Etna Iron Works

Encyclopedia

The Etna Iron Works was a 19th century ironworks

and manufacturing plant for marine steam engine

s located in New York City

. The Etna Works was a failing small business when purchased by ironmolder

John Roach

and three partners in 1852. Roach soon gained full ownership of the business and quickly transformed it into a successful general-purpose ironworks.

Roach took advantage of the American Civil War

to transform the Etna Works into one of New York's leading manufacturers of marine steam engine

s. By the end of the war, he was in a position to acquire the businesses of most of his major New York competitors, who had fallen on hard times. Roach subsequently consolidated his operations at the Morgan Iron Works

, and some time afterward rented the Etna Works to the inventor Thomas Edison

, who turned it into a dynamo

factory. The Roach family sold the former Etna Works property in 1887. The Etna Works buildings, along with the street on which they were located, were later liquidated in a city redevelopment.

Notable achievements of the Etna Iron Works include the building of the steam-operated Third Avenue Harlem Bridge in 1864, and the manufacture in the 1860s of the engines for the giant ironclad and for the passenger steamers Bristol

and Providence

, the latter two of which were the largest marine engines built in the United States

to that date.

to the United States in 1832 at the age of sixteen, eventually obtaining employment as a common laborer at the Howell Works

of James P. Allaire at an initial wage of 25c a day. After securing an apprenticeship as an ironmolder at Howell Works, Roach later transferred to Allaire's other plant, the Allaire Iron Works

in New York, where he learned the manufacturing method for marine steam engine

s. Roach would remain an employee of Allaire's for twenty years.

By the end of the first year of operations, the partners had made a modest profit of $1,000, but now a dispute broke out over how to employ the money. Roach wanted to use it to expand the business, but his three partners voted to divide it into dividends of $250 each. Realizing that they had reached the limit of their ambition, Roach took out a mortgage on the property and used the loan to buy his partners out, thus becoming sole proprietor.

Roach thereafter began canvassing the local shipyards for business. Although New York's shipbuilders were still at this time constructing mostly wooden sailing ships, each ship needed about forty pounds of iron fastenings and cables, in addition to a number of anchors. In one ninety-day period, Roach made a profit from such sales of $8,000, giving his business a solid foundation.

Roach was able to continue expanding the business through the sale of a variety of products, including Franklin stove

s, firebacks, slats for iron shutters and other items. In 1856 he added a new steam boiler

to the ironworks for driving a blower which forced a draft into the melting furnace, thus obtaining a higher temperature and melting the iron faster, which saved valuable man-hours. He also purchased the adjoining property at 104-106 Goerck St., upon which stood a small three-storey building. Roach used the third floor as a pattern shop, while renting out the first and second floors to an iron shutter manufacturer.

By 1859, Roach was employing forty men and his property was valued at $15,000. A contemporary evaluator noted that Roach was "getting along well" and deemed him "safe for a fair amount of credit".

Undeterred, Roach negotiated the use of a boiler in a neighbouring factory, ran 200 feet of pipe from their boiler to his workshop, and was back in production within 48 hours.

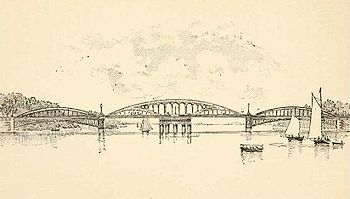

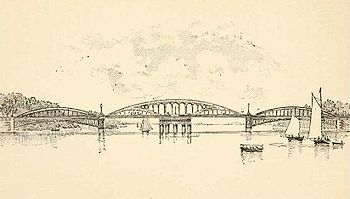

The largest project undertaken by the Etna Iron Works in its early period was for construction of the Third Avenue Harlem Bridge over the Harlem River

The largest project undertaken by the Etna Iron Works in its early period was for construction of the Third Avenue Harlem Bridge over the Harlem River

, New York. The project was submitted to public tender by the City of New York in 1860 and Roach secured the contract with the lowest bid. The contract called for a bridge with a pivoting center section which could be rotated to allow large ships to pass through one of two channels beneath.

