Roman glass

Encyclopedia

Roman Empire

The Roman Empire was the post-Republican period of the ancient Roman civilization, characterised by an autocratic form of government and large territorial holdings in Europe and around the Mediterranean....

in domestic, industrial and funerary contexts. Glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

was used primarily for the production of vessels, although mosaic tiles and window glass were also produced. Roman glass production developed from Hellenistic

Hellenistic period

The Hellenistic period or Hellenistic era describes the time which followed the conquests of Alexander the Great. It was so named by the historian J. G. Droysen. During this time, Greek cultural influence and power was at its zenith in Europe and Asia...

technical traditions, initially concentrating on the production of intensely coloured cast glass vessels. However, during the 1st century AD the industry underwent rapid technical growth that saw the introduction of glass blowing and the dominance of colourless or ‘aqua’ glasses. Production of raw glass was undertaken in geographically separate locations to the working of glass into finished vessels, and by the end of the 1st century AD large scale manufacturing resulted in the establishment of glass as a commonly available material in the Roman world, and one which also had technically very difficult specialized types of luxury glass, which must have been very expensive.

Growth of the Roman glass industry

Despite the growth of glass working in the Hellenistic World and the growing place of glass in material cultureArchaeological culture

An archaeological culture is a recurring assemblage of artifacts from a specific time and place, which are thought to constitute the material culture remains of a particular past human society. The connection between the artifacts is based on archaeologists' understanding and interpretation and...

, at the beginning of the 1st century AD there was still no Latin word for it in the Roman World. However, glass was being produced in Roman contexts using primarily Hellenistic

Hellenistic period

The Hellenistic period or Hellenistic era describes the time which followed the conquests of Alexander the Great. It was so named by the historian J. G. Droysen. During this time, Greek cultural influence and power was at its zenith in Europe and Asia...

techniques and styles (see glass, history) by the late Republican

Roman Republic

The Roman Republic was the period of the ancient Roman civilization where the government operated as a republic. It began with the overthrow of the Roman monarchy, traditionally dated around 508 BC, and its replacement by a government headed by two consuls, elected annually by the citizens and...

period. The majority of manufacturing techniques were time-consuming, and the initial product was a thick-walled vessel which required considerable finishing. This, combined with the cost of importing natron

Natron

Natron is a naturally occurring mixture of sodium carbonate decahydrate and about 17% sodium bicarbonate along with small quantities of household salt and sodium sulfate. Natron is white to colourless when pure, varying to gray or yellow with impurities...

for the production of raw glass, contributed to the limited use of glass and its position as an expensive and high-status material.

The glass industry was therefore a relatively minor craft during the Republican period; although, during the early decades of the 1st century AD the quantity and diversity of glass vessels available increased dramatically. This was a direct result of the massive growth of the Roman influence at the end of the Republican period, the Pax Romana

Pax Romana

Pax Romana was the long period of relative peace and minimal expansion by military force experienced by the Roman Empire in the 1st and 2nd centuries AD. Since it was established by Caesar Augustus it is sometimes called Pax Augusta...

that followed the decades of civil war, and the stabilisation of the state that occurred under Augustus

Augustus

Augustus ;23 September 63 BC – 19 August AD 14) is considered the first emperor of the Roman Empire, which he ruled alone from 27 BC until his death in 14 AD.The dates of his rule are contemporary dates; Augustus lived under two calendars, the Roman Republican until 45 BC, and the Julian...

’ rule. Still, Roman glasswares were already making their way from Western Asia (i.e. the Parthian Empire

Parthian Empire

The Parthian Empire , also known as the Arsacid Empire , was a major Iranian political and cultural power in ancient Persia...

