Venturi scrubber

Encyclopedia

Air pollution

Air pollution is the introduction of chemicals, particulate matter, or biological materials that cause harm or discomfort to humans or other living organisms, or cause damage to the natural environment or built environment, into the atmosphere....

controls collectively referred to as wet scrubber

Wet scrubber

The term wet scrubber describes a variety of devices that remove pollutants from a furnace flue gas or from other gas streams. In a wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid, or by...

s.

Venturi

Venturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The Venturi effect is named after Giovanni Battista Venturi , an Italian physicist.-Background:...

devices have also been used for over 100 years to measure fluid flow (Venturi tubes

Venturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The Venturi effect is named after Giovanni Battista Venturi , an Italian physicist.-Background:...

derived their name from Giovanni Battista Venturi

Giovanni Battista Venturi

Giovanni Battista Venturi was an Italian physicist. He was the discoverer and eponym of Venturi effect. He was also the eponym of the Venturi pump and Venturi tube....

, an Italian physicist).

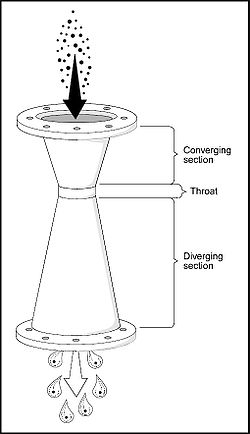

About 35 years ago, Johnstone (1949) and other researchers found that they could effectively use the venturi configuration to remove particles from gas streams. Figure 1 illustrates the classic venturi configuration.

A venturi scrubber consists of three sections: a converging section, a throat section, and a diverging section. The inlet gas stream enters the converging section and, as the area decreases, gas velocity increases (in accordance with the Bernoulli equation

Bernoulli's principle

In fluid dynamics, Bernoulli's principle states that for an inviscid flow, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy...

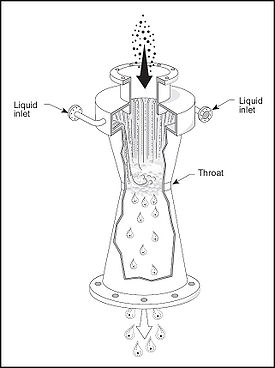

). Liquid is introduced either at the throat or at the entrance to the converging section.

The inlet gas, forced to move at extremely high velocities in the small throat section, shears the liquid from its walls, producing an enormous number of very tiny droplets.

Particle and gas removal occur in the throat section as the inlet gas stream mixes with the fog of tiny liquid droplets. The inlet stream then exits through the diverging section, where it is forced to slow down.

Venturis can be used to collect both particulate and gaseous pollutants, but they are more effective in removing particles than gaseous pollutants.

Dust

Dust consists of particles in the atmosphere that arise from various sources such as soil dust lifted up by wind , volcanic eruptions, and pollution...

. Otherwise, the dust would have a tendency to cake on or abrade a dry throat. These venturis are sometimes referred to as having a wetted approach.

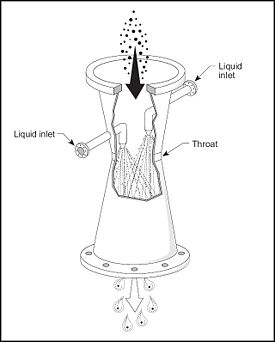

Figure 3 shows liquid injected at the venturi throat. Since it is sprayed at or just before the throat, it does not actually coat the throat surface. These throats are susceptible to solids buildup when the throat is dry. They are also susceptible to abrasion by dust particles. These venturis are best used when the inlet stream is cool and moist. These venturis are referred to as having a non-wetted approach.

Venturis with round throats (Figures 2 and 3) can handle inlet flows as large as 88,000 m³/h (40,000 cfm) (Brady and Legatski 1977). At inlet flow rates greater than this, achieving uniform liquid distribution is difficult, unless additional weirs or baffles are used.

