Viscometer

Encyclopedia

A viscometer is an instrument used to measure the viscosity

of a fluid

. For liquids with viscosities which vary with flow conditions

, an instrument called a rheometer

is used. Viscometers only measure under one flow condition.

In general, either the fluid remains stationary and an object moves through it, or the object is stationary and the fluid moves past it. The drag caused by relative motion of the fluid and a surface is a measure of the viscosity. The flow conditions must have a sufficiently small value of Reynolds number for there to be laminar flow

.

At 20.00 degrees Celsius the viscosity of water is 1.002 mPa·s and its kinematic viscosity (ratio of viscosity to density) is 1.0038 mm2/s. These values are used for calibrating certain types of viscometer.

. Another version is the Ubbelohde viscometer

, which consists of a U-shaped glass tube held vertically in a controlled temperature bath. In one arm of the U is a vertical section of precise narrow bore (the capillary). Above this is a bulb, with it is another bulb lower down on the other arm. In use, liquid is drawn into the upper bulb by suction, then allowed to flow down through the capillary into the lower bulb. Two marks (one above and one below the upper bulb) indicate a known volume. The time taken for the level of the liquid to pass between these marks is proportional to the kinematic viscosity. Most commercial units are provided with a conversion factor, or can be calibrated by a fluid of known properties.

The time required for the test liquid to flow through a capillary of a known diameter of a certain factor between two marked points is measured. By multiplying the time taken by the factor of the viscometer, the kinematic viscosity is obtained.

Such viscometers are also classified as direct flow or reverse flow. Reverse flow viscometers have the reservoir above the markings and direct flow are those with the reservoir below the markings. Such classifications exists so that the level can be determined even when opaque or staining liquids are measured, otherwise the liquid will cover the markings and make it impossible to gauge the time the level passes the mark. This also allows the viscometer to have more than 1 set of marks to allow for an immediate timing of the time it takes to reach the 3rd mark, therefore yielding 2 timings and allowing for subsequent calculation of Determinability to ensure accurate results.

Stokes' law

Stokes' law

is the basis of the falling sphere viscometer, in which the fluid is stationary in a vertical glass tube. A sphere of known size and density is allowed to descend through the liquid. If correctly selected, it reaches terminal velocity

, which can be measured by the time it takes to pass two marks on the tube. Electronic sensing can be used for opaque fluids. Knowing the terminal velocity, the size and density of the sphere, and the density

of the liquid, Stokes' law can be used to calculate the viscosity

of the fluid. A series of steel ball bearings of different diameter is normally used in the classic experiment to improve the accuracy of the calculation. The school experiment uses glycerine as the fluid, and the technique is used industrially to check the viscosity of fluids used in processes. It includes many different oils, and polymer

liquids such as solutions.

In 1851, George Gabriel Stokes

derived an expression for the frictional force (also called drag force) exerted on spherical objects with very small Reynolds numbers (e.g., very small particles) in a continuous viscous

fluid

by changing the small fluid-mass limit of the generally unsolvable Navier-Stokes equations

:

where:

If the particles are falling in the viscous fluid by their own weight, then a terminal velocity, also known as the settling velocity, is reached when this frictional force combined with the buoyant force exactly balance the gravitational force. The resulting settling velocity (or terminal velocity

) is given by:

where:

Note that Stokes flow is assumed, so the Reynolds number must be small.

A limiting factor on the validity of this result is the Roughness of the sphere being used.

A modification of the straight falling sphere viscometer is a rolling ball viscometer which times a ball rolling down a slope whilst immersed in the test fluid. This can be further improved by using a patented V plate which increases the number of rotations to distance traveled, allowing smaller more portable devices. This type of device is also suitable for ship board use.

Industrial use is popular due to simplicity, repeatability, low maintenance and longevity. This type of measurement is not affected by flow rate or external vibrations. The principle of operation can be adopted for many different conditions, making it ideal for process control environments.

The Oscillating Piston Viscometer technology has been adapted for small sample viscosity and micro-sample viscosity testing in laboratory applications. It has also been adapted to measure high pressure viscosity and high temperature viscosity measurements in both laboratory and process environments. The viscosity sensors have been scaled for a wide range of industrial applications such as small size viscometers for use in compressors and engines, flow-through viscometers for dip coating processes, in-line viscometers for use in refineries, and hundreds of other applications. Improvements in sensitivity from modern electronics, is stimulating a growth in Oscillating Piston Viscometer popularity with academic laboratories exploring gas viscosity.

