Valveless pulse jet

Encyclopedia

A Valveless pulse jet is one of the simplest jet propulsion

devices ever designed, and is the simplest form of jet engine that does not require forward motion to run continuously. Valveless pulsejets are low in cost, light weight, powerful and easy to operate. They have all the advantages (and most of the disadvantages) of conventional valved pulse jets, but without the troublesome reed valve

s that need frequent replacement - a valveless pulsejet can operate for its entire useful life with practically zero maintenance. They have been used to power model aircraft, experimental go-kart

s and even some unmanned military aircraft such as cruise missile

s and target drone

s.

employing an ongoing sequence of discrete combustion

events rather than a constant level of combustion. This clearly distinguishes it from other reaction engine types such as rocket

s, turbojets and ramjets, which are all constant combustion devices. All other reaction engines are driven by maintaining high internal pressure; pulsejets are driven by an alternation between high and low pressure. This alternation is not maintained by any mechanical contrivance, but rather by the natural acoustic resonance

of the rigid tubular engine structure. The valveless pulsejet is, mechanically speaking, the simplest form of pulsejet, and is, in fact, the simplest known air-breathing propulsion device that can operate "statically", i.e. without forward motion.

The combustion events driving a pulsejet are often informally called "explosion

s"; however, the preferred term is "deflagration

s". They are not the violent, very high energy detonation

s employed in "Pulse Detonation Engine

s (PDEs)"; rather, deflagration within the combustion zone of a pulsejet is characterized by a sudden rise in temperature and pressure followed by a rapid subsonic expansion in gas volume. It is this expansion that performs the main work of moving air rearward through the device as well as setting up conditions in the main tube for the cycle to continue.

All pulsejet engines work by alternately accelerating a contained mass of air rearward and then breathing in a fresh mass of air to replace it. The energy to accelerate the air mass is provided by the deflagration of fuel mixed thoroughly into the newly acquired fresh air mass. This cycle is repeated many times per second. During the brief mass acceleration phase of each cycle, the engine’s physical action is more or less identical to that of other reaction engines — that is, gas mass is accelerated rearward, accompanied by an application of force forward into the body of the engine. These small "pulses" of force, rapidly repeated over time, comprise the measurable thrust force of the engine.

Some basic differences between valved and valveless pulsejets are:

"buzz bomb" of World War II, there are two ducts connected to the combustion zone where the explosions occur. These are generally known as the "intake" (a very short duct) and the "tailpipe" (a very long duct). The function of the forward-facing intake is to provide air (and in many smaller pulsejets, the fuel/air mixing action) for combustion. The purpose of the rear-facing tailpipe is to provide air mass for acceleration by the explosive blast as well as to direct the accelerated mass totally rearward. The combustion zone (usually a widened "chamber" section) and tailpipe make up the main tube of the engine. A flexible, low mass one-way valve (or multiple identical valves) separates the intake from the combustion zone.

At the beginning of each cycle, air must be pulled into the combustion zone. At the end of each cycle, the tailpipe must be reloaded with air from the surrounding atmosphere. Both of these basic actions are accomplished by a significant drop in pressure that occurs naturally after the deflagration expansion, a phenomenon known as the Kadenacy effect

(named after the scientist who first fully described it). This temporary low pressure opens the metal valve and draws in the intake air (or air/fuel mixture). It also causes a reversal of flow in the tailpipe that draws fresh air forward to re-fill the pipe. When the next deflagration occurs, the rapid pressure rise slams the valve shut very quickly, ensuring that almost no explosion mass exits in the forward direction so the expansion of the combustion gases will all be used to accelerate the replenished mass of air in the long tailpipe rearward.

