Visbreaker

Encyclopedia

A visbreaker is a processing unit in oil refinery

whose purpose is to reduce the quantity of residual oil produced in the distillation

of crude oil and to increase the yield of more valuable middle distillates

(heating oil

and diesel) by the refinery. A visbreaker thermally cracks

large hydrocarbon

molecules in the oil by heating in a furnace

to reduce its viscosity and to produce small quantities of light hydrocarbons (LPG and gasoline

). The process name of "visbreaker" refers to the fact that the process reduces (i.e., breaks) the viscosity

of the residual oil. The process is non-catalytic.

The term coil (or furnace

The term coil (or furnace

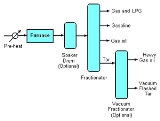

) visbreaking is applied to units where the cracking process occurs in the furnace tubes (or "coils"). Material exiting the furnace is quenched to halt the cracking reactions: frequently this is achieved by heat exchange with the virgin material being fed to the furnace, which in turn is a good energy efficiency step, but sometimes a stream of cold oil (usually gas oil) is used to the same effect. The gas oil is recovered and re-used. The extent of the cracking reaction is controlled by regulation of the speed of flow of the oil through the furnace tubes. The quenched oil then passes to a fractionator where the products of the cracking (gas, LPG, gasoline, gas oil and tar) are separated and recovered.

. In soaker visbreaking, lower temperatures are used than in coil visbreaking. The comparatively long duration of the cracking reaction is used instead.

. Here additional heavy gas oil may be recovered and routed either to catalytic cracking, hydrocracking or thermal cracking units on the refinery. The vacuum-flashed tar (sometimes referred to as pitch

) is then routed to fuel oil blending. In a few refinery locations, visbreaker tar is routed to a delayed coker

for the production of certain specialist cokes such as anode coke or needle coke.

and widely refined around the world):

Once this material has been run through a visbreaker (and, again, there will be considerable variation from visbreaker to visbreaker as no two will operate under exactly the same conditions) the reduction in viscosity is dramatic:

Stability in this case is taken to mean the tendency of a fuel oil to produce sediments when stored. These sediments are undesirable as they can quickly foul the filters of pumps used to move the oil necessitating time-consuming maintenance.

Vacuum residue fed to a visbreaker can be considered to be composed of the following:

Visbreaking preferentially cracks aliphatic compounds which have relatively low sulphur contents, low density and high viscosity and the effect of their removal can be clearly seen in the change in quality between feed and product. A too severe cracking in a visbreaker will lead to the asphaltene colloid becoming metastable. Subsequent addition of a diluent to manufacture a finished fuel oil can cause the colloid to break down, preciptating asphaltenes as a sludge. It has been observed that a paraffinic diluent is more likely to cause precipitation than an aromatic one. Stability of fuel oil is assessed using a number of proprietary tests (for example "P" value and SHF tests).

VBN = 14.534 × ln[ln(v + 0.8)] + 10.975

where v is the viscosity in square millimeters per second (mm²/s) or centistokes (cSt) and ln is the natural logarithm

(loge). It is important that the viscosity of each component of the blend be obtained at the same temperature.

The next step is to calculate the VBN of the blend, using this equation:

VBNBlend = [wA × VBNA] + [wB × VBNB] + ... + [wX × VBNX]

where w is the weight fraction (i.e., % ÷ 100) of each component of the blend.

Once the viscosity blending number of a blend has been calculated using equation (2), the final step is to determine the viscosity of the blend by using the invert of equation (1):

v = ee(VBN - 10.975) ÷ 14.534 − 0.8

where VBN is the viscosity blending number of the blend and e is the transcendental number

2.71828, also known as Euler's number.

(4) %cutter stock = [VBN40 − VBNresidue] ÷ [VBNcutter stock − VBNresidue]

Using the viscosities quoted in the tables above for the residues from Arab Light crude oil and calculating VBNs according to equation (1) gives:

For virgin residue (i.e., the unconverted feed to the visbreaker): 27.5% cutter stock in the blend

For visbroken residue: 13.3% cutter stock in the blend.

