GM 2300 engine

Encyclopedia

Straight-4

The inline-four engine or straight-four engine is an internal combustion engine with all four cylinders mounted in a straight line, or plane along the crankcase. The single bank of cylinders may be oriented in either a vertical or an inclined plane with all the pistons driving a common crankshaft....

automobile engine produced by the Chevrolet

Chevrolet

Chevrolet , also known as Chevy , is a brand of vehicle produced by General Motors Company . Founded by Louis Chevrolet and ousted GM founder William C. Durant on November 3, 1911, General Motors acquired Chevrolet in 1918...

division of General Motors

General Motors

General Motors Company , commonly known as GM, formerly incorporated as General Motors Corporation, is an American multinational automotive corporation headquartered in Detroit, Michigan and the world's second-largest automaker in 2010...

for the 1971–1977 model years. The Chevrolet Vega

Chevrolet Vega

The Chevrolet Vega is a subcompact, two-door automobile that was produced by the Chevrolet division of General Motors for the 1971-1977 model years. Named after the star Vega, the car was powered by a lightweight aluminum-block inline four-cylinder engine...

engine was ahead of its time with its die-cast aluminum-alloy cylinder block

Cylinder block

A cylinder block is an integrated structure comprising the cylinder of a reciprocating engine and often some or all of their associated surrounding structures...

. The high-tech block features an alloy with 17 percent silicon

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

. During the machining process, the cylinders were etched leaving the pure silicon particles exposed providing the piston wear surface, eliminating the need for iron cylinder liners. The block has cast iron main caps and a cast iron crankshaft. The engine's cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

is cast iron for lower cost, structural integrity and longer camshaft bearing life. The valvetrain features a direct-acting single overhead camshaft design.

Overview

The tall, long-stroke motor's vibration tendencies are helped by large rubber engine mounts. 1 and 2 barrel carb versions were offered. The 2-barrel version, the L11 option, also included a hotter camshaftCamshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

for a power increase of 20 hp (15 kW). The engine used a 3.501 in (88.9 mm) bore and 3.625 in (92.2 mm) stroke and 8:1 compression.

Overheating is a serious concern for the engine, since the engine block is of an open-deck design, severe overheating could cause the cylinder barrels to warp and pull away from the head gasket, causing coolant leaks into the cylinders and cylinder scuffing. Maintaining oil and coolant levels is crucial for the engine. Chevrolet dealers installed a coolant recovery tank, a low coolant warning light and extended Vega's engine warranty to 50000 miles (80,467 km) to all Vega owners. This proved costly for Chevrolet.

The 1976–'77 2300 engine received a new cylinder head design incorporating hydraulic lifters to replace the taper-screw valve adjusters, improved coolant pathways, longer-life valve stem seals, a redesigned water pump and thermostat, and a five-year, 60000 miles (96,560.4 km) engine warranty. The engine's name was changed to Dura-Built 140.

1975–'76 Pontiac Astre and 1975–77 Chevrolet Monza

Chevrolet Monza

The Chevrolet Monza is a subcompact, four-passenger automobile produced by the Chevrolet division of General Motors for the 1975–1980 model years. The Monza is based on the Chevrolet Vega, sharing its wheelbase, width and 140 CID inline-4 engine...

had the Vega engine as standard equipment. Monza's H-body variants, the Pontiac Sunbird

Pontiac Sunbird

The Pontiac Sunbird, produced by the Pontiac division of General Motors, was Pontiac's second small-car offering of the 70's. The Sunbird model ran for 18 years and was then replaced in 1995 by the Pontiac Sunfire...

and Oldsmobile Starfire

Oldsmobile Starfire

Oldsmobile Starfire are automobiles produced by the Oldsmobile division of General Motors in two generations from 1961–1966 and 1975–1980. The Starfire nameplate was also used for the 1954–1956 Ninety- Eight series convertibles, and all 1957 Ninety-Eight series models. 1961 was the first year for...

adopted Vega's revised Dura-built 140 engine one year only, for 1976 and 1977 respectively.

