Shell higher olefin process

Encyclopedia

The Shell higher olefin process is a chemical process

for the production of linear alpha olefin

s via ethylene oligomerization and olefin metathesis

invented and exploited by Royal Dutch Shell

. The olefin products are converted to fatty aldehydes and then to fatty alcohol

s, which are precursors plasticizer

s and detergent

s.

, which causes the internal double bond to break up into new internal double bonds in olefins of the desired intermediate molecular weight.

The C6 to C18 olefins subsequently are subjected to hydroformylation

(oxo process) to give aldehydes. Use of a cobalt catalyst (dicobalt octacarbonyl

) allows internal alkenes used, as they are isomerized to primary alkenes which thereafter undergo hydroformylation. The aldehyde is hydrogenated to give fatty alcohols, which are suitable for manufacturing detergents.

The process was commercialized in 1977 by Royal Dutch Shell

and in 1993 global annual production capacity was ten million tons.

oligomerization to a mixture of even-numbered α-olefins at 80 to 120 °C and 70 to 140 bar (7 to 14 MPa) catalyzed by a nickel-phosphine

complex. Such catalysts are typically prepared from diarylphosphinoacetic acids, such as (C6H5)2PCH2CO2H. The process and its mechanism was intensively studied by the group of Professor Wilhelm Keim

at the RWTH Aachen

, who is also regarded as one of the key figures in the development of the process.

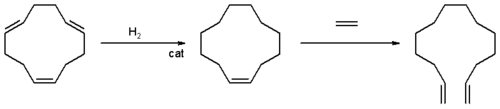

is partially hydrogenated

to cyclododecene and then subjected to ethenolysis to the terminal linear open-chain diene. The process is still in use at Shell Stanlow refinery.

Chemical process

In a "scientific" sense, a chemical process is a method or means of somehow changing one or more chemicals or chemical compounds. Such a chemical process can occur by itself or be caused by somebody. Such a chemical process commonly involves a chemical reaction of some sort...

for the production of linear alpha olefin

Linear alpha olefin

Linear Alpha Olefins or Normal Alpha Olefins are olefins or alkenes with a chemical formula CxH2x, distinguished from other mono-olefins with a similar molecular formula by linearity of the hydrocarbon chain and the position of the double bond at the primary or alpha position.Linear alpha olefins...

s via ethylene oligomerization and olefin metathesis

Olefin metathesis

Olefin metathesis or transalkylidenation is an organic reaction that entails redistribution of alkylene fragments by the scission of carbon - carbon double bonds in olefins . Its advantages include the creation of fewer sideproducts and hazardous wastes. Yves Chauvin, Robert H. Grubbs, and Richard R...

invented and exploited by Royal Dutch Shell

Royal Dutch Shell

Royal Dutch Shell plc , commonly known as Shell, is a global oil and gas company headquartered in The Hague, Netherlands and with its registered office in London, United Kingdom. It is the fifth-largest company in the world according to a composite measure by Forbes magazine and one of the six...

. The olefin products are converted to fatty aldehydes and then to fatty alcohol

Fatty alcohol

Fatty alcohols are aliphatic alcohols consisting of a chain of 8 to 22 carbon atoms. Fatty alcohols usually have even number of carbon atoms and a single alcohol group attached to the terminal carbon. Some are unsaturated and some are branched...

s, which are precursors plasticizer

Plasticizer

Plasticizers or dispersants are additives that increase the plasticity or fluidity of the material to which they are added; these include plastics, cement, concrete, wallboard, and clay. Although the same compounds are often used for both plastics and concretes the desired effects and results are...

s and detergent

Detergent

A detergent is a surfactant or a mixture of surfactants with "cleaning properties in dilute solutions." In common usage, "detergent" refers to alkylbenzenesulfonates, a family of compounds that are similar to soap but are less affected by hard water...

s.