As middle distillates have a far higher value in the market place than fuel oils, it can be seen that the use of a visbreaker will considerably improve the economics of fuel oil manufacture. For example, if the cutter stock is taken to have a value of $300 per tonne and fuel oil $150 per ton (oil prices naturally change quickly, but these prices, and more importantly the differences between them, are not unrealistic), it is a simple matter to calculate the value of the different residues in this example as being:

Virgin residue: $93.1 per tonne

Visbroken residue: $127.0 per tonne

Oil refinery

An oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful petroleum products, such as gasoline, diesel fuel, asphalt base, heating oil, kerosene, and liquefied petroleum gas...

whose purpose is to reduce the quantity of residual oil produced in the distillation

Distillation

Distillation is a method of separating mixtures based on differences in volatilities of components in a boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction....

of crude oil and to increase the yield of more valuable middle distillates

Oil refinery

An oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful petroleum products, such as gasoline, diesel fuel, asphalt base, heating oil, kerosene, and liquefied petroleum gas...

(heating oil

Heating oil

Heating oil, or oil heat, is a low viscosity, flammable liquid petroleum product used as a fuel for furnaces or boilers in buildings. Home heating oil is often abbreviated as HHO...

and diesel) by the refinery. A visbreaker thermally cracks

Cracking (chemistry)

In petroleum geology and chemistry, cracking is the process whereby complex organic molecules such as kerogens or heavy hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon-carbon bonds in the precursors. The rate of cracking and the end products...

large hydrocarbon

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons from which one hydrogen atom has been removed are functional groups, called hydrocarbyls....

molecules in the oil by heating in a furnace

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

to reduce its viscosity and to produce small quantities of light hydrocarbons (LPG and gasoline

Gasoline

Gasoline , or petrol , is a toxic, translucent, petroleum-derived liquid that is primarily used as a fuel in internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. Some gasolines also contain...

). The process name of "visbreaker" refers to the fact that the process reduces (i.e., breaks) the viscosity

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

of the residual oil. The process is non-catalytic.

Process objectives

The objectives of visbreaking are:- Reduce the viscosity of the feed stream: Typically this is the residue from vacuum distillationVacuum distillationVacuum distillation is a method of distillation whereby the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure causing evaporation of the most volatile liquid...

of crude oil but can also be the residue from hydroskimmingHydroskimmingHydroskimming is one of the simplest types of refinery used in the petroleum industry. A hydroskimming refinery is defined as a refinery equipped with atmospheric distillation, naphtha reforming and necessary treating processes...

operations, natural bitumen from seeps in the ground or tar sandsTar sandsBituminous sands, colloquially known as oil sands or tar sands, are a type of unconventional petroleum deposit. The sands contain naturally occurring mixtures of sand, clay, water, and a dense and extremely viscous form of petroleum technically referred to as bitumen...

, and even certain high viscosity crude oils.

- Reduce the amount of residual fuel oil produced by a refinery: Residual fuel oil is generally regarded as a low value product. Demand for residual fuel continues to decrease as it is replaced in its traditional markets, such as fuel needed to generate steam in power stationPower stationA power station is an industrial facility for the generation of electric energy....

s, by cleaner burning alternative fuels such as natural gasNatural gasNatural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

.

- Increase the proportion of middle distillates in the refinery output: Middle distillate is used as a diluent with residual oils to bring their viscosity down to a marketable level. By reducing the viscosity of the residual stream in a visbreaker, a fuel oil can be made using less diluent and the middle distillate saved can be diverted to higher value diesel or heating oil manufacture.

Coil visbreaking

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

) visbreaking is applied to units where the cracking process occurs in the furnace tubes (or "coils"). Material exiting the furnace is quenched to halt the cracking reactions: frequently this is achieved by heat exchange with the virgin material being fed to the furnace, which in turn is a good energy efficiency step, but sometimes a stream of cold oil (usually gas oil) is used to the same effect. The gas oil is recovered and re-used. The extent of the cracking reaction is controlled by regulation of the speed of flow of the oil through the furnace tubes. The quenched oil then passes to a fractionator where the products of the cracking (gas, LPG, gasoline, gas oil and tar) are separated and recovered.

Soaker visbreaking

In soaker visbreaking, the bulk of the cracking reaction occurs not in the furnace but in a drum located after the furnace called the soaker. Here the oil is held at an elevated temperature for a pre-determined period of time to allow cracking to occur before being quenched. The oil then passes to a fractionatorFractionating column

A fractionating column or fractionation column is an essential item used in the distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in their volatilities...

