Microreactor

Encyclopedia

Chemical reaction

A chemical reaction is a process that leads to the transformation of one set of chemical substances to another. Chemical reactions can be either spontaneous, requiring no input of energy, or non-spontaneous, typically following the input of some type of energy, such as heat, light or electricity...

s take place in a confinement with typical lateral dimensions below 1 mm;

the most typical form of such confinement are microchannel

Micro heat exchanger

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which fluid flows in lateral confinements with typical dimensions below 1 mm...

s. Microreactors are studied in the field of micro process engineering

Micro process engineering

Micro process engineering is the science of conducting chemical orphysical processes inside small volumina,typically inside channels with diameters of less than 1 mm or other structures with sub-millimeter dimensions....

, together with other devices (such as micro heat exchanger

Micro heat exchanger

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which fluid flows in lateral confinements with typical dimensions below 1 mm...

s) in which physical processes occur. The microreactor is usually a continuous flow reactor (contrast with/to a batch reactor

Batch reactor

The Batch reactor is the generic term for a type of vessel widely used in the process industries. Its name is something of a misnomer since vessels of this type are used for a variety of process operations such as solids dissolution, product mixing, chemical reactions, batch distillation,...

). Microreactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control.

History

Gas-phase microreactors have a long history but those involving liquids started to appear in the late 1990s. One of the first microreactors with embedded high performance heat exchangerHeat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

s were made in the early 1990s by the Central Experimentation Department (Hauptabteilung Versuchstechnik, HVT) of Forschungszentrum Karlsruhe

in Germany, using mechanical micromachining techniques that were a spinoff from the manufacture of separation nozzles for uranium

Uranium

Uranium is a silvery-white metallic chemical element in the actinide series of the periodic table, with atomic number 92. It is assigned the chemical symbol U. A uranium atom has 92 protons and 92 electrons, of which 6 are valence electrons...

enrichment

Enrichment

Enrichment may mean:*Education. *The process of adding nutrients to cereals or grain: see food fortification.*The process of adding sugar to grape must during winemaking in order to achieve a higher alcohol content of the wine, more commonly referred to as chaptalization.*Behavioral...

. As research on nuclear technology was drastically reduced in Germany, microstructured heat exchangers were investigated for their application in handling highly exothermic and dangerous chemical reactions. This new concept, known by names as microreaction technology or micro process engineering

Micro process engineering

Micro process engineering is the science of conducting chemical orphysical processes inside small volumina,typically inside channels with diameters of less than 1 mm or other structures with sub-millimeter dimensions....

, was further developed by various research institutions. An early example from 1997 involved that of azo coupling

Azo coupling

An azo coupling is an organic reaction between a diazonium compound and a dialkylaniline , phenol or other aromatic compound which produces an azo compound. In this reaction the diazonium salt is an electrophile and the activated arene is a nucleophile in an electrophilic aromatic substitution...

s in a pyrex

Pyrex

Pyrex is a brand name for glassware, introduced by Corning Incorporated in 1915.Originally, Pyrex was made from borosilicate glass. In the 1940s the composition was changed for some products to tempered soda-lime glass, which is the most common form of glass used in glass bakeware in the US and has...

reactor with channel dimensions 90 micrometres deep and 190 micrometres wide.

Benefits

Using microreactors is somewhat different from using a glass vessel. These reactors may be a valuable tool in the hands of an experienced chemist or reaction engineer:- Microreactors typically have heat exchange coefficients of at least 1 megawatt per cubic meter per kelvinKelvinThe kelvin is a unit of measurement for temperature. It is one of the seven base units in the International System of Units and is assigned the unit symbol K. The Kelvin scale is an absolute, thermodynamic temperature scale using as its null point absolute zero, the temperature at which all...

