Pulse tube refrigerator

Encyclopedia

The pulse tube refrigerator or pulse tube cryocooler is a developing technology that emerged largely in the early 1980s with a series of other innovations in the broader field of thermoacoustics

. In contrast with other cryocoolers (eg Stirling cryocooler and Gifford-McMahon cooler), this cryocooler can be made without moving parts

in the low temperature part of the device, making the cooler suitable for a wide variety of applications.

applications such as semiconductor

fabrication and in military

applications such as for the cooling of infrared sensors. Pulse tubes are also being developed for cooling of astronomical detectors where liquid cryogens are typically used, such as the Atacama Cosmology Telescope

or the QUBIC experiment

(an interferometer for cosmology studies). Pulse tubes will be particularly useful in space-based telescopes where it is not possible to replenish the cryogens as they are depleted. It has also been suggested that pulse tubes could be used to liquefy oxygen

on Mars

.

The ice cream

manufacturer Ben and Jerry's invested in a related thermoacoustic cooling technology, funding a pilot thermoacoustic ice-cream refrigerator project in New York City

. The technology's environmentally clean

alternative to chemicals

used in conventional freezers is attractive to Ben and Jerry's.

The part in between

The part in between  and

and  is thermally insulated from the surroundings, usually by vacuum. The cooler is filled with helium at a pressure in the range from 10 to 30 bar. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is very misleading since there are no pulses whatsoever in the system.

is thermally insulated from the surroundings, usually by vacuum. The cooler is filled with helium at a pressure in the range from 10 to 30 bar. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is very misleading since there are no pulses whatsoever in the system.

and leaves the regenerator at the cold end with temperature

and leaves the regenerator at the cold end with temperature  , hence heat is transferred into the regenerator material. On its return the heat stored within the regenerator is transferred back into the gas.

, hence heat is transferred into the regenerator material. On its return the heat stored within the regenerator is transferred back into the gas.

The thermal environment of a gas element near , that moves back and forth in the system, changes when it passes the heat exchanger. In the regenerator and in the heat exchanger (X1) the heat contact between the gas and its surrounding material is good. Here the temperature of the gas is practically the same as of the surrounding medium. However, in the pulse tube the gas element is thermally isolated, so, in the pulse tube, the temperature of the gas element varies with the pressure.

, that moves back and forth in the system, changes when it passes the heat exchanger. In the regenerator and in the heat exchanger (X1) the heat contact between the gas and its surrounding material is good. Here the temperature of the gas is practically the same as of the surrounding medium. However, in the pulse tube the gas element is thermally isolated, so, in the pulse tube, the temperature of the gas element varies with the pressure.

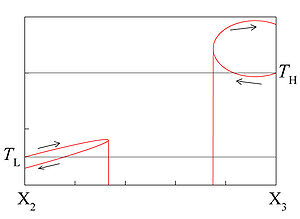

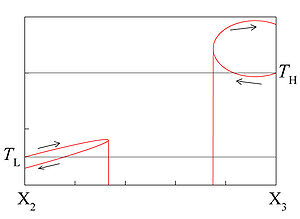

Look at figure 2 and concentrate on gas elements close to

Look at figure 2 and concentrate on gas elements close to  (at the hot end) which move in and out of the pulse tube. A gas element that flows into the tube does so when the pressure in the tube is low (it is sucked into the tube via

(at the hot end) which move in and out of the pulse tube. A gas element that flows into the tube does so when the pressure in the tube is low (it is sucked into the tube via  coming from the orifice and the buffer). At the moment it enters the tube it has the temperature

coming from the orifice and the buffer). At the moment it enters the tube it has the temperature  . Later in the cycle it is pushed out the tube again when the pressure inside the tube is high. As a consequence its temperature will be higher than

. Later in the cycle it is pushed out the tube again when the pressure inside the tube is high. As a consequence its temperature will be higher than  . In the heat exchanger

. In the heat exchanger  it releases heat and cools to the ambient temperature

it releases heat and cools to the ambient temperature  .

.

At the cold end of the pulse tube there is the opposite effect: here gas elements enter the tube via when the pressure is high with temperature

when the pressure is high with temperature  and return when the pressure is low with a temperature below

and return when the pressure is low with a temperature below  . They take up heat from

. They take up heat from  : this gives the desired cooling power.

: this gives the desired cooling power.

