Titanium boride

Encyclopedia

Titanium diboride is an extremely hard ceramic

compound composed of titanium

and boron

which has excellent resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, an unusual property for a ceramic, so it can be used as a cathode material in aluminium smelting

and can be shaped by electrical discharge machining

.

, an important base material for cermet

s, and many of its properties (e.g. hardness, thermal conductivity

, electrical conductivity and oxidation resistance) are superior to those of TiC:

or silicon nitride

.

TiB2 is resistant to oxidation in air at temperatures up to 1100 °C, and to hydrochloric

and hydrofluoric

acids, but reacts with alkali

s, nitric acid

and sulfuric acid

.

or its oxides/hydrides, with elemental boron

over 1000 °C, carbothermal reduction by thermite reaction of titanium oxide

and boron oxide, or hydrogen reduction of boron halides in the presence of the metal or its halides. Among various synthesis routes, electrochemical

synthesis and solid state reactions have been developed to prepare finer titanium diboride in large quantity. An example of solid state reaction is the borothermic reduction, which can be illustrated by the following reaction

These synthesis routes, however, cannot produce nanosized powders. Nanocrystalline (5–100 nm) TiB2 was synthesized using the following techniques:

Many TiB2 applications are inhibited by economic factors, particularly the costs of densifying a high melting point material - the melting point is about 2970 °C, and, thanks to a layer of titanium dioxide that forms on the surface of the particles of a powder, it is very resistant to sintering

. Admixture of about 10% silicon nitride

facilitates the sintering, though sintering without silicon nitride has been demonstrated as well.

Thin films of TiB2 can be produced by several techniques. The electroplating

of TiB2 layers possess two main advantages compared with physical vapor deposition

or chemical vapor deposition

: the growing rate of the layer is 200 times higher (up to 5 μm/s) and the inconveniences of covering complex shaped products are dramatically reduced.

s, crucible

s and wear resistant coatings.

TiB2 is extensively used as evaporation boats for vapour coating of aluminium

. It is an attractive material for the aluminium industry as an inoculant to refine the grain size

when casting aluminium alloy

s, because of its wettability by and low solubility in molten aluminium and good electrical conductivity.

Thin film

s of TiB2 can be used for wear and corrosion

resistance that TiB2 can provide to a cheap and/or tough substrate.

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

compound composed of titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

and boron

Boron

Boron is the chemical element with atomic number 5 and the chemical symbol B. Boron is a metalloid. Because boron is not produced by stellar nucleosynthesis, it is a low-abundance element in both the solar system and the Earth's crust. However, boron is concentrated on Earth by the...

which has excellent resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, an unusual property for a ceramic, so it can be used as a cathode material in aluminium smelting

Aluminium smelting

Aluminium smelting is the process of extracting aluminium from its oxide alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore Bauxite by means of the Bayer process at an alumina refinery....

and can be shaped by electrical discharge machining

Electrical discharge machining

Electric discharge machining , sometimes colloquially also referred to as spark machining, spark eroding, burning, die sinking or wire erosion, is a manufacturing process whereby a desired shape is obtained using electrical discharges...

.

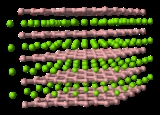

Physical properties

TiB2 is very similar to titanium carbideTitanium carbide

Titanium carbide, TiC, is an extremely hard refractory ceramic material, similar to tungsten carbide.It is commercially used in tool bits. It has the appearance of black powder with NaCl-type face centered cubic crystal structure...

, an important base material for cermet

Cermet

A cermet is a composite material composed of ceramic and metallic materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used...

s, and many of its properties (e.g. hardness, thermal conductivity

Thermal conductivity

In physics, thermal conductivity, k, is the property of a material's ability to conduct heat. It appears primarily in Fourier's Law for heat conduction....

, electrical conductivity and oxidation resistance) are superior to those of TiC:

- Exceptional hardness (~25–35 GPa at room temperature, more than three times harder than fully hardened structural steelStructural steelStructural steel is steel construction material, a profile, formed with a specific shape or cross section and certain standards of chemical composition and mechanical properties...

), which is retained up to high temperature. - High melting pointMelting pointThe melting point of a solid is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends on pressure and is usually specified at standard atmospheric pressure...

(3225 °C), - High thermal conductivityThermal conductivityIn physics, thermal conductivity, k, is the property of a material's ability to conduct heat. It appears primarily in Fourier's Law for heat conduction....

(60-120 W/(m K)), - High electrical conductivity (~105 S/cm)

Chemical properties

With respect to chemical stability, TiB2 is more stable in contact with pure iron than tungsten carbideTungsten carbide

Tungsten carbide is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. Colloquially, tungsten carbide is often simply called carbide. In its most basic form, it is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery,...

or silicon nitride

Silicon nitride

Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen...

.

TiB2 is resistant to oxidation in air at temperatures up to 1100 °C, and to hydrochloric

Hydrochloric acid

Hydrochloric acid is a solution of hydrogen chloride in water, that is a highly corrosive, strong mineral acid with many industrial uses. It is found naturally in gastric acid....

and hydrofluoric

Hydrofluoric acid

Hydrofluoric acid is a solution of hydrogen fluoride in water. It is a valued source of fluorine and is the precursor to numerous pharmaceuticals such as fluoxetine and diverse materials such as PTFE ....

acids, but reacts with alkali

Alkali

In chemistry, an alkali is a basic, ionic salt of an alkali metal or alkaline earth metal element. Some authors also define an alkali as a base that dissolves in water. A solution of a soluble base has a pH greater than 7. The adjective alkaline is commonly used in English as a synonym for base,...

s, nitric acid

Nitric acid

Nitric acid , also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming...

and sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

.

