Sneath Glass Company

Encyclopedia

The Sneath Glass Company was an American manufacturer of glass

that was established in 1889 in Tiffin, Ohio

, under the name Tiffin Glass Company. Two years later, the company was renamed Sneath Glass Company, and it was reorganized and moved to Hartford City, Indiana

, in 1894. Originally, lantern

globes and founts (which held the lantern’s fuel) were the company’s main products. The company evolved to be a maker of glassware

for portable kitchen

cabinets, and later evolved again to be a maker of glass products for refrigerator

s. While these were the major products made by the company, it also made a wide variety of additional glass products, ranging from glass mailboxes to fish tanks. The factory closed in 1952 when it did not adapt to competition from the new plastic

s industry, and could not raise product prices for its shrinking market due to post-war government price controls.

Sneath Glass Company moved from Ohio to Hartford City, Indiana in 1894 to take advantage of the Indiana Gas Boom

Sneath Glass Company moved from Ohio to Hartford City, Indiana in 1894 to take advantage of the Indiana Gas Boom

. The east-central Indiana territory around Hartford City had a “boom” period at that time caused by the discovery of natural gas, which was thought to be "practically unlimited". The town also had excellent transportation resources including two railroads, and, a decade later, the Indiana interurban street car system. The Sneath Glass plant was located on North Walnut Street. (Walnut Street eventually became part of Indiana State Road 3

, and is now the main north-south highway through town.)

Early officers of the company included Ralph Davis Sneath, president; J. W. Geiger, treasurer; Alvie Clyde Crimmel, secretary; and Henry Crimmel

, manager. These four men were also the founders of the company, each owning equal shares of its stock. The board of directors consisted of the four founders plus Ralph's father, Samuel B. Sneath. The Sneaths came from a family of prominent businessmen, and the Crimmels came from a family of glassmakers. Ralph Sneath also became involved in a grain dealership, railroading, and banking. He eventually became president of the Commercial National Bank of Tiffin, Ohio, and also president of the Ohio Banker’s Association. Civil War veteran Henry Crimmel brought over 20 years of glass making experience to the company, having learned and sharpened his skills in Bellaire

and Fostoria, Ohio

. Henry’s deceased brother, Johannes (a.k.a. John) had been a manager at the Belmont Glass Works, and his brother Jacob helped found the American Flint Glass Workers Union. Both Henry and Jacob Crimmel were considered key craftsmen in the early days of Fostoria Glass Company

. While the Sneaths remained in Tiffin to oversee their many business interests, the Crimmels and J. W. Geiger moved to Hartford City.

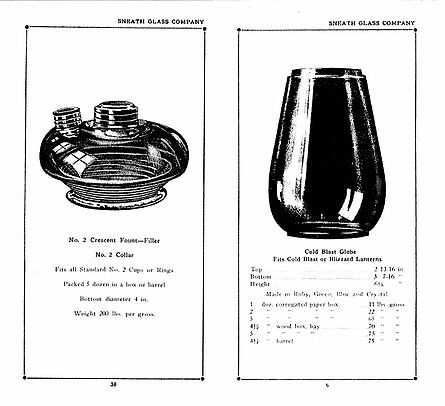

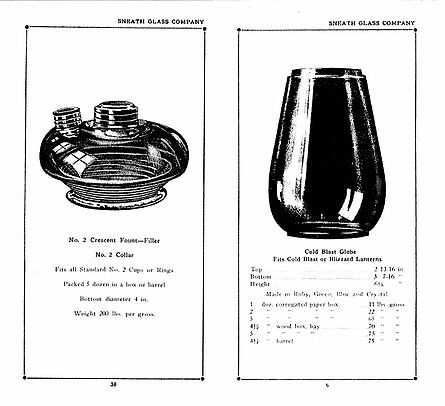

Originally, Sneath Glass prospered making kerosene lanterns and globes. Ruby, green, and blue globes were a specialty. At one time, Sneath Glass was one of only three factories in the United States that made copper ruby globes. Major customers of lantern globes were railroads and ships. Sneath globes were also used during the construction of the Panama Canal.

Originally, Sneath Glass prospered making kerosene lanterns and globes. Ruby, green, and blue globes were a specialty. At one time, Sneath Glass was one of only three factories in the United States that made copper ruby globes. Major customers of lantern globes were railroads and ships. Sneath globes were also used during the construction of the Panama Canal.

