Limekiln

Encyclopedia

Calcium oxide

Calcium oxide , commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline crystalline solid at room temperature....

through the calcination

Calcination

Calcination is a thermal treatment process applied to ores and other solid materials to bring about a thermal decomposition, phase transition, or removal of a volatile fraction. The calcination process normally takes place at temperatures below the melting point of the product materials...

of limestone

Limestone

Limestone is a sedimentary rock composed largely of the minerals calcite and aragonite, which are different crystal forms of calcium carbonate . Many limestones are composed from skeletal fragments of marine organisms such as coral or foraminifera....

(calcium carbonate

Calcium carbonate

Calcium carbonate is a chemical compound with the formula CaCO3. It is a common substance found in rocks in all parts of the world, and is the main component of shells of marine organisms, snails, coal balls, pearls, and eggshells. Calcium carbonate is the active ingredient in agricultural lime,...

). The chemical equation

Chemical equation

A chemical equation is the symbolic representation of a chemical reaction where the reactant entities are given on the left hand side and the product entities on the right hand side. The coefficients next to the symbols and formulae of entities are the absolute values of the stoichiometric numbers...

for this reaction

Chemical reaction

A chemical reaction is a process that leads to the transformation of one set of chemical substances to another. Chemical reactions can be either spontaneous, requiring no input of energy, or non-spontaneous, typically following the input of some type of energy, such as heat, light or electricity...

is

- CaCO3Calcium carbonateCalcium carbonate is a chemical compound with the formula CaCO3. It is a common substance found in rocks in all parts of the world, and is the main component of shells of marine organisms, snails, coal balls, pearls, and eggshells. Calcium carbonate is the active ingredient in agricultural lime,...

+ heat → CaOCalcium oxideCalcium oxide , commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline crystalline solid at room temperature....

+ CO2Carbon dioxideCarbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

This reaction takes place at 900°C (at which temperature the partial pressure of CO2 is 1 atmosphere

Atmosphere (unit)

The standard atmosphere is an international reference pressure defined as 101325 Pa and formerly used as unit of pressure. For practical purposes it has been replaced by the bar which is 105 Pa...

), but a temperature around 1000°C (at which temperature the partial pressure

Partial pressure

In a mixture of ideal gases, each gas has a partial pressure which is the pressure which the gas would have if it alone occupied the volume. The total pressure of a gas mixture is the sum of the partial pressures of each individual gas in the mixture....

of CO2 is 3.8 atmospheres

Atmosphères

Atmosphères is a piece for full orchestra, composed by György Ligeti in 1961. It is noted for eschewing conventional melody and metre in favor of dense sound textures...

) is usually used to make the reaction proceed quickly. Excessive temperature is avoided because it produces unreactive, "dead-burned" lime.

Early lime use

Because it is so readily made by heating limestone, lime must have been known from the earliest times, and all the early civilizations used it in building mortarsMortar (masonry)

Mortar is a workable paste used to bind construction blocks together and fill the gaps between them. The blocks may be stone, brick, cinder blocks, etc. Mortar becomes hard when it sets, resulting in a rigid aggregate structure. Modern mortars are typically made from a mixture of sand, a binder...

and as a stabilizer in mud renders and floors. Knowledge of its value in agriculture

Agriculture

Agriculture is the cultivation of animals, plants, fungi and other life forms for food, fiber, and other products used to sustain life. Agriculture was the key implement in the rise of sedentary human civilization, whereby farming of domesticated species created food surpluses that nurtured the...

is also ancient, but agricultural use only became widely possible when the use of coal made it cheap in the coalfields in the late 13th century, and an account of agricultural use was given in 1523. The earliest descriptions of limekilns differ little from those used for small-scale manufacture a century ago. Because land transportation of minerals like limestone and coal was difficult in the pre-industrial era, they were distributed by sea, and lime was most often manufactured at small coastal ports. Many preserved kilns are still to be seen on quaysides around the coasts of Britain.

