Glidcop

Encyclopedia

Trademark

A trademark, trade mark, or trade-mark is a distinctive sign or indicator used by an individual, business organization, or other legal entity to identify that the products or services to consumers with which the trademark appears originate from a unique source, and to distinguish its products or...

name of SCM Metal Products, Inc. that refers to a family of copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

-based metal matrix composite

Metal matrix composite

A metal matrix composite is composite material with at least two constituent parts, one being a metal. The other material may be a different metal or another material, such as a ceramic or organic compound. When at least three materials are present, it is called a hybrid composite...

(MMC) alloys mixed primarily with aluminum oxide ceramic

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

particles. The addition of small amounts of aluminum oxide has minuscule effects on the performance of the copper at room temperature (such as a small decrease in thermal and electrical conductivity), but greatly increases the copper's resistance to thermal softening and enhances high elevated temperature strength. The addition of aluminum oxide also increases resistance to radiation damage. As such, the alloy has found use in applications where high thermal conductivity or electrical conductivity is required while also maintaining strength at elevated temperatures or radiation levels.

Composition and Physical Properties

Glidcop is available in several grades which have varying amounts of aluminum oxide content.| Grade | Aluminum Oxide Content |

UNS Unified numbering system The unified numbering system is an alloy designation system widely accepted in North America. It consists of a prefix letter and five digits designating a material composition. A prefix of S indicates stainless steel alloys, C for copper, brass, or bronze alloys, T for tool steels, etc... Alloy Number |

Melting Point | Density | Electrical Conductivity |

Thermal Conductivity |

Coefficient of Thermal Expansion (range 20-150 °C, 68-300 °F) |

Modulus of Elasticity |

|---|---|---|---|---|---|---|---|---|

| OFC Oxygen-free copper Oxygen-free copper or Oxygen-free high thermal conductivity copper generally refers to a group of wrought high conductivity copper alloys that have been electrolytically refined to reduce the level of oxygen to .001% or below.... |

0% | - | 1083 °C (1,981.4 °F) | 8.94 g/cm3 (0.323 lb/in3) |

58 Meg S/m (101 % IACS) |

391 watt/m/°K (226 BTU/ft/hr/°F) |

17.7 µm/m/°C (9.8 µ-in/in/°F) |

115 GPa (17 Mpsi) |

| Glidcop AL-15 | 0.3 wt. % | UNS-C15715 | 1083 °C (1,981.4 °F) | 8.90 g/cm3 (0.321 lb/in3) |

54 Meg S/m (92 % IACS) |

365 watt/m/°K (211 BTU/ft/hr/°F) |

16.6 µm/m/°C (9.2 µ-in/in/°F) |

130 GPa (19 Mpsi) |

| Glidcop AL-25 | 0.5 wt. % | UNS-C15725 | 1083 °C (1,981.4 °F) | 8.86 g/cm3 (0.320 lb/in3) |

50 Meg S/m (87 % IACS) |

344 watt/m/°K (199 BTU/ft/hr/°F) |

16.6 µm/m/°C (9.2 µ-in/in/°F) |

130 GPa (19 Mpsi) |

| Glidcop AL-60 | 1.1 wt. % | UNS-C15760 | 1083 °C (1,981.4 °F) | 8.81 g/cm3 (0.318 lb/in3) |

45 Meg S/m (78 % IACS) |

322 watt/m/°K (186 BTU/ft/hr/°F) |

16.6 µm/m/°C (9.2 µ-in/in/°F) |

130 GPa (19 Mpsi) |

Additional materials and elements can be added if lower thermal expansion

Thermal expansion

Thermal expansion is the tendency of matter to change in volume in response to a change in temperature.When a substance is heated, its particles begin moving more and thus usually maintain a greater average separation. Materials which contract with increasing temperature are rare; this effect is...

is required, or higher room temperature and elevated temperature strengths. The hardness can also be increased. A composite material of Glidcop AL-60 and 10% Niobium provides high strength and high conductivity. The hardness is comparable to many copper-beryllium

Beryllium copper

Beryllium copper , also known as copper beryllium, beryllium bronze and spring copper, is a copper alloy with 0.5—3% beryllium and sometimes with other alloying elements. Beryllium copper combines high strength with non-magnetic and non-sparking qualities. It has excellent metalworking, forming...

and copper-tungsten alloys, while the electrical conductivity is comparable to RWMA Class 2 alloy. Other additives for specialized applications include molybdenum

Molybdenum

Molybdenum , is a Group 6 chemical element with the symbol Mo and atomic number 42. The name is from Neo-Latin Molybdaenum, from Ancient Greek , meaning lead, itself proposed as a loanword from Anatolian Luvian and Lydian languages, since its ores were confused with lead ores...