, up to 500 MW m−3 K−1 vs. a few kilowatts in conventional glassware (1 l flask ~10 kW m−3 K−1)). Thus, microreactors can remove heat much more efficiently than vessels and even critical reactions such as nitrationNitrationNitration is a general chemical process for the introduction of a nitro group into a chemical compound. The dominant application of nitration is for the production of nitrobenzene, the precursor to methylene diphenyl diisocyanate...

s can be performed safely at high temperatures. Hot spot temperatures as well as the duration of high temperature exposition due to exothermicExothermicIn thermodynamics, the term exothermic describes a process or reaction that releases energy from the system, usually in the form of heat, but also in the form of light , electricity , or sound...

ity decreases remarkably. Thus, microreactors may allow better kineticChemical kineticsChemical kinetics, also known as reaction kinetics, is the study of rates of chemical processes. Chemical kinetics includes investigations of how different experimental conditions can influence the speed of a chemical reaction and yield information about the reaction's mechanism and transition...

investigations, because local temperature gradients affecting reaction rates are much smaller than in any batch vessel. Heating and cooling a microreactor is also much quicker and operating temperatureOperating temperatureAn operating temperature is the temperature at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the...

s can be as low as −100 °C. As a result of the superior heat transfer, reaction temperatures may be much higher than in conventional batch-reactors. Many low temperature reactions as organo-metal chemistry can be performed in microreactors at temperatures of −10 °C rather than −50 °C to −78 °C as in laboratory glassware equipment.

- Microreactors are normally operated continuously. This allows the subsequent processing of unstable intermediates and avoids typical batch workupWork-upIn chemistry, work-up refers to the series of manipulations required to isolate and purify the product of a chemical reaction.Typically, these manipulations include:* quenching a reaction to deactivate any unreacted reagents...

delays. Especially low temperature chemistry with reaction times in the millisecond to second range are no longer stored for hours until dosing of reagents is finished and the next reaction step may be performed. This rapid work up avoids decay of precious intermediates and often allows better selectivities. - Continuous operation and mixing causes a very different concentration profile when compared with a batch process. In a batch, reagentReagentA reagent is a "substance or compound that is added to a system in order to bring about a chemical reaction, or added to see if a reaction occurs." Although the terms reactant and reagent are often used interchangeably, a reactant is less specifically a "substance that is consumed in the course of...

A is filled in and reagent B is slowly added. Thus, B encounters initially a high excess of A. In a microreactor, A and B are mixed nearly instantly and B won't be exposed to a large excess of A. This may be an advantage or disadvantage depending on the reaction mechanismReaction mechanismIn chemistry, a reaction mechanism is the step by step sequence of elementary reactions by which overall chemical change occurs.Although only the net chemical change is directly observable for most chemical reactions, experiments can often be designed that suggest the possible sequence of steps in...

- it is important to be aware of such different concentration profiles. - Although a bench-top microreactor can synthesize chemicals only in small quantities, scale-up to industrial volumes is simply a process of multiplying the number of microchannels. In contrast, batch processes too often perform well on R&D bench-top level but fail at batch pilot plant level.

- Pressurisation of materials within microreactors (and associated components) is generally easier than with traditional batch reactors. This allows reactions to be increased in rate by raising the temperature beyond the boiling point of the solvent. This, although typical Arrhenius behaviour, is more easily facilitated in microreactors and should be considered a key advantage. Pressurisation may also allow dissolution of reactant gasses within the flow stream.

Problems

- Although there have been reactors made for handling particles, microreactors generally do not tolerate particulates well, often clogging. Clogging has been identified by a number of researchers as the biggest hurdle for microreactors being widely accepted as a beneficial alternative to batch reactors. Only the so called microjetreactor is free of clogging by precipitating products. Gas evolved may also shorten the residence time of reagents by pushing out material much faster than anticipated (though the application of backpressure can solve this issue).

- Pumping by mechanical pumping may generate a pulsating flow which can be disadvantageous. Much work has been devoted to development of low pulse or pulseless pumps. A continuous flow solution is electroosmotic flow (EOF).

