.gif)

Stripping (chemistry)

Encyclopedia

Stripping is a physical separation process

where one or more components are removed from a liquid stream by a vapor stream. In industrial applications the liquid and vapor streams can have co-current or countercurrent flows. Stripping is usually carried out in either a packed or trayed column.

. The idea is to make the conditions favorable for the component, A, in the liquid phase to transfer to the vapor phase. This involves a gas-liquid interface that A must cross. The total amount of A that has moved across this boundary can be defined as the flux

of A, NA.

Stripping is mainly conducted in trayed towers (plate columns) and packed columns, and less often in spray towers, bubble columns

Stripping is mainly conducted in trayed towers (plate columns) and packed columns, and less often in spray towers, bubble columns

, and centrifugal contactors.

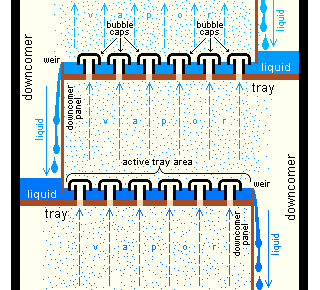

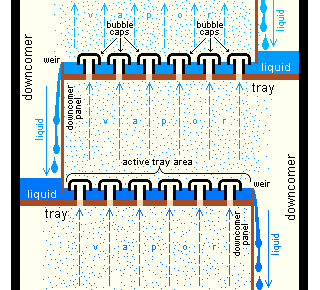

Trayed towers consist of a vertical column with liquid flowing in the top and out the bottom. The vapor phase enters in the bottom of the column and exits out of the top. Inside of the column are trays or plates. These trays force the liquid to flow back and forth horizontally while the vapor bubbles up through holes in the trays. The purpose of these trays is to increase the amount of contact area between the liquid and vapor phases.

Packed columns are similar to trayed columns in that the liquid and vapor flows enter and exit in the same manner. The difference is that in packed towers there are no trays. Instead, packing is used to increase the contact area between the liquid and vapor phases. There are many different types of packing used and each one has advantages and disadvantages.

The degree of recovery is often determined by environmental regulations, such as for volatile organic compound

s like chloroform

.

Frequently, steam

, air, inert gas

es, and hydrocarbon

gases are used as stripping agents. This is based on solubility

, stability, degree of corrosive

ness, and availability. As stripping agents are gases, operation at nearly the highest temperature and lowest pressure that will maintain the components and not vaporize the liquid feed stream is desired. This allows for the minimization of flow. As with all other variables, minimizing cost while achieving efficient separation is the ultimate goal.

The size of the equipment, and particularly the height and diameter, is important in determining the possibility of flow channeling that would reduce the contact area between the liquid and vapor streams. If flow channeling is suspected to be occurring, a redistribution plate is often necessary to, as the name indicates, redistribute the liquid flow evenly to reestablish a higher contact area.

As mentioned previously, strippers can be trayed or packed. Packed columns, and particularly when random packing is used, are usually favored for smaller columns with a diameter less than 2 feet and a packed height of not more than 20 feet. Packed columns can also be advantageous for corrosive

fluids, high foaming fluids, when fluid velocity is high, and when particularly low pressure drop is desired. Trayed strippers are advantageous because of ease of design and scale up. Structured packing

can be used similar to trays despite possibly being the same material as dumped (random) packing. Using structured packing is a common method to increase the capacity for separation or to replace damaged trays.

Trayed strippers can have sieve, valve, or bubble cap trays while packed strippers can have either structured packing

or random packing. Trays and packing are used to increase the contact area over which mass transfer can occur as mass transfer theory dictates. Packing can have varying material, surface area, flow area, and associated pressure drop. Older generation packing include ceramic Raschig rings and Berl saddles. More common packing materials are metal and plastic Pall rings, metal Michael Bialecki rings, and ceramic Intalox saddles. Each packing material of this newer generation improves the surface area, the flow area, and/or the associated pressure drop across the packing. Also important, is the ability of the packing material to not stack on top of itself. If such stacking occurs, it drastically reduces the surface area of the material. Lattice design work has been increasing of late that will further improve these characteristics.

During operation, monitoring the pressure drop

across the column can help to determine the performance of the stripper. A changed pressure drop over a significant range of time can be an indication that the packing may need to be replaced or cleaned.

and PAH contaminants from harbor soils. The soils are dredged from the bottom of contaminated harbors, mixed with water to make a slurry and then stripped with steam. The cleaned soil and contaminant rich steam mixture are then separated. This process is able to decontaminate soils almost completely.

Steam

is also frequently used as a stripping agent for water treatment

. Volatile organic compounds are partially soluble in water and because of environmental considerations and regulations, must be removed from groundwater

, surface water

, and wastewater

. These compounds can be present because of industrial, agricultural, and commercial activity.