When the deflagration begins, a zone of significantly elevated pressure travels outward through both air masses as a "compression wave". This wave moves at the speed of sound through both the intake and tailpipe air masses. (Because these air masses are significantly elevated in temperature as a result of earlier cycles, the speed of sound in them is much higher than it would be in normal outdoor air.) When a compression wave reaches the open end of either tube, a low pressure rarefaction

wave starts back in the opposite direction, as if "reflected" by the open end. This low pressure region returning to the combustion zone is, in fact, the internal mechanism of the Kadenacy effect. There will be no "breathing" of fresh air into the combustion zone until the arrival of the rarefaction wave.

The wave motion through the air masses should not be confused with the separate motions of the masses themselves. At the start of deflagration, the pressure wave immediately moves through both air masses, while the gas expansion (due to combustion heat) is just beginning in the combustion zone. The intake air mass will be rapidly accelerated outward behind the pressure wave, because its mass is relatively small. The tailpipe air mass will follow the outgoing pressure wave much more slowly. Also, the eventual flow reversal will take place much sooner in the intake, due to its smaller air mass. The timing of the wave motions is determined basically by the lengths of the intake and main tube of the engine; the timing of mass motions is determined mostly by the volumes and exact shapes of these sections. Both are affected by local gas temperature

s.

In the valveless engine, there will actually be two arrivals of rarefaction waves — first, from the intake and then from the tailpipe. In typical valveless designs, the wave that comes back from the intake will be relatively weak. Its main effect is to begin flow reversal in the intake itself, in effect "pre-loading" the intake duct with fresh outdoor air. The actual "breathing" of the engine as a whole will not begin in earnest until the major low pressure wave from the tailpipe reaches the combustion zone. Once that happens, significant flow reversal begins, driven by the drop in combustion zone pressure.

During this phase, too, there is a difference in action between the very different masses in the intake and tailpipe. The intake air mass is again fairly low, but it now almost totally consists of outside air; therefore, fresh air is available almost immediately to begin re-filling the combustion zone from the front. The tailpipe air mass is also pulled, eventually reversing direction as well. The tailpipe will never be completely purged of hot combustion gases, but at reversal it will be easily able to pull in fresh air from all sides around the tailpipe opening, so its contained mass will be gradually increasing until the next deflagration event. As air flows rapidly into the combustion zone, the rarefaction wave is reflected rearward by the front of the engine body, and as it moves rearward the air density in the combustion zone naturally rises until the pressure of the air/fuel mixture reaches a value where deflagration can again commence.

— the combustion zone is never totally purged of combustion gases and free radicals, so there is enough chemical action in the residue in the combustion zone to act as an igniter for the next blast once the mixture is up to a reasonable density and pressure. So, the cycle repeats, controlled only by the synchronization of pressure and flow events in the two ducts.

It is theoretically possible to have such an engine without a distinct "combustion chamber" larger than the tailpipe diameter; however, all successful valveless engines designed so far have a widened chamber of some sort, roughly similar to that found in typical valved engine designs. The chamber typically takes up a fairly small fraction of the overall main tube length.

Obviously, the acceleration of air mass out through the intake duct doesn’t make sense for engine thrust if the intake is aimed forward, since the intake thrust is usually equivalent to a fairly large fraction of the tailpipe thrust. Various engine geometries have been used to make the thrust forces from the two ducts act in the same direction. One simple method is to turn the engine around and then put a U-bend in the tailpipe, so both ducts are spouting rearward, as in the Ecrevisse and Lockwood (also known as Lockwood-Hiller) types. The Escopette and Kentfield designs use recuperator

s (U-shaped auxiliary tubes) mounted in front of the front-firing intakes to turn the intake blast and flow rearward. The so-called "Chinese" and Thermojet styles simply mount the intake on the chamber in a rear-spouting direction, leaving the front face of the chamber unbroken. The basic internal operation of the engine with these geometries is no different from that described above, however. The Lockwood is unique in one respect, namely, its very large diameter intake — the thrust from this large tube is no less than 40 percent of the engine thrust as a whole! The tailpipe volume of this design is quite large, though, so the imbalance of the contained masses is still clearly seen.

