Compression seal fitting

Encyclopedia

A Compression seal fitting, also known as a sealing gland, is intended to seal some type of element (probe

, wire, conductor

, pipe

, tube, fiber optic cable) when the element must pass through a pressure or environmental boundary. A compression seal fitting may serve several purposes:

A compression seal fitting, unlike an epoxy

seal or a gasket

, uses mechanical components and an axial force to compress a soft sealant inside a body which then creates a seal. An epoxy seal differs in that it is composed of some type of compound which is poured into a mold in an attempt to create a seal.

s, autoclave

s, holding tanks, pipeline

s, furnace

s, or anywhere wires or sensors need to pass from inside to outside a vessel or wall where the pressure differentials or hazardous environments cause concern.

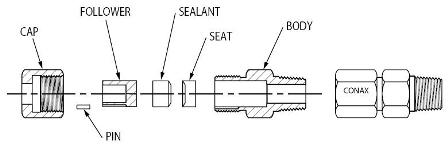

A single compression seal fitting may seal on a single or multiple elements. Sealing glands designed to seal on single elements consist of a body, cap, sealant and follower. When sealing on multiple elements, gland designs also include a seat and an anti-rotation pin to prevent wires/conductors from twisting and shearing. One or more insulators may also be included when electrical isolation is required.

Single Element Sealing

Single element compression seal fittings are used to seal a single element such as a temperature probe, tubewell, pipe, etc.

Multiple Element Sealing

Multiple element compression seal fittings are used when multiple elements of the same or different diameters such as metal tubing, ceramic or rigid plastic tube or pipe, temperature probe, a tubewell, low voltage instrumentation wire or a power supply feedthrough.

Temperature measurement

Attempts of standardized temperature measurement have been reported as early as 170 AD by Claudius Galenus. The modern scientific field has its origins in the works by Florentine scientists in the 17th century. Early devices to measure temperature were called thermoscopes. The first sealed...

, wire, conductor

Electrical conductor

In physics and electrical engineering, a conductor is a material which contains movable electric charges. In metallic conductors such as copper or aluminum, the movable charged particles are electrons...

, pipe

Pipe (material)

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases , slurries, powders, masses of small solids...

, tube, fiber optic cable) when the element must pass through a pressure or environmental boundary. A compression seal fitting may serve several purposes:

- It restrains the element from moving as a result of a pressure difference.

- It prohibits the leakage of gas/liquid media along the element.

- In some cases, it electrically isolates the element from the mounting device.

A compression seal fitting, unlike an epoxy

Epoxy

Epoxy, also known as polyepoxide, is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives....

seal or a gasket

Gasket

thumb|sright|250px|Some seals and gaskets1. [[o-ring]]2. fiber [[Washer |washer]]3. paper gaskets4. [[cylinder head]] [[head gasket|gasket]]...

, uses mechanical components and an axial force to compress a soft sealant inside a body which then creates a seal. An epoxy seal differs in that it is composed of some type of compound which is poured into a mold in an attempt to create a seal.

Applications

Typical applications include pressure vesselPressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

s, autoclave

Autoclave

An autoclave is an instrument used to sterilize equipment and supplies by subjecting them to high pressure saturated steam at 121 °C for around 15–20 minutes depending on the size of the load and the contents. It was invented by Charles Chamberland in 1879, although a precursor known as the...

s, holding tanks, pipeline

Pipeline transport

Pipeline transport is the transportation of goods through a pipe. Most commonly, liquids and gases are sent, but pneumatic tubes that transport solid capsules using compressed air are also used....

s, furnace

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

s, or anywhere wires or sensors need to pass from inside to outside a vessel or wall where the pressure differentials or hazardous environments cause concern.

Components

A very basic compression seal fitting is composed of four mechanical parts:- The body, which holds the elements being sealed and enables the other components to compress into it.

- The cap, which secures the sealant and follower into the body. Most importantly, when it is torqued into the body, it pushes the follower into the sealant which creates the axial force and creates the seal.

- The follower, which is pushed into the sealant from the torque on the cap and compresses the sealant. The sealant then fills all void spaces around the element and between the body.

- The soft sealant (a solid rubber-like component, not a liquid or paste), which surrounds the elements being sealed and when it is compressed by axial force, a hermetic(airtight) seal is created. The continuous tension in the torqued body acts like a spring to maintain compression on the sealant and maintain a positive seal. Some soft sealants include NeopreneNeopreneNeoprene or polychloroprene is a family of synthetic rubbers that are produced by polymerization of chloroprene. Neoprene in general has good chemical stability, and maintains flexibility over a wide temperature range...

, VitonVitonViton is a brand of synthetic rubber and fluoropolymer elastomer commonly used in O-rings and other molded or extruded goods. The name is a registered trademark of DuPont Performance Elastomers L.L.C.....

, Teflon, Lava and Grafoil. The appropriate sealant for a gland depends on the environment you are trying to seal against.

A single compression seal fitting may seal on a single or multiple elements. Sealing glands designed to seal on single elements consist of a body, cap, sealant and follower. When sealing on multiple elements, gland designs also include a seat and an anti-rotation pin to prevent wires/conductors from twisting and shearing. One or more insulators may also be included when electrical isolation is required.

History and development

Soft sealant technology for compression seal fittings was developed in the 1950s by Conax Technologies. Since then, compression seal fittings have evolved to include multiple variations for different applications. Some applications include:Single Element Sealing

Single element compression seal fittings are used to seal a single element such as a temperature probe, tubewell, pipe, etc.

- Packing Gland (PG) Series- For sealing on anything from fragile tubes and soft cables to solid probes or instruments

- Midlock (MK) Series- Best used for sealing on metal elements and/or high vibration environments.

- Electrode (EG) Series- Fully isolating for electrical power or instrument isolation to 8000 V. Teflon insulation and sealant material used for high performance and chemical resistance.

- Split (PGS) Series- seals cables and leads when larger probes or connectors are attached.

Multiple Element Sealing

Multiple element compression seal fittings are used when multiple elements of the same or different diameters such as metal tubing, ceramic or rigid plastic tube or pipe, temperature probe, a tubewell, low voltage instrumentation wire or a power supply feedthrough.

- Transducer (TG) Series-For bare wire sealing where elements remain fully electrically isolated throughout the fitting

- Multi-hole Ceramic (MHC) Series-Non-insolating fitting for multiple elements up to 0.125 in (3.175 mm) diameter.

- Multi-hole Metal (MHM) Series-A flexible design for special hole patterns, irregular shapes and mixtures of element sizes.

- Split (PGS/SPG/DSPG) Series-For sealing elements that can pass through gland body but not the internal components.

- Sensor Wire Seal (BSWS) Series-Used for sealing on sensor leads in low temperature and pressure applications. Ideal for embedded bearing temperature sensors, vibrations sensors and proximity probes.