Separation process

In chemistry and chemical engineering, a separation process, or simply a separation, is any mass transfer process used to convert a mixture of substances into two or more distinct product mixtures, at least one of which is enriched in one or more of the mixture's constituents. In some cases, a...

where one or more components are removed from a liquid stream by a vapor stream. In industrial applications the liquid and vapor streams can have co-current or countercurrent flows. Stripping is usually carried out in either a packed or trayed column.

Theory

Stripping works on the basis of mass transferMass transfer

Mass transfer is the net movement of mass from one location, usually meaning a stream, phase, fraction or component, to another. Mass transfer occurs in many processes, such as absorption, evaporation, adsorption, drying, precipitation, membrane filtration, and distillation. Mass transfer is used...

. The idea is to make the conditions favorable for the component, A, in the liquid phase to transfer to the vapor phase. This involves a gas-liquid interface that A must cross. The total amount of A that has moved across this boundary can be defined as the flux

Flux

In the various subfields of physics, there exist two common usages of the term flux, both with rigorous mathematical frameworks.* In the study of transport phenomena , flux is defined as flow per unit area, where flow is the movement of some quantity per time...

of A, NA.

Equipment

Bubble column reactor

A bubble column reactor is an apparatus used for gas-liquid reactions first applied by Helmut Gerstenberg. It consists of vertical arranged cylindrical columns. The introduction of gas takes place at the bottom of the column and causes a turbulent stream to enable an optimum gas exchange. It is...

, and centrifugal contactors.

Trayed towers consist of a vertical column with liquid flowing in the top and out the bottom. The vapor phase enters in the bottom of the column and exits out of the top. Inside of the column are trays or plates. These trays force the liquid to flow back and forth horizontally while the vapor bubbles up through holes in the trays. The purpose of these trays is to increase the amount of contact area between the liquid and vapor phases.

Packed columns are similar to trayed columns in that the liquid and vapor flows enter and exit in the same manner. The difference is that in packed towers there are no trays. Instead, packing is used to increase the contact area between the liquid and vapor phases. There are many different types of packing used and each one has advantages and disadvantages.

Variables

The variables and design considerations for strippers are many. Among them are the entering conditions, the degree of recovery of the solute needed, the choice of the stripping agent and its flow, the operating conditions, the number of stages, the heat effects, and the type and size of the equipment.The degree of recovery is often determined by environmental regulations, such as for volatile organic compound

Volatile organic compound

Volatile organic compounds are organic chemicals that have a high vapor pressure at ordinary, room-temperature conditions. Their high vapor pressure results from a low boiling point, which causes large numbers of molecules to evaporate or sublimate from the liquid or solid form of the compound and...

s like chloroform

Chloroform

Chloroform is an organic compound with formula CHCl3. It is one of the four chloromethanes. The colorless, sweet-smelling, dense liquid is a trihalomethane, and is considered somewhat hazardous...

.

Frequently, steam

Steam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

, air, inert gas

Inert gas

An inert gas is a non-reactive gas used during chemical synthesis, chemical analysis, or preservation of reactive materials. Inert gases are selected for specific settings for which they are functionally inert since the cost of the gas and the cost of purifying the gas are usually a consideration...

es, and hydrocarbon

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons from which one hydrogen atom has been removed are functional groups, called hydrocarbyls....

gases are used as stripping agents. This is based on solubility

Solubility

Solubility is the property of a solid, liquid, or gaseous chemical substance called solute to dissolve in a solid, liquid, or gaseous solvent to form a homogeneous solution of the solute in the solvent. The solubility of a substance fundamentally depends on the used solvent as well as on...

, stability, degree of corrosive

Corrosive

A corrosive substance is one that will destroy or irreversibly damage another surface or substance with which it comes into contact. The main hazards to people include damage to the eyes, the skin, and the tissue under the skin; inhalation or ingestion of a corrosive substance can damage the...

ness, and availability. As stripping agents are gases, operation at nearly the highest temperature and lowest pressure that will maintain the components and not vaporize the liquid feed stream is desired. This allows for the minimization of flow. As with all other variables, minimizing cost while achieving efficient separation is the ultimate goal.

The size of the equipment, and particularly the height and diameter, is important in determining the possibility of flow channeling that would reduce the contact area between the liquid and vapor streams. If flow channeling is suspected to be occurring, a redistribution plate is often necessary to, as the name indicates, redistribute the liquid flow evenly to reestablish a higher contact area.