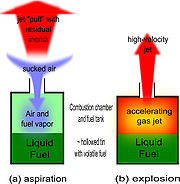

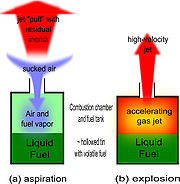

Most of pulse jet engines use independent intake and exhaust pipe, although this is not needed, but if your pipe gets smaller as it goes up, the more thrust. There is even simpler design where the intake and exhaust pipe (or rather just aperture) is the same. This is possible due to the oscillating behaviour of a pulse engine. One aperture can act as exhaust pipe during the high-pressure phase of the work cycle and as intake during the aspiration phase.

Most of pulse jet engines use independent intake and exhaust pipe, although this is not needed, but if your pipe gets smaller as it goes up, the more thrust. There is even simpler design where the intake and exhaust pipe (or rather just aperture) is the same. This is possible due to the oscillating behaviour of a pulse engine. One aperture can act as exhaust pipe during the high-pressure phase of the work cycle and as intake during the aspiration phase.

This engine design is a bit less efficient in this primitive form due to its lack of a resonant pipe and thus a lack of reflected compressing and sucking acoustic waves. However it works fairly well with a simple instrument such as jam jar with a pierced lid and fuel inside, hence the name.

Successful versions of the jam jar jet have been run by a New Zealand man (Mitchell Laughton) in a plastic bottle. The bottle is far more inefficient than the jam jar versions and is unable to sustain a decent jet for more than a few seconds. It is theorized that the alcohol that was used to operate the simple jet was acting as a barrier to stop the heat getting all the way through to the plastic. For the jam jar jet design to work the propellant must be vaporised to ignite which is most often done by a shaking of the jet which causes the propellant to coat the container, therefore giving the theory some validity.

or hydrogen

, for example). Medium and larger sized engines can be made to burn almost any flammable material that can be delivered uniformly to the combustion zone, though of course volatile flammable liquids (gasoline, kerosene

, various alcohols) and standard fuel gases (LPG

, propane

, butane

, MAPP gas

) are easiest to use. Because of the deflagration

nature of pulsejet combustion, these engines are extremely efficient combustors, producing practically no hazardous pollutants, even when using hydrocarbon

fuels. With modern high-temperature metals for the main structure, engine weight can be kept extremely low. Without the presence of a mechanical valve, the engines require practically no ongoing maintenance to remain operational.

Up to the present, the physical size of successful valveless designs has always been somewhat larger than valved engines for the same thrust value, though this is theoretically not a requirement. Like valved pulsejets, heat (engines frequently run white hot) and very high operational noise levels (140 decibels is possible) are among the greatest disadvantages of these engines. An ignition system of some sort is required for engine startup. In the smallest sizes, forced air at the intake is also typically needed for startup. There is still much room for improvement in the development of really efficient, fully practical designs for propulsion uses.

Jet propulsion

Jet propulsion is motion produced by passing a jet of fluid in the opposite direction to the direction of motion. By conservation of momentum, the moving body is propelled in the opposite direction to the jet....

devices ever designed, and is the simplest form of jet engine that does not require forward motion to run continuously. Valveless pulsejets are low in cost, light weight, powerful and easy to operate. They have all the advantages (and most of the disadvantages) of conventional valved pulse jets, but without the troublesome reed valve

Reed valve

Reed valves are a type of check valve which restrict the flow of fluids to a single direction, opening and closing under changing pressure on each face...

s that need frequent replacement - a valveless pulsejet can operate for its entire useful life with practically zero maintenance. They have been used to power model aircraft, experimental go-kart

Go-kart

thumb|A [[Kart racing|racing kart]] at the [[Commission Internationale de Karting|CIK-FIA]] European Championship 2008A go-kart is a small four-wheeled vehicle...

s and even some unmanned military aircraft such as cruise missile

Cruise missile

A cruise missile is a guided missile that carries an explosive payload and is propelled, usually by a jet engine, towards a land-based or sea-based target. Cruise missiles are designed to deliver a large warhead over long distances with high accuracy...

s and target drone

Target drone

A target drone is an unmanned, remote controlled aerial vehicle, usually used in the training of anti-aircraft crews.In their simplest form, target drones often resemble radio controlled model aircraft...

s.

