Mechanization

Encyclopedia

British English

British English, or English , is the broad term used to distinguish the forms of the English language used in the United Kingdom from forms used elsewhere...

) is providing human operators with machinery that assists them with the muscular requirements of work or displaces muscular work. In some fields, mechanization includes the use of hand tools. In modern usage, such as in engineering or economics, mechanization implies machinery more complex than hand tools and would not include simple devices such as an un-geared horse or donkey mill. Devices that cause speed changes or changes to or from reciprocating to rotary motion, using means such as gears

Gear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

, pulleys

Pulley

A pulley, also called a sheave or a drum, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. A rope, cable, belt, or chain usually runs over the wheel and inside the groove, if present...

or sheaves

Line shaft

A line shaft is a power transmission system used extensively during the Industrial Revolution. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery...

and belts, shafts, cams

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

and cranks

Crank (mechanism)

A crank is an arm attached at right angles to a rotating shaft by which reciprocating motion is imparted to or received from the shaft. It is used to change circular into reciprocating motion, or reciprocating into circular motion. The arm may be a bent portion of the shaft, or a separate arm...

, usually are considered machines.

History

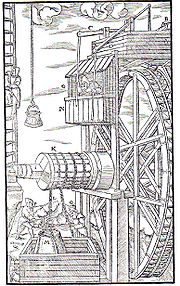

Water wheels date to the Roman period and were used to grind grain and lift irrigation water. By the 13th century water wheels powered sawmills and power trip hammerTrip hammer

A trip hammer, also known as a helve hammer, is a massive powered hammer used in:* agriculture to facilitate the labor of pounding, decorticating and polishing of grain;...

s to full cloth and pound flax and later cotton rags into pulp for making paper. Trip hammers are shown crushing ore in De re Metallica

De re metallica

De re metallica is a book cataloguing the state of the art of mining, refining, and smelting metals, published in 1556. The author was Georg Bauer, whose pen name was the Latinized Georgius Agricola...

(1555).

Clocks

Clock

A clock is an instrument used to indicate, keep, and co-ordinate time. The word clock is derived ultimately from the Celtic words clagan and clocca meaning "bell". A silent instrument missing such a mechanism has traditionally been known as a timepiece...

were some of the most complex early mechanical devices. Clock makers were important developers of machine tools including gear and screw cutting machines and were also involved in the mathematical development of gear designs. Clocks were some of the earliest mass produced items, beginning around 1830.

Water powered bellows for blast furnaces were in use in the 15th century.

The Newcomen steam engine

Newcomen steam engine

The atmospheric engine invented by Thomas Newcomen in 1712, today referred to as a Newcomen steam engine , was the first practical device to harness the power of steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines,...

was first used, to pump water from a mine, in 1712.

John Smeaton

John Smeaton

John Smeaton, FRS, was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent physicist...

introduced metal gears and axles to water wheels in the mid to last half of the 18th century.

The Industrial Revolution

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

started mainly with textile machinery, such as the spinning jenny

Spinning jenny

The spinning jenny is a multi-spool spinning frame. It was invented c. 1764 by James Hargreaves in Stanhill, Oswaldtwistle, Lancashire in England. The device reduced the amount of work needed to produce yarn, with a worker able to work eight or more spools at once. This grew to 120 as technology...

(1764) and water frame

Water frame

The water frame is the name given to the spinning frame, when water power is used to drive it. Both are credited to Richard Arkwright who patented the technology in 1768. It was based on an invention by Thomas Highs and the patent was later overturned...

(1768). Demand for metal parts used in textile machinery led to the invention of many machine tool

Machine tool

A machine tool is a machine, typically powered other than by human muscle , used to make manufactured parts in various ways that include cutting or certain other kinds of deformation...

s in the late 1700s until the mid 1800s, and it was during this time that iron replaced wood in gearing and shafts in textile machinery. Machine tools changed over from hand power to water and steam power and became self-acting in the mid 19th century.

Mathematical gear designs, such as epicycloidal

Epicycloid

In geometry, an epicycloid is a plane curve produced by tracing the path of a chosen point of a circle — called an epicycle — which rolls without slipping around a fixed circle...

, were developed in the late 17th century. In the 18th century involute gears

Involute gear

The involute gear profile is the most commonly used system for gearing today. In an involute gear, the profiles of the teeth are involutes of a circle. In involute gear design contact between a pair of gear teeth occurs...