. In soaker visbreaking, lower temperatures are used than in coil visbreaking. The comparatively long duration of the cracking reaction is used instead.

Process options

Visbreaker tar can be further refined by feeding it to a vacuum fractionatorVacuum distillation

Vacuum distillation is a method of distillation whereby the pressure above the liquid mixture to be distilled is reduced to less than its vapor pressure causing evaporation of the most volatile liquid...

. Here additional heavy gas oil may be recovered and routed either to catalytic cracking, hydrocracking or thermal cracking units on the refinery. The vacuum-flashed tar (sometimes referred to as pitch

Pitch (resin)

Pitch is the name for any of a number of viscoelastic, solid polymers. Pitch can be made from petroleum products or plants. Petroleum-derived pitch is also called bitumen. Pitch produced from plants is also known as resin. Products made from plant resin are also known as rosin.Pitch was...

) is then routed to fuel oil blending. In a few refinery locations, visbreaker tar is routed to a delayed coker

Delayed coker

A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke...

for the production of certain specialist cokes such as anode coke or needle coke.

Soaker visbreaking versus coil visbreaking

From the standpoint of yield, there is little or nothing to choose between the two approaches. However, each offers significant advantages in particular situations:- De-coking: The cracking reaction forms petroleum cokePetroleum cokePetroleum coke is a carbonaceous solid derived from oil refinery coker units or other cracking processes. Other coke has traditionally been derived from coal....

as a byproduct. In coil visbreaking, this lays down in the tubes of the furnace and will eventually lead to fouling or blocking of the tubes. The same will occur in the drum of a soaker visbreaker, though the lower temperatures used in the soaker drum lead to fouling at a much slower rate. Coil visbreakers therefore require frequent de-coking. This is quite labour intensive, but can be developed into a routine where tubes are de-coked sequentially without the need to shutdown the visbreaking operation. Soaker drums require far less frequent attention but their being taken out of service normally requires a complete halt to the operation. Which is the more disruptive activity will vary from refinery to refinery.

- Fuel Economy: The lower temperatures used in the soaker approach mean that these units use less fuel. In cases where a refinery buys fuel to support process operations, any savings in fuel consumption could be extremely valuable. In such cases, soaker visbreaking may be advantageous.

Feed quality and product quality

The quality of the feed going into a visbreaker will vary considerably with the type of crude oil that the refinery is processing. The following is a typical quality for the vacuum distillation residue of Arabian light (a crude oil from Saudi ArabiaSaudi Arabia

The Kingdom of Saudi Arabia , commonly known in British English as Saudi Arabia and in Arabic as as-Sa‘ūdiyyah , is the largest state in Western Asia by land area, constituting the bulk of the Arabian Peninsula, and the second-largest in the Arab World...

and widely refined around the world):

| Density Density The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight... (kg/l) |

Viscosity Viscosity Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity... at 100 °C (centistokes Viscosity Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity... ) |

Sulphur Content (wt%) |

|---|---|---|

| 1.020 | 930 | 4.0 |

Once this material has been run through a visbreaker (and, again, there will be considerable variation from visbreaker to visbreaker as no two will operate under exactly the same conditions) the reduction in viscosity is dramatic:

| Density Density The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight... (kg/l) |

Viscosity Viscosity Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity... at 100 °C (centistokes Viscosity Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity... ) |

Sulphur Content (wt%) |

|---|---|---|

| 1.048 | 115 | 4.7 |

Yields

The yields of the various hydrocarbon products will depend on the "severity" of the cracking operation as determined by the temperature the oil is heated to in the visbreaker furnace. At the low end of the scale, a furnace heating to 425 °C would crack only mildly, while operations at 500 °C would be considered as very severe. Arabian light crude residue when visbroken at 450 °C would yield around 76% (by weight) of tar, 15% middle distillates, 6% gasolines and 3% gas and LPG.Fuel oil stability

The severity of visbreaker operation is normally limited by the need to produce a visbreaker tar that can be blended to make a stable fuel oil.Stability in this case is taken to mean the tendency of a fuel oil to produce sediments when stored. These sediments are undesirable as they can quickly foul the filters of pumps used to move the oil necessitating time-consuming maintenance.