The Cosworth Vega engine was produced in 1975 and 1976 using the 2300 engine block. The engine is de-stroked to 3.16 in (80 mm), giving 122 cu in (1994 cc), with a 16-valve aluminum cylinder head, double overhead cams (DOHC), forged

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. Forging is often classified according to the temperature at which it is performed: '"cold," "warm," or "hot" forging. Forged parts can range in weight from less than a kilogram to 580 metric tons...

components and solid lifter

Lifter

Lifter can mean:* Ionocraft, a device that can generate thrust using ionised air with no moving parts* Tappet, part of an internal combustion engine that actuates a poppet valve through rocker arms and pushrods...

s. It produces 110 hp and 107 lbft .

Aluminum engine block

GM Research Labs had been working on a sleeveless aluminum block since the late '50s. The incentive was cost. Engineering out the four-cylinder's block liners would save $8 per unit — a substantial amount of money at the time. Reynolds Metal Co. developed an eutecticEutectic system

A eutectic system is a mixture of chemical compounds or elements that has a single chemical composition that solidifies at a lower temperature than any other composition. This composition is known as the eutectic composition and the temperature is known as the eutectic temperature...

aluminum alloy called A-390, composed of 77 percent aluminum, 17 percent silicon

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

, 4 percent copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

, 1 percent iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

, and traces of phosphorus

Phosphorus

Phosphorus is the chemical element that has the symbol P and atomic number 15. A multivalent nonmetal of the nitrogen group, phosphorus as a mineral is almost always present in its maximally oxidized state, as inorganic phosphate rocks...

, zinc

Zinc

Zinc , or spelter , is a metallic chemical element; it has the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. Zinc is, in some respects, chemically similar to magnesium, because its ion is of similar size and its only common oxidation state is +2...

, manganese

Manganese

Manganese is a chemical element, designated by the symbol Mn. It has the atomic number 25. It is found as a free element in nature , and in many minerals...

, and titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

. The A-390 alloy was suitable for faster production diecasting which made the Vega block less expensive to manufacture than other aluminum engines. Sealed Power Corp. developed special chrome-plated piston rings for the engine that were blunted to prevent scuffing.which was suitable for faster production diecasting, making the Vega block less expensive to manufacture than other aluminum engines. Sealed Power Corp.

SPX Corporation

SPX Corporation is a Fortune 500 multi-industry manufacturing firm. SPX's business segments serve developing and emerging end markets, such as global infrastructure, process equipment, and diagnostic tool industries. With corporate headquarters in Charlotte, North Carolina, they have operations in...

developed special chrome-plated piston rings for the engine that were blunted to prevent scuffing. Basic work had been done under Eudell Jackobson of GM engineering, not at Chevrolet. But then, suddenly, Chevrolet got handed the job of putting this ohc sleeveless, aluminum block into production — a feat never before attempted.

The Vega engine block was cast in Massena, New York

Massena (town), New York

Massena is a town in St. Lawrence County, New York, United States. The town is on the northern border of the county and is nicknamed "The Gateway to the Fourth Coast". The population was 13,121 at the 2000 census. The town of Massena contains a village also called Massena...

, at the same factory that had produced the Corvair engine

Chevrolet Corvair engine

The Chevrolet Corvair engine was a flat-6 piston engine used exclusively in the 1960s Chevrolet Corvair automobile. It was a highly unusual engine for General Motors: It was air-cooled, used a flat design, with aluminum heads and crankcase, with individual iron cylinder barrels...