The vibrational instrument also suffers from a lack of a defined shear field, which makes it unsuited to measuring the viscosity of a fluid whose flow behaviour is not known before hand.

Vibrating viscometers are rugged industrial systems used to measure viscosity in the process condition. The active part of the sensor is a vibrating rod. The vibration amplitude varies according to the viscosity of the fluid in which the rod is immersed. These viscosity meters are suitable for measuring clogging fluid and high-viscosity fluids, including those with fibers (up to 1,000 Pa·s). Currently, many industries around the world consider these viscometers to be the most efficient system with which to measure the viscosities of a wide range of fluids; by contrast, rotational viscometers require more maintenance, are unable to measure clogging fluid, and require frequent calibration after intensive use. Vibrating viscometers have no moving parts, no weak parts and the sensitive part is very small. Even very basic or acidic fluids can be measured by adding a protective coating or by changing the material of the sensor to a material such as 316L, SUS316, or enamel

'Cup and bob' viscometers work by defining the exact volume of a sample which is to be sheared within a test cell; the torque required to achieve a certain rotational speed is measured and plotted. There are two classical geometries in "cup and bob" viscometers, known as either the "Couette" or "Searle" systems - distinguished by whether the cup or bob rotates. The rotating cup is preferred in some cases because it reduces the onset of Taylor vortices, but is more difficult to measure accurately.

'Cone and Plate' viscometers use a cone of very shallow angle in bare contact with a flat plate. With this system the shear rate beneath the plate is constant to a modest degree of precision and deconvolution of a flow curve; a graph of shear stress (torque) against shear rate (angular velocity) yields the viscosity in a straightforward manner.

s. The formerly inevitable bearing friction

is thus fully avoided. The speed

and torque

measurement is implemented without direct contact by a rotating magnetic field

and an eddy current brake. This allows for a previously unprecedented torque

resolution of 50 pN·m

and an exceedingly large measuring range from 0.2 to 20,000 mPa·s with a single measuring system. A built-in density

measurement based on the oscillating U-tube

principle allows the determination of kinematic viscosity

from the measured dynamic viscosity employing the relation

The Stabinger Viscometer was presented for the first time by Anton Paar GmbH at the ACHEMA in the year 2000. The measuring principle is named after its inventor Dr. Hans Stabinger.

s are usually called rheometer

s or plastometers.

In the I.C.I "Oscar" viscometer, a sealed can of fluid was oscillated torsionally, and by clever measurement techniques it was possible to measure both viscosity and elasticity in the sample.

The Marsh funnel

viscometer measures viscosity from the time (efflux time) it takes a known volume of liquid to flow from the base of a cone through a short tube. This is similar in principle to the flow cups (efflux cups) like the Ford

, Zahn

and Shell

cups which use different shapes to the cone and various nozzle sizes. The measurements can be done according to ISO 2431, ASTM D1200 - 10 or DIN

53411.

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

of a fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

. For liquids with viscosities which vary with flow conditions

Flow conditioning

Flow conditioning ensures that the “real world” environment closely resembles the “laboratory” environment for proper performance of inferential flowmeters like orifice, turbine, coriolis, ultrasonic etc.- Types of Flow :...

, an instrument called a rheometer

Rheometer

A rheometer is a laboratory device used to measure the way in which a liquid, suspension or slurry flows in response to applied forces. It is used for those fluids which cannot be defined by a single value of viscosity and therefore require more parameters to be set and measured than is the case...

is used. Viscometers only measure under one flow condition.

In general, either the fluid remains stationary and an object moves through it, or the object is stationary and the fluid moves past it. The drag caused by relative motion of the fluid and a surface is a measure of the viscosity. The flow conditions must have a sufficiently small value of Reynolds number for there to be laminar flow

Laminar flow

Laminar flow, sometimes known as streamline flow, occurs when a fluid flows in parallel layers, with no disruption between the layers. At low velocities the fluid tends to flow without lateral mixing, and adjacent layers slide past one another like playing cards. There are no cross currents...