Basic characteristics

A pulsejet engine is an air-breathing reaction engineReaction engine

A reaction engine is an engine or motor which provides propulsion by expelling reaction mass, in accordance with Newton's third law of motion...

employing an ongoing sequence of discrete combustion

Combustion

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

events rather than a constant level of combustion. This clearly distinguishes it from other reaction engine types such as rocket

Rocket

A rocket is a missile, spacecraft, aircraft or other vehicle which obtains thrust from a rocket engine. In all rockets, the exhaust is formed entirely from propellants carried within the rocket before use. Rocket engines work by action and reaction...

s, turbojets and ramjets, which are all constant combustion devices. All other reaction engines are driven by maintaining high internal pressure; pulsejets are driven by an alternation between high and low pressure. This alternation is not maintained by any mechanical contrivance, but rather by the natural acoustic resonance

Acoustic resonance

Acoustic resonance is the tendency of an acoustic system to absorb more energy when it is forced or driven at a frequency that matches one of its own natural frequencies of vibration than it does at other frequencies....

of the rigid tubular engine structure. The valveless pulsejet is, mechanically speaking, the simplest form of pulsejet, and is, in fact, the simplest known air-breathing propulsion device that can operate "statically", i.e. without forward motion.

The combustion events driving a pulsejet are often informally called "explosion

Explosion

An explosion is a rapid increase in volume and release of energy in an extreme manner, usually with the generation of high temperatures and the release of gases. An explosion creates a shock wave. If the shock wave is a supersonic detonation, then the source of the blast is called a "high explosive"...

s"; however, the preferred term is "deflagration

Deflagration

Deflagration is a term describing subsonic combustion that usually propagates through thermal conductivity; hot burning material heats the next layer of cold material and ignites it. Most "fire" found in daily life, from flames to explosions, is deflagration...

s". They are not the violent, very high energy detonation

Detonation

Detonation involves a supersonic exothermic front accelerating through a medium that eventually drives a shock front propagating directly in front of it. Detonations are observed in both conventional solid and liquid explosives, as well as in reactive gases...

s employed in "Pulse Detonation Engine

Pulse detonation engine

A pulse detonation engine, or "PDE", is a type of propulsion system that uses detonation waves to combust the fuel and oxidizer mixture. The engine is pulsed because the mixture must be renewed in the combustion chamber between each detonation wave initiated by an ignition source. Theoretically, a...

s (PDEs)"; rather, deflagration within the combustion zone of a pulsejet is characterized by a sudden rise in temperature and pressure followed by a rapid subsonic expansion in gas volume. It is this expansion that performs the main work of moving air rearward through the device as well as setting up conditions in the main tube for the cycle to continue.

All pulsejet engines work by alternately accelerating a contained mass of air rearward and then breathing in a fresh mass of air to replace it. The energy to accelerate the air mass is provided by the deflagration of fuel mixed thoroughly into the newly acquired fresh air mass. This cycle is repeated many times per second. During the brief mass acceleration phase of each cycle, the engine’s physical action is more or less identical to that of other reaction engines — that is, gas mass is accelerated rearward, accompanied by an application of force forward into the body of the engine. These small "pulses" of force, rapidly repeated over time, comprise the measurable thrust force of the engine.

