Gore-Tex

Encyclopedia

Gore-Tex is a waterproof/breathable fabric

, and a registered trademark of W. L. Gore and Associates. It was co-invented by Wilbert L. Gore

, Rowena Taylor, and Gore's son, Robert W. Gore

. Robert Gore was granted on April 27, 1976, for a porous form of polytetrafluoroethylene

(the chemical constituent of Teflon) with a micro-structure characterized by nodes interconnected by fibrils. Robert Gore, Rowena Taylor, and Samuel Allen were granted on March 18, 1980 for a "waterproof laminate." For its invention, Robert W. Gore was inducted into the National Inventors Hall of Fame

in 2006.

In 1969, Bob Gore independently discovered expanded polytetrafluoroethylene

(ePTFE) and introduced it to the public under the trademark Gore-Tex, for which he promptly applied for and obtained , issued April 27, 1976 and , issued February 5, 1980.

In the 1970s Garlock, Inc. infringed Gore's patents and was promptly sued by Gore in the Federal District Court of Ohio. After a "bitterly contested case" that "involved over two years of discovery, five weeks of trial, the testimony of 35 witnesses (19 live, 16 by deposition), and over 300 exhibits," (quoting the Federal Circuit) the District Court held Gore's patents to be invalid. On appeal, however, the Federal Circuit disagreed in the famous case of Gore v. Garlock, reversing the lower court's decision on the ground, inter alia, that Cropper forfeited any superior claim to the invention by virtue of having concealed the process for making ePTFE from the public, thereby establishing Gore as the legal inventor.

PTFE is made using an emulsion polymerization

process that utilizes the fluorosurfactant

PFOA

, a persistent environmental contaminant. As Gore-Tex is PTFE-based, PFOA is used in its production.

Gore-Tex materials are typically based on thermo-mechanically expanded polytetrafluoroethylene

Gore-Tex materials are typically based on thermo-mechanically expanded polytetrafluoroethylene

(PTFE) and other fluoropolymer

products. They are used in a wide variety of applications such as high performance fabric

s, medical implants, filter media, insulation

for wires and cables, gasket

s, and sealants. However, Gore-Tex fabric is best known for its use in protective, yet breathable, rainwear.

The simplest sort of rain wear is a two layer sandwich. The outer layer is typically nylon

or polyester

and provides strength. The inner one is polyurethane

(abbreviated: PU), and provides water resistance, at the cost of breathability.

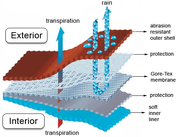

Early Gore-Tex fabric replaced the inner layer of PU with a thin, porous fluoropolymer membrane (Teflon) coating that is bonded to a fabric. This membrane had about 9 billion pores per square inch

(around 1.4 billion pores per square centimeter). Each pore is approximately 1/20,000 the size of a water droplet, making it impenetrable to liquid water while still allowing the more autonomous water vapour molecules to pass through.

However it was found that when used in clothing the exposed Teflon membrane layer was easily damaged, as well as being compromised by exposure to the wearer's own perspiration. As a result a third, monolithic PU layer was added, denoted in the schematic (see right) as the inner of the "protection" layers. Finally either a loose fabric shell layer, or a bonded coating (typically a grid fabric, or occasionally a carbon layer as in Gore-Tex Paclite Shell) is added to the garment to protect the membrane sandwich. This final design has been criticized as offering greatly reduced performance and more marketing

benefits than performance ones.

More recent fabrics such as eVent, Nikwax Analogy

and Epic avoid the need for this inner PU coating and have been shown to have higher breathability as a result, while still being rainproof.

, is similar to Gore-Tex in being windproof and breathable, but has ability to stretch and is not waterproof.

Gore-Tex is also playing an increasing role in the conservation of illuminated manuscripts

.

Explosive sensors have been printed on Gore-Tex clothing leading to the sensitive voltammetric detection of nitroaromatic compounds.

The Gore naming system does not imply specific technology or material but instead specific set of performance characteristics.

The "Gore-Tex" brand name was formerly used for industrial and medical products.

Waterproof fabric

Waterproof fabrics are fabrics that are inherently, or have been treated to become, resistant to penetration by water and wetting. They are usually natural or synthetic fabrics that are laminated to or coated with a waterproofing material such as rubber, polyvinyl chloride , polyurethane , silicone...

, and a registered trademark of W. L. Gore and Associates. It was co-invented by Wilbert L. Gore

Bill Gore

Wilbert L. "Bill" Gore was a businessman and entrepreneur who co-founded W. L. Gore and Associates with his wife, Genevieve . He gained international attention and respect for nurturing the company from a home-based family business into a worldwide corporation while practicing a unique management...