By 1897, the company had over 60 employees. Although plant manager Henry Crimmel was known for his craftsmanship, he was also mechanically inclined. The Sneath plant had a unique system of air hose

s that would allow glass blowers

to quickly finish glassware that was started without the aid of machinery, enabling the skilled workers to achieve a much higher production rate. Henry Crimmel received a patent in 1904 for a “Glass Drawing Machine” that was an improvement for glass blowing and prevented irregularities in the glass.

In 1905, Sneath Glass bought the Jones plant of the American Window Glass Company, located on Wabash Avenue in the west side of Hartford City. The Wabash Avenue site had direct access to a railroad, and was close to Washington Street, which eventually became part of Indiana State Road 26

, now the major east-west highway through the city. The Jones plant was quickly remodeled, and both operations and headquarters were moved to that site. This location became the permanent home of Sneath Glass Company.

In the early 20th century, the company began making other products in addition to globes. By 1908, Sneath Glass began hand-making three sizes of Mason jar

In the early 20th century, the company began making other products in addition to globes. By 1908, Sneath Glass began hand-making three sizes of Mason jar

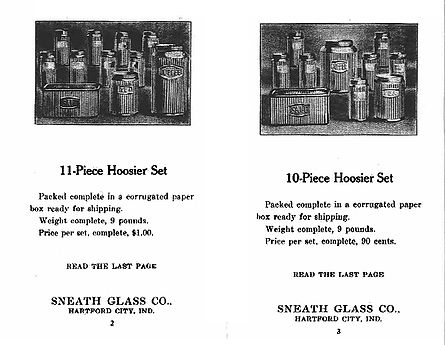

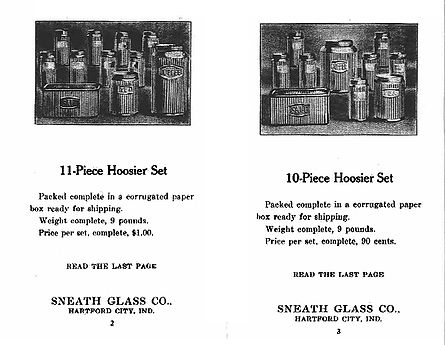

s. During the next decade, the company began making glass canisters for kitchen cabinet companies, including the Hoosier cabinet

made by Hoosier Manufacturing Company. This began the gradual (but important) transition from manufacturer of globes to manufacturer of glass products for portable kitchen cabinets. Cabinet products included salt and sugar bins, spice jars, and coffee and tea jars. From 1914 to 1916, management patented dispensing caps, a dispensing jar, and a dispensing bin used in kitchen cabinets.

Henry Crimmel suffered a stroke

in 1916, and died about one year later. His son (and company co-founder) Alva (a.k.a. Alvie) Clyde Crimmel took more management responsibilities at that time, and by 1920 his title was Vice-President and Treasurer. Clyde’s oldest son Henry Hays Crimmel joined the company’s management in 1918, focusing on sales. Henry Hays had been working at Sneath since he was a child, and was very familiar with the company's products. (The elder Henry Crimmel was fined $11.95 in 1901 by the state of Indiana for employing children under the age of 14. While this may seem "backward" today, child labor was common in glass factories during the 19th century and early 20th century. There is a high probability that Henry Crimmel began his glassmaking career as a child laborer in Wheeling, West Virginia. Henry's brother Jacob began working in Wheeling around the age of 13.

Sneath Glass continued making glassware for kitchen cabinet manufacturers such as Hoosier and Sellers, and the 1920s were peak years for that cabinet style. Sneath management also patented more of its products used in kitchen cabinets. In addition to its main products, the company began making glass mail boxes in 1921, after employee William Chapman, working under the supervision of Ray Pruden, was granted his first of three patents. Ray Pruden was superintendent of the factory, assuming that title after Henry Crimmel’s stroke. William Chapman was a well-known glass blower, and he also secured a patent for a decorative ash tray. Other products included a drawer pull, a caster for furniture, a newspaper receptacle, and a chick feeding fount. Manufacturing skills also continued to develop within the company, as employees James A. Lewis and Alvie Clyde Crimmel were granted an important patent for a means to remove glass from molds.