Early kilns

Only lump stone could be used, because the charge needed to "breathe" during firing. This also limited the size of kilns and explains why kilns were all much the same size. Above a certain diameter, the half-burned charge would be likely to collapse under its own weight, extinguishing the fire. So kilns always made 25-30 tonne

Tonne

The tonne, known as the metric ton in the US , often put pleonastically as "metric tonne" to avoid confusion with ton, is a metric system unit of mass equal to 1000 kilograms. The tonne is not an International System of Units unit, but is accepted for use with the SI...

s of lime in a batch. Typically the kiln took a day to load, three days to fire, two days to cool and a day to unload, so a one-week turnaround was normal. The degree of burning was controlled by trial and error from batch to batch by varying the amount of fuel used. Because there were large temperature differences between the center of the charge and the material close to the wall, a mixture of under-burned (i.e. high loss on ignition

Loss on ignition

Loss on Ignition is a test used in inorganic analytical chemistry, particularly in the analysis of minerals. It consists of strongly heating a sample of the material at a specified temperature, allowing volatile substances to escape, until its mass ceases to change. This may be done in air, or...

), well-burned and dead-burned lime was normally produced. Typical fuel efficiency was low, with 0.5 tonnes or more of coal being used per tonne of finished lime (15 MJ/kg).

Devon

Devon is a large county in southwestern England. The county is sometimes referred to as Devonshire, although the term is rarely used inside the county itself as the county has never been officially "shired", it often indicates a traditional or historical context.The county shares borders with...

, near Torrington

Torrington

-People:* Jeff Torrington, Scottish writer* George Byng, 1st Viscount Torrington, British naval officer and statesman-Places:In Australia:* Torrington, New South WalesIn Canada:* Torrington, AlbertaIn the United Kingdom:...

, was made up of three kilns grouped together in an 'L' shape and was situated beside the Torrington canal

Rolle Canal

The Rolle Canal in North Devon, England runs 6 miles from Landcross, where it joins the River Torridge, to the limekilns at Rosemoor...

and the River Torridge

River Torridge

The River Torridge is a river in Devon in England. It was the home of Tarka the Otter in Henry Williamson's book. The Torridge local government district is named after the river....

to bring in the limestone and coal, and to transport away the calcined lime in the days before properly metalled

Metal (pavement)

The term road metal refers to the crushed rock used for road beds, surfaces, 'all-weather' walkways and paths, foundations, and railway embankments, among other things. The use of road metal dates back to antiquity.-History:...

roads existed.

Sets of seven kilns were common. A loading gang and an unloading gang would work the kilns in rotation through the week.

The large kiln at Crindledykes near Haydon Bridge

Haydon Bridge

Haydon Bridge is a village in Northumberland, England, with a population of about 2000. Its most distinctive features are the two bridges crossing the River South Tyne; the picturesque original bridge for which the village was named and a modern bridge which used to carry the A69 road...

, Northumbria, was one of more than 300 in the county. It was unique to the area in having four draw arches to a single pot. As production was cut back, the two side arches were blocked up, but were restored in 1989 by English Heritage

English Heritage

English Heritage . is an executive non-departmental public body of the British Government sponsored by the Department for Culture, Media and Sport...

.

The development of the national rail network increasingly made the local small-scale kilns unprofitable, and they gradually died out through the 19th century, replaced by larger industrial plants. At the same time, new uses for lime in the chemical

Chemical industry

The chemical industry comprises the companies that produce industrial chemicals. Central to the modern world economy, it converts raw materials into more than 70,000 different products.-Products:...

, steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

and sugar

Sugar

Sugar is a class of edible crystalline carbohydrates, mainly sucrose, lactose, and fructose, characterized by a sweet flavor.Sucrose in its refined form primarily comes from sugar cane and sugar beet...

industries led to large-scale plants. These also saw the development of more efficient kilns.

A 'lazy kiln' was the name given to a lime kiln which only saw intermittent use.

Modern kilns

Shaft kilns

The theoretical heat (the standard enthalpyEnthalpy

Enthalpy is a measure of the total energy of a thermodynamic system. It includes the internal energy, which is the energy required to create a system, and the amount of energy required to make room for it by displacing its environment and establishing its volume and pressure.Enthalpy is a...

) of reaction required to make high-calcium lime is around 3.15 MJ per kg of lime, so the batch kilns were only around 20% efficient. The key to development in efficiency was the invention of continuous kilns, avoiding the wasteful heat-up and cool-down cycles of the batch kilns. The first were simple shaft kilns, similar in construction to blast furnace

Blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron.In a blast furnace, fuel and ore and flux are continuously supplied through the top of the furnace, while air is blown into the bottom of the chamber, so that the chemical reactions...

s. These are counter-current shaft kilns. Modern variants include regenerative and annular kilns. Output is usually in the range 100-500 tonnes per day.