Vacuum residue fed to a visbreaker can be considered to be composed of the following:

- Asphaltenes: large polycyclic molecules that are suspended in the oil in a coloidal form

- Resins: also polycyclic but of a lower molecular weight than asphaltenes

- Aromatic hydrocarbons: derivatives of benzeneBenzeneBenzene is an organic chemical compound. It is composed of 6 carbon atoms in a ring, with 1 hydrogen atom attached to each carbon atom, with the molecular formula C6H6....

, tolueneTolueneToluene, formerly known as toluol, is a clear, water-insoluble liquid with the typical smell of paint thinners. It is a mono-substituted benzene derivative, i.e., one in which a single hydrogen atom from the benzene molecule has been replaced by a univalent group, in this case CH3.It is an aromatic...

and xylenes

- Parafinic hydrocarbons: alkanes

Visbreaking preferentially cracks aliphatic compounds which have relatively low sulphur contents, low density and high viscosity and the effect of their removal can be clearly seen in the change in quality between feed and product. A too severe cracking in a visbreaker will lead to the asphaltene colloid becoming metastable. Subsequent addition of a diluent to manufacture a finished fuel oil can cause the colloid to break down, preciptating asphaltenes as a sludge. It has been observed that a paraffinic diluent is more likely to cause precipitation than an aromatic one. Stability of fuel oil is assessed using a number of proprietary tests (for example "P" value and SHF tests).

Viscosity blending

The viscosity blending of two or more liquids having different viscosities is a three-step procedure. The first step is to calculate the Viscosity Blending Index (VBI) of each component of the blend using the following equation (known as a Refutas equation):VBN = 14.534 × ln[ln(v + 0.8)] + 10.975

where v is the viscosity in square millimeters per second (mm²/s) or centistokes (cSt) and ln is the natural logarithm

Natural logarithm

The natural logarithm is the logarithm to the base e, where e is an irrational and transcendental constant approximately equal to 2.718281828...

(loge). It is important that the viscosity of each component of the blend be obtained at the same temperature.

The next step is to calculate the VBN of the blend, using this equation:

VBNBlend = [wA × VBNA] + [wB × VBNB] + ... + [wX × VBNX]

where w is the weight fraction (i.e., % ÷ 100) of each component of the blend.

Once the viscosity blending number of a blend has been calculated using equation (2), the final step is to determine the viscosity of the blend by using the invert of equation (1):

v = ee(VBN - 10.975) ÷ 14.534 − 0.8

where VBN is the viscosity blending number of the blend and e is the transcendental number

Transcendental number

In mathematics, a transcendental number is a number that is not algebraic—that is, it is not a root of a non-constant polynomial equation with rational coefficients. The most prominent examples of transcendental numbers are π and e...

2.71828, also known as Euler's number.

Example economics for a two-component blend

A marketable fuel oil, such as for fueling a power station, might be required to have a viscosity of 40 centistokes at 100 °C. It might be prepared using either the virgin or visbroken residue described above combined with a distillate diluent ("cutter stock"). Such a cutter stock could typically have a viscosity at 100 °C of 1.3 centistokes. Rearranging equation (2) above for a simple two component blend shows that the percentage of cutterstock required in the blend is found by:(4) %cutter stock = [VBN40 − VBNresidue] ÷ [VBNcutter stock − VBNresidue]

Using the viscosities quoted in the tables above for the residues from Arab Light crude oil and calculating VBNs according to equation (1) gives:

For virgin residue (i.e., the unconverted feed to the visbreaker): 27.5% cutter stock in the blend

For visbroken residue: 13.3% cutter stock in the blend.

As middle distillates have a far higher value in the market place than fuel oils, it can be seen that the use of a visbreaker will considerably improve the economics of fuel oil manufacture. For example, if the cutter stock is taken to have a value of $300 per tonne and fuel oil $150 per ton (oil prices naturally change quickly, but these prices, and more importantly the differences between them, are not unrealistic), it is a simple matter to calculate the value of the different residues in this example as being:

Virgin residue: $93.1 per tonne

Visbroken residue: $127.0 per tonne