DISAMATIC

Encyclopedia

DISAMATIC is an automatic production line

used for fast manufacturing

of sand molds for sand casting

. This process is commonly used to mass manufacture of metal castings for the automotive

and machine

industry

.

for a device producing flaskless molds of sand mixtures with vertical parting lines for casting metal parts. In 1960, Danish company

Dansk Industri Syndikat A/S (DISA) acquired the patent and started working on its implementation.

In 1962, a half scale prototype

of a sand molding machine with flaskless and vertically parted molds under the name of DISAMATIC was ready to be disclosed. During the International Foundry Trade Fair (GIFA) in 1962 in Düsseldorf

the scale model

was demonstrated on DISA's stand. This resulted in sales of two first DISAMATICs to Europe

an foundries. The first automatic DISAMATIC molding lines could produce up to 240 complete sand molds per hour.

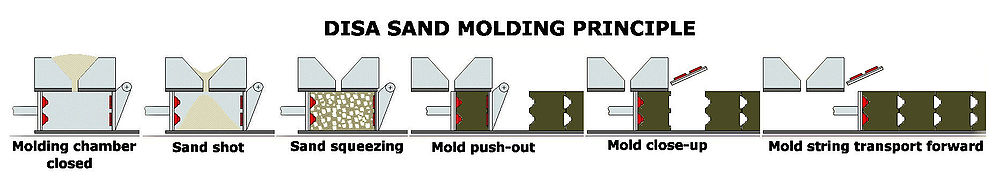

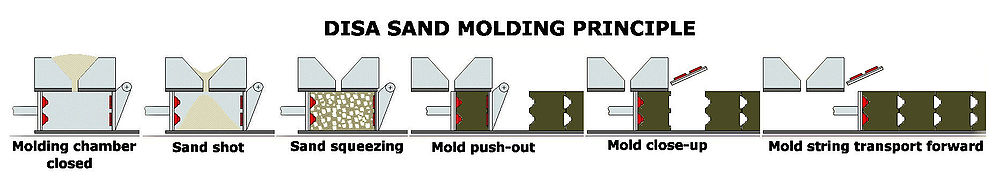

DISAMATIC consists of a molding machine and mold transporting conveyor. A molding sand mixture, usually green sand

DISAMATIC consists of a molding machine and mold transporting conveyor. A molding sand mixture, usually green sand

or bentonite

, is blown into a rectangular steel chamber using compressed air

. The molding sand is then squeezed against two pattern

s, which are on the two ends of the chamber. After squeezing, one of the chamber plates swings open and the opposite plate pushes the finished mold onto a conveyor. Finally, any cores

are automatically set into the mold cavity while the next mold is being prepared. The cycle repeats until a chain of finished molds butt up to each other on the conveyor.

The molds are then filled with molten metal and placed on a cooling conveyor, which moves at the same pace as the fabrication conveyor. At the end of the conveyor the solidified castings are separated from the molds and processed further, while the sand is directed to the sand preparation plant for reconditioning and reuse in the next cycles of the DISAMATIC molding process.

A modern DISAMATIC molding line can mold at the rate of 550 sand molds per hour (one complete mold in 6.5 seconds). Maximum mis-match of two halves of the castings does not exceed 0.1 mm (0.00393700787401575 in). Total uptime

exceeds 98%. Possible mold sizes range from 400 x 500 to 850 x 1200 millimeters. A DISAMATIC line can be completed with automatic casting and sand cooling drums, robotized

devices for extracting castings from the molds and automatic casting cleaning and abrasive blasting

machines placed inline. In such automatic production lines there is no need of any human manual labor until the castings are completely finished and ready for dispatch.

Production line

A production line is a set of sequential operations established in a factory whereby materials are put through a refining process to produce an end-product that is suitable for onward consumption; or components are assembled to make a finished article....

used for fast manufacturing

Manufacturing

Manufacturing is the use of machines, tools and labor to produce goods for use or sale. The term may refer to a range of human activity, from handicraft to high tech, but is most commonly applied to industrial production, in which raw materials are transformed into finished goods on a large scale...

of sand molds for sand casting

Sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.It is relatively cheap and sufficiently refractory even for steel foundry use. A suitable bonding agent is mixed or occurs with the sand...

. This process is commonly used to mass manufacture of metal castings for the automotive

Automotive industry

The automotive industry designs, develops, manufactures, markets, and sells motor vehicles, and is one of the world's most important economic sectors by revenue....

and machine

Machine

A machine manages power to accomplish a task, examples include, a mechanical system, a computing system, an electronic system, and a molecular machine. In common usage, the meaning is that of a device having parts that perform or assist in performing any type of work...

industry

Industry

Industry refers to the production of an economic good or service within an economy.-Industrial sectors:There are four key industrial economic sectors: the primary sector, largely raw material extraction industries such as mining and farming; the secondary sector, involving refining, construction,...

.

