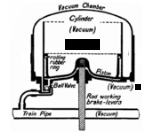

Vacuum brake

Overview

Brake

A brake is a mechanical device which inhibits motion. Its opposite component is a clutch. The rest of this article is dedicated to various types of vehicular brakes....

system employed on train

Train

A train is a connected series of vehicles for rail transport that move along a track to transport cargo or passengers from one place to another place. The track usually consists of two rails, but might also be a monorail or maglev guideway.Propulsion for the train is provided by a separate...

s and introduced in the mid-1860s. A variant, the automatic vacuum brake system, became almost universal in British train equipment and in those countries influenced by British practice. Vacuum brakes also enjoyed a brief period of adoption in the USA

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

, primarily on narrow gauge railroads. However, its limitations caused it to be progressively superseded by compressed air

Compressed air

Compressed air is air which is kept under a certain pressure, usually greater than that of the atmosphere. In Europe, 10 percent of all electricity used by industry is used to produce compressed air, amounting to 80 terawatt hours consumption per year....

systems starting in the United Kingdom

United Kingdom

The United Kingdom of Great Britain and Northern IrelandIn the United Kingdom and Dependencies, other languages have been officially recognised as legitimate autochthonous languages under the European Charter for Regional or Minority Languages...

from the 1970s onward.

Discussions