) to the Kushan Empire

Kushan Empire

The Kushan Empire originally formed in the early 1st century AD under Kujula Kadphises in the territories of ancient Bactria on either side of the middle course of the Oxus in what is now northern Afghanistan, Pakistan, and southern Tajikistan and Uzbekistan.During the 1st and early 2nd centuries...

in Afghanistan and India and as far Han Empire

Han Dynasty

The Han Dynasty was the second imperial dynasty of China, preceded by the Qin Dynasty and succeeded by the Three Kingdoms . It was founded by the rebel leader Liu Bang, known posthumously as Emperor Gaozu of Han. It was briefly interrupted by the Xin Dynasty of the former regent Wang Mang...

of China

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

; the first Roman glass found in China

History of the Han Dynasty

The Han Dynasty , founded by the peasant rebel leader Liu Bang ,From the Shang to the Sui dynasties, Chinese rulers were referred to in later records by their posthumous names, while emperors of the Tang to Yuan dynasties were referred to by their temple names, and emperors of the Ming and Qing...

came from an early 1st century BC tomb

Economy of the Han Dynasty

The Han Dynasty of ancient China experienced contrasting periods of economic prosperity and decline. It is normally divided into three periods: Western Han , the Xin Dynasty , and Eastern Han . The Xin Dynasty, established by the former regent Wang Mang, formed a brief interregnum between lengthy...

at Guangzhou

Guangzhou

Guangzhou , known historically as Canton or Kwangchow, is the capital and largest city of the Guangdong province in the People's Republic of China. Located in southern China on the Pearl River, about north-northwest of Hong Kong, Guangzhou is a key national transportation hub and trading port...

.

In addition to this a major new technique in glass production had been introduced during the first century AD. Glassblowing

Glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble, or parison, with the aid of a blowpipe, or blow tube...

allowed glass workers to produce vessels with considerably thinner walls, decreasing the amount of glass needed for each vessel. Glass blowing was also considerably quicker than other techniques, and vessels required considerably less finishing, representing a further saving in time, raw material and equipment. Although earlier techniques dominated during the early Augustan and Julio-Claudian

Julio-Claudian Dynasty

The Julio-Claudian dynasty normally refers to the first five Roman Emperors: Augustus, Tiberius, Caligula , Claudius, and Nero, or the family to which they belonged; they ruled the Roman Empire from its formation, in the second half of the 1st century BC, until AD 68, when the last of the line,...

periods, by the middle to late first century AD earlier techniques had been largely abandoned in favour of blowing.

As a result of these factors, the cost of production was reduced and glass became available for a wider section of society in a growing variety of forms. By the mid first century AD this meant that glass vessels had moved from a valuable, high-status commodity, to a material commonly available: “a [glass] drinking cup could be bought for a copper coin” (Strabo, Geographica

Géographica

Géographica is the French-language magazine of the Royal Canadian Geographical Society , published under the Society's French name, the Société géographique royale du Canada . Introduced in 1997, Géographica is not a stand-alone publication, but is published as an irregular supplement to La...

XVI.2). This growth also saw the production of the first glass tesserae for mosaics, and the first window glass, as furnace technology improved allowing molten glass to be produced for the first time. At the same time, the expansion of the empire also brought an influx of people and an expansion of cultural influences that resulted in the adoption of eastern decorative styles. The changes that took place in the Roman glass industry during this period can therefore be seen as a result of three primary influences: historical events, technical innovation and contemporary fashions. They are also linked to the fashions and technologies developed in the ceramic trade, from which a number of forms and techniques were drawn.

Glass making reached its peak at the beginning of the 2nd century AD, with glass objects in domestic contexts of every kind. The primary production techniques of blowing, and to a lesser extent casting, remained in use for the rest of the Roman period, with changes in vessel types but little change in technology. From the 2nd century onwards styles became increasingly regionalised, and evidence indicates that bottles and closed vessels such as unguentaria moved as a by-product of the trade in their contents, and many appear to have matched the Roman scale of liquid measurement. The use of coloured glass as a decorative addition to pale and colourless glasses also increased, and metal vessels continued to influence the shape of glass vessels. After the conversion of Constantine, glass works began to move more quickly from depicting Pagan religious imagery towards adopting scenes from Christian mythology. The movement of the capital to Constantinople

Constantinople

Constantinople was the capital of the Roman, Eastern Roman, Byzantine, Latin, and Ottoman Empires. Throughout most of the Middle Ages, Constantinople was Europe's largest and wealthiest city.-Names:...

rejuvenated the Eastern glass industry, and the presence of the Roman military

Roman legion

A Roman legion normally indicates the basic ancient Roman army unit recruited specifically from Roman citizens. The organization of legions varied greatly over time but they were typically composed of perhaps 5,000 soldiers, divided into maniples and later into "cohorts"...

in the western provinces did much to prevent any downturn there. By the mid 4th century mould-blowing was in use only sporadically.