Sneath Glass continued making glassware for kitchen cabinet manufacturers such as Hoosier and Sellers, and the 1920s were peak years for that cabinet style. Sneath management also patented more of its products used in kitchen cabinets. In addition to its main products, the company began making glass mail boxes in 1921, after employee William Chapman, working under the supervision of Ray Pruden, was granted his first of three patents. Ray Pruden was superintendent of the factory, assuming that title after Henry Crimmel’s stroke. William Chapman was a well-known glass blower, and he also secured a patent for a decorative ash tray. Other products included a drawer pull, a caster for furniture, a newspaper receptacle, and a chick feeding fount. Manufacturing skills also continued to develop within the company, as employees James A. Lewis and Alvie Clyde Crimmel were granted an important patent for a means to remove glass from molds.

Several factors contributed to the need for a transition from globe manufacturer, and all related to less demand. First, the railroads were a major customer for lanterns and globes, but they had stopped expanding. Railroad route miles peaked around 1916, and railroad employees peaked around 1920. Since the railroad industry was shrinking, its demand for globes would diminish. Second, electrification

and the incandescent light bulb

began replacing oil lamps, and thus there was less need for lamp globes and fonts. Finally (and later), rural electrification

also decreased farmers' need for oil lamps.

Glassware made by Sneath Glass Company could be identified by a small "S" on the bottom of the product. The adjacent picture shows the bottom of a Sneath spice jar that was probably made in the 1920s. The "S" mark for that product, from that time period, is easily to identify.

Glassware made by Sneath Glass Company could be identified by a small "S" on the bottom of the product. The adjacent picture shows the bottom of a Sneath spice jar that was probably made in the 1920s. The "S" mark for that product, from that time period, is easily to identify.

When the moulds

for the glassware became unclean, they would need to be scrubbed – and after time the "S" would wear off. Eventually, the "S" was eliminated to save mould-cleaning time, but it also made Sneath product identification difficult for products made in the later years of the company's existence. That mistake enabled competitors to make their own products that appeared very similar to Sneath glassware.

of the 1930s, Sneath kept much of its workforce employed by shortening shifts. This kept the company from losing its skilled workers, and enabled more people to be employed. The glass business was thought to have one advantage during difficult economic times: people purchased glass products rather than metal products.

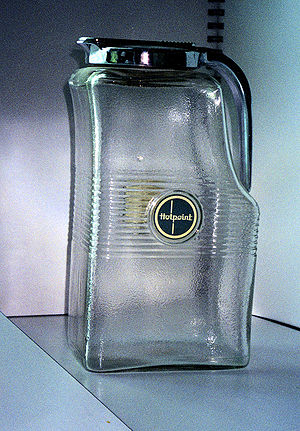

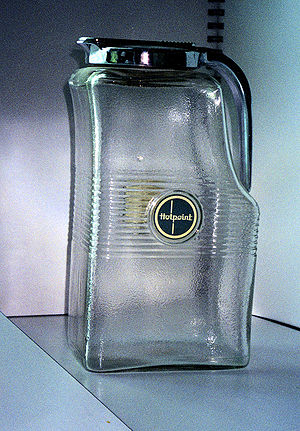

In addition to their kitchen glassware products, Sneath began to make refrigeration products. Between 1933 and 1941, management secured at least six patents related to mechanical refrigerators. At one time, Sneath Glass produced almost 90 percent of the glassware used in consumer refrigerators in the United States. This glassware was produced under the name of the appliance manufacturer, and included the major manufacturers of the time. Some of the consumer refrigeration products produced were defroster trays, cold water pitchers, and butter dishes. Additional products made by Sneath included sundae dishes, ink wells, fish tanks, and battery jars used by farmers' windmills.

In addition to their kitchen glassware products, Sneath began to make refrigeration products. Between 1933 and 1941, management secured at least six patents related to mechanical refrigerators. At one time, Sneath Glass produced almost 90 percent of the glassware used in consumer refrigerators in the United States. This glassware was produced under the name of the appliance manufacturer, and included the major manufacturers of the time. Some of the consumer refrigeration products produced were defroster trays, cold water pitchers, and butter dishes. Additional products made by Sneath included sundae dishes, ink wells, fish tanks, and battery jars used by farmers' windmills.