History

In 1957, Vagn Aage Jeppesen - professor at the Danish Technical University claimed a patentPatent

A patent is a form of intellectual property. It consists of a set of exclusive rights granted by a sovereign state to an inventor or their assignee for a limited period of time in exchange for the public disclosure of an invention....

for a device producing flaskless molds of sand mixtures with vertical parting lines for casting metal parts. In 1960, Danish company

Denmark

Denmark is a Scandinavian country in Northern Europe. The countries of Denmark and Greenland, as well as the Faroe Islands, constitute the Kingdom of Denmark . It is the southernmost of the Nordic countries, southwest of Sweden and south of Norway, and bordered to the south by Germany. Denmark...

Dansk Industri Syndikat A/S (DISA) acquired the patent and started working on its implementation.

In 1962, a half scale prototype

Prototype

A prototype is an early sample or model built to test a concept or process or to act as a thing to be replicated or learned from.The word prototype derives from the Greek πρωτότυπον , "primitive form", neutral of πρωτότυπος , "original, primitive", from πρῶτος , "first" and τύπος ,...

of a sand molding machine with flaskless and vertically parted molds under the name of DISAMATIC was ready to be disclosed. During the International Foundry Trade Fair (GIFA) in 1962 in Düsseldorf

Düsseldorf

Düsseldorf is the capital city of the German state of North Rhine-Westphalia and centre of the Rhine-Ruhr metropolitan region.Düsseldorf is an important international business and financial centre and renowned for its fashion and trade fairs. Located centrally within the European Megalopolis, the...

the scale model

Scale model

A scale model is a physical model, a representation or copy of an object that is larger or smaller than the actual size of the object, which seeks to maintain the relative proportions of the physical size of the original object. Very often the scale model is used as a guide to making the object in...

was demonstrated on DISA's stand. This resulted in sales of two first DISAMATICs to Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

an foundries. The first automatic DISAMATIC molding lines could produce up to 240 complete sand molds per hour.

Process

Green sand

Green sand may refer to:*Green sand , slightly damp sand, used in sand casting of metals*Greensand, a mineral containing glauconite*Olivine sand, which can form "green sand beaches"...

or bentonite

Bentonite

Bentonite is an absorbent aluminium phyllosilicate, essentially impure clay consisting mostly of montmorillonite. There are different types of bentonite, each named after the respective dominant element, such as potassium , sodium , calcium , and aluminum . Experts debate a number of nomenclatorial...

, is blown into a rectangular steel chamber using compressed air

Compressed air

Compressed air is air which is kept under a certain pressure, usually greater than that of the atmosphere. In Europe, 10 percent of all electricity used by industry is used to produce compressed air, amounting to 80 terawatt hours consumption per year....

. The molding sand is then squeezed against two pattern

Pattern (casting)

In casting, a pattern is a replica of the object to be cast, used to prepare the cavity into which molten material will be poured during the casting process.Patterns used in sand casting may be made of wood, metal, plastics or other materials...

s, which are on the two ends of the chamber. After squeezing, one of the chamber plates swings open and the opposite plate pushes the finished mold onto a conveyor. Finally, any cores

Core (manufacturing)

A core is a device used in casting and molding processes to produce internal cavities and reentrant angles. The core is normally a disposable item that is destroyed to get it out of the piece. They are most commonly used in sand casting, but are also used in injection molding.An intriguing example...

are automatically set into the mold cavity while the next mold is being prepared. The cycle repeats until a chain of finished molds butt up to each other on the conveyor.

The molds are then filled with molten metal and placed on a cooling conveyor, which moves at the same pace as the fabrication conveyor. At the end of the conveyor the solidified castings are separated from the molds and processed further, while the sand is directed to the sand preparation plant for reconditioning and reuse in the next cycles of the DISAMATIC molding process.

Advantages

The DISAMATIC sand molding process has several advantages comparing to other molding processes. It does not use flasks, which avoids a need of their transporting, storing and maintaining. It is fully automatic and requires only one monitoring operator, which reduces labor costs. Molding sand consumption can be minimized due to variable mold thickness that can be adjusted to the necessary minimum.A modern DISAMATIC molding line can mold at the rate of 550 sand molds per hour (one complete mold in 6.5 seconds). Maximum mis-match of two halves of the castings does not exceed 0.1 mm (0.00393700787401575 in). Total uptime

Uptime

Uptime is a measure of the time a machine has been up without any downtime.It is often used as a measure of computer operating system reliability or stability, in that this time represents the time a computer can be left unattended without crashing, or needing to be rebooted for administrative or...

exceeds 98%. Possible mold sizes range from 400 x 500 to 850 x 1200 millimeters. A DISAMATIC line can be completed with automatic casting and sand cooling drums, robotized

Industrial robot

An industrial robot is defined by ISO as an automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes...

devices for extracting castings from the molds and automatic casting cleaning and abrasive blasting

Abrasive blasting

Abrasive blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically air, or a centrifugal wheel is used to...

machines placed inline. In such automatic production lines there is no need of any human manual labor until the castings are completely finished and ready for dispatch.