, another mathematical derived design, came into use. Gear cutting machines came into use in the 18th century.

One of the first mechanical devices used in agriculture was the seed drill

Seed drill

A seed drill is a sowing device that precisely positions seeds in the soil and then covers them. Before the introduction of the seed drill, the common practice was to plant seeds by hand. Besides being wasteful, planting was very imprecise and led to a poor distribution of seeds, leading to low...

invented by Jethro Tull

Jethro Tull (agriculturist)

Jethro Tull was an English agricultural pioneer who helped bring about the British Agricultural Revolution. He perfected a horse-drawn seed drill in 1701 that economically sowed the seeds in neat rows, and later a horse-drawn hoe...

around 1700. The seed drill allowed more uniform spacing of seed and planting depth than hand methods, increasing yields and saving valuable seed. Mechanized agriculture greatly increased in the late eighteenth and early nineteenth centuries with horse drawn reaper

Reaper

A reaper is a person or machine that reaps crops at harvest, when they are ripe.-Hand reaping:Hand reaping is done by various means, including plucking the ears of grains directly by hand, cutting the grain stalks with a sickle, cutting them with a scythe, or with a later type of scythe called a...

s and horse powered threshing machine

Threshing machine

The thrashing machine, or, in modern spelling, threshing machine , was a machine first invented by Scottish mechanical engineer Andrew Meikle for use in agriculture. It was invented for the separation of grain from stalks and husks. For thousands of years, grain was separated by hand with flails,...

s. By the late nineteenth century steam power was applied to threshing and steam tractors appeared. Internal combustion began being used for tractors in the early twentieth century. Threshing and harvesting was originally done with attachments for tractors, but in the 1930s independently powered combine harvesters were in use.

Categories

Inside factories, warehouses, lumber yards and other manufacturing and distribution operations, material handling

Material handling

-Material Handling Industry:Material Handling is the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal. The focus is on the methods, mechanical equipment, systems and related controls used to...

equipment replaced manual carrying or hand trucks and carts.

See: list of agricultural machinery

See also: Productivity improving technologies (historical)

Productivity improving technologies (historical)

Productivity improving technologies date back to antiquity, with rather slow progress until the late Middle Ages. Technological progress was aided by literacy and the diffusion of knowledge that accelerated after the spinning wheel spread to Western Europe in the 13th century...

Section 4

See also: Mechanized agriculture

In mining and excavation, power shovels replaced picks and shovels.

Bulk material handling

Bulk material handling

Bulk material handling is an engineering field that is centered around the design of equipment used for the handling of dry materials such as ores, coal, cereals, wood chips, sand, gravel and stone in loose bulk form...

systems and equipment are used for for a variety of materials including coal, ores, grains, sand, gravel and wood products.

Powered machinery

Powered machinery today usually means either by electric motor or internal combustion engine. Before the first decade of the 20th century powered usually meant by steam engine, water or wind.Before electrification

Electrification

Electrification originally referred to the build out of the electrical generating and distribution systems which occurred in the United States, England and other countries from the mid 1880's until around 1940 and is in progress in developing countries. This also included the change over from line...

, mill and factory power was usually transmitted using a line shaft

Line shaft

A line shaft is a power transmission system used extensively during the Industrial Revolution. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery...

. Electrification allowed individual machines to each be powered by a separate motor in what in called unit drive. Unit drive allowed factories to be better arranged and allowed different machines to run at different speeds. Unit drive also allowed much higher speeds, which was especially important for machine tools.

A step beyond mechanization is automation

Automation

Automation is the use of control systems and information technologies to reduce the need for human work in the production of goods and services. In the scope of industrialization, automation is a step beyond mechanization...

. Early production machinery, such as the glass bottle blowing machine (ca. 1890s), required a lot of operator involvement. By the 1920s fully automatic machines, which required much less operator attention, were being used.

Military usage

The term is also used in the military to refer to the use of trackedCaterpillar track

Continuous tracks or caterpillar tracks are a system of vehicle propulsion in which modular metal plates linked into a continuous band are driven by two or more wheels...

armoured vehicles

Armoured fighting vehicle

An armoured fighting vehicle is a combat vehicle, protected by strong armour and armed with weapons. AFVs can be wheeled or tracked....