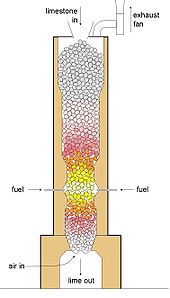

Counter-current shaft kilns

The fuel is injected part-way up the shaft, producing maximum temperature at this point. The fresh feed fed in at the top is first dried then heated to 800°C, where de-carbonation begins, and proceeds progressively faster as the temperature rises. Below the burner, the hot lime transfers heat to, and is cooled by, the combustion air. A mechanical grate withdraws the lime at the bottom. A fanFan (mechanical)

A mechanical fan is a machine used to create flow within a fluid, typically a gas such as air.A fan consists of a rotating arrangement of vanes or blades which act on the air. Usually, it is contained within some form of housing or case. This may direct the airflow or increase safety by preventing...

draws the gases through the kiln, and the level in the kiln is kept constant by adding feed through an airlock. As with batch kilns, only large, graded stone can be used, in order to ensure uniform gas-flows through the charge. The degree of burning can be adjusted by changing the rate of withdrawal of lime. Heat consumption as low as 4 MJ/kg is possible.

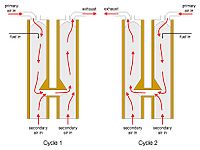

Regenerative kilns

These typically consist of a pair of shafts, operated alternately. In shaft A, combustion air and fuel are added near the top and pass downward, cross to shaft B and pass upward to exhaust. The direction of flow is reversed periodically (typically 5-10 times per hour). The cycling produces a long zone of constant, relatively low temperature (around 950°C) that is ideal for lime quality.

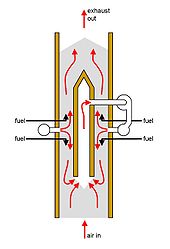

Annular kilns

These contain a concentric internal cylinder. This gathers pre-heated air from the cooling zone, which is then used to pressurize the middle annular zone of the kiln. Air spreading outward from the pressurized zone causes counter-current flow upwards, and co-current flow downwards. This again produces a long, relatively cool calcining zone.

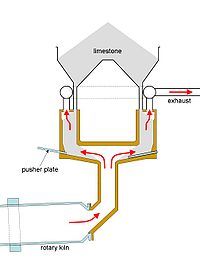

Rotary kilns

Rotary kilns started to be used for lime manufacture at the start of the 20th century and now account for a large proportion of new installations. The early use of simple rotary kilns had the advantages that a much wider range of limestone size could be used, from fines upwards, and undesirable elements such as sulfurSulfur

Sulfur or sulphur is the chemical element with atomic number 16. In the periodic table it is represented by the symbol S. It is an abundant, multivalent non-metal. Under normal conditions, sulfur atoms form cyclic octatomic molecules with chemical formula S8. Elemental sulfur is a bright yellow...

can be removed. On the other hand, fuel consumption was relatively high because of poor heat exchange compared with shaft kilns, leading to excessive heat loss in exhaust gases. Modern installations partially overcome this disadvantage by adding a preheater, which has the same good solids/gas contact as a shaft kiln, but fuel consumption is still somewhat higher. In the design shown, a circle of shafts (typically 8-15) is arranged around the kiln riser duct. Hot limestone is discharged from the shafts in sequence, by the action of a hydraulic "pusher plate". Kilns of 1000 tonnes per day output are typical.

Exhibits

A lime kiln erected at DudleyDudley

Dudley is a large town in the West Midlands county of England. At the 2001 census , the Dudley Urban Sub Area had a population of 194,919, making it the 26th largest settlement in England, the second largest town in the United Kingdom behind Reading, and the largest settlement in the UK without...

, West Midlands

West Midlands (county)

The West Midlands is a metropolitan county in western central England with a 2009 estimated population of 2,638,700. It came into existence as a metropolitan county in 1974 after the passage of the Local Government Act 1972, formed from parts of Staffordshire, Worcestershire and Warwickshire. The...

(formerly Worcestershire

Worcestershire

Worcestershire is a non-metropolitan county, established in antiquity, located in the West Midlands region of England. For Eurostat purposes it is a NUTS 3 region and is one of three counties that comprise the "Herefordshire, Worcestershire and Warwickshire" NUTS 2 region...

, England, in 1842 survives to this day as part of the Black Country Living Museum

Black Country Living Museum

The Black Country Living Museum is an open-air museum of rebuilt historic buildings, located in Dudley in the West Midlands of England. The museum occupies a urban heritage park in the shadow of Dudley Castle in the centre of the Black Country conurbation...

which opened in 1976, although the kilns were last used during the 1920s

1920s

File:1920s decade montage.png|From left, clockwise: Third Tipperary Brigade Flying Column No. 2 under Sean Hogan during the Irish Civil War; Prohibition agents destroying barrels of alcohol in accordance to the 18th amendment, which made alcoholic beverages illegal throughout the entire decade; In...

. It is now among the last still existing in a region which was dominated by coalmining and limestone mining for generations until the 1960s

1960s

The 1960s was the decade that started on January 1, 1960, and ended on December 31, 1969. It was the seventh decade of the 20th century.The 1960s term also refers to an era more often called The Sixties, denoting the complex of inter-related cultural and political trends across the globe...

.http://www.bclm.co.uk/map18.htm

Gas cleaning

All the above kiln designs produce exhaust gas that carries an appreciable amount of dust. Lime dust is particularly corrosive. Equipment is installed to trap this dust, typically in the form of electrostatic precipitatorElectrostatic precipitator

An electrostatic precipitator , or electrostatic air cleaner is a particulate collection device that removes particles from a flowing gas using the force of an induced electrostatic charge...

s or bag filters. The dust usually contains a high concentration of elements such as alkali metal

Alkali metal

The alkali metals are a series of chemical elements in the periodic table. In the modern IUPAC nomenclature, the alkali metals comprise the group 1 elements, along with hydrogen. The alkali metals are lithium , sodium , potassium , rubidium , caesium , and francium...

s, halogen

Halogen

The halogens or halogen elements are a series of nonmetal elements from Group 17 IUPAC Style of the periodic table, comprising fluorine , chlorine , bromine , iodine , and astatine...

s and sulfur.

Carbon dioxide emissions

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

emitter. The manufacture of one tonne of calcium oxide involves decomposing calcium carbonate, with the formation of 785 kg of CO2 in some applications, such as when used as mortar; this CO2 is later re-adsorbed as the mortar goes off. Additionally, if the heat supplied to form the lime (3.75 MJ/kg in an efficient kiln) is obtained by burning fossil fuel it will release CO2: in the case of coal fuel 295 kg/t; in the case of natural gas fuel 206 kg/t. The electric power consumption of an efficient plant is around 20 kWh per tonne of lime. This additional input is the equivalent of around 20 kg CO2 per ton if the electricity is coal-generated. Thus, total emission may be around 1 tonne of CO2 for every tonne of lime even in efficient industrial plants, but is typically 1.3 t/t http://www.dti.gov.uk/files/file28608.pdf. However, if the source of heat energy used in its manufacture is a fully renewable source, such as solar, wind, hydro or even nuclear, and depending on the ultimate use of the lime there may be no net emission of CO2. Less energy is required in production per weight than portland cement

Portland cement

Portland cement is the most common type of cement in general use around the world because it is a basic ingredient of concrete, mortar, stucco and most non-specialty grout...

, primarily because a lower temperature is required.

See also

- Buffalo Grove Lime KilnBuffalo Grove Lime KilnBuffalo Grove Lime Kiln is one of two old lime kilns in Illinois listed on the National Register of Historic Places. The other is the Griggsville Landing Lime Kiln in Pike County. Buffalo Grove Lime Kiln is located near the Ogle County city of Polo. When in use, the kiln would have produced raw...

- Griggsville Landing Lime KilnGriggsville Landing Lime KilnThe Griggsville Landing Lime Kiln is located near village of Valley City, Illinois in Pike County. The periodic lime kiln is listed on the National Register of Historic Places, a designation it gained in August 1999. It is actually within the boundaries of the Ray Norbut State Fish and Wildlife Area...

- Annery kilnAnnery kilnThe former Annery lime kiln is situated just off the road from Bideford to Great Torrington, near Weare Giffard in the Torridge District of North Devon, England. The old lime kiln overlooks the River Torridge and lies close to the old 1827 canal and also to the railway that ran from Bideford to...