Roach had no prior experience of bridge building, so he hired an engineer with appropriate experience to design and oversee the project, and subcontracted out the masonry work. The bridge that was eventually constructed was 526 feet long, with masonry foundations, a cast-and-wrought iron superstructure, and a 216-foot steam-powered pivoting center section spanning two 80 feet (24.4 m) ship channels. The bridge opened for traffic in 1864, and operated reliably for about thirty years until increasing maintenance costs and traffic persuaded the city fathers to construct a new bridge with faster operation and higher and wider dimensions.

Roach had long nurtured a desire to become a builder of marine steam engines like his mentor James Allaire. Competition in the industry was fierce, and entry difficult due to high capital costs, but Roach believed that by utilization of the best tools, labor-saving devices and practices, he could compete successfully. Accordingly, through the late 1850s he sent engineers to the United Kingdom

Roach had long nurtured a desire to become a builder of marine steam engines like his mentor James Allaire. Competition in the industry was fierce, and entry difficult due to high capital costs, but Roach believed that by utilization of the best tools, labor-saving devices and practices, he could compete successfully. Accordingly, through the late 1850s he sent engineers to the United Kingdom

to study the latest in marine engine technology, and was not above hiring himself out as a mechanic to New York's leading engine builders of the day to spy on their organization, technology and practices.

When the American Civil War broke out in 1861, Roach was thus already well prepared to take advantage of the huge demand for marine engines generated by the conflict. He began by contacting the shipbuilder William H. Webb

, who had just secured a contract for the huge new ironclad . Webb's usual engine suppliers, the Morgan Iron Works

and Novelty Iron Works, were heavily inundated with orders and unable to meet his needs. Webb was so relieved to find an alternative source of supply, he not only awarded the Dunderberg's engine contract to Roach, but also became guarantor for the higher line of credit Roach would need to re-equip his works for completing the job.

Roach next travelled to Washington to meet the U.S. Navy's Chief of the Bureau of Steam Engineering, Benjamin Franklin Isherwood. On October 24, 1862, Isherwood awarded Roach a contract to supply the machinery for the Navy's new gunboat Peoria - the first of many such contracts Roach would fulfill for the Navy in coming years. Roach also secured contracts for the engines for two new Neptune Steamship Company vessels, Electra and Galatea.

Having secured these contracts, Roach set about equipping the Etna Iron Works for its new role. He began by hiring Thomas Main, a leading engineer with experience in a number of the world's most advanced engine works, as the plant's superintendent. Roach then began reorganizing the Works, adding a boilershop, machine shop, coppersmith shop and blacksmith, and equipping the plant with a host of new machines including traveling and swing cranes and the steam engines to power them, along with planers, lathes, boring mills, punches, shears and rollers. Amongst the new equipment was a planer capable of finishing 100-ton iron plates, and a lathe capable of boring a 112 inches (2,844.8 mm) cylinder—the two largest machine tools in the entire country.

Over the next two years, Roach's plant produced the engines for at least fifteen vessels, including return orders from the U.S. Navy and a dozen engines for the Van Deusen Brothers. At its wartime peak, the Etna Iron Works employed almost 2,000 workers and was valued at $150,000, putting it in the front rank of New York's engine builders.

.jpg) Shortly after the war, the U.S. Navy auctioned off hundreds of ships it had requisitioned for the war effort, flooding the market and seriously depressing prices. The resulting slump in the U.S. shipping industry sent many long-established American shipyards and marine engineers to the wall, and New York was one of the worst affected locations, with its maritime industry all but wiped out by the slump. By 1867, most of Roach's marine engine competitors had gone bankrupt.

Shortly after the war, the U.S. Navy auctioned off hundreds of ships it had requisitioned for the war effort, flooding the market and seriously depressing prices. The resulting slump in the U.S. shipping industry sent many long-established American shipyards and marine engineers to the wall, and New York was one of the worst affected locations, with its maritime industry all but wiped out by the slump. By 1867, most of Roach's marine engine competitors had gone bankrupt.