Like the company's transition from lantern globes to glassware for kitchen cabinets, the transition to refrigerator products was important for the company's survival. By the mid-1930s, the Hoosier style cabinets, many of which contained glassware made by Sneath Glass, had lost their popularity. New houses typically contained built-in cabinetry.

Although the company had transitioned to refrigerator products as a focal point, it still made other merchandise. One product was the company's own version of borosilicate glass

, which was called "heat proof" glass. This glass could be moved from a refrigerator to an oven without breaking from the extreme temperature change. Heat proof glass was used for ovenware and coffee makers, – and during World War II, it was used in searchlight products. Unfortunately, the Sneath version of borosilicate glass, like the Sneath brand

, was not promoted.

In 1940, millionaire Ralph Sneath died shortly after receiving severe injuries in an automobile accident, and the last of the founders, Alvie Clyde Crimmel, became chief executive. Although Mr. Sneath did not spend much time at the glass plant, he was well liked and watched the company finances. Despite this loss, an aging workforce, and an aging infrastructure, the company continued to have talent both in the manufacturing process and creatively. Employee James A. Lewis received three patents related to glassmaking during the early 1940s, and master glass blower Bill Claytor was well known in the industry. Mr. Claytor became renowned in Hartford City because of the hand-blown Christmas gifts he made from a small furnace in the garage of his home.

During World War II

, the company made water-tight globes and lenses for search lights. Additional consumer products included glass irons, skillets, and even kitchen sink

s. The 1946 management team was A. C. Crimmel president; Henry Hays Crimmel, Vice President; H.C. Hill, Secretary and Sales Manager; S.B. Sneath Jr., Treasurer; John Richard Crimmel, Assistant Treasurer and Purchasing Agent; and Ray Pruden, Superintendent. Refrigeration products continued to be the most important segment of the product portfolio at that time.

During 1952, the nation had a system of price controls that attempted to control post-war inflation. Workers at the Sneath Glass plant held a strike (the first ever for Sneath Glass), demanding better wage

s and fringe benefits. Unfortunately, even if the competitive market would accept higher prices for Sneath glassware, the nation’s Price Stabilization Board would not allow Sneath to increase prices – and the company was already losing money. The plant was closed, and approximately 125 families lost a source of income. The remaining company founder, A.C. Crimmel, died within two years. Ironically, Henry Crimmel helped found a company that lasted 60 years, and his brother Jacob helped found a union that contributed (along with management) to the company’s demise.

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

that was established in 1889 in Tiffin, Ohio

Tiffin, Ohio

Tiffin is a city in and the county seat of Seneca County, Ohio, United States. The population was 18,135 at the 2000 census. The National Arbor Day Foundation has designated Tiffin as a Tree City USA....

, under the name Tiffin Glass Company. Two years later, the company was renamed Sneath Glass Company, and it was reorganized and moved to Hartford City, Indiana

Hartford City, Indiana

Hartford City is a city in the U.S. state of Indiana, and the county seat of Blackford County. Located in the northeast central portion of the state, the small farming community experienced a 15-year “boom” beginning in the late 1880s...

, in 1894. Originally, lantern

Lantern

A lantern is a portable lighting device or mounted light fixture used to illuminate broad areas. Lanterns may also be used for signaling, as 'torches', or as general light sources outdoors . Low light level varieties are used for decoration. The term "lantern" is also used more generically to...

globes and founts (which held the lantern’s fuel) were the company’s main products. The company evolved to be a maker of glassware

Glassware

This list of glassware includes drinking vessels , tableware, such as dishes, and flatware used to set a table for eating a meal, general glass items such as vases, and glasses used in the catering industry whether made of glass or plastics such as polystyrene and...

for portable kitchen

Kitchen

A kitchen is a room or part of a room used for cooking and food preparation.In the West, a modern residential kitchen is typically equipped with a stove, a sink with hot and cold running water, a refrigerator and kitchen cabinets arranged according to a modular design. Many households have a...

cabinets, and later evolved again to be a maker of glass products for refrigerator

Refrigerator

A refrigerator is a common household appliance that consists of a thermally insulated compartment and a heat pump that transfers heat from the inside of the fridge to its external environment so that the inside of the fridge is cooled to a temperature below the ambient temperature of the room...

s. While these were the major products made by the company, it also made a wide variety of additional glass products, ranging from glass mailboxes to fish tanks. The factory closed in 1952 when it did not adapt to competition from the new plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

s industry, and could not raise product prices for its shrinking market due to post-war government price controls.