.

At 20.00 degrees Celsius the viscosity of water is 1.002 mPa·s and its kinematic viscosity (ratio of viscosity to density) is 1.0038 mm2/s. These values are used for calibrating certain types of viscometer.

Standard laboratory viscometers for liquids

U-tube viscometers

These devices also are known as glass capillary viscometers or Ostwald viscometers, named after Wilhelm OstwaldWilhelm Ostwald

Friedrich Wilhelm Ostwald was a Baltic German chemist. He received the Nobel Prize in Chemistry in 1909 for his work on catalysis, chemical equilibria and reaction velocities...

. Another version is the Ubbelohde viscometer

Ubbelohde viscometer

A Ubbelohde type viscometer or suspended-level viscometer is a measuring instrument which uses a capillary based method of measuring viscosity . It is recommended for higher viscosity cellulosic polymer solutions. The advantage of this instrument is that the values obtained are independent of the...

, which consists of a U-shaped glass tube held vertically in a controlled temperature bath. In one arm of the U is a vertical section of precise narrow bore (the capillary). Above this is a bulb, with it is another bulb lower down on the other arm. In use, liquid is drawn into the upper bulb by suction, then allowed to flow down through the capillary into the lower bulb. Two marks (one above and one below the upper bulb) indicate a known volume. The time taken for the level of the liquid to pass between these marks is proportional to the kinematic viscosity. Most commercial units are provided with a conversion factor, or can be calibrated by a fluid of known properties.

The time required for the test liquid to flow through a capillary of a known diameter of a certain factor between two marked points is measured. By multiplying the time taken by the factor of the viscometer, the kinematic viscosity is obtained.

Such viscometers are also classified as direct flow or reverse flow. Reverse flow viscometers have the reservoir above the markings and direct flow are those with the reservoir below the markings. Such classifications exists so that the level can be determined even when opaque or staining liquids are measured, otherwise the liquid will cover the markings and make it impossible to gauge the time the level passes the mark. This also allows the viscometer to have more than 1 set of marks to allow for an immediate timing of the time it takes to reach the 3rd mark, therefore yielding 2 timings and allowing for subsequent calculation of Determinability to ensure accurate results.

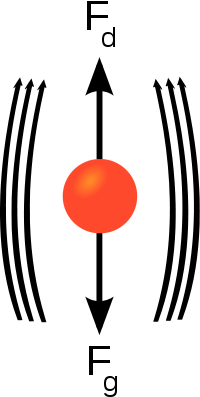

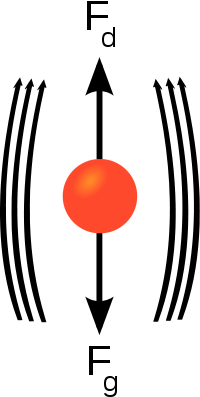

Falling sphere viscometers

Stokes' law

In 1851, George Gabriel Stokes derived an expression, now known as Stokes' law, for the frictional force – also called drag force – exerted on spherical objects with very small Reynolds numbers in a continuous viscous fluid...

is the basis of the falling sphere viscometer, in which the fluid is stationary in a vertical glass tube. A sphere of known size and density is allowed to descend through the liquid. If correctly selected, it reaches terminal velocity

Terminal velocity

In fluid dynamics an object is moving at its terminal velocity if its speed is constant due to the restraining force exerted by the fluid through which it is moving....

, which can be measured by the time it takes to pass two marks on the tube. Electronic sensing can be used for opaque fluids. Knowing the terminal velocity, the size and density of the sphere, and the density

Density

The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

of the liquid, Stokes' law can be used to calculate the viscosity

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

of the fluid. A series of steel ball bearings of different diameter is normally used in the classic experiment to improve the accuracy of the calculation. The school experiment uses glycerine as the fluid, and the technique is used industrially to check the viscosity of fluids used in processes. It includes many different oils, and polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

liquids such as solutions.