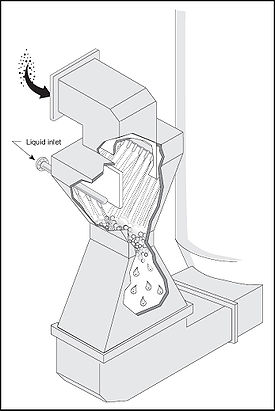

To handle large inlet flows, scrubbers designed with long, narrow, rectangular throats (Figure 4) have been used.

Certain types of orifices (throat areas) that create more turbulence than a true venturi were found to be equally efficient for a given unit of energy consumed (McIlvaine Company 1974).

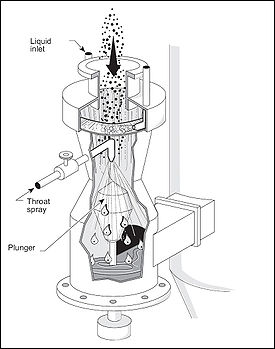

Results of these findings led to the development of the annular-orifice, or adjustable-throat, venturi scrubber (Figure 5). The size of the throat area is varied by moving a plunger, or adjustable disk, up or down in the throat, thereby decreasing or increasing the annular opening. Gas flows through the annular opening and atomizes liquid that is sprayed onto the plunger or swirled in from the top.

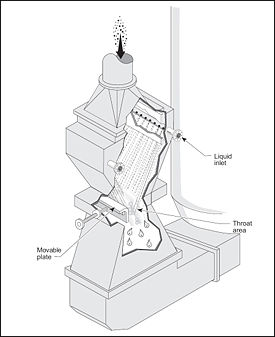

Another adjustable-throat venturi is shown in Figure 6. In this scrubber, the throat area is varied by using a movable plate. A water-wash spray is used to continually wash collected material from the plate.

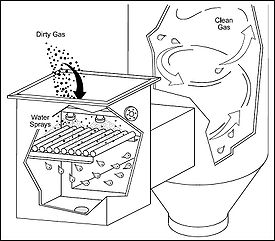

Another modification can be seen in the venturi-rod or rod deck scrubber. By placing a number of pipes parallel to each other, a series of longitudinal venturi openings can be created as shown in Figure 7. The area between adjacent rods is a small venturi throat.

All venturi scrubbers require an entrainment

Entrainment (engineering)

Entrainment as commonly used in various branches of engineering may be defined as the entrapment of one substance by another substance. For example:* The entrapment of liquid droplets or solid particulates in a flowing gas, as with smoke....

separator because the high velocity of gas through the scrubber will have a tendency to entrain the droplets with the outlet clean gas stream.

Cyclonic, mesh-pad, and blade separators are all used to remove liquid droplets from the flue gas

Flue gas

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants...

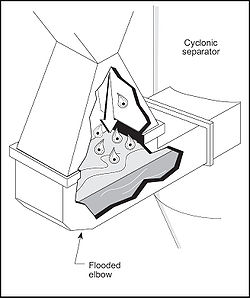

and return the liquid to the scrubber water. Cyclonic separators, the most popular for use with venturi scrubbers, are connected to the venturi vessel by a flooded elbow (Figure 8). The liquid reduces abrasion of the elbow as the outlet gas flows at high velocities from the venturi into the separator.

Particle collection

Wet scrubber

The term wet scrubber describes a variety of devices that remove pollutants from a furnace flue gas or from other gas streams. In a wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid, or by...

system. As the inlet stream enters the throat, its velocity increases greatly, atomizing and turbulently mixing with any liquid present.

The atomized liquid provides an enormous number of tiny droplets for the dust particles to impact on. These liquid droplets incorporating the particles must be removed from the scrubber outlet stream, generally by cyclonic separators.

Particle removal efficiency increases with increasing pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

because of increased turbulence due to high gas velocity in the throat. Venturis can be operated with pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

s ranging from 12 to 250 cm (5 to 100 in) of water.