The so-called Coefficient Of Performance (COP) of coolers is defined as the ratio between the cooling power

(COP) of coolers is defined as the ratio between the cooling power  and the compressor power P. In formula

and the compressor power P. In formula  . For a perfectly reversible cooler,

. For a perfectly reversible cooler,  is given by the famous relation

is given by the famous relation

which is also called the Carnot COP. However, a pulse-tube refrigerator is not perfectly reversible due to the presence of the orifice, which has flow resistance. Therefore equation (1) does not hold. Instead, the COP of an ideal PTR is given by

Comparing relations 1 and 2 shows that the COP of PTR’s is lower than that of ideal coolers.

At the moment, the lowest temperature is below the boiling point of helium (4.2 K). Originally this was considered to be impossible. For some time it looked as if it would be impossible to cool below the lambda point of 4He (2.17 K), but the Low-Temperature group of the Eindhoven University of Technology managed to cool to a temperature of 1.73 K by replacing the usual 4He as refrigerant by its rare isotope 3He. Later this record was broken by the Giessen Group that managed to get even below 1.3 K. In a collaboration between the groups from Giessen and Eindhoven a temperature of 1.2 K was reached by combining a PTR with a superfluid vortex cooler.

At the moment, the lowest temperature is below the boiling point of helium (4.2 K). Originally this was considered to be impossible. For some time it looked as if it would be impossible to cool below the lambda point of 4He (2.17 K), but the Low-Temperature group of the Eindhoven University of Technology managed to cool to a temperature of 1.73 K by replacing the usual 4He as refrigerant by its rare isotope 3He. Later this record was broken by the Giessen Group that managed to get even below 1.3 K. In a collaboration between the groups from Giessen and Eindhoven a temperature of 1.2 K was reached by combining a PTR with a superfluid vortex cooler.

s) for the temperature region down to 2 mK is attractive since in this way the whole temperature range from room temperature to 2 mK will be easier to access.

Thermoacoustics

Thermoacoustics is about the interaction between thermodynamic and acoustic phenomena. Thermoacoustics is a relatively new field of science and engineering. Few devices based on this principle have been made thus far...

. In contrast with other cryocoolers (eg Stirling cryocooler and Gifford-McMahon cooler), this cryocooler can be made without moving parts

Moving parts

The moving parts of a machine are those parts of it that move. Machines comprise both moving and fixed parts. The moving parts have controlled and constrained motions....

in the low temperature part of the device, making the cooler suitable for a wide variety of applications.

Uses

Pulse tube cryocoolers have been used in industrialIndustry

Industry refers to the production of an economic good or service within an economy.-Industrial sectors:There are four key industrial economic sectors: the primary sector, largely raw material extraction industries such as mining and farming; the secondary sector, involving refining, construction,...

applications such as semiconductor

Semiconductor

A semiconductor is a material with electrical conductivity due to electron flow intermediate in magnitude between that of a conductor and an insulator. This means a conductivity roughly in the range of 103 to 10−8 siemens per centimeter...

fabrication and in military

Military

A military is an organization authorized by its greater society to use lethal force, usually including use of weapons, in defending its country by combating actual or perceived threats. The military may have additional functions of use to its greater society, such as advancing a political agenda e.g...

applications such as for the cooling of infrared sensors. Pulse tubes are also being developed for cooling of astronomical detectors where liquid cryogens are typically used, such as the Atacama Cosmology Telescope

Atacama Cosmology Telescope

The Atacama Cosmology Telescope is a six-metre telescope on Cerro Toco in the Atacama Desert in the north of Chile, near the Llano de Chajnantor Observatory. It is designed to make high-resolution, microwave-wavelength surveys of the sky in order to study the cosmic microwave background radiation...

or the QUBIC experiment

Qubic experiment

Qubic is a ground-based project of observational cosmology dedicated to measuring the Cosmic microwave background polarization anisotropies. Qubic is an international collaboration between France, Italy, U.K. and U.S.A., that results from the merging of the BRAIN and MBI collaborations...

(an interferometer for cosmology studies). Pulse tubes will be particularly useful in space-based telescopes where it is not possible to replenish the cryogens as they are depleted. It has also been suggested that pulse tubes could be used to liquefy oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

on Mars

Mars

Mars is the fourth planet from the Sun in the Solar System. The planet is named after the Roman god of war, Mars. It is often described as the "Red Planet", as the iron oxide prevalent on its surface gives it a reddish appearance...

.

The ice cream

Ice cream

Ice cream is a frozen dessert usually made from dairy products, such as milk and cream, and often combined with fruits or other ingredients and flavours. Most varieties contain sugar, although some are made with other sweeteners...

manufacturer Ben and Jerry's invested in a related thermoacoustic cooling technology, funding a pilot thermoacoustic ice-cream refrigerator project in New York City

New York City

New York is the most populous city in the United States and the center of the New York Metropolitan Area, one of the most populous metropolitan areas in the world. New York exerts a significant impact upon global commerce, finance, media, art, fashion, research, technology, education, and...