, particularly armoured personnel carrier

Armoured personnel carrier

An armoured personnel carrier is an armoured fighting vehicle designed to transport infantry to the battlefield.APCs are usually armed with only a machine gun although variants carry recoilless rifles, anti-tank guided missiles , or mortars...

s, to move troops that would otherwise have marched or ridden trucks into combat. Mechanization dramatically improved the mobility and fighting capability of infantry

Infantry

Infantrymen are soldiers who are specifically trained for the role of fighting on foot to engage the enemy face to face and have historically borne the brunt of the casualties of combat in wars. As the oldest branch of combat arms, they are the backbone of armies...

. In the armed forces of industrialized countries, all infantry is typically mechanized, with the possible exception of airborne forces

Airborne forces

Airborne forces are military units, usually light infantry, set up to be moved by aircraft and 'dropped' into battle. Thus they can be placed behind enemy lines, and have an ability to deploy almost anywhere with little warning...

.

Mechanization may also refer in the broader military sense to "motorization" or the replacement of horses with motor vehicles for all functions, including logistics, artillery tractors, etc.

Mechanical vs human labour

When we compare the efficiency of a labourer, we see that he has an efficiency of about 1%-5.5% (depending on whether he uses arms, or a combination of arms and legs). Internal combustion engines mostly have an efficiency of about 20%, although large diesel enginesWärtsilä-Sulzer RTA96-C

The Wärtsilä RT-flex96C is a two-stroke turbocharged low-speed diesel engine designed by the Finnish manufacturer Wärtsilä. It is currently considered the largest reciprocating engine in the world, designed for large container ships, running on heavy fuel oil...

, such as those used to power ships, may have efficiencies of nearly 50%. Industrial electric motors have efficiencies up to the low 90% range, before correcting for the conversion efficiency of fuel to electricity of about 35%.

When we compare the costs of using an internal combustion engine to a worker to perform work, we notice that an engine can perform more work at a comparative cost. 1 liter of fossil fuel burnt with a IC engine equals about 50 hands of workers operating for 24 hours or 275 arms and legs for 24 hours.

In addition, the combined work capability of a human is also much lower than that of a machine. An average human can provide work good for around 250Wh/day, while a machine (depending on the type and size) can provide for far greater amounts of work. For example it takes four days of hard labour to deliver only one kWh - which a small engine could deliver in less than one hour while burning less than one litre of petroleum fuel. This implies that a gang of 20 to 40 men will require a financial compensation for their work at least equal to the required expended food calories (which is at least 4 to 20 times higher). In most situations, the worker will also want compensation for the lost time, which is easily 96 times greater per day. Even if we assume the real wage cost for the human labour to be at US $1.00/day, an energy cost is generated of about $4.00/kWh. Despite this being a low wage for hard labour, even in some of the countries with the lowest wages, it represents an energy cost that is significantly more expensive than even exotic power sources such as solar photovoltaic panels (and thus even more expensive when compared to wind energy harvesters or luminescent solar concentrators).

Levels of Mechanization

For simplification, Mechanization can be studied under different steps. Many students refer to this as a basic to advanced form of Mechanical society.- Hand/ Muscle power

- Hand tools

- Powered hand tools, e.g. electric controlled

- Powered tools, single functioned, fixed cycle

- Powered tools, multi-functioned, program controlled

- Powered tools, remote controlled

- Powered tools, activated by work piece, e.g. coin phone

- Measurement

- Selected signaling control, e.g. hydro power control

- Performance recording

- Machine action altered through measurement

- Segregation/rejection according to measurement

- Selection of appropriate action cycle

- Correcting performance after operation

- Correcting performance during operation

See also

- AutomationAutomationAutomation is the use of control systems and information technologies to reduce the need for human work in the production of goods and services. In the scope of industrialization, automation is a step beyond mechanization...

- Productivity improving technologies (historical)#4. Mechanization (general) and in agriculture

- Mass productionMass productionMass production is the production of large amounts of standardized products, including and especially on assembly lines...

- Assembly lineAssembly lineAn assembly line is a manufacturing process in which parts are added to a product in a sequential manner using optimally planned logistics to create a finished product much faster than with handcrafting-type methods...

- Mechanized agriculture

- Bulk materials handling