Roach himself, however, was able to prosper during this time by securing a diversity of machinery contracts. The Navy through Benjamin Isherwood ordered three engines and six large boilers for the Guerriere class vessels, while shipbuilder William Webb contracted with Roach for the machinery for two large new sidewheel steamers, and . The engines for the latter two ships, with their massive 110-inch cylinders, were the largest ship engines ever produced in the United States up to that time. More importantly for Roach however, he realized that the government was planning to modernize its own shipyards, and he made a timely shift into the manufacture of machine tool

s in 1866. He was rewarded by the securing of almost a million dollars in government machine tool contracts between 1866 and 1868.

At this point, Roach decided that his business had outgrown its original location. He was keen to establish a plant with direct water frontage, which would both save him the cost of transporting his engines to the docks, and also enable him to move into the potentially lucrative business of ship repair. The obvious target for acquisition was the Morgan Iron Works, a leading ironworks with frontage on the East River, and which like most other marine engineering plants had lain mostly idle since the Civil War. Fortuitously for Roach, the proprietor, shipping magnate Charles Morgan

, had recently experienced a setback in his own business dealings, as a result of which he was short of capital. Morgan quickly agreed to sell the premises along with all of its equipment for the sum of $450,000.

At around the same time, two of Roach's former competitors, the Allaire Iron Works

and the Franklin Forge, went bankrupt, and Roach purchased the best of their equipment at firesale prices and also hired their best workers. To these he added the best workers and equipment from the Etna and Morgan establishments, and consolidated his operations at the latter, vacating his former premises at Goerck Street. Roach profited further at this time from the sale of his surplus equipment to the U.S. Navy, but on this occasion some rival business interests raised a protest and the deal became the subject of an acrimonious government inquiry (see the John Roach

article for details).

relocated there. Edison renamed the plant the Edison Machine Works, using it to build DC dynamos until 1887. In that year, the Roach family business sold the premises, and Edison moved out. The property, along with the street in which it was situated, was later liquidated in a 1940s redevelopment.

Roach himself went on to establish his own shipyard in Chester, Pennsylvania

, the Delaware River Iron Ship Building and Engine Works

, which became America's largest and most productive shipyard from its establishment in 1871 until the mid-1880s.

Ironworks

An ironworks or iron works is a building or site where iron is smelted and where heavy iron and/or steel products are made. The term is both singular and plural, i.e...

and manufacturing plant for marine steam engine

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

s located in New York City

New York City

New York is the most populous city in the United States and the center of the New York Metropolitan Area, one of the most populous metropolitan areas in the world. New York exerts a significant impact upon global commerce, finance, media, art, fashion, research, technology, education, and...

. The Etna Works was a failing small business when purchased by ironmolder

Sand casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.It is relatively cheap and sufficiently refractory even for steel foundry use. A suitable bonding agent is mixed or occurs with the sand...

John Roach

John Roach

John Robert Roach was an American clergyman of the Roman Catholic Church. He served as Archbishop of Saint Paul and Minneapolis from 1975 to 1995.-Biography:...

and three partners in 1852. Roach soon gained full ownership of the business and quickly transformed it into a successful general-purpose ironworks.

Roach took advantage of the American Civil War

American Civil War

The American Civil War was a civil war fought in the United States of America. In response to the election of Abraham Lincoln as President of the United States, 11 southern slave states declared their secession from the United States and formed the Confederate States of America ; the other 25...

to transform the Etna Works into one of New York's leading manufacturers of marine steam engine

Marine steam engine

A marine steam engine is a reciprocating steam engine that is used to power a ship or boat. Steam turbines and diesel engines largely replaced reciprocating steam engines in marine applications during the 20th century, so this article describes the more common types of marine steam engine in use...

s. By the end of the war, he was in a position to acquire the businesses of most of his major New York competitors, who had fallen on hard times. Roach subsequently consolidated his operations at the Morgan Iron Works

Morgan iron works

The Morgan Iron Works was a 19th century manufacturing plant for marine steam engines located in New York City, United States. Originally founded as T. F...