. The technology's environmentally clean

Environmentalism

Environmentalism is a broad philosophy, ideology and social movement regarding concerns for environmental conservation and improvement of the health of the environment, particularly as the measure for this health seeks to incorporate the concerns of non-human elements...

alternative to chemicals

Refrigerant

A refrigerant is a substance used in a heat cycle usually including, for enhanced efficiency, a reversible phase change from a liquid to a gas. Traditionally, fluorocarbons, especially chlorofluorocarbons, were used as refrigerants, but they are being phased out because of their ozone depletion...

used in conventional freezers is attractive to Ben and Jerry's.

Description

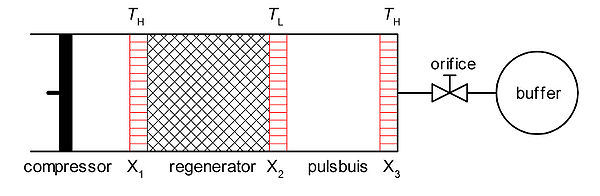

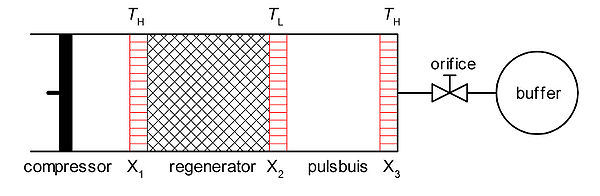

Here the so-called Stirling-type single-orifice pulse-tube refrigerator will be treated operating with an ideal gas (helium) as the working fluid. Figure 1 represents the Stirling-type single-orifice Pulse-Tube Refrigerator (PTR). From left to right the components are:- a compressor, with a piston moving back and forth at room temperature

;

; - a heat exchanger

where heat is released to the surroundings;

where heat is released to the surroundings; - a regenerator consisting of a porous medium with a large specific heat;

- a heat exchanger

where the useful cooling power

where the useful cooling power  is delivered at the low temperature

is delivered at the low temperature  ;

; - a tube, often called "the pulse tube";

- a heat exchanger

at room temperature where heat is released to the surroundings;

at room temperature where heat is released to the surroundings; - a flow resistance (often called orifice);

- a buffer volume (a large closed volume at practically constant pressure).

and

and  is thermally insulated from the surroundings, usually by vacuum. The cooler is filled with helium at a pressure in the range from 10 to 30 bar. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is very misleading since there are no pulses whatsoever in the system.

is thermally insulated from the surroundings, usually by vacuum. The cooler is filled with helium at a pressure in the range from 10 to 30 bar. The pressure varies gradually and the velocities of the gas are low. So the name "pulse" tube cooler is very misleading since there are no pulses whatsoever in the system.How it operates

The piston moves periodically from left to right and back. As a result the gas also moves from left to right and back while the pressure within the system increases and decreases. If the gas from the compressor space moves to the right it enters the regenerator with temperature and leaves the regenerator at the cold end with temperature

and leaves the regenerator at the cold end with temperature  , hence heat is transferred into the regenerator material. On its return the heat stored within the regenerator is transferred back into the gas.

, hence heat is transferred into the regenerator material. On its return the heat stored within the regenerator is transferred back into the gas.The thermal environment of a gas element near

, that moves back and forth in the system, changes when it passes the heat exchanger. In the regenerator and in the heat exchanger (X1) the heat contact between the gas and its surrounding material is good. Here the temperature of the gas is practically the same as of the surrounding medium. However, in the pulse tube the gas element is thermally isolated, so, in the pulse tube, the temperature of the gas element varies with the pressure.

, that moves back and forth in the system, changes when it passes the heat exchanger. In the regenerator and in the heat exchanger (X1) the heat contact between the gas and its surrounding material is good. Here the temperature of the gas is practically the same as of the surrounding medium. However, in the pulse tube the gas element is thermally isolated, so, in the pulse tube, the temperature of the gas element varies with the pressure.