Early years

Indiana Gas Boom

The Indiana Gas Boom was a period of active drilling and production of natural gas in the Trenton Gas Field, in the US state of Indiana and the adjacent northwest part of Ohio The boom began in the early 1880s and lasted into the early twentieth century....

. The east-central Indiana territory around Hartford City had a “boom” period at that time caused by the discovery of natural gas, which was thought to be "practically unlimited". The town also had excellent transportation resources including two railroads, and, a decade later, the Indiana interurban street car system. The Sneath Glass plant was located on North Walnut Street. (Walnut Street eventually became part of Indiana State Road 3

Indiana State Road 3

State Road 3 in the U.S. State of Indiana is a discontinuous state road running through east central Indiana from near the Michigan state line to near the Ohio River...

, and is now the main north-south highway through town.)

Early officers of the company included Ralph Davis Sneath, president; J. W. Geiger, treasurer; Alvie Clyde Crimmel, secretary; and Henry Crimmel

Henry Crimmel

Henry Crimmel was an American glassmaker who became well known in Ohio and Indiana. A German that came with his family to America at the age of eight years old, the American Civil War veteran started at the lowest level in glass making, and learned every aspect of the business...

, manager. These four men were also the founders of the company, each owning equal shares of its stock. The board of directors consisted of the four founders plus Ralph's father, Samuel B. Sneath. The Sneaths came from a family of prominent businessmen, and the Crimmels came from a family of glassmakers. Ralph Sneath also became involved in a grain dealership, railroading, and banking. He eventually became president of the Commercial National Bank of Tiffin, Ohio, and also president of the Ohio Banker’s Association. Civil War veteran Henry Crimmel brought over 20 years of glass making experience to the company, having learned and sharpened his skills in Bellaire

Bellaire, Ohio

Bellaire is a village in Belmont County, Ohio, United States. It is part of the Wheeling, West Virginia Metropolitan Statistical Area. The population was 4,278 at the 2010 census. The village is located along the Ohio River...

and Fostoria, Ohio

Fostoria, Ohio

As of the census of 2000, there were 13,931 people, 5,565 households, and 3,628 families residing in the city. The population density was 1,917.6 people per square mile . There were 6,024 housing units at an average density of 829.2 per square mile...

. Henry’s deceased brother, Johannes (a.k.a. John) had been a manager at the Belmont Glass Works, and his brother Jacob helped found the American Flint Glass Workers Union. Both Henry and Jacob Crimmel were considered key craftsmen in the early days of Fostoria Glass Company

Fostoria Glass Company

The Fostoria Glass Company manufactured pressed, blown and hand-molded glassware and tableware for almost 90 years. It began operations in Fostoria, Ohio, USA, on December 15, 1887, at South Vine Street, near Railroad, on free land donated by the townspeople...

. While the Sneaths remained in Tiffin to oversee their many business interests, the Crimmels and J. W. Geiger moved to Hartford City.

By 1897, the company had over 60 employees. Although plant manager Henry Crimmel was known for his craftsmanship, he was also mechanically inclined. The Sneath plant had a unique system of air hose

Air hose

Air hoses are used in underwater diving, such as scuba diving, to carry air from the surface or from air tanks or diving pumps to the diver. Air hoses are therefore a necessary part of standard diving dress and any type of surface supplied diving equipment....

s that would allow glass blowers

Glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble, or parison, with the aid of a blowpipe, or blow tube...

to quickly finish glassware that was started without the aid of machinery, enabling the skilled workers to achieve a much higher production rate. Henry Crimmel received a patent in 1904 for a “Glass Drawing Machine” that was an improvement for glass blowing and prevented irregularities in the glass.

In 1905, Sneath Glass bought the Jones plant of the American Window Glass Company, located on Wabash Avenue in the west side of Hartford City. The Wabash Avenue site had direct access to a railroad, and was close to Washington Street, which eventually became part of Indiana State Road 26

Indiana State Road 26

State Road 26 is an east–west road in central Indiana in the United States that crosses the entire state from east to west, covering a distance of about .-Route description:...