Most venturis normally operate with pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

s in the range of 50 to 150 cm (20 to 60 in) of water. At these pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

s, the gas velocity in the throat section is usually between 30 and 120 m/s (100 to 400 ft/s), or approximately 270 mph at the high end. These high pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

s result in high operating costs.

The liquid-injection rate, or liquid-to-gas ratio

Liquid-to-gas ratio

An important parameter in wet scrubbing systems is the rate of liquid flow. It is common in wet scrubber terminology to express the liquid flow as a function of the gas flow rate that is being treated...

(L/G), also affects particle collection. The proper amount of liquid must be injected to provide adequate liquid coverage over the throat area and make up for any evaporation losses. If there is insufficient liquid, then there will not be enough liquid targets to provide the required capture efficiency.

Most venturi systems operate with an L/G ratio of 0.4 to 1.3 l/m3 (3 to 10 gal/1000 ft3) (Brady and Legatski 1977). L/G ratios less than 0.4 l/m3 (3 gal/1000 ft3) are usually not sufficient to cover the throat, and adding more than 1.3 l/m3 (10 gal/1000 ft3) does not usually significantly improve particle collection efficiency.

Gas collection

The high inlet gas velocities in a venturi scrubber result in a very short contact time between the liquid and gas phases. This short contact time limits gas absorption. However, because venturis have a relatively open design compared to other scrubbers, they are very useful for simultaneous gaseous and particulate pollutant

Pollutant

A pollutant is a waste material that pollutes air, water or soil, and is the cause of pollution.Three factors determine the severity of a pollutant: its chemical nature, its concentration and its persistence. Some pollutants are biodegradable and therefore will not persist in the environment in the...

removal, especially when:

- ScalingFoulingFouling refers to the accumulation of unwanted material on solid surfaces, most often in an aquatic environment. The fouling material can consist of either living organisms or a non-living substance...

could be a problem - A high concentration of dust is in the inlet stream

- The dust is sticky or has a tendency to plug openings

- The gaseous contaminant is very soluble or chemically reactive with the liquid

To maximize the absorption of gases, venturis are designed to operate at a different set of conditions from those used to collect particles. The gas velocities are lower and the liquid-to-gas ratio

Liquid-to-gas ratio

An important parameter in wet scrubbing systems is the rate of liquid flow. It is common in wet scrubber terminology to express the liquid flow as a function of the gas flow rate that is being treated...

s are higher for absorption.

For a given venturi design, if the gas velocity is decreased, then the pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

(resistance to flow) will also decrease and vice versa. Therefore, by reducing pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

, the gas velocity is decreased and the corresponding residence time

Residence time

Residence time is the average amount of time that a particle spends in a particular system. This measurement varies directly with the amount of substance that is present in the system....

is increased. Liquid-to-gas ratio

Liquid-to-gas ratio

An important parameter in wet scrubbing systems is the rate of liquid flow. It is common in wet scrubber terminology to express the liquid flow as a function of the gas flow rate that is being treated...

s for these gas absorption applications are approximately 2.7 to 5.3 l/m3 (20 to 40 gal/1000 ft3). The reduction in gas velocity allows for a longer contact time between phases and better absorption.

Increasing the liquid-to-gas ratio

Liquid-to-gas ratio

An important parameter in wet scrubbing systems is the rate of liquid flow. It is common in wet scrubber terminology to express the liquid flow as a function of the gas flow rate that is being treated...

will increase the potential solubility of the pollutant in the liquid.

Though capable of some incidental control of volatile organic compounds

(VOC), generally venturi scrubbers are limited to control PM (particulate matter) and high solubility gases (EPA, 1992; EPA, 1996).