, Rowena Taylor, and Gore's son, Robert W. Gore

Robert W. Gore

Robert W. "Bob" Gore is an American engineer and scientist, inventor and businessman, who along with his father Bill Gore invented Gore-Tex, a waterproof/breathable fabric made from polytetrafluoroethylene ....

. Robert Gore was granted on April 27, 1976, for a porous form of polytetrafluoroethylene

Polytetrafluoroethylene

Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene that finds numerous applications. PTFE is most well known by the DuPont brand name Teflon....

(the chemical constituent of Teflon) with a micro-structure characterized by nodes interconnected by fibrils. Robert Gore, Rowena Taylor, and Samuel Allen were granted on March 18, 1980 for a "waterproof laminate." For its invention, Robert W. Gore was inducted into the National Inventors Hall of Fame

National Inventors Hall of Fame

The National Inventors Hall of Fame is a not-for-profit organization dedicated to recognizing, honoring and encouraging invention and creativity through the administration of its programs. The Hall of Fame honors the men and women responsible for the great technological advances that make human,...

in 2006.

History and manufacture

In 1966, John W. Cropper of New Zealand developed and constructed a machine for producing stretched PTFE tape. Rather than file for a patent, however, Cropper chose to keep the process of creating expanded PTFE as a closely held trade secret and required his producer and its employees to sign confidentiality agreements.In 1969, Bob Gore independently discovered expanded polytetrafluoroethylene

Polytetrafluoroethylene

Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene that finds numerous applications. PTFE is most well known by the DuPont brand name Teflon....

(ePTFE) and introduced it to the public under the trademark Gore-Tex, for which he promptly applied for and obtained , issued April 27, 1976 and , issued February 5, 1980.

In the 1970s Garlock, Inc. infringed Gore's patents and was promptly sued by Gore in the Federal District Court of Ohio. After a "bitterly contested case" that "involved over two years of discovery, five weeks of trial, the testimony of 35 witnesses (19 live, 16 by deposition), and over 300 exhibits," (quoting the Federal Circuit) the District Court held Gore's patents to be invalid. On appeal, however, the Federal Circuit disagreed in the famous case of Gore v. Garlock, reversing the lower court's decision on the ground, inter alia, that Cropper forfeited any superior claim to the invention by virtue of having concealed the process for making ePTFE from the public, thereby establishing Gore as the legal inventor.

PTFE is made using an emulsion polymerization

Emulsion polymerization

Emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water, monomer, and surfactant. The most common type of emulsion polymerization is an oil-in-water emulsion, in which droplets of monomer are emulsified in a continuous phase of water...

process that utilizes the fluorosurfactant

Fluorosurfactant

Fluorosurfactants, or fluorinated surfactants, are synthetic organofluorine chemical compounds that have multiple fluorine atoms. They can be polyfluorinated or fluorocarbon-based . As surfactants, they are more effective at lowering the surface tension of water than comparable hydrocarbon...

PFOA

Perfluorooctanoic acid

Perfluorooctanoic acid , also known as C8 and perfluorooctanoate, is a synthetic, stable perfluorinated carboxylic acid and fluorosurfactant. One industrial application is as a surfactant in the emulsion polymerization of fluoropolymers. It has been used in the manufacture of such prominent...

, a persistent environmental contaminant. As Gore-Tex is PTFE-based, PFOA is used in its production.

Design

Polytetrafluoroethylene

Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene that finds numerous applications. PTFE is most well known by the DuPont brand name Teflon....

(PTFE) and other fluoropolymer

Fluoropolymer

A fluoropolymer is a fluorocarbon based polymer with multiple strong carbon–fluorine bonds. It is characterized by a high resistance to solvents, acids, and bases.-History:Fluoropolymers were accidentally discovered in 1938 by Dr. Roy J...

products. They are used in a wide variety of applications such as high performance fabric

Textile

A textile or cloth is a flexible woven material consisting of a network of natural or artificial fibres often referred to as thread or yarn. Yarn is produced by spinning raw fibres of wool, flax, cotton, or other material to produce long strands...

s, medical implants, filter media, insulation

Electrical insulation

thumb|250px|[[Coaxial Cable]] with dielectric insulator supporting a central coreThis article refers to electrical insulation. For insulation of heat, see Thermal insulation...

for wires and cables, gasket

Gasket

thumb|sright|250px|Some seals and gaskets1. [[o-ring]]2. fiber [[Washer |washer]]3. paper gaskets4. [[cylinder head]] [[head gasket|gasket]]...

s, and sealants. However, Gore-Tex fabric is best known for its use in protective, yet breathable, rainwear.