, now the major east-west highway through the city. The Jones plant was quickly remodeled, and both operations and headquarters were moved to that site. This location became the permanent home of Sneath Glass Company.

Transition from globes to other products

Mason jar

A Mason jar is a glass jar used in canning to preserve food. They were invented and patented by John Landis Mason, a Philadelphia tinsmith in 1858. They are also called Ball jars, after Ball Corp., a popular and early manufacturer of the jars; fruit jars because they are often used to store...

s. During the next decade, the company began making glass canisters for kitchen cabinet companies, including the Hoosier cabinet

Hoosier cabinet

A Hoosier cabinet is a type of cupboard popular in the first decades of the 20th century. Named after the Hoosier Manufacturing Co. of New Castle, Indiana, they were also made by several other companies, most also located in Indiana....

made by Hoosier Manufacturing Company. This began the gradual (but important) transition from manufacturer of globes to manufacturer of glass products for portable kitchen cabinets. Cabinet products included salt and sugar bins, spice jars, and coffee and tea jars. From 1914 to 1916, management patented dispensing caps, a dispensing jar, and a dispensing bin used in kitchen cabinets.

Henry Crimmel suffered a stroke

Stroke

A stroke, previously known medically as a cerebrovascular accident , is the rapidly developing loss of brain function due to disturbance in the blood supply to the brain. This can be due to ischemia caused by blockage , or a hemorrhage...

in 1916, and died about one year later. His son (and company co-founder) Alva (a.k.a. Alvie) Clyde Crimmel took more management responsibilities at that time, and by 1920 his title was Vice-President and Treasurer. Clyde’s oldest son Henry Hays Crimmel joined the company’s management in 1918, focusing on sales. Henry Hays had been working at Sneath since he was a child, and was very familiar with the company's products. (The elder Henry Crimmel was fined $11.95 in 1901 by the state of Indiana for employing children under the age of 14. While this may seem "backward" today, child labor was common in glass factories during the 19th century and early 20th century. There is a high probability that Henry Crimmel began his glassmaking career as a child laborer in Wheeling, West Virginia. Henry's brother Jacob began working in Wheeling around the age of 13.

Several factors contributed to the need for a transition from globe manufacturer, and all related to less demand. First, the railroads were a major customer for lanterns and globes, but they had stopped expanding. Railroad route miles peaked around 1916, and railroad employees peaked around 1920. Since the railroad industry was shrinking, its demand for globes would diminish. Second, electrification

Electrification

Electrification originally referred to the build out of the electrical generating and distribution systems which occurred in the United States, England and other countries from the mid 1880's until around 1940 and is in progress in developing countries. This also included the change over from line...

and the incandescent light bulb

Incandescent light bulb

The incandescent light bulb, incandescent lamp or incandescent light globe makes light by heating a metal filament wire to a high temperature until it glows. The hot filament is protected from air by a glass bulb that is filled with inert gas or evacuated. In a halogen lamp, a chemical process...

began replacing oil lamps, and thus there was less need for lamp globes and fonts. Finally (and later), rural electrification

Rural electrification

Rural electrification is the process of bringing electrical power to rural and remote areas. Electricity is used not only for lighting and household purposes, but it also allows for mechanization of many farming operations, such as threshing, milking, and hoisting grain for storage; in areas...

also decreased farmers' need for oil lamps.

Sneath Glass Company Sales Brochure circa 1920

While this brochure mentions a patented dispenser cap, which was patented in 1915, it does not mention a patented bracket (1916) or patented rack (1924). Therefore, this brochure could have been made as early as 1915.The Sneath S mark

When the moulds

Molding (process)

Molding or moulding is the process of manufacturing by shaping pliable raw material using a rigid frame or model called a pattern....

for the glassware became unclean, they would need to be scrubbed – and after time the "S" would wear off. Eventually, the "S" was eliminated to save mould-cleaning time, but it also made Sneath product identification difficult for products made in the later years of the company's existence. That mistake enabled competitors to make their own products that appeared very similar to Sneath glassware.