Maintenance problems

Abrasion can be reduced by lining the throat with silicon carbide

Silicon carbide

Silicon carbide , also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive...

brick or fitting it with a replaceable liner. Abrasion can also occur downstream of the throat section. To reduce abrasion here, the elbow at the bottom of the scrubber (leading into the separator) can be flooded (i.e. filled with a pool of scrubbing liquid).

Particles and droplets impact on the pool of liquid, reducing wear on the scrubber shell.

Another technique to help reduce abrasion is to use a precleaner (i.e., quench sprays

Quench

In materials science, quenching is the rapid cooling of a workpiece to obtain certain material properties. It prevents low-temperature processes, such as phase transformations, from occurring by only providing a narrow window of time in which the reaction is both thermodynamically favorable and...

or cyclone

Cyclonic separation

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids...

) to remove the larger particles.

The method of liquid injection at the venturi throat can also cause problems. Spray nozzle

Nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe via an orifice....

s are used for liquid distribution because they are more efficient (have a more effective spray pattern) for liquid injection than weirs. However, spray nozzle

Nozzle

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe via an orifice....

s can easily plug when liquid is recirculated. Automatic or manual reamers can be used to correct this problem. However, when heavy liquid slurries

Slurry

A slurry is, in general, a thick suspension of solids in a liquid.-Examples of slurries:Examples of slurries include:* Lahars* A mixture of water and cement to form concrete* A mixture of water, gelling agent, and oxidizers used as an explosive...

(either viscous or particle-loaded) are recirculated, open-weir injection is often necessary.

Summary

Wet scrubber

The term wet scrubber describes a variety of devices that remove pollutants from a furnace flue gas or from other gas streams. In a wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid, or by...

.

They are the most widely used scrubbers because their open construction enables them to remove most particles without plugging or scaling. Venturis can also be used to absorb pollutant gases; however, they are not as efficient for this as are packed

Packed bed

In chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packing can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structured packing...

or plate

Theoretical plate

A theoretical plate in many separation processes is a hypothetical zone or stage in which two phases, such as the liquid and vapor phases of a substance, establish an equilibrium with each other. Such equilibrium stages may also be referred to as an equilibrium stage, ideal stage or a theoretical...

towers.

Venturi scrubbers have been designed to collect particles at very high collection efficiencies, sometimes exceeding 99%. The ability of venturis to handle large inlet volumes at high temperatures makes them very attractive to many industries; consequently, they are used to reduce particulate emissions in a number of industrial applications.

This ability is particularly desirable for cement kiln

Cement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates...

emission reduction and for control of emissions from basic oxygen furnaces in the steel industry, where the inlet gas enters the scrubber at temperatures greater than 350 °C (660 °F).

Venturis are also used to control fly ash

Fly ash

Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal...

and sulfur dioxide

Sulfur dioxide

Sulfur dioxide is the chemical compound with the formula . It is released by volcanoes and in various industrial processes. Since coal and petroleum often contain sulfur compounds, their combustion generates sulfur dioxide unless the sulfur compounds are removed before burning the fuel...

emissions from industrial and utility boiler

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

s.

The operating characteristics of venturi scrubbers are listed in Table 1.

| Table 1. Operating characteristics of venturi scrubbers | |||||

|---|---|---|---|---|---|

| Pollutant | Pressure drop (Δp) | Liquid-to-gas ratio (L/G) | Liquid-inlet pressure (pL) | Removal efficiency | |

| Gases | 13-250 cm of water (5-100 in of water) | 2.7-5.3 l/m3 (20-40 gal/1,000 ft3) | < 7-100 kPa (< 1-15 psig) | 30-60% per venturi, depending on pollutant solubility | |

| Particles | 50-250 cm of water (50-150 cm of water is common) 20-100 in of water (20-60 in. of water is common) |

0.67-1.34 l/m3(5-10 gal/1,000 ft3) | 90-99% is typical | ||

External links

- Air Pollution Training Courses (from website of U.S. EPA's Air Pollution Training Institute)