- Typically, reactions performing very well in a microreactor encounter many problems in vessels, especially when scaling up. Microreactors are well suitable for fast and exothermic reactions (traditional semi-batch application) but cause trouble as soon as particles (i.e. unsoluble/unexpected side-products) are involved.

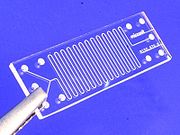

T reactors

One of the simplest forms of a microreactor is a 'T' reactor. A 'T' shape is etched into a plate with a depth that may be 40 micrometreMicrometre

A micrometer , is by definition 1×10-6 of a meter .In plain English, it means one-millionth of a meter . Its unit symbol in the International System of Units is μm...

s and a width of 100 micrometres: the etched path is turned into a tube by sealing a flat plate over the top of the etched groove. The cover plate has three holes that align to the top-left, top-right, and bottom of the 'T' so that fluids can be added and removed. A solution of reagent 'A' is pumped into the top left of the 'T' and solution 'B' is pumped into the top right of the 'T'. If the pumping rate is the same, the components meet at the top of the vertical part of the 'T' and begin to mix and react as they go down the trunk of the 'T'. A solution of product is removed at the base of the 'T'.

Applications

Synthesis

Microreactors can be used to synthesise material more effectively than current batch techniques allow. The benefits here are primarily enabled by the mass transferMass transfer

Mass transfer is the net movement of mass from one location, usually meaning a stream, phase, fraction or component, to another. Mass transfer occurs in many processes, such as absorption, evaporation, adsorption, drying, precipitation, membrane filtration, and distillation. Mass transfer is used...

, thermodynamics

Thermodynamics

Thermodynamics is a physical science that studies the effects on material bodies, and on radiation in regions of space, of transfer of heat and of work done on or by the bodies or radiation...

, and high surface area to volume ratio environment as well as engineering advantages in handling unstable intermediates. Microreactors are applied in combination with photochemistry

Photochemistry

Photochemistry, a sub-discipline of chemistry, is the study of chemical reactions that proceed with the absorption of light by atoms or molecules.. Everyday examples include photosynthesis, the degradation of plastics and the formation of vitamin D with sunlight.-Principles:Light is a type of...

, electrosynthesis

Electrosynthesis

Electrosynthesis in organic chemistry is the synthesis of chemical compounds in a electrochemical cell The main advantage of electrosynthesis over an ordinary redox reaction is avoidance of the potential wasteful other half-reaction and the ability to precisely tune the required potential...

, multicomponent reactions and polymerization

Polymerization

In polymer chemistry, polymerization is a process of reacting monomer molecules together in a chemical reaction to form three-dimensional networks or polymer chains...

(for example that of butyl acrylate). It can involve liquid-liquid systems but also solid-liquid systems with for example the channel walls coated with a heterogeneous catalyst. Synthesis is also combined with online purification of the product. Following Green Chemistry

Green Chemistry

Green Chemistry is a peer-reviewed scientific journal covering any aspect of green chemistry. It is published monthly by the Royal Society of Chemistry and was established in 1999 by James Clark . Articles have to be conceptually accessible to a wide audience...

principles, microreactors can be used to synthesize and purify extremely reactive Organometallic Compounds for ALD

Atomic layer deposition

Atomic layer deposition is a thin film deposition technique that is based on the sequential use of a gas phase chemical process. The majority of ALD reactions use two chemicals, typically called precursors. These precursors react with a surface one-at-a-time in a sequential manner...

and CVD

Chemical vapor deposition

Chemical vapor deposition is a chemical process used to produce high-purity, high-performance solid materials. The process is often used in the semiconductor industry to produce thin films. In a typical CVD process, the wafer is exposed to one or more volatile precursors, which react and/or...

applications, with improved safety in operations and higher purity products.