Process

Ethylene reacts by the catalyst to give longer chains. Unlike the Ziegler-Natta process, which aims to produce very long polymers, the oligomer stops growing after addition of 1-10 repeating units of ethylene. The fraction containing C6 to C18 olefins has commercial value and is removed. The remaining higher and lower olefins next undergo isomerization reactions leading to internal double bonds and then, in the presence of ethylene, to olefin metathesisOlefin metathesis

Olefin metathesis or transalkylidenation is an organic reaction that entails redistribution of alkylene fragments by the scission of carbon - carbon double bonds in olefins . Its advantages include the creation of fewer sideproducts and hazardous wastes. Yves Chauvin, Robert H. Grubbs, and Richard R...

, which causes the internal double bond to break up into new internal double bonds in olefins of the desired intermediate molecular weight.

The C6 to C18 olefins subsequently are subjected to hydroformylation

Hydroformylation

Hydroformylation, also known as oxo synthesis or oxo process, is an important industrial process for the production of aldehydes from alkenes. This chemical reaction entails the addition of a formyl group and a hydrogen atom to a carbon-carbon double bond...

(oxo process) to give aldehydes. Use of a cobalt catalyst (dicobalt octacarbonyl

Dicobalt octacarbonyl

Dicobalt octacarbonyl is the inorganic compound Co28. This metal carbonyl is a reagent and catalyst in organometallic chemistry and organic synthesis. It is used as a catalyst for hydroformylation, the conversion of alkenes to aldehydes....

) allows internal alkenes used, as they are isomerized to primary alkenes which thereafter undergo hydroformylation. The aldehyde is hydrogenated to give fatty alcohols, which are suitable for manufacturing detergents.

The process was commercialized in 1977 by Royal Dutch Shell

Royal Dutch Shell

Royal Dutch Shell plc , commonly known as Shell, is a global oil and gas company headquartered in The Hague, Netherlands and with its registered office in London, United Kingdom. It is the fifth-largest company in the world according to a composite measure by Forbes magazine and one of the six...

and in 1993 global annual production capacity was ten million tons.

Catalytic cycle

The first step in this process is the ethyleneEthylene

Ethylene is a gaseous organic compound with the formula . It is the simplest alkene . Because it contains a carbon-carbon double bond, ethylene is classified as an unsaturated hydrocarbon. Ethylene is widely used in industry and is also a plant hormone...

oligomerization to a mixture of even-numbered α-olefins at 80 to 120 °C and 70 to 140 bar (7 to 14 MPa) catalyzed by a nickel-phosphine

Phosphine

Phosphine is the compound with the chemical formula PH3. It is a colorless, flammable, toxic gas. Pure phosphine is odourless, but technical grade samples have a highly unpleasant odor like garlic or rotting fish, due to the presence of substituted phosphine and diphosphine...

complex. Such catalysts are typically prepared from diarylphosphinoacetic acids, such as (C6H5)2PCH2CO2H. The process and its mechanism was intensively studied by the group of Professor Wilhelm Keim

Wilhelm Keim

Wilhelm Keim is a German chemist and Professor Emeritus for Technical Chemistry and former director of the Institute for Technical and Petrol Chemistry at RWTH Aachen in Germany....

at the RWTH Aachen

RWTH Aachen

RWTH Aachen University is a research university located in Aachen, North Rhine-Westphalia, Germany with roughly 33,000 students enrolled in 101 study programs....

, who is also regarded as one of the key figures in the development of the process.

Alternative routes

In another olefin application of Shell cyclododecatrieneCyclododecatriene

Cyclododecatriene C12H18 is a cycloalkene with three alkene groups. The 1,3,5-trans-trans-cis isomer has some industrial importance and is obtained by cyclotrimerization of butadiene with titanium tetrachloride and an organoaluminium co-catalyst :...

is partially hydrogenated

Hydrogenation

Hydrogenation, to treat with hydrogen, also a form of chemical reduction, is a chemical reaction between molecular hydrogen and another compound or element, usually in the presence of a catalyst. The process is commonly employed to reduce or saturate organic compounds. Hydrogenation typically...

to cyclododecene and then subjected to ethenolysis to the terminal linear open-chain diene. The process is still in use at Shell Stanlow refinery.