In 1851, George Gabriel Stokes

George Gabriel Stokes

Sir George Gabriel Stokes, 1st Baronet FRS , was an Irish mathematician and physicist, who at Cambridge made important contributions to fluid dynamics , optics, and mathematical physics...

derived an expression for the frictional force (also called drag force) exerted on spherical objects with very small Reynolds numbers (e.g., very small particles) in a continuous viscous

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

by changing the small fluid-mass limit of the generally unsolvable Navier-Stokes equations

Navier-Stokes equations

In physics, the Navier–Stokes equations, named after Claude-Louis Navier and George Gabriel Stokes, describe the motion of fluid substances. These equations arise from applying Newton's second law to fluid motion, together with the assumption that the fluid stress is the sum of a diffusing viscous...

:

where:

is the frictional force,

is the frictional force, is the radius of the spherical object,

is the radius of the spherical object, is the fluid viscosity, and

is the fluid viscosity, and is the particle's velocity.

is the particle's velocity.

If the particles are falling in the viscous fluid by their own weight, then a terminal velocity, also known as the settling velocity, is reached when this frictional force combined with the buoyant force exactly balance the gravitational force. The resulting settling velocity (or terminal velocity

Terminal velocity

In fluid dynamics an object is moving at its terminal velocity if its speed is constant due to the restraining force exerted by the fluid through which it is moving....

) is given by:

where:

- Vs is the particles' settling velocity (m/s) (vertically downwards if

, upwards if

, upwards if  ),

),  is the Stokes radiusStokes radiusThe Stokes radius, Stokes-Einstein radius, or hydrodynamic radius RH, named after George Gabriel Stokes, is not the effective radius of a hydrated molecule in solution as often mentioned. Rather it is the radius of a hard sphere that diffuses at the same rate as the molecule. The behavior of this...

is the Stokes radiusStokes radiusThe Stokes radius, Stokes-Einstein radius, or hydrodynamic radius RH, named after George Gabriel Stokes, is not the effective radius of a hydrated molecule in solution as often mentioned. Rather it is the radius of a hard sphere that diffuses at the same rate as the molecule. The behavior of this...

of the particle (m),- g is the gravitational accelerationGravitational accelerationIn physics, gravitational acceleration is the acceleration on an object caused by gravity. Neglecting friction such as air resistance, all small bodies accelerate in a gravitational field at the same rate relative to the center of mass....

(m/s2), - ρp is the densityDensityThe mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

of the particles (kg/m3), - ρf is the densityDensityThe mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

of the fluid (kg/m3), and  is the (dynamic) fluid viscosityViscosityViscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

is the (dynamic) fluid viscosityViscosityViscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

(Pa s).

Note that Stokes flow is assumed, so the Reynolds number must be small.

A limiting factor on the validity of this result is the Roughness of the sphere being used.

A modification of the straight falling sphere viscometer is a rolling ball viscometer which times a ball rolling down a slope whilst immersed in the test fluid. This can be further improved by using a patented V plate which increases the number of rotations to distance traveled, allowing smaller more portable devices. This type of device is also suitable for ship board use.

Falling Piston Viscometer

Also known as Norcross viscometer due to inventor, Austin Norcross. The principle of viscosity measurement in this rugged and sensitive industrial device is based on piston and cylinder assembly. The piston is periodically raised by an air lifting mechanism, drawing the material being measured down through the clearance(gap)between the piston and the wall of the cylinder into the space which is formed below the piston as it is raised. The assembly is then typically held up for a few seconds, then allowed to fall by gravity, expelling the sample out through the same path that it entered, creating a shearing effect on the measured liquid, which makes this viscometer particularly sensitive and good for measuring certain thixotropic liquids. The time of fall is a measure of viscosity, with the clearance between the piston and inside of the cylinder forming the measuring orifice. The viscosity controller measures the time of fall (Time-of-fall seconds being the measure of viscosity) and displays the resulting viscosity value. Controller can calibrate time-of-fall value to cup seconds(known efflux cup), SSU or centipoise.Industrial use is popular due to simplicity, repeatability, low maintenance and longevity. This type of measurement is not affected by flow rate or external vibrations. The principle of operation can be adopted for many different conditions, making it ideal for process control environments.

