result of subsequent welding

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

of the formed structure.

Several methods have been used to control or minimize the intergranular corrosion of susceptible alloys, particularly of the austenitic stainless steels

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

. Thus a high-temperature solution heat treatment

Heat treatment

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass...

, commonly termed solution-annealing

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

, quench

Quench

In materials science, quenching is the rapid cooling of a workpiece to obtain certain material properties. It prevents low-temperature processes, such as phase transformations, from occurring by only providing a narrow window of time in which the reaction is both thermodynamically favorable and...

-annealing or solution-quenching, has been used. The alloy is heated to a temperature of about 1,060° to 1,120°C and then water quenched. This method is generally unsuitable for treating large assemblies, and also ineffective where welding is subsequently used for making repairs or for attaching other structures.

Another control technique for preventing intergranular corrosion involves incorporating strong carbide

Carbide

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by chemical bonding type as follows: salt-like, covalent compounds, interstitial compounds, and "intermediate" transition metal carbides...

formers or stabilizing elements such as niobium

Niobium

Niobium or columbium , is a chemical element with the symbol Nb and atomic number 41. It's a soft, grey, ductile transition metal, which is often found in the pyrochlore mineral, the main commercial source for niobium, and columbite...

or titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

in the stainless steels. Such elements have a much greater affinity for carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

than does chromium

Chromium

Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable...

; carbide formation with these elements reduces the carbon available in the alloy for formation of chromium carbide

Chromium carbide

Chromium carbide is an extremely hard refractory ceramic material. It is usually processed by sintering. It has the appearance of a gray powder with orthorhombic crystal structure. The orthorhombic Cr3C2 occurs extremely rarely as mineral tongbaite....

s. Such a stabilized titanium-bearing austenitic chromium-nickel-copper stainless steel is shown in U.S. Pat. No. 3,562,781. Or the stainless steel may initially be reduced in carbon content below 0.03 percent so that insufficient carbon is provided for carbide formation. These techniques are expensive and only partially effective since sensitization may occur with time. The low-carbon steels also frequently exhibit lower strengths at high temperatures.

External links

- Intergranular Corrosion (information scraped from Perry's Chemical Engineers' Handbook, by Don W. Green and James O. Maloney. 7th ed., 1997.)