Composition

(see also glass)Roman glass production relied on the application of heat to fuse two primary ingredients: silica and soda. Technical studies of archaeological glasses divide the ingredients of glass as formers, fluxes, stabilisers, as well as possible opacifiers or colourants.

- Former: The major component of the glass is silica, which during the Roman period was sandSandSand is a naturally occurring granular material composed of finely divided rock and mineral particles.The composition of sand is highly variable, depending on the local rock sources and conditions, but the most common constituent of sand in inland continental settings and non-tropical coastal...

(quartz), which contains some alumina (typically 2.5%) and nearly 8% lime. Alumina contents vary, peaking around 3% in glasses from the western EmpireWestern Roman EmpireThe Western Roman Empire was the western half of the Roman Empire after its division by Diocletian in 285; the other half of the Roman Empire was the Eastern Roman Empire, commonly referred to today as the Byzantine Empire....

, and remaining notably lower in glasses from the Middle East. - Flux: This ingredient was used to lower the melting pointMelting pointThe melting point of a solid is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends on pressure and is usually specified at standard atmospheric pressure...

of the silica to form glass. Analysis of Roman glass has shown that soda was used exclusively in glass production. During this period, the primary source of soda was natronNatronNatron is a naturally occurring mixture of sodium carbonate decahydrate and about 17% sodium bicarbonate along with small quantities of household salt and sodium sulfate. Natron is white to colourless when pure, varying to gray or yellow with impurities...

, a naturally occurring salt found in dry lake beds. The main source of natron during the Roman period was Wadi El NatrunWadi El NatrunWadi El Natrun is a valley located in Beheira Governorate, Egypt, including a town with the same name. The name refers to the presence of eight different lakes in the region that produce natron salt. In Christian literature, the region is also referred to as the Nitrian Desert...

, Egypt, although there may have been a source in Italy. - Stabiliser: Glasses formed of silica and soda are naturally soluble, and require the addition of a stabiliser such as lime or magnesia. Lime was the primary stabiliser in use during the Roman period, entering the glass through calcareousCalcareousCalcareous is an adjective meaning mostly or partly composed of calcium carbonate, in other words, containing lime or being chalky. The term is used in a wide variety of scientific disciplines.-In zoology:...

particles in the beach sand, rather than as a separate component.

Roman glass has also been shown to contain around 1% to 2% chlorine, in contrast to later glasses. This is thought to have originated either in the addition of salt (NaCl) to reduce the melting temperature and viscosity of the glass, or as a contaminant in the natron.

Glass making

Archaeological evidence for glass making during the Roman period is scarce, but by drawing comparisons with the later IslamicIslamic Golden Age

During the Islamic Golden Age philosophers, scientists and engineers of the Islamic world contributed enormously to technology and culture, both by preserving earlier traditions and by adding their own inventions and innovations...

and Byzantine

Byzantine

Byzantine usually refers to the Roman Empire during the Middle Ages.Byzantine may also refer to:* A citizen of the Byzantine Empire, or native Greek during the Middle Ages...

periods, it is clear that glass making was a significant industry. By the end of the Roman period glass was being produced in large quantities contained in tanks situated inside highly specialised furnaces, as the 8-tonne glass slab recovered from Bet She-arim illustrates. These workshops could produce many tonnes of raw glass in a single furnace firing, and although this firing might have taken weeks, a single primary workshop could potentially supply multiple secondary glass working sites. It is therefore thought that raw glass production was centred around a relatively small number of workshops, where glass was produced on a large scale and then broken into chunks. There is only limited evidence for local glass making, and only in context of window glass. The development of this large-scale industry is not fully understood, but Pliny's Natural History (36, 194), in addition to evidence for the first use of molten glass in the mid 1st century AD, indicates that furnace technologies experienced marked development during the early to mid 1st century AD, in tandem with the expansion of glass production.