In one microreactor study a Knoevenagel condensation

Knoevenagel condensation

The Knoevenagel condensation reaction is an organic reaction named after Emil Knoevenagel. It is a modification of the Aldol condensation.A Knoevenagel condensation is a nucleophilic addition of an active hydrogen compound to a carbonyl group followed by a dehydration reaction in which a molecule...

was performed with the channel coated with a zeolite

Zeolite

Zeolites are microporous, aluminosilicate minerals commonly used as commercial adsorbents. The term zeolite was originally coined in 1756 by Swedish mineralogist Axel Fredrik Cronstedt, who observed that upon rapidly heating the material stilbite, it produced large amounts of steam from water that...

catalyst layer which also serves to remove water generated in the reaction:

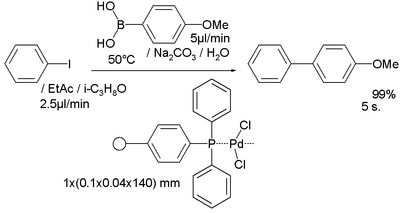

A Suzuki reaction

Suzuki reaction

The Suzuki reaction is the organic reaction of an aryl- or vinyl-boronic acid with an aryl- or vinyl-halide catalyzed by a palladium complex. It is widely used to synthesize poly-olefins, styrenes, and substituted biphenyls, and has been extended to incorporate alkyl bromides...

was examined in another study with a palladium catalyst confined in a polymer network of polyacrylamide

Polyacrylamide

Polyacrylamide is a polymer formed from acrylamide subunits. It can be synthesized as a simple linear-chain structure or cross-linked, typically using N,N-methylenebisacrylamide. Polyacrylamide is not toxic...

and a triarylphosphine

Triphenylphosphine

Triphenylphosphine is a common organophosphorus compound with the formula P3 - often abbreviated to PPh3 or Ph3P. It is widely used in the synthesis of organic and organometallic compounds. PPh3 exists as relatively air stable, colorless crystals at room temperature...

formed by interfacial polymerization:

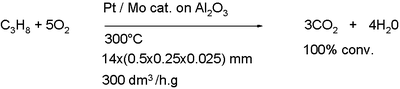

The combustion

Combustion

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

of propane

Propane

Propane is a three-carbon alkane with the molecular formula , normally a gas, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as a fuel for engines, oxy-gas torches, barbecues, portable stoves, and residential central...

was demonstrated to occur at temperatures as low as 300°C in a microchannel setup filled up with an aluminum oxide lattice coated with a platinum

Platinum

Platinum is a chemical element with the chemical symbol Pt and an atomic number of 78. Its name is derived from the Spanish term platina del Pinto, which is literally translated into "little silver of the Pinto River." It is a dense, malleable, ductile, precious, gray-white transition metal...

/ molybdenum

Molybdenum

Molybdenum , is a Group 6 chemical element with the symbol Mo and atomic number 42. The name is from Neo-Latin Molybdaenum, from Ancient Greek , meaning lead, itself proposed as a loanword from Anatolian Luvian and Lydian languages, since its ores were confused with lead ores...

catalyst:

Analysis

Microreactors can also enable experiments to be performed at a far lower scale and far higher experimental rates than currently possible in batch production, while not collecting the physical experimental output. The benefits here are primarily derived from the low operating scale, and the integration of the required sensor technologies to allow high quality understanding of an experiment. The integration of the required synthesisChemical synthesis

In chemistry, chemical synthesis is purposeful execution of chemical reactions to get a product, or several products. This happens by physical and chemical manipulations usually involving one or more reactions...

, purification

Purification

Purification is the process of rendering something pure, i.e. clean of foreign elements and/or pollution, and may refer to:* List of purification methods in chemistry* Water purification** Organisms used in water purification...

and analytical

Analytical chemistry

Analytical chemistry is the study of the separation, identification, and quantification of the chemical components of natural and artificial materials. Qualitative analysis gives an indication of the identity of the chemical species in the sample and quantitative analysis determines the amount of...

capabilities is impractical when operating outside of a microfluidic context.