As mentioned previously, strippers can be trayed or packed. Packed columns, and particularly when random packing is used, are usually favored for smaller columns with a diameter less than 2 feet and a packed height of not more than 20 feet. Packed columns can also be advantageous for corrosive

Corrosive

A corrosive substance is one that will destroy or irreversibly damage another surface or substance with which it comes into contact. The main hazards to people include damage to the eyes, the skin, and the tissue under the skin; inhalation or ingestion of a corrosive substance can damage the...

fluids, high foaming fluids, when fluid velocity is high, and when particularly low pressure drop is desired. Trayed strippers are advantageous because of ease of design and scale up. Structured packing

Structured packing

The term structured packing refers to a range of specially designed materials for use in absorption and distillation columns and chemical reactors...

can be used similar to trays despite possibly being the same material as dumped (random) packing. Using structured packing is a common method to increase the capacity for separation or to replace damaged trays.

Trayed strippers can have sieve, valve, or bubble cap trays while packed strippers can have either structured packing

Structured packing

The term structured packing refers to a range of specially designed materials for use in absorption and distillation columns and chemical reactors...

or random packing. Trays and packing are used to increase the contact area over which mass transfer can occur as mass transfer theory dictates. Packing can have varying material, surface area, flow area, and associated pressure drop. Older generation packing include ceramic Raschig rings and Berl saddles. More common packing materials are metal and plastic Pall rings, metal Michael Bialecki rings, and ceramic Intalox saddles. Each packing material of this newer generation improves the surface area, the flow area, and/or the associated pressure drop across the packing. Also important, is the ability of the packing material to not stack on top of itself. If such stacking occurs, it drastically reduces the surface area of the material. Lattice design work has been increasing of late that will further improve these characteristics.

During operation, monitoring the pressure drop

Pressure drop

Pressure drop is a term used to describe the decrease in pressure from one point in a pipe or tube to another point downstream. "Pressure drop" is the result of frictional forces on the fluid as it flows through the tube. The frictional forces are caused by a resistance to flow. The main...

across the column can help to determine the performance of the stripper. A changed pressure drop over a significant range of time can be an indication that the packing may need to be replaced or cleaned.

Typical applications

Stripping is commonly used in industrial applications to remove harmful contaminants from waste streams. One example would be the removal of TBTTributyltin

Tributyltin compounds are a group of compounds containing the 3Sn moiety, such as tributyltin hydride or tributyltin oxide. They are the main active ingredients in certain biocides used to control a broad spectrum of organisms...

and PAH contaminants from harbor soils. The soils are dredged from the bottom of contaminated harbors, mixed with water to make a slurry and then stripped with steam. The cleaned soil and contaminant rich steam mixture are then separated. This process is able to decontaminate soils almost completely.

Steam

Steam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

is also frequently used as a stripping agent for water treatment

Water treatment

Water treatment describes those processes used to make water more acceptable for a desired end-use. These can include use as drinking water, industrial processes, medical and many other uses. The goal of all water treatment process is to remove existing contaminants in the water, or reduce the...

. Volatile organic compounds are partially soluble in water and because of environmental considerations and regulations, must be removed from groundwater

Groundwater

Groundwater is water located beneath the ground surface in soil pore spaces and in the fractures of rock formations. A unit of rock or an unconsolidated deposit is called an aquifer when it can yield a usable quantity of water. The depth at which soil pore spaces or fractures and voids in rock...

, surface water

Surface water

Surface water is water collecting on the ground or in a stream, river, lake, wetland, or ocean; it is related to water collecting as groundwater or atmospheric water....

, and wastewater

Wastewater

Wastewater is any water that has been adversely affected in quality by anthropogenic influence. It comprises liquid waste discharged by domestic residences, commercial properties, industry, and/or agriculture and can encompass a wide range of potential contaminants and concentrations...

. These compounds can be present because of industrial, agricultural, and commercial activity.

See also

- Steam distillationSteam distillationSteam distillation is a special type of distillation for temperature sensitive materials like natural aromatic compounds....

- DistillationDistillationDistillation is a method of separating mixtures based on differences in volatilities of components in a boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and not a chemical reaction....

- Theoretical plateTheoretical plateA theoretical plate in many separation processes is a hypothetical zone or stage in which two phases, such as the liquid and vapor phases of a substance, establish an equilibrium with each other. Such equilibrium stages may also be referred to as an equilibrium stage, ideal stage or a theoretical...

- Continuous distillationContinuous distillationContinuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. A distillation is the separation or partial separation of a liquid feed mixture into components or...

- Fractionating columnFractionating columnA fractionating column or fractionation column is an essential item used in the distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in their volatilities...

- Distillation DesignDistillation DesignDistillation Design is a book which provides complete coverage of the design of industrial distillation columns for the petroleum refining, chemical and petrochemical plants, natural gas processing, pharmaceutical, food and alcohol distilling industries...

- Packed bedPacked bedIn chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packing can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structured packing...