The siting of glass-making workshops was governed by three primary factors: the availability of fuel which was needed in large quantities, sources of sand which represented the major constituent of the glass, and natron to act as a flux. Roman glass relied on natron from Wadi El Natrun, and as a result it is thought that glass-making workshops during the Roman period may have been confined to near-coastal regions of the eastern Mediterranean. This facilitated the trade in the raw colourless or naturally coloured glass which they produced, which reached glass-working sites across the Roman empire.

The scarcity of archaeological evidence for Roman glass-making facilities has resulted in the use of chemical compositions as evidence for production models, as the division of production indicates that any variation is related to differences in raw glass making. However, the Roman reliance on natron from Wadi El Natrun as a flux, has resulted in a largely homogenous composition in the majority of Roman glasses. Despite the publication of major analyses, comparisons of chemical analyses produced by different analytical methods have only recently been attempted, and although there is some variation in Roman glass compositions, meaningful compositional groups have been difficult to establish for this period.

Recycling

The Roman writers StatiusStatius

Publius Papinius Statius was a Roman poet of the 1st century CE . Besides his poetry in Latin, which include an epic poem, the Thebaid, a collection of occasional poetry, the Silvae, and the unfinished epic, the Achilleid, he is best known for his appearance as a major character in the Purgatory...

and Martial

Martial

Marcus Valerius Martialis , was a Latin poet from Hispania best known for his twelve books of Epigrams, published in Rome between AD 86 and 103, during the reigns of the emperors Domitian, Nerva and Trajan...

both indicate that recycling broken glass was an important part of the glass industry, and this seems to be supported by the fact that only rarely are glass fragments of any size recovered from domestic sites of this period. In the western empire there is evidence that recycling of broken glass was frequent and extensive(cullet), and that quantities of broken glassware were concentrated at local sites prior to melting back into raw glass. Compositionally, repeated recycling is visible via elevated levels of those metals used as colourants.

Melting does not appear to have taken place in crucibles; rather, cooking pots appear to have been used for small scale operations. For larger work, large tanks or tank-like ceramic containers were utilised. In the largest cases, large furnaces were built to surround these tanks.

Glass working

In comparison to glass making, there is evidence for glass working in many locations across the empire. Unlike the making process, the working of glass required significantly lower temperatures and substantially less fuel. As a result of this and the expansion of the Empire, glass working sites developed in Rome, Campania and the Po Valley by the end of the 1st century BC, producing the new blown vessels alongside cast vessels. Italy is known to have been a centre for the working and export of brightly coloured vessels at this time, with production peaking during the mid 1st century AD.By the early to mid 1st century AD, the growth of the Empire saw the establishment of glass working sites at locations along trade routes, with Cologne and other Rhineland centres becoming important glass working sites from the Imperial period, and Syrian glass being exported as far as Italy. During this period vessel forms varied between workshops, with areas such as the Rhineland and northern France producing distinctive forms which are not seen further south. Growth in the industry continued into the 3rd century CE, when sites at the Colonia Claudia Agrippinensis appear to have experienced significant expansion, and by the 3rd and early 4th centuries producers north of the Alps were exporting down to the north of Italy and the transalpine regions.

Glass working sites such as those at Aquileia also had an important role in the spread of glassworking traditions and the trade in materials that used hollow glasswares as containers. However, by the 4th and 5th centuries Italian glass workshops predominate.

Styles

Cobalt blue

Cobalt blue is a cool, slightly desaturated blue color, historically made using cobalt salts of alumina. It is used in certain ceramics and painting; the different cobalt pigment smalt, based on silica, is more often used directly in tinted transparent glasses...

, a deep blue-green and Persian or ‘peacock’ blue are most commonly associated with this period, and other colours are very rare. Of these, Emerald green and peacock blue were new colours introduced by the Romano-Italian industry and almost exclusively associated with the production of fine wares.