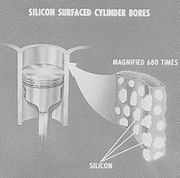

. Molten aluminum was transported from Reynolds and Alcoa reduction plants to the foundry, inside thermos tank trucks. The block was cast using the Accurad process. The casting process provided a uniform distribution of fine primary silicon particles

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

approximately 0.001 inch in size. Pure silicon provides a hard scuff and wear resistant surface, having a rating of 7 on the mohs scale of hardness, the same as quartz

Quartz

Quartz is the second-most-abundant mineral in the Earth's continental crust, after feldspar. It is made up of a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall formula SiO2. There are many different varieties of quartz,...

, as compared to diamond

Diamond

In mineralogy, diamond is an allotrope of carbon, where the carbon atoms are arranged in a variation of the face-centered cubic crystal structure called a diamond lattice. Diamond is less stable than graphite, but the conversion rate from diamond to graphite is negligible at ambient conditions...

which is 10. The blocks were aged 8 hours at 450 °F (232.2 °C) to achieve dimensional stability. The technical breakthroughs of the block lay in the precision die-casting method used to produce it, and in the silicon alloying which provided a compatible bore surface without liners. Before being shipped to Tonawanda, the blocks were inpregnated with sodium silicate

Sodium silicate

Sodium silicate is the common name for a compound sodium metasilicate, Na2SiO3, also known as water glass or liquid glass. It is available in aqueous solution and in solid form and is used in cements, passive fire protection, refractories, textile and lumber processing, and automobiles...

, where they were machined through the outer skin.

From Massena, the cast engine blocks were shipped as raw castings to Chevy's engine plant in Tonawanda, New York

Tonawanda (town), New York

Tonawanda is a town in Erie County, New York, United States. As of the 2000 census, the town had a population of 78,155. The town is at the north border of the county and is the northern suburb of Buffalo...

. Here they underwent the messy etch and machining operations. The cylinder bores were rough and finish-honed conventionally to a 7 uin finish then etched by a new (then) electro-chemical process. The etching removed approximately 0.00015 inch of aluminum leaving the pure silicon particles prominent to form the bore surface.

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

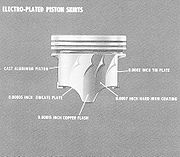

skirts was necessary to put a hard iron skirt surface opposite the silicon of the block to prevent scuffing. The plating was a four layer electo-plating process. The first plate was a flash of zinc followed by a very thin flash of copper. The third and primary coating was hard iron, 0.0007 inch thick. The final layer was a flash of tin. The zinc and copper were necessary to adhere the iron while the tin prevented corrosion before assembly of the piston into the engine. Piston plating was done on a 46 operation automatic line. From Tonawanda, the engines went to the Chevrolet assembly plant in Lordstown, Ohio.

Eudell Jackobson of GM engineering pointed out one of the early problems with unexplained scuffing and discovered excessive pressure on the bore hones was causing the silicon to crack. This need to both develop and actually manufacture the engine was a product of the program schedule. He said, "...We were trying to put a product into production and learning the technology simultaneously. And the pressure becomes very, very great when that happens. The hone-pressure problem was solved before engines actually went out the door, affecting pre-production engines only."

| Year | 1 barrel | 2 barrel | ||||||

|---|---|---|---|---|---|---|---|---|

| power | torque | power | torque | |||||

| hp | kW | ft·lbf | N·m | hp | kW | ft·lbf | N·m | |

| 1971 | 90 | 67 | 136 | 184 | 110 | 82 | 138 | 187 |

| 1972 | 80 | 60 | 121 | 164 | 90 | 67 | 121 | 164 |

| 1973 | 75 | 56 | 115 | 156 | 85 | 63 | 122 | 165 |

| 1974 | 75 | 56 | 115 | 156 | 85 | 63 | 122 | 165 |

| 1975 | 78 | 58 | 120 | 163 | 87 | 65 | 122 | 165 |

| 1976 | 70 | 52 | 107 | 145 | 84 | 63 | 113 | 153 |

| 1977 | 84 | 63 | 117 | 159 | ||||

| Note: Entries in italics are gross power values. | ||||||||