, tungsten

Tungsten

Tungsten , also known as wolfram , is a chemical element with the chemical symbol W and atomic number 74.A hard, rare metal under standard conditions when uncombined, tungsten is found naturally on Earth only in chemical compounds. It was identified as a new element in 1781, and first isolated as...

, Kovar

Kovar

Kovar is a nickel-cobalt ferrous alloy designed to be compatible with the thermal expansion characteristics of borosilicate glass in order to allow direct mechanical connections over a range of temperatures...

, and Alloy 42.

At elevated temperatures, Glidcop maintains its strength much better than oxygen-free copper. The aluminum oxide particles in the copper block dislocation movement, which retards recrystallization

Recrystallization (metallurgy)

Recrystallization is a process by which deformed grains are replaced by a new set of undeformed grains that nucleate and grow until the original grains have been entirely consumed. Recrystallization is usually accompanied by a reduction in the strength and hardness of a material and a simultaneous...

and prevents grain growth

Grain growth

Grain growth is the increase in size of grains in a material at high temperature. This occurs when recovery and recrystallisation are complete and further reduction in the internal energy can only be achieved by reducing the total area of grain boundary...

. At 500 °C (932 °F) Glidcop AL-15 has a yield strength of over 29 ksi (200 MPa). Glidcop also has exceptional elevated temperature stress rupture strength when compared to oxygen-free copper.

Glidcop also has excellent resistance to softening after exposure to elevated temperatures.

Post Neutron Irradiated Properties

Glidcop is resistant to degradation by neutronNeutron

The neutron is a subatomic hadron particle which has the symbol or , no net electric charge and a mass slightly larger than that of a proton. With the exception of hydrogen, nuclei of atoms consist of protons and neutrons, which are therefore collectively referred to as nucleons. The number of...

irradiation. For samples irradiated by neutrons at 411 °C (771.8 °F) and cooled to room temperature, the tensile strengths, swelling, and electrical conductivity were greater than that of pure copper. For samples irradiated from 0 to 150 dpm (displacements per atom), the tensile strength was nearly consistent, while the pure copper experienced a linear decrease in tensile strength on the range from 0 to 50 dpm. For sample swelling, the Glidcop had no noticeable swelling to 150 dpm while the pure copper had a linear growth to approximately 50 dpm, where swelling was 30% of the original. For electrical conductivity, both the pure copper and Glidcop experienced linear drops in performance, though the Glidcop was less affected by the radiation.

Workability

Glidcop material is often acquired with a layer of claddingCladding (metalworking)

Cladding is the bonding together of dissimilar metals. It is distinct from welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.The United States Mint uses...

, typically 10 - 15% of the cross-sectional area of the stock piece, though this varies depending on the production process. The cladding, which is a remnant of the extrusion

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

process often used with Glidcop, must be machined (usually by milling or grinding) off the stock piece in order to take full advantage of the Glidcop properties. After the cladding is removed, machining and working with Glidcop is similar to that of pure copper.

Joining Glidcop material through brazing

Brazing

Brazing is a metal-joining process whereby a filler metal is heated above and distributed between two or more close-fitting parts by capillary action. The filler metal is brought slightly above its melting temperature while protected by a suitable atmosphere, usually a flux...

can be somewhat difficult. Brazing with silver based braze alloys can lead to problems due to the excessive diffusion of silver along grain boundaries. This is often circumvented by first electroplating

Electroplating

Electroplating is a plating process in which metal ions in a solution are moved by an electric field to coat an electrode. The process uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal...

the Glidcop part with either copper or nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

. The copper plating is often done in a copper cyanide

Copper(I) cyanide

Copper cyanide in an inorganic compound with the formula CuCN. This off-white solid occurs in two polymorphs; impure samples can be green due to the presence of Cu impurities. The compound is useful as a catalyst, in electroplating copper, and as a reagent in the preparation of...

solution since other solutions were found to be problematic. Brazing alloys used include 3565 AuCu and 5050 AuCu, which are used in a dry hydrogen atmosphere.

Glidcop also has excellent cold workability

Work hardening

Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements within the crystal structure of the material. Any material with a reasonably high melting point such as metals and...