, and some time afterward rented the Etna Works to the inventor Thomas Edison

Thomas Edison

Thomas Alva Edison was an American inventor and businessman. He developed many devices that greatly influenced life around the world, including the phonograph, the motion picture camera, and a long-lasting, practical electric light bulb. In addition, he created the world’s first industrial...

, who turned it into a dynamo

Dynamo

- Engineering :* Dynamo, a magnetic device originally used as an electric generator* Dynamo theory, a theory relating to magnetic fields of celestial bodies* Solar dynamo, the physical process that generates the Sun's magnetic field- Software :...

factory. The Roach family sold the former Etna Works property in 1887. The Etna Works buildings, along with the street on which they were located, were later liquidated in a city redevelopment.

Notable achievements of the Etna Iron Works include the building of the steam-operated Third Avenue Harlem Bridge in 1864, and the manufacture in the 1860s of the engines for the giant ironclad and for the passenger steamers Bristol

Bristol (1866)

Bristol was a large sidewheel steamer launched in 1866 by William H. Webb of New York for the Merchants Steamship Company. One of Narragansett Bay's so-called "floating palaces", the luxuriously outfitted Bristol and her sister ship Providence, each of which could carry up to 1,200 passengers,...

and Providence

Providence (1866)

Providence was a large sidewheel steamer launched in 1866 by William H. Webb of New York for the Merchants Steamship Company. The first of Narragansett Bay's so-called "floating palaces", the luxuriously outfitted Providence and her sister ship Bristol, each of which could carry up to 1,200 ...

, the latter two of which were the largest marine engines built in the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

to that date.

Background

John Roach emigrated from IrelandIreland

Ireland is an island to the northwest of continental Europe. It is the third-largest island in Europe and the twentieth-largest island on Earth...

to the United States in 1832 at the age of sixteen, eventually obtaining employment as a common laborer at the Howell Works

Howell Works

Howell Works was a bog iron-based production facility for pig iron which was established in New Jersey in the early 19th century by American engineer and philanthropist James P. Allaire...

of James P. Allaire at an initial wage of 25c a day. After securing an apprenticeship as an ironmolder at Howell Works, Roach later transferred to Allaire's other plant, the Allaire Iron Works

Allaire Iron Works

The Allaire Iron Works was a leading 19th-century American marine engineering company based in New York City. Founded in 1816 by engineer and philanthropist James P...

in New York, where he learned the manufacturing method for marine steam engine

Marine steam engine

A marine steam engine is a reciprocating steam engine that is used to power a ship or boat. Steam turbines and diesel engines largely replaced reciprocating steam engines in marine applications during the 20th century, so this article describes the more common types of marine steam engine in use...

s. Roach would remain an employee of Allaire's for twenty years.

Early years

Following their purchase, Roach was given the task of promoting the business while his three partners attended to management of the shop floor. Roach began by touting for custom piecework, his first sale being for cast grate bars for a Brooklyn distillery.By the end of the first year of operations, the partners had made a modest profit of $1,000, but now a dispute broke out over how to employ the money. Roach wanted to use it to expand the business, but his three partners voted to divide it into dividends of $250 each. Realizing that they had reached the limit of their ambition, Roach took out a mortgage on the property and used the loan to buy his partners out, thus becoming sole proprietor.

Roach thereafter began canvassing the local shipyards for business. Although New York's shipbuilders were still at this time constructing mostly wooden sailing ships, each ship needed about forty pounds of iron fastenings and cables, in addition to a number of anchors. In one ninety-day period, Roach made a profit from such sales of $8,000, giving his business a solid foundation.