Some basic differences between valved and valveless pulsejets are:

- Valveless pulsejet engines have no mechanical valve, eliminating the only internal "moving part" of the conventional pulsejet;

- In valveless engines, the intake section has an important role to play throughout the entire pulsejet cycle;

- Valveless engines produce thrustThrustThrust is a reaction force described quantitatively by Newton's second and third laws. When a system expels or accelerates mass in one direction the accelerated mass will cause a force of equal magnitude but opposite direction on that system....

forces in two distinct but synchronized mass acceleration events per cycle, rather than just one.

Basic (valved) pulsejet theory

In a conventional "valved" pulsejet, like the engine of the infamous V-1V-1 flying bomb

The V-1 flying bomb, also known as the Buzz Bomb or Doodlebug, was an early pulse-jet-powered predecessor of the cruise missile....

"buzz bomb" of World War II, there are two ducts connected to the combustion zone where the explosions occur. These are generally known as the "intake" (a very short duct) and the "tailpipe" (a very long duct). The function of the forward-facing intake is to provide air (and in many smaller pulsejets, the fuel/air mixing action) for combustion. The purpose of the rear-facing tailpipe is to provide air mass for acceleration by the explosive blast as well as to direct the accelerated mass totally rearward. The combustion zone (usually a widened "chamber" section) and tailpipe make up the main tube of the engine. A flexible, low mass one-way valve (or multiple identical valves) separates the intake from the combustion zone.

At the beginning of each cycle, air must be pulled into the combustion zone. At the end of each cycle, the tailpipe must be reloaded with air from the surrounding atmosphere. Both of these basic actions are accomplished by a significant drop in pressure that occurs naturally after the deflagration expansion, a phenomenon known as the Kadenacy effect

Kadenacy effect

The Kadenacy effect is an effect of pressure-waves in gases. It is named after Michel Kadenacy who obtained a French patent for an engine utilizing the effect in 1933. There are also European and US patents...

(named after the scientist who first fully described it). This temporary low pressure opens the metal valve and draws in the intake air (or air/fuel mixture). It also causes a reversal of flow in the tailpipe that draws fresh air forward to re-fill the pipe. When the next deflagration occurs, the rapid pressure rise slams the valve shut very quickly, ensuring that almost no explosion mass exits in the forward direction so the expansion of the combustion gases will all be used to accelerate the replenished mass of air in the long tailpipe rearward.

Valveless pulsejet operation

The "valveless" pulsejet is not really valveless — it just uses the mass of air in the intake tube as its valve, in place of a mechanical valve. It cannot do this without moving the intake air outward, and this volume of air itself has significant mass, just as the air in the tailpipe does — therefore, it is not blown away instantly by the deflagration but is accelerated over a significant fraction of the cycle time. In all known successful valveless pulsejet designs, the intake air mass is a small fraction of the tailpipe air mass (due to the smaller dimensions of the intake duct). This means that the intake air mass will be cleared out of contact with the body of the engine faster than the tailpipe mass will. The carefully designed imbalance of these two air masses is important for the proper timing of all parts of the cycle.When the deflagration begins, a zone of significantly elevated pressure travels outward through both air masses as a "compression wave". This wave moves at the speed of sound through both the intake and tailpipe air masses. (Because these air masses are significantly elevated in temperature as a result of earlier cycles, the speed of sound in them is much higher than it would be in normal outdoor air.) When a compression wave reaches the open end of either tube, a low pressure rarefaction

Rarefaction

Rarefaction is the reduction of a medium's density, or the opposite of compression.A natural example of this is as a phase in a sound wave or phonon. Half of a sound wave is made up of the compression of the medium, and the other half is the decompression or rarefaction of the medium.Another...

wave starts back in the opposite direction, as if "reflected" by the open end. This low pressure region returning to the combustion zone is, in fact, the internal mechanism of the Kadenacy effect. There will be no "breathing" of fresh air into the combustion zone until the arrival of the rarefaction wave.