Oscillating Piston Viscometer

Sometimes referred to as Electromagnetic Viscometer or EMV viscometer, was invented at Cambridge Viscosity in 1986. The sensor (see figure below) comprises a measurement chamber and magnetically influenced piston. Measurements are taken whereby a sample is first introduced into the thermally controlled measurement chamber where the piston resides. Electronics drive the piston into oscillatory motion within the measurement chamber with a controlled magnetic field. A shear stress is imposed on the liquid (or gas) due to the piston travel and the viscosity is determined by measuring the travel time of the piston. The construction parameters for the annular spacing between the piston and measurement chamber, the strength of the electromagnetic field, and the travel distance of the piston are used to calculate the viscosity according to Newton’s Law of Viscosity.The Oscillating Piston Viscometer technology has been adapted for small sample viscosity and micro-sample viscosity testing in laboratory applications. It has also been adapted to measure high pressure viscosity and high temperature viscosity measurements in both laboratory and process environments. The viscosity sensors have been scaled for a wide range of industrial applications such as small size viscometers for use in compressors and engines, flow-through viscometers for dip coating processes, in-line viscometers for use in refineries, and hundreds of other applications. Improvements in sensitivity from modern electronics, is stimulating a growth in Oscillating Piston Viscometer popularity with academic laboratories exploring gas viscosity.

Vibrational viscometers

Vibrational viscometers date back to the 1950s Bendix instrument, which is of a class that operates by measuring the damping of an oscillating electromechanical resonator immersed in a fluid whose viscosity is to be determined. The resonator generally oscillates in torsion or transversely (as a cantilever beam or tuning fork). The higher the viscosity, the larger the damping imposed on the resonator. The resonator's damping may be measured by one of several methods:- Measuring the power input necessary to keep the oscillator vibrating at a constant amplitude. The higher the viscosity, the more power is needed to maintain the amplitude of oscillation.

- Measuring the decay time of the oscillation once the excitation is switched off. The higher the viscosity, the faster the signal decays.

- Measuring the frequency of the resonator as a function of phase angle between excitation and response waveforms. The higher the viscosity, the larger the frequency change for a given phase change.

The vibrational instrument also suffers from a lack of a defined shear field, which makes it unsuited to measuring the viscosity of a fluid whose flow behaviour is not known before hand.

Vibrating viscometers are rugged industrial systems used to measure viscosity in the process condition. The active part of the sensor is a vibrating rod. The vibration amplitude varies according to the viscosity of the fluid in which the rod is immersed. These viscosity meters are suitable for measuring clogging fluid and high-viscosity fluids, including those with fibers (up to 1,000 Pa·s). Currently, many industries around the world consider these viscometers to be the most efficient system with which to measure the viscosities of a wide range of fluids; by contrast, rotational viscometers require more maintenance, are unable to measure clogging fluid, and require frequent calibration after intensive use. Vibrating viscometers have no moving parts, no weak parts and the sensitive part is very small. Even very basic or acidic fluids can be measured by adding a protective coating or by changing the material of the sensor to a material such as 316L, SUS316, or enamel

Rotational viscometers

Rotational viscometers use the idea that the torque required to turn an object in a fluid is a function of the viscosity of that fluid. They measure the torque required to rotate a disk or bob in a fluid at a known speed.'Cup and bob' viscometers work by defining the exact volume of a sample which is to be sheared within a test cell; the torque required to achieve a certain rotational speed is measured and plotted. There are two classical geometries in "cup and bob" viscometers, known as either the "Couette" or "Searle" systems - distinguished by whether the cup or bob rotates. The rotating cup is preferred in some cases because it reduces the onset of Taylor vortices, but is more difficult to measure accurately.

'Cone and Plate' viscometers use a cone of very shallow angle in bare contact with a flat plate. With this system the shear rate beneath the plate is constant to a modest degree of precision and deconvolution of a flow curve; a graph of shear stress (torque) against shear rate (angular velocity) yields the viscosity in a straightforward manner.