Roach was able to continue expanding the business through the sale of a variety of products, including Franklin stove

Franklin stove

The Franklin stove is a metal-lined fireplace named after its inventor, Benjamin Franklin. It was invented in 1741.L.W. Labaree, W. Bell, W.B. Willcox, et al., eds., The Papers of Benjamin Franklin , vol. 2, page 419...

s, firebacks, slats for iron shutters and other items. In 1856 he added a new steam boiler

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

to the ironworks for driving a blower which forced a draft into the melting furnace, thus obtaining a higher temperature and melting the iron faster, which saved valuable man-hours. He also purchased the adjoining property at 104-106 Goerck St., upon which stood a small three-storey building. Roach used the third floor as a pattern shop, while renting out the first and second floors to an iron shutter manufacturer.

By 1859, Roach was employing forty men and his property was valued at $15,000. A contemporary evaluator noted that Roach was "getting along well" and deemed him "safe for a fair amount of credit".

Foundry explosion

On September 2, 1859, the forced-draft boiler for the Etna Works' furnace exploded after accidentally being allowed to run dry, killing one man and seriously injuring two others, and gutting the building in which it stood. The $5,000 damage was covered by insurance, but the foundry would be forced to close without steam power.Undeterred, Roach negotiated the use of a boiler in a neighbouring factory, ran 200 feet of pipe from their boiler to his workshop, and was back in production within 48 hours.

Windfall capital injection

In 1859, one of Roach's closest friends, a lawyer named John Baker, died and left Roach the trustee of his estate. The estate, worth $70,000, was entrusted to Roach for investment until Baker's four children came of age. Since the money could not be claimed until 1881, it was as good as a long-term interest-free loan to Roach, who was soon to take advantage of it to expand his business.Third Avenue Harlem Bridge

Harlem River

The Harlem River is a navigable tidal strait in New York City, USA that flows 8 miles between the Hudson River and the East River, separating the boroughs of Manhattan and the Bronx...

, New York. The project was submitted to public tender by the City of New York in 1860 and Roach secured the contract with the lowest bid. The contract called for a bridge with a pivoting center section which could be rotated to allow large ships to pass through one of two channels beneath.

Roach had no prior experience of bridge building, so he hired an engineer with appropriate experience to design and oversee the project, and subcontracted out the masonry work. The bridge that was eventually constructed was 526 feet long, with masonry foundations, a cast-and-wrought iron superstructure, and a 216-foot steam-powered pivoting center section spanning two 80 feet (24.4 m) ship channels. The bridge opened for traffic in 1864, and operated reliably for about thirty years until increasing maintenance costs and traffic persuaded the city fathers to construct a new bridge with faster operation and higher and wider dimensions.

American Civil War

United Kingdom

The United Kingdom of Great Britain and Northern IrelandIn the United Kingdom and Dependencies, other languages have been officially recognised as legitimate autochthonous languages under the European Charter for Regional or Minority Languages...

to study the latest in marine engine technology, and was not above hiring himself out as a mechanic to New York's leading engine builders of the day to spy on their organization, technology and practices.

When the American Civil War broke out in 1861, Roach was thus already well prepared to take advantage of the huge demand for marine engines generated by the conflict. He began by contacting the shipbuilder William H. Webb

William H. Webb

William Henry Webb was a 19th-century New York shipbuilder and philanthropist, who has been called America's first true naval architect....

, who had just secured a contract for the huge new ironclad . Webb's usual engine suppliers, the Morgan Iron Works

Morgan iron works

The Morgan Iron Works was a 19th century manufacturing plant for marine steam engines located in New York City, United States. Originally founded as T. F...

and Novelty Iron Works, were heavily inundated with orders and unable to meet his needs. Webb was so relieved to find an alternative source of supply, he not only awarded the Dunderberg

Roach next travelled to Washington to meet the U.S. Navy's Chief of the Bureau of Steam Engineering, Benjamin Franklin Isherwood. On October 24, 1862, Isherwood awarded Roach a contract to supply the machinery for the Navy's new gunboat Peoria - the first of many such contracts Roach would fulfill for the Navy in coming years. Roach also secured contracts for the engines for two new Neptune Steamship Company vessels, Electra and Galatea.