The wave motion through the air masses should not be confused with the separate motions of the masses themselves. At the start of deflagration, the pressure wave immediately moves through both air masses, while the gas expansion (due to combustion heat) is just beginning in the combustion zone. The intake air mass will be rapidly accelerated outward behind the pressure wave, because its mass is relatively small. The tailpipe air mass will follow the outgoing pressure wave much more slowly. Also, the eventual flow reversal will take place much sooner in the intake, due to its smaller air mass. The timing of the wave motions is determined basically by the lengths of the intake and main tube of the engine; the timing of mass motions is determined mostly by the volumes and exact shapes of these sections. Both are affected by local gas temperature

Temperature

Temperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot...

s.

In the valveless engine, there will actually be two arrivals of rarefaction waves — first, from the intake and then from the tailpipe. In typical valveless designs, the wave that comes back from the intake will be relatively weak. Its main effect is to begin flow reversal in the intake itself, in effect "pre-loading" the intake duct with fresh outdoor air. The actual "breathing" of the engine as a whole will not begin in earnest until the major low pressure wave from the tailpipe reaches the combustion zone. Once that happens, significant flow reversal begins, driven by the drop in combustion zone pressure.

During this phase, too, there is a difference in action between the very different masses in the intake and tailpipe. The intake air mass is again fairly low, but it now almost totally consists of outside air; therefore, fresh air is available almost immediately to begin re-filling the combustion zone from the front. The tailpipe air mass is also pulled, eventually reversing direction as well. The tailpipe will never be completely purged of hot combustion gases, but at reversal it will be easily able to pull in fresh air from all sides around the tailpipe opening, so its contained mass will be gradually increasing until the next deflagration event. As air flows rapidly into the combustion zone, the rarefaction wave is reflected rearward by the front of the engine body, and as it moves rearward the air density in the combustion zone naturally rises until the pressure of the air/fuel mixture reaches a value where deflagration can again commence.

Practical design issues

As in all practical pulsejets, there is no need for a continuous ignition systemIgnition system

An ignition system is a system for igniting a fuel-air mixture. Ignition systems are well known in the field of internal combustion engines such as those used in petrol engines used to power the majority of motor vehicles, but they are also used in many other applications such as in oil-fired and...

— the combustion zone is never totally purged of combustion gases and free radicals, so there is enough chemical action in the residue in the combustion zone to act as an igniter for the next blast once the mixture is up to a reasonable density and pressure. So, the cycle repeats, controlled only by the synchronization of pressure and flow events in the two ducts.

It is theoretically possible to have such an engine without a distinct "combustion chamber" larger than the tailpipe diameter; however, all successful valveless engines designed so far have a widened chamber of some sort, roughly similar to that found in typical valved engine designs. The chamber typically takes up a fairly small fraction of the overall main tube length.

Obviously, the acceleration of air mass out through the intake duct doesn’t make sense for engine thrust if the intake is aimed forward, since the intake thrust is usually equivalent to a fairly large fraction of the tailpipe thrust. Various engine geometries have been used to make the thrust forces from the two ducts act in the same direction. One simple method is to turn the engine around and then put a U-bend in the tailpipe, so both ducts are spouting rearward, as in the Ecrevisse and Lockwood (also known as Lockwood-Hiller) types. The Escopette and Kentfield designs use recuperator

Recuperator

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat...

s (U-shaped auxiliary tubes) mounted in front of the front-firing intakes to turn the intake blast and flow rearward. The so-called "Chinese" and Thermojet styles simply mount the intake on the chamber in a rear-spouting direction, leaving the front face of the chamber unbroken. The basic internal operation of the engine with these geometries is no different from that described above, however. The Lockwood is unique in one respect, namely, its very large diameter intake — the thrust from this large tube is no less than 40 percent of the engine thrust as a whole! The tailpipe volume of this design is quite large, though, so the imbalance of the contained masses is still clearly seen.

"Jam jar jet" design

This engine design is a bit less efficient in this primitive form due to its lack of a resonant pipe and thus a lack of reflected compressing and sucking acoustic waves. However it works fairly well with a simple instrument such as jam jar with a pierced lid and fuel inside, hence the name.