NMR

Researchers at the Radboud University Nijmegen and Twente University, the Netherlands, have developed a microfluidic high-resolution NMR flow probe. They have shown a model reaction being followed in real-time. The combination of the uncompromised (sub-Hz) resolution and a low sample volume can prove to be a valuable tool for flow chemistry.Academic research

Microreactors, and more generally, micro process engineeringMicro process engineering

Micro process engineering is the science of conducting chemical orphysical processes inside small volumina,typically inside channels with diameters of less than 1 mm or other structures with sub-millimeter dimensions....

, are the subject of worldwide academic research. A prominent recurring conference is IMRET, the International Conference on Microreaction Technology. Microreactors and micro process engineering have also been featured in dedicated sessions of other conferences, such as the Annual Meeting of the American Institute of Chemical Engineers

American Institute of Chemical Engineers

The American Institute of Chemical Engineers is a professional organization for chemical engineers.AIChE was established in 1908 with the purpose of establishing chemical engineers as a profession independent from chemists and mechanical engineers.As of 2010, AIChE had over 40,000 members,...

(AIChE), or the International Symposia on Chemical Reaction Engineering (ISCRE). Research is now also conducted at various academic institutions around the world, e.g. at the Massachusetts Institute of Technology

Massachusetts Institute of Technology

The Massachusetts Institute of Technology is a private research university located in Cambridge, Massachusetts. MIT has five schools and one college, containing a total of 32 academic departments, with a strong emphasis on scientific and technological education and research.Founded in 1861 in...

(MIT) in Cambridge/MA, University of Illinois Urbana-Champaign, Oregon State University

Oregon State University

Oregon State University is a coeducational, public research university located in Corvallis, Oregon, United States. The university offers undergraduate, graduate and doctoral degrees and a multitude of research opportunities. There are more than 200 academic degree programs offered through the...

in Corvallis/OR, at University of California, Berkeley

University of California, Berkeley

The University of California, Berkeley , is a teaching and research university established in 1868 and located in Berkeley, California, USA...

in Berkeley/CA in the United States, at the EPFL in Lausanne, Switzerland, at Eindhoven University of Technology

Eindhoven University of Technology

The ' is a university of technology located in Eindhoven, Netherlands. The motto of the university is: Mens agitat molem . The university was the second of its kind in the Netherlands, only Delft University of Technology existed previously. Until mid-1980 it was known as the...

in Eindhoven, at Radboud University Nijmegen

Radboud University Nijmegen

Radboud University Nijmegen is a public university with a strong focus on research in Nijmegen, the Netherlands...

in Nijmegen, Netherlands and at the LIPHT http://www-lipht.u-strasbg.fr/Interface/index.php of Université de Strasbourg in Strasbourg, France.

Market structure

- Ready to Run (turnkey) systems are being used where the application environment stands to benefit from new chemical synthesis schemes, enhanced investigational throughput of up to approximately 10 - 100 experiments per day (depends on reaction time) and reaction subsystem, and actual synthesis conduct at scales ranging from 10 milligrams per experiment to triple digit tons per year (continuous operation of a reactor battery).

- Modular (open) systems are serving the niche for investigations on continuous process engineering lay-outs, where a measurable process advantage over the use of standardized equipment is anticipated by chemical engineers. Multiple process lay-outs can be rapidly assembled and chemical process results obtained on a scale ranging from several grams per experiment up to approximately 100 kg at a moderate number of experiments per day (3-15). A secondary transfer of engineering findings in the context of a plant engineering exercise (scale-out) then provides target capacity of typically single product dedicated plants. This mimics the success of engineering contractors for the petro-chemical process industry.

- Dedicated developments. Manufacturer of microstructured components are mostly commercial development partners to scientists in search of novel synthesis technologies. Such development partners typically excel in the set-up of comprehensive investigation and supply schemes, to model a desired contacting pattern or spatial arrangement of matter. To do so they predominantly offer information from proprietary integrated modeling systems that combine computational fluid dynamics with thermokinetic modelling. Moreover, as a rule, such development partners establish the overall application analytics to the point where the critical initial hypothesis can be validated and further confined.