However, during the last thirty years of the 1st century AD there was a marked change in style, with strong colours disappearing rapidly, replaced by ‘aqua’ and true colourless glasses. Colourless and ‘aqua’ glasses had been in use for vessels and some mosaic designs prior to this, but start to dominate the blown glass market at this time. The use of strong colours in cast glass died out during this period, with colourless or 'aqua' glasses dominating the last class of cast vessels to be produced in quantity, as mould and free-blowing took over during the 1st century AD.

From around 70 AD colourless glass becomes the predominant material for fine wares, and the cheaper glasses move towards pale shades of blue, green, and yellow. Debate continues whether this change in fashion indicates a change in attitude that placed glass as individual material of merit no longer required to imitate precious stones, ceramics of metal, or whether the shift to colourless glass indicated an attempt to mimic highly prized rock crystal. Pliny's Natural History states that “the most highly valued glass is colourless and transparent, as closely as possible resembling rock crystal” (36, 192), which is thought to support this last position, as is evidence for the persistence of casting as a production technique, which produced the thickly walled vessels necessary to take the pressure of extensive cutting and polishing associated with crystal working.

Vessel production techniques

Core and rod formed vessels

Artisans used a mass of mud and straw fixed around a metal rod to form a core, and built up a vessel by either dipping the core in liquified glass, or by trailing liquid glass over the core. The core was removed after the glass had cooled, and handles, rims and bases were then added. These vessels are characterised by relatively thick walls, bright colours and zigzagging patterns of contrasting colours, and were limited in size to small unguentUnguent

An unguent is a soothing preparation spread on wounds, burns, rashes, abrasions or other topical injuries . It is similar to an ointment, though typically an unguent is less viscous and more oily....

or scent containers. This early technique continued in popularity during the 1st century BC, despite the earlier introduction of slumped

Slumping

Slumping is one broad technique of warm glass working, for the forming of glass by applying heat to the point where the glass will soften. The increasing fluidity of the glass with temperature causes the glass to 'slump' into or onto the mold under the force of gravity.- Technique :Glass is most...

and cast

Glass casting

Glass casting is the process in which glass objects are cast by directing molten glass into a mould where it solidifies. The technique has been used since the Egyptian period...

vessels.

Cold-cut vessels

This technique is related to the origin of glass as a substitute for gemstoneGemstone

A gemstone or gem is a piece of mineral, which, in cut and polished form, is used to make jewelry or other adornments...

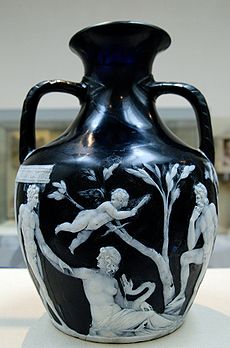

s. By borrowing techniques for stone and carved gems, artisans were able to produce a variety of small containers from blocks of raw glass or thick moulded blanks, including cameo glass

Cameo Glass

Cameo glass is a luxury form of glass art produced by etching and carving through fused layers of differently colored glass to produce designs, usually with white opaque glass figures and motifs on a dark-colored background...

in two or more colours, and cage cup

Cage cup

A cage cup, Greek diatreton, also vas diatretum, plural diatreta, or "reticulated cup" is a type of luxury Late Roman glass vessel, found from roughly the 4th century, and "the pinnacle of Roman achievements in glass-making"...

s (still thought by most scholars to have been decorated by cutting, despite some debate).

Glass blowing: free and mould blown vessels

These techniques, which were to dominate the Roman glass working industry after the late 1st century AD, are discussed in detail on the glass blowing page. Mould-blown glass appears in the second quarter of the 1st century AD.Other production techniques

A number of other techniques were in use during the Roman period:- Cage cup productionCage cupA cage cup, Greek diatreton, also vas diatretum, plural diatreta, or "reticulated cup" is a type of luxury Late Roman glass vessel, found from roughly the 4th century, and "the pinnacle of Roman achievements in glass-making"...

- Cameo glass productionCameo GlassCameo glass is a luxury form of glass art produced by etching and carving through fused layers of differently colored glass to produce designs, usually with white opaque glass figures and motifs on a dark-colored background...