(at the hot end) which move in and out of the pulse tube. A gas element that flows into the tube does so when the pressure in the tube is low (it is sucked into the tube via

(at the hot end) which move in and out of the pulse tube. A gas element that flows into the tube does so when the pressure in the tube is low (it is sucked into the tube via  coming from the orifice and the buffer). At the moment it enters the tube it has the temperature

coming from the orifice and the buffer). At the moment it enters the tube it has the temperature  . Later in the cycle it is pushed out the tube again when the pressure inside the tube is high. As a consequence its temperature will be higher than

. Later in the cycle it is pushed out the tube again when the pressure inside the tube is high. As a consequence its temperature will be higher than  . In the heat exchanger

. In the heat exchanger  it releases heat and cools to the ambient temperature

it releases heat and cools to the ambient temperature  .

.At the cold end of the pulse tube there is the opposite effect: here gas elements enter the tube via

when the pressure is high with temperature

when the pressure is high with temperature  and return when the pressure is low with a temperature below

and return when the pressure is low with a temperature below  . They take up heat from

. They take up heat from  : this gives the desired cooling power.

: this gives the desired cooling power.Performance

The performance of the cooler is determined mainly by the quality of the regenerator. It has to satisfy conflicting requirements: it must have a low flow resistance (so it must be short with wide channels), but the heat exchange should also be good (so it must be long with narrow channels). The material must have a large heat capacity. At temperatures above 50 K practically all materials are suitable. Bronze or stainless steel is often used. For temperatures between 10 and 50 K lead is most suitable. Below 10 K one uses magnetic materials which are specially developed for this application.The so-called Coefficient Of Performance

(COP) of coolers is defined as the ratio between the cooling power

(COP) of coolers is defined as the ratio between the cooling power  and the compressor power P. In formula

and the compressor power P. In formula  . For a perfectly reversible cooler,

. For a perfectly reversible cooler,  is given by the famous relation

is given by the famous relation  |

(1) |

which is also called the Carnot COP. However, a pulse-tube refrigerator is not perfectly reversible due to the presence of the orifice, which has flow resistance. Therefore equation (1) does not hold. Instead, the COP of an ideal PTR is given by

. . |

(2) |

Comparing relations 1 and 2 shows that the COP of PTR’s is lower than that of ideal coolers.

Comparison with other coolers

In most coolers gas is compressed and expanded periodically. Well-known coolers such as the Stirling coolers and the popular Gifford-McMahon coolers have a displacer that ensures that the cooling (due to expansion) takes place in a different region of the machine than the heating (due to compression). Due to its clever design the PTR does not have such a displacer. This means that the construction of a PTR is simpler, cheaper, and more reliable. Furthermore there are no mechanical vibrations and no electro-magnetic interferences.History

The Pulse Tube Refrigeration was first experienced by the W. E. Gifford and R. C. Longsworth in 1960's and it was called Basic Pulse Tube Refrigerator. And modern PTR was invented by Mikulin by introducing orifice in Basic pulse tube in 1984. He reached a temperature of 105 K. Soon after that, PTR’s became better due to the invention of new variations. This is shown in figure 3, where the lowest temperature for PTR’s is plotted as a function of time.

Prospects

The C.O.P of PTR’s at room temperature is low, so it is not likely that they will play a role in domestic cooling. However, below about 80 K the COP is comparable with other coolers (compare Eqs.(1) and (2)) and in the low-temperature region the advantages get the upper hand. For the 70K- and the 4K temperature regions PTR’s are commercially available. They are applied in infrared detection systems, for reduction of thermal noise in devices based on (high-Tc) superconductivity such as SQUID's, and filters for telecommunication. PTR’s are also suitable for cooling MRI-systems and energy-related systems using superconducting magnets. In so-called dry magnets, coolers are used so that no cryoliquid is needed at all or for the recondensation of the evaporated helium. Also the combination of cryocoolers with 3He-4He dilution refrigerators (dry dilution refrigeratorDry dilution refrigerator

A dry dilution refrigerator is a type of dilution refrigerator that does not require the use of any external cryogens, in particular liquid helium, to operate....

s) for the temperature region down to 2 mK is attractive since in this way the whole temperature range from room temperature to 2 mK will be easier to access.

See also

- CryocoolerCryocoolerCryocoolers are the devices used to reach cryogenic temperatures by cycling certain gases.A cryostat is likely to be used to reach and/or maintain similar conditions or keep some environment in cryogenic stasis...

- Regenerative coolingRegenerative coolingRegenerative cooling in rockets is where some or all of the propellant is passed through tubes, channels or otherwise in a jacket around the combustion chamber or nozzle to cool the engine because the fuel in particular and sometimes the oxidizer are good coolants...

- Timeline of low-temperature technologyTimeline of low-temperature technologyThe following is a timeline of low-temperature technology and cryogenic technology .-16th century BCE – 17th century CE :...