Successful versions of the jam jar jet have been run by a New Zealand man (Mitchell Laughton) in a plastic bottle. The bottle is far more inefficient than the jam jar versions and is unable to sustain a decent jet for more than a few seconds. It is theorized that the alcohol that was used to operate the simple jet was acting as a barrier to stop the heat getting all the way through to the plastic. For the jam jar jet design to work the propellant must be vaporised to ignite which is most often done by a shaking of the jet which causes the propellant to coat the container, therefore giving the theory some validity.

Pros and cons

Successful valveless pulsejets have been built from a few centimeters in length to huge sizes, though the largest and smallest have not been used for propulsion. The smallest ones are only successful when extremely fast-burning fuels are employed (acetyleneAcetylene

Acetylene is the chemical compound with the formula C2H2. It is a hydrocarbon and the simplest alkyne. This colorless gas is widely used as a fuel and a chemical building block. It is unstable in pure form and thus is usually handled as a solution.As an alkyne, acetylene is unsaturated because...

or hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

, for example). Medium and larger sized engines can be made to burn almost any flammable material that can be delivered uniformly to the combustion zone, though of course volatile flammable liquids (gasoline, kerosene

Kerosene

Kerosene, sometimes spelled kerosine in scientific and industrial usage, also known as paraffin or paraffin oil in the United Kingdom, Hong Kong, Ireland and South Africa, is a combustible hydrocarbon liquid. The name is derived from Greek keros...

, various alcohols) and standard fuel gases (LPG

Liquified petroleum gas

Liquefied petroleum gas is a flammable mixture of hydrocarbon gases used as a fuel in heating appliances and vehicles. It is increasingly used as an aerosol propellant and a refrigerant, replacing chlorofluorocarbons in an effort to reduce damage to the ozone layer...

, propane

Propane

Propane is a three-carbon alkane with the molecular formula , normally a gas, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as a fuel for engines, oxy-gas torches, barbecues, portable stoves, and residential central...

, butane

Butane

Butane is a gas with the formula C4H10 that is an alkane with four carbon atoms. The term may refer to any of two structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, butane refers only to the unbranched n-butane isomer; the other one being called "methylpropane" or...

, MAPP gas

MAPP gas

MAPP gas is a trademarked name belonging to Linde Group, previously to Dow, for a fuel gas based on a stabilized mixture of methylacetylene and propadiene. The name comes from the original chemical composition: methylacetylene-propadiene propane...

) are easiest to use. Because of the deflagration

Deflagration

Deflagration is a term describing subsonic combustion that usually propagates through thermal conductivity; hot burning material heats the next layer of cold material and ignites it. Most "fire" found in daily life, from flames to explosions, is deflagration...

nature of pulsejet combustion, these engines are extremely efficient combustors, producing practically no hazardous pollutants, even when using hydrocarbon

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons from which one hydrogen atom has been removed are functional groups, called hydrocarbyls....

fuels. With modern high-temperature metals for the main structure, engine weight can be kept extremely low. Without the presence of a mechanical valve, the engines require practically no ongoing maintenance to remain operational.

Up to the present, the physical size of successful valveless designs has always been somewhat larger than valved engines for the same thrust value, though this is theoretically not a requirement. Like valved pulsejets, heat (engines frequently run white hot) and very high operational noise levels (140 decibels is possible) are among the greatest disadvantages of these engines. An ignition system of some sort is required for engine startup. In the smallest sizes, forced air at the intake is also typically needed for startup. There is still much room for improvement in the development of really efficient, fully practical designs for propulsion uses.

External links

- http://www.pulse-jets.com/ - An international site dedicated to pulsejets, including design and experimentation. Includes an extremely active forum composed of knowledgeable enthusiasts.

- Valveless you can find under Pulso