Having secured these contracts, Roach set about equipping the Etna Iron Works for its new role. He began by hiring Thomas Main, a leading engineer with experience in a number of the world's most advanced engine works, as the plant's superintendent. Roach then began reorganizing the Works, adding a boilershop, machine shop, coppersmith shop and blacksmith, and equipping the plant with a host of new machines including traveling and swing cranes and the steam engines to power them, along with planers, lathes, boring mills, punches, shears and rollers. Amongst the new equipment was a planer capable of finishing 100-ton iron plates, and a lathe capable of boring a 112 inches (2,844.8 mm) cylinder—the two largest machine tools in the entire country.

Over the next two years, Roach's plant produced the engines for at least fifteen vessels, including return orders from the U.S. Navy and a dozen engines for the Van Deusen Brothers. At its wartime peak, the Etna Iron Works employed almost 2,000 workers and was valued at $150,000, putting it in the front rank of New York's engine builders.

Postwar consolidation

.jpg)

Roach himself, however, was able to prosper during this time by securing a diversity of machinery contracts. The Navy through Benjamin Isherwood ordered three engines and six large boilers for the Guerriere class vessels, while shipbuilder William Webb contracted with Roach for the machinery for two large new sidewheel steamers, and . The engines for the latter two ships, with their massive 110-inch cylinders, were the largest ship engines ever produced in the United States up to that time. More importantly for Roach however, he realized that the government was planning to modernize its own shipyards, and he made a timely shift into the manufacture of machine tool

Machine tool

A machine tool is a machine, typically powered other than by human muscle , used to make manufactured parts in various ways that include cutting or certain other kinds of deformation...

s in 1866. He was rewarded by the securing of almost a million dollars in government machine tool contracts between 1866 and 1868.

At this point, Roach decided that his business had outgrown its original location. He was keen to establish a plant with direct water frontage, which would both save him the cost of transporting his engines to the docks, and also enable him to move into the potentially lucrative business of ship repair. The obvious target for acquisition was the Morgan Iron Works, a leading ironworks with frontage on the East River, and which like most other marine engineering plants had lain mostly idle since the Civil War. Fortuitously for Roach, the proprietor, shipping magnate Charles Morgan

Charles Morgan

Charles Morgan may refer to:* Sir Charles Morgan , military governor of Bergen op Zoom* Charles Gould Morgan, Sir Charles Morgan, 1st Baronet , Member of Parliament for Brecon, 1778–1787, and Breconshire, 1787–1806...

, had recently experienced a setback in his own business dealings, as a result of which he was short of capital. Morgan quickly agreed to sell the premises along with all of its equipment for the sum of $450,000.

At around the same time, two of Roach's former competitors, the Allaire Iron Works

Allaire Iron Works

The Allaire Iron Works was a leading 19th-century American marine engineering company based in New York City. Founded in 1816 by engineer and philanthropist James P...

and the Franklin Forge, went bankrupt, and Roach purchased the best of their equipment at firesale prices and also hired their best workers. To these he added the best workers and equipment from the Etna and Morgan establishments, and consolidated his operations at the latter, vacating his former premises at Goerck Street. Roach profited further at this time from the sale of his surplus equipment to the U.S. Navy, but on this occasion some rival business interests raised a protest and the deal became the subject of an acrimonious government inquiry (see the John Roach

John Roach

John Robert Roach was an American clergyman of the Roman Catholic Church. He served as Archbishop of Saint Paul and Minneapolis from 1975 to 1995.-Biography:...

article for details).

Later developments

Following the consolidation of his business at the Morgan Iron Works, Roach rented out his old Etna Iron Works property to various tenants. The Etna Works continued to operate as a general ironworks under new management until about 1881, when inventor Thomas EdisonThomas Edison

Thomas Alva Edison was an American inventor and businessman. He developed many devices that greatly influenced life around the world, including the phonograph, the motion picture camera, and a long-lasting, practical electric light bulb. In addition, he created the world’s first industrial...

relocated there. Edison renamed the plant the Edison Machine Works, using it to build DC dynamos until 1887. In that year, the Roach family business sold the premises, and Edison moved out. The property, along with the street in which it was situated, was later liquidated in a 1940s redevelopment.