. Cold working by drawing

Drawing (manufacturing)

Drawing is a metalworking process which uses tensile forces to stretch metal. It is broken up into two types: sheet metal drawing and wire, bar, and tube drawing. The specific definition for sheet metal drawing is that it involves plastic deformation over a curved axis...

, cold heading

Heading (metalworking)

Heading is a metalworking process which incorporates the forging, extruding and upsetting process. It is often performed in the cold state, resulting in cold working...

, or cold forming increase strength while reducing ductility

Ductility

In materials science, ductility is a solid material's ability to deform under tensile stress; this is often characterized by the material's ability to be stretched into a wire. Malleability, a similar property, is a material's ability to deform under compressive stress; this is often characterized...

.

Applications

Glidcop has been successfully applied to resistance weldingResistance welding

Electric resistance welding refers to a group of welding processes such as spot and seam welding that produce coalescence of faying surfaces where heat to form the weld is generated by the electical reistance of material vs the time and the force used to hold the materials together during welding...

electrodes to reduce stick to galvanized

Galvanization

Galvanization is the process of applying a protective zinc coating to steel or iron, in order to prevent rusting. The term is derived from the name of Italian scientist Luigi Galvani....

and other coated steels, and in incandescent light bulb

Incandescent light bulb

The incandescent light bulb, incandescent lamp or incandescent light globe makes light by heating a metal filament wire to a high temperature until it glows. The hot filament is protected from air by a glass bulb that is filled with inert gas or evacuated. In a halogen lamp, a chemical process...

leads by resisting softening after exposure to high temperatures. Likewise, Glidcop has found used in relay

Relay

A relay is an electrically operated switch. Many relays use an electromagnet to operate a switching mechanism mechanically, but other operating principles are also used. Relays are used where it is necessary to control a circuit by a low-power signal , or where several circuits must be controlled...

blades and contactor

Contactor

A contactor is an electrically controlled switch used for switching a power circuit, similar to a relay except with higher current ratings. A contactor is controlled by a circuit which has a much lower power level than the switched circuit....

supports. The alloy's ability to maintain strength after high temperature brazing has led to use in hybrid circuit packages. Furthermore, it has found use in other high temperature applications such as x-ray tube

X-ray tube

An X-ray tube is a vacuum tube that produces X-rays. They are used in X-ray machines. X-rays are part of the electromagnetic spectrum, an ionizing radiation with wavelengths shorter than ultraviolet light...

components, and heat exchanger

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

sections for fusion power

Fusion power

Fusion power is the power generated by nuclear fusion processes. In fusion reactions two light atomic nuclei fuse together to form a heavier nucleus . In doing so they release a comparatively large amount of energy arising from the binding energy due to the strong nuclear force which is manifested...

and synchrotron

Synchrotron

A synchrotron is a particular type of cyclic particle accelerator in which the magnetic field and the electric field are carefully synchronised with the travelling particle beam. The proton synchrotron was originally conceived by Sir Marcus Oliphant...

units. Other uses include high field magnetic coils, sliding electrical contacts, arc welder

Arc welding

Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct or alternating current, and consumable or non-consumable electrodes...

electrodes, electronic leadframes, MIG

Gas metal arc welding

Gas metal arc welding , sometimes referred to by its subtypes metal inert gas welding or metal active gas welding, is a semi-automatic or automatic arc welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun...

contact tips, commutators

Commutator (electric)

A commutator is a rotary electrical switch in certain types of electric motors or electrical generators that periodically reverses the current direction between the rotor and the external circuit. In a motor, it applies power to the best location on the rotor, and in a generator, picks off power...

, high speed motor and generator components, and microwave power tube components.

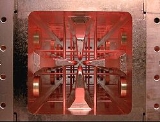

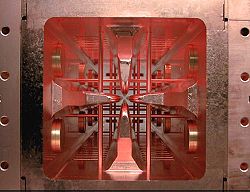

One of the more intensive uses of Glidcop has been in particle accelerator components, where the alloy may be subjected to high temperatures and high radiation simultaneously. Examples include Radio Frequency Quadrupoles (RFQs) and Compact Absorbers for High-Heat-Load X-ray Undulator Beamlines.

External links

- UNS Number Lookup, MatWeb Entering the UNS number shows a data sheet on the alloy.

- Glidcop data sheets and references

- MatWeb GlidCop Technical Data Sheets