- SlumpingSlumpingSlumping is one broad technique of warm glass working, for the forming of glass by applying heat to the point where the glass will soften. The increasing fluidity of the glass with temperature causes the glass to 'slump' into or onto the mold under the force of gravity.- Technique :Glass is most...

- CastingGlass castingGlass casting is the process in which glass objects are cast by directing molten glass into a mould where it solidifies. The technique has been used since the Egyptian period...

Cast glass patterns

The glass sheets used for slumping could be produced of plain or multicoloured glass, or even formed of ‘mosaic’ pieces. The production of these objects later developed into the modern caneworkingCaneworking

Caneworking is a glassblowing technique that is used to add intricate patterns and stripes to vessels or other blown glass objects.Cane refers to rods of glass with color; these rods can be simple, containing a single color, or they can be complex and contain many strands of multiple colors in...

and millefiori

Millefiori

Millefiori is a glasswork technique which produces distinctive decorative patterns on glassware.The term millefiori is a combination of the Italian words "mille" and "fiori" . Apsley Pellatt was the first to use the term "millefiori", which appeared in the Oxford Dictionary in 1849...

techniques, but is noticeably different. Six primary patterns of ‘mosaic’ glass have been identified:

- Floral (millefiori) and spiral patterns: This was produced by binding rods of coloured glass together and heating and fusing them into a single piece. These were then cut in cross-section, and the resulting discs could be fused together to create complex patterns. Alternately, two strips of contrasting-coloured glass could be fused together, and then wound round a glass rod whilst still hot to produce a spiral pattern. Cross-sections of this were also cut, and could be fused together to form a plate or fused to plain glass.

- Marbled and dappled patterns: Some of these patterns are clearly formed through the distortion of the original pattern during the slumpingSlumpingSlumping is one broad technique of warm glass working, for the forming of glass by applying heat to the point where the glass will soften. The increasing fluidity of the glass with temperature causes the glass to 'slump' into or onto the mold under the force of gravity.- Technique :Glass is most...

of the glass plate during melting. However, by using spiral and circular patterns of alternating colours producers were also able to deliberately imitate the appearance of natural stones such as sardonyx. This occurs most often on pillar-moulded bowls, which are one of the commonest glass finds on 1st century sites.

- Lace patterns: Strips of coloured glass were twisted with a contrasting coloured thread of glass before being fused together. This was a popular method in the early period, but appears to have gone out of fashion by the mid 1st century AD.

- Striped patterns: Lengths of monochrome and lacework glass were fused together to create vivid striped designs, a technique that developed from the lace pattern technique during the last decades of the 1st century AD.

The production of multicoloured vessels declined after the mid 1st century, but remained in use for some time after.

Other decorative techniques

A number of other techniques were in use during the Roman period:Enamelling

Engraving

Tesserase and window glass

Shards of broken glass or glass rods were being used in mosaics from the Augustan period onwards, but by the beginning of the 1st century small glass tiles (tesserae) were being produced specifically for use in mosaics. These were usually in shades of yellow, blue or green, and were predominantly used in mosaics laid under fountains or as highlights.Around the same time the first window panes are thought to have been produced. The earliest panes were rough cast

Rough cast

Roughcast or pebbledash is a coarse plaster surface used on outside walls that consists of lime and sometimes cement mixed with sand, small gravel, and often pebbles or shells. The materials are mixed into a slurry and are then thrown at the working surface with a trowel or scoop...

into a wooden frame on top of a layer of sand or stone, but from the late 3rd century onwards window glass was made by the muff process, where a blown cylinder was cut laterally and flattened out to produce a sheet.