Stabinger viscometer

By modifying the classic Couette rotational viscometer, an accuracy comparable to that of kinematic viscosity determination is achieved. The internal cylinder in the Stabinger Viscometer is hollow and specifically lighter than the sample, thus floats freely in the sample, centered by centrifugal forceCentrifugal force

Centrifugal force can generally be any force directed outward relative to some origin. More particularly, in classical mechanics, the centrifugal force is an outward force which arises when describing the motion of objects in a rotating reference frame...

s. The formerly inevitable bearing friction

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

is thus fully avoided. The speed

Speed

In kinematics, the speed of an object is the magnitude of its velocity ; it is thus a scalar quantity. The average speed of an object in an interval of time is the distance traveled by the object divided by the duration of the interval; the instantaneous speed is the limit of the average speed as...

and torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

measurement is implemented without direct contact by a rotating magnetic field

Magnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

and an eddy current brake. This allows for a previously unprecedented torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

resolution of 50 pN·m

Newton metre

A newton metre is a unit of torque in the SI system. The symbolic form is N m or N·m, and sometimes hyphenated newton-metre...

and an exceedingly large measuring range from 0.2 to 20,000 mPa·s with a single measuring system. A built-in density

Density

The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

measurement based on the oscillating U-tube

Oscillating U-tube

The oscillating U-tube is a technique to determine the density of liquids and gases based on an electronic measurement of the frequency of oscillation, from which the density value is calculated. This measuring principle is based on the Mass-Spring Model....

principle allows the determination of kinematic viscosity

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

from the measured dynamic viscosity employing the relation

The Stabinger Viscometer was presented for the first time by Anton Paar GmbH at the ACHEMA in the year 2000. The measuring principle is named after its inventor Dr. Hans Stabinger.

Bubble viscometer

Bubble viscometers are used to quickly determine kinematic viscosity of known liquids such as resins and varnishes. The time required for an air bubble to rise is directly proportional to the viscosity of the liquid, so the faster the bubble rises, the lower the viscosity. The Alphabetical Comparison Method uses 4 sets of lettered reference tubes, A5 through Z10, of known viscosity to cover a viscosity range from 0.005 to 1,000 stokes. The Direct Time Method uses a single 3-line times tube for determining the "bubble seconds", which may then be converted to stokes.Miscellaneous viscometer types

Other viscometer types use balls or other objects. Viscometers that can characterize non-Newtonian fluidNon-Newtonian fluid

A non-Newtonian fluid is a fluid whose flow properties differ in any way from those of Newtonian fluids. Most commonly the viscosity of non-Newtonian fluids is not independent of shear rate or shear rate history...

s are usually called rheometer

Rheometer

A rheometer is a laboratory device used to measure the way in which a liquid, suspension or slurry flows in response to applied forces. It is used for those fluids which cannot be defined by a single value of viscosity and therefore require more parameters to be set and measured than is the case...

s or plastometers.

In the I.C.I "Oscar" viscometer, a sealed can of fluid was oscillated torsionally, and by clever measurement techniques it was possible to measure both viscosity and elasticity in the sample.

The Marsh funnel

Marsh funnel

The Marsh funnel viscometer is a simple device for measuring viscosity from the time it takes a known volume of liquid to flow from the base of a cone through a short tube...

viscometer measures viscosity from the time (efflux time) it takes a known volume of liquid to flow from the base of a cone through a short tube. This is similar in principle to the flow cups (efflux cups) like the Ford

Ford viscosity cup

The Ford viscosity cup is a simple gravity device that permits the timed flow of a known volume of liquid passing through an orifice located at the bottom. Under ideal conditions, this rate of flow would be proportional to the kinematic viscosity that is dependent upon the specific gravity of the...

, Zahn

Zahn cup

A Zahn cup is a viscosity measurement device widely used in the paint industry. It is commonly a stainless steel cup with a tiny hole drilled in the center of the bottom of the cup. There is also a long handle attached to the sides. There are five cup specifications, labeled Zahn cup #x, where x is...

and Shell

Shell Cup

The Shell Cup could be:* Shell Cup, renamed the Caribbean Cup* Shell Cup, New Zealand limited overs cricket competition now known as the State Shield* Shell Cup – Defensive, renamed the Telus Cup – Defensive, an ice-hockey trophy in Quebec...

cups which use different shapes to the cone and various nozzle sizes. The measurements can be done according to ISO 2431, ASTM D1200 - 10 or DIN

Din

DIN or Din or din can have several meanings:* A din is a loud noise.* Dīn, an Arabic term meaning "religion" or "way of life".* Din is one of the ten aspects of the Ein Sof in Kabbalah ....

53411.

External links

- ASTM International (ASTM D7042)

- Viscosity conversion tables