The simplest sort of rain wear is a two layer sandwich. The outer layer is typically nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

or polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

and provides strength. The inner one is polyurethane

Polyurethane

A polyurethane is any polymer composed of a chain of organic units joined by carbamate links. Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer with another monomer in the presence of a catalyst.Polyurethanes are...

(abbreviated: PU), and provides water resistance, at the cost of breathability.

Early Gore-Tex fabric replaced the inner layer of PU with a thin, porous fluoropolymer membrane (Teflon) coating that is bonded to a fabric. This membrane had about 9 billion pores per square inch

Porosity

Porosity or void fraction is a measure of the void spaces in a material, and is a fraction of the volume of voids over the total volume, between 0–1, or as a percentage between 0–100%...

(around 1.4 billion pores per square centimeter). Each pore is approximately 1/20,000 the size of a water droplet, making it impenetrable to liquid water while still allowing the more autonomous water vapour molecules to pass through.

However it was found that when used in clothing the exposed Teflon membrane layer was easily damaged, as well as being compromised by exposure to the wearer's own perspiration. As a result a third, monolithic PU layer was added, denoted in the schematic (see right) as the inner of the "protection" layers. Finally either a loose fabric shell layer, or a bonded coating (typically a grid fabric, or occasionally a carbon layer as in Gore-Tex Paclite Shell) is added to the garment to protect the membrane sandwich. This final design has been criticized as offering greatly reduced performance and more marketing

Marketing

Marketing is the process used to determine what products or services may be of interest to customers, and the strategy to use in sales, communications and business development. It generates the strategy that underlies sales techniques, business communication, and business developments...

benefits than performance ones.

More recent fabrics such as eVent, Nikwax Analogy

Nikwax Analogy

Nikwax Analogy is a two-component fabric system for weatherproof clothing based on "biomimicry" of fur .-Technology:...

and Epic avoid the need for this inner PU coating and have been shown to have higher breathability as a result, while still being rainproof.

Care of Gore-Tex fabric

- As dirt - and even human sweat - will block the pores that allow Gore-Tex to breathe, clothing that uses it should be kept clean for best performance, as well as hygiene and appearance reasons.

- Both wear and cleaning will reduce the performance of Gore-Tex clothes by wearing away the Durable Water RepellentDurable Water RepellentDWR is a coating added to fabrics at the factory to make them water-resistant . Most factory-applied treatments are fluoropolymer based. Durable water repellents are commonly used in conjunction with waterproof breathable fabrics such as Gore-Tex to prevent the outer layer of fabric from becoming...

(DWR) treatment on the surface of the fabric. The DWR prevents the face fabric from becoming wet and thus reducing breathability. However, the DWR is not responsible for the jacket being waterproof. This is a common misconception, so when the face fabric becomes soaked due to an absence of DWR, there is no breathability and the wearer's sweat will cause condensation to form inside the jacket. This may give the appearance that a jacket is leaking when is not, but the DWR is still crucial to the best performance of any membrane-based waterproof. It can be reinvigorated by tumble drying the garment or ironing on a low setting. If this does not work, re-proofing the garment by applying a topical water repellency restorative (DWR treatment) for outdoor fabrics can be used. Wash-in re-proofers are not recommended for this use, as they can hinder the garment's breathability.

- A guide to maintaining Gore-Tex fabrics is available.

Other uses

Gore requires that all garments made from their material have taping over the seams, to eliminate leaks. Gore's sister product, WindstopperWindstopper

Windstopper is a fabric laminate made by W.L. Gore & Associates. It is similar to Gore-Tex, except that it is only windproof and breathable, not waterproof...

, is similar to Gore-Tex in being windproof and breathable, but has ability to stretch and is not waterproof.

Gore-Tex is also playing an increasing role in the conservation of illuminated manuscripts

Preservation of Illuminated Manuscripts

Preserving parchment becomes more difficult when pigments, inks, and illumination are added into the equation. Pigments do not dye parchment; instead, they lie on the surface of the parchment and so are rather fragile. The goal of restoring illuminated manuscripts should be to make them as...

.

Explosive sensors have been printed on Gore-Tex clothing leading to the sensitive voltammetric detection of nitroaromatic compounds.

The Gore naming system does not imply specific technology or material but instead specific set of performance characteristics.

The "Gore-Tex" brand name was formerly used for industrial and medical products.