Chemistry and colours

See also modern glass colors.| Colourant | Content | Comments | Furnace Conditions | |

|---|---|---|---|---|

| 'Aqua' | Iron(II) oxide Iron(II) oxide Iron oxide, also known as ferrous oxide, is one of the iron oxides. It is a black-colored powder with the chemical formula . It consists of the chemical element iron in the oxidation state of 2 bonded to oxygen. Its mineral form is known as wüstite. Iron oxide should not be confused with rust,... (FeO) |

‘Aqua’, a pale blue-green colour, is the common natural colour of untreated glass. Many early Roman vessels are this colour. | ||

| Colourless | Iron(III) oxide Iron(III) oxide Iron oxide or ferric oxide is the inorganic compound with the formula Fe2O3. It is one of the three main oxides of iron, the other two being iron oxide , which is rare, and iron oxide , which also occurs naturally as the mineral magnetite. As the mineral known as hematite, Fe2O3 is the main... (Fe2O3) |

Colourless glass was produced in the Roman period by adding manganese oxide. This oxidised the iron (II) oxide to iron (III) oxide, which although yellow, is a much weaker colourant, allowing the glass to appear colourless. The use of manganese as a decolourant was a Roman invention first noted in the Imperial period; prior to this, antimony Antimony Antimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite... -rich minerals were used. |

||

| Amber | Iron Iron Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust... -sulfur Sulfur Sulfur or sulphur is the chemical element with atomic number 16. In the periodic table it is represented by the symbol S. It is an abundant, multivalent non-metal. Under normal conditions, sulfur atoms form cyclic octatomic molecules with chemical formula S8. Elemental sulfur is a bright yellow... compounds |

0.2%-1.4% S 0.3% Fe |

Sulfur is likely to have entered the glass as a contaminant of natron, producing a green tinge. Formation of iron-sulfur compounds produces an amber colour. | Reducing |

| Purple | Manganese Manganese Manganese is a chemical element, designated by the symbol Mn. It has the atomic number 25. It is found as a free element in nature , and in many minerals... (such as pyrolusite Pyrolusite Pyrolusite is a mineral consisting essentially of manganese dioxide and is important as an ore of manganese. It is a black, amorphous appearing mineral, often with a granular, fibrous or columnar structure, sometimes forming reniform crusts. It has a metallic luster, a black or bluish-black... ) |

Around 3% | Oxidising | |

| Blue and green | Copper Copper Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish... |

2%-13% | The natural ‘aqua’ shade can be intensified with the addition of copper. During the Roman period this was derived from the recovery of oxide scale from scrap copper when heated, to avoid the contaminants present in copper minerals. Copper produced a translucent blue moving towards a darker and denser green. | Oxidising |

| Dark green | Lead Lead Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed... |

By adding lead, the green colour produced by copper could be darkened. | ||

| Royal blue to navy | Cobalt Cobalt Cobalt is a chemical element with symbol Co and atomic number 27. It is found naturally only in chemically combined form. The free element, produced by reductive smelting, is a hard, lustrous, silver-gray metal.... |

0.1% | Intense colouration | |

| Powder blue | Egyptian blue Egyptian Blue Egyptian blue is chemically known as calcium copper silicate . It is a pigment used by Egyptians for thousands of years. It is considered to be the first synthetic pigment. The pigment was known to the Romans by the name caeruleum... |

|||

| Opaque red to brown (Pliny's Haematinum Purpurin (glass) Purpurin , sometimes referred to as glass porphyr, is an opaque glass of brownish to lustrous deep-reddish color which in classical antiquity was used for residential luxury objects, mosaics and various decorative purposes... ) |

Copper Copper Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish... lead Lead Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed... |

>10% Cu 1% - 20% Pb |

Under strongly reducing conditions, copper present in the glass will precipitate inside the matrix as cuprous oxide, making the glass appear brown to blood red. Lead encourages precipitation and brilliance. The red is a rare find, but is known to have been in production during the 4th, 5th and later centuries on the continent. | Strongly reducing |

| White | Antimony Antimony Antimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite... (such as stibnite) |

1-10% | Antimony reacts with the lime in the glass matrix to precipitate calcium antimonite crystals creating a white with high opacity. | Oxidising |

| Yellow | Antimony Antimony Antimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite... and lead Lead Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed... (such as bindheimite). |

Precipitation of lead pyroantimonate creates an opaque yellow. Yellow rarely appears alone in Roman glass, but was used for the mosaic and polychrome pieces. |

These colours formed the basis of all Roman glass, and although some of them required high technical ability and knowledge, a degree of uniformity was achieved.