Production

TiB2 does not occur naturally in the earth. Titanium diboride powder can be prepared by a variety of high-temperature methods, such as the direct reactions of titaniumTitanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

or its oxides/hydrides, with elemental boron

Boron

Boron is the chemical element with atomic number 5 and the chemical symbol B. Boron is a metalloid. Because boron is not produced by stellar nucleosynthesis, it is a low-abundance element in both the solar system and the Earth's crust. However, boron is concentrated on Earth by the...

over 1000 °C, carbothermal reduction by thermite reaction of titanium oxide

Titanium oxide

Titanium oxide may refer to:* Titanium dioxide , TiO2* Titanium oxide , TiO, a non-stoichiometric oxide* Titanium oxide , Ti2O3* Ti3O* Ti2O* δ-TiOx...

and boron oxide, or hydrogen reduction of boron halides in the presence of the metal or its halides. Among various synthesis routes, electrochemical

synthesis and solid state reactions have been developed to prepare finer titanium diboride in large quantity. An example of solid state reaction is the borothermic reduction, which can be illustrated by the following reaction

- 2 TiO2 + B4C → 2 TiB2 + 4 CO

These synthesis routes, however, cannot produce nanosized powders. Nanocrystalline (5–100 nm) TiB2 was synthesized using the following techniques:

- Solution phase reaction of NaBH4 and TiCl4, followed by annealing the amorphous precursor obtained at 900–1100 °C.

- Mechanical alloying of a mixture of elemental Ti and B powders.

- Self-propagating high temperature synthesis process involving addition of varying amounts of NaCl.

- Solvothermal reaction in benzene of metallic sodium with amorphous boron powder and TiCl4 at 400 °C:

-

- TiCl4 + 2 B + 4 Na → TiB2 + 4 NaCl

Many TiB2 applications are inhibited by economic factors, particularly the costs of densifying a high melting point material - the melting point is about 2970 °C, and, thanks to a layer of titanium dioxide that forms on the surface of the particles of a powder, it is very resistant to sintering

Sintering

Sintering is a method used to create objects from powders. It is based on atomic diffusion. Diffusion occurs in any material above absolute zero, but it occurs much faster at higher temperatures. In most sintering processes, the powdered material is held in a mold and then heated to a temperature...

. Admixture of about 10% silicon nitride

Silicon nitride

Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen...

facilitates the sintering, though sintering without silicon nitride has been demonstrated as well.

Thin films of TiB2 can be produced by several techniques. The electroplating

Electroplating

Electroplating is a plating process in which metal ions in a solution are moved by an electric field to coat an electrode. The process uses electrical current to reduce cations of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal...

of TiB2 layers possess two main advantages compared with physical vapor deposition

Physical vapor deposition

Physical vapor deposition is a variety of vacuum deposition and is a general term used to describe any of a variety of methods to deposit thin films by the condensation of a vaporized form of the desired film material onto various workpiece surfaces...

or chemical vapor deposition

Chemical vapor deposition

Chemical vapor deposition is a chemical process used to produce high-purity, high-performance solid materials. The process is often used in the semiconductor industry to produce thin films. In a typical CVD process, the wafer is exposed to one or more volatile precursors, which react and/or...

: the growing rate of the layer is 200 times higher (up to 5 μm/s) and the inconveniences of covering complex shaped products are dramatically reduced.

Potential applications

Current use of TiB2 appears to be limited to specialized applications in such areas as impact resistant armor, cutting toolCutting tool

In the context of machining, a cutting tool is any tool that is used to remove material from the workpiece by means of shear deformation. Cutting may be accomplished by single-point or multipoint tools. Single-point tools are used in turning, shaping, plaining and similar operations, and remove...

s, crucible

Crucible

A crucible is a container used for metal, glass, and pigment production as well as a number of modern laboratory processes, which can withstand temperatures high enough to melt or otherwise alter its contents...

s and wear resistant coatings.

TiB2 is extensively used as evaporation boats for vapour coating of aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

. It is an attractive material for the aluminium industry as an inoculant to refine the grain size

Crystallite

Crystallites are small, often microscopic crystals that, held together through highly defective boundaries, constitute a polycrystalline solid. Metallurgists often refer to crystallites as grains.- Details :...

when casting aluminium alloy

Aluminium alloy

Aluminium alloys are alloys in which aluminium is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories...

s, because of its wettability by and low solubility in molten aluminium and good electrical conductivity.

Thin film

Thin film

A thin film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness. Electronic semiconductor devices and optical coatings are the main applications benefiting from thin film construction....

s of TiB2 can be used for wear and corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

resistance that TiB2 can provide to a cheap and/or tough substrate.

See also

- BorideBorideIn chemistry a boride is a chemical compound between boron and a less electronegative element, for example silicon boride . The borides are a very large group of compounds that are generally high melting and are not ionic in nature. Some borides exhibit very useful physical properties. The term...

- Titanium carbideTitanium carbideTitanium carbide, TiC, is an extremely hard refractory ceramic material, similar to tungsten carbide.It is commercially used in tool bits. It has the appearance of black powder with NaCl-type face centered cubic crystal structure...

- CermetCermetA cermet is a composite material composed of ceramic and metallic materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used...

- SinteringSinteringSintering is a method used to create objects from powders. It is based on atomic diffusion. Diffusion occurs in any material above absolute zero, but it occurs much faster at higher temperatures. In most sintering processes, the powdered material is held in a mold and then heated to a temperature...

- Hot pressingHot pressingHot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure....