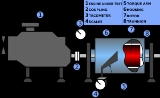

Dynamometer

Overview

- For the dynamometer used in railroading, see dynamometer carDynamometer carA dynamometer car is a railroad maintenance of way car used for measuring various aspects of a locomotive's performance. Measurements include tractive effort , power, top speed, etc.-History:...

.

A dynamometer or "dyno" for short, is a device for measuring force

Force

In physics, a force is any influence that causes an object to undergo a change in speed, a change in direction, or a change in shape. In other words, a force is that which can cause an object with mass to change its velocity , i.e., to accelerate, or which can cause a flexible object to deform...

, moment of force (torque), or power

Power (physics)

In physics, power is the rate at which energy is transferred, used, or transformed. For example, the rate at which a light bulb transforms electrical energy into heat and light is measured in watts—the more wattage, the more power, or equivalently the more electrical energy is used per unit...

. For example, the power produced by an engine

Heat engine

In thermodynamics, a heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. It does this by bringing a working substance from a high temperature state to a lower temperature state. A heat "source" generates thermal energy that brings the working substance...

, motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

or other rotating prime mover can be calculated by simultaneously measuring torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

and rotational speed

Rotational speed

Rotational speed tells how many complete rotations there are per time unit. It is therefore a cyclic frequency, measured in hertz in the SI System...

(RPM

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

).

A dynamometer can also be used to determine the torque and power required to operate a driven machine such as a pump.

Unanswered Questions