The Great Depression and World War II

In 1930, management consisted of Ralph D. Sneath, president; Alvie Clyde Crimmel, vice president; Henry Hays Crimmel, treasurer and general manager; Harry C. Hill, secretary and sales manager; and Ray Pruden, factory manager. During the Great DepressionGreat Depression

The Great Depression was a severe worldwide economic depression in the decade preceding World War II. The timing of the Great Depression varied across nations, but in most countries it started in about 1929 and lasted until the late 1930s or early 1940s...

of the 1930s, Sneath kept much of its workforce employed by shortening shifts. This kept the company from losing its skilled workers, and enabled more people to be employed. The glass business was thought to have one advantage during difficult economic times: people purchased glass products rather than metal products.

Like the company's transition from lantern globes to glassware for kitchen cabinets, the transition to refrigerator products was important for the company's survival. By the mid-1930s, the Hoosier style cabinets, many of which contained glassware made by Sneath Glass, had lost their popularity. New houses typically contained built-in cabinetry.

Although the company had transitioned to refrigerator products as a focal point, it still made other merchandise. One product was the company's own version of borosilicate glass

Borosilicate glass

Borosilicate glass is a type of glass with the main glass-forming constituents silica and boron oxide. Borosilicate glasses are known for having very low coefficients of thermal expansion , making them resistant to thermal shock, more so than any other common glass...

, which was called "heat proof" glass. This glass could be moved from a refrigerator to an oven without breaking from the extreme temperature change. Heat proof glass was used for ovenware and coffee makers, – and during World War II, it was used in searchlight products. Unfortunately, the Sneath version of borosilicate glass, like the Sneath brand

Brand

The American Marketing Association defines a brand as a "Name, term, design, symbol, or any other feature that identifies one seller's good or service as distinct from those of other sellers."...

, was not promoted.

In 1940, millionaire Ralph Sneath died shortly after receiving severe injuries in an automobile accident, and the last of the founders, Alvie Clyde Crimmel, became chief executive. Although Mr. Sneath did not spend much time at the glass plant, he was well liked and watched the company finances. Despite this loss, an aging workforce, and an aging infrastructure, the company continued to have talent both in the manufacturing process and creatively. Employee James A. Lewis received three patents related to glassmaking during the early 1940s, and master glass blower Bill Claytor was well known in the industry. Mr. Claytor became renowned in Hartford City because of the hand-blown Christmas gifts he made from a small furnace in the garage of his home.

During World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

, the company made water-tight globes and lenses for search lights. Additional consumer products included glass irons, skillets, and even kitchen sink

Kitchen sink

Kitchen sink is a term often used in the phrase everything but the kitchen sinkKitchen sink may also refer to:* A sink in a kitchen for washing dishes, vegetables, etc* Kitchen Sink, a 1989 short film by Alison Maclean...

s. The 1946 management team was A. C. Crimmel president; Henry Hays Crimmel, Vice President; H.C. Hill, Secretary and Sales Manager; S.B. Sneath Jr., Treasurer; John Richard Crimmel, Assistant Treasurer and Purchasing Agent; and Ray Pruden, Superintendent. Refrigeration products continued to be the most important segment of the product portfolio at that time.

The end of Sneath Glass

In the early 1950s, glass manufacturers faced competition from the new plastics industry. Glass companies needed to change with the times or face extinction, and Sneath Glass did not make enough changes. Refrigerator parts such as drip plates were being made of plastic instead of glass, and the company declined opportunities in both fibreglass and plastics. By making glassware mostly for other companies, Sneath had lost brand recognition, and it did not promote the Sneath brand or products such as its heat proof glass. Competitors making ovenware products had gained much better brand recognition. This meant that the company faced declining demand for its top two categories of products.During 1952, the nation had a system of price controls that attempted to control post-war inflation. Workers at the Sneath Glass plant held a strike (the first ever for Sneath Glass), demanding better wage

Wage

A wage is a compensation, usually financial, received by workers in exchange for their labor.Compensation in terms of wages is given to workers and compensation in terms of salary is given to employees...

s and fringe benefits. Unfortunately, even if the competitive market would accept higher prices for Sneath glassware, the nation’s Price Stabilization Board would not allow Sneath to increase prices – and the company was already losing money. The plant was closed, and approximately 125 families lost a source of income. The remaining company founder, A.C. Crimmel, died within two years. Ironically, Henry Crimmel helped found a company that lasted 60 years, and his brother Jacob helped found a union that contributed (along with management) to the company’s demise.