Roach himself went on to establish his own shipyard in Chester, Pennsylvania

Chester, Pennsylvania

Chester is a city in Delaware County, Pennsylvania, United States, with a population of 33,972 at the 2010 census. Chester is situated on the Delaware River, between the cities of Philadelphia and Wilmington, Delaware.- History :...

, the Delaware River Iron Ship Building and Engine Works

Delaware River Iron Ship Building and Engine Works

The Delaware River Iron Ship Building and Engine Works, often referred to by its parent company name of John Roach & Sons, or just known as the Roach shipyard, was a major late–19th century American shipyard founded in 1871 by John Roach...

, which became America's largest and most productive shipyard from its establishment in 1871 until the mid-1880s.

Total marine engine production 1863-66

At least 26 marine steam engines for 19 ships were produced by the Etna Iron Works. The following is a list of those ships, together with basic details of the engines fitted to each.| Ship | Engine | ||||||

|---|---|---|---|---|---|---|---|

| Name | Type | Launched | Tonnage | No. | Cylinder (inches) | Stroke (feet) | Type |

| IC | 5/10/1862 | 7800 | 2 | 100 | 4.75 | Horiz/BA | |

| Electra | P | n/a | n/a | 2 | 44 | 3 | Vert/DA |

| GB | 1862 | 1244 | 2 | 44 | 3 | Vert/DA | |

| GB | 30/6/1863 | 1173 | 1 | 58 | 8.75 | Inclined | |

| GB | 29/10/1863 | N/A | 1 | 66 | 10 | n/a | |

| Doris | P | n/a | n/a | 1 | 50 | 3.33 | n/a |

| Glaucus | P | n/a | n/a | 2 | 44 | 3 | Inv/DA |

| Metis | P | n/a | n/a | 1 | 50 | 3.33 | n/a |

| Neptune | P | n/a | n/a | 2 | 44 | 3 | Inv/DA |

| Nereus | P | n/a | n/a | 2 | 44 | 3 | Inv/DA |

| Oceanus | P | n/a | n/a | 2 | 44 | 3 | Inv/DA |

| Pequot | n/a | n/a | n/a | n/a | n/a | n/a | n/a |

| Nebraska | P | n/a | n/a | 1 | 81 | 12 | SB |

| Rising Star | P | 1865 | 2500 | 1 | 100 | 12 | SB |

| Java | SF | Never | 3954 | 1 | 60 | 3 | Horiz/BA |

| Ontario | SF | Never | 3954 | 1 | 60 | 3 | Horiz/BA |

| SF | 5/10/1865 | 3852 | 2 | 100 | 4 | Geared | |

| Bristol Bristol (1866) Bristol was a large sidewheel steamer launched in 1866 by William H. Webb of New York for the Merchants Steamship Company. One of Narragansett Bay's so-called "floating palaces", the luxuriously outfitted Bristol and her sister ship Providence, each of which could carry up to 1,200 passengers,... |

P | 4/1866 | 2962 | 1 | 110 | 12 | SB |

| Providence Providence (1866) Providence was a large sidewheel steamer launched in 1866 by William H. Webb of New York for the Merchants Steamship Company. The first of Narragansett Bay's so-called "floating palaces", the luxuriously outfitted Providence and her sister ship Bristol, each of which could carry up to 1,200 ... |

P | 28/6/1866 | 2962 | 1 | 110 | 12 | SB |

| Legend—Ship type: IC=ironclad, GB=gunboat, P=passenger, SF=screw frigate. Engine type: BA=back-acting, DA=direct acting, SB=simple beam; Horiz=horizontal, Vert=vertical, Inv=inverted. Other: n/a=information not available. See marine steam engine Marine steam engine A marine steam engine is a reciprocating steam engine that is used to power a ship or boat. Steam turbines and diesel engines largely replaced reciprocating steam engines in marine applications during the 20th century, so this article describes the more common types of marine steam engine in use... for an explanation of engine types. |

|||||||