Eco Pickled Surface

Encyclopedia

Eco Pickled Surface is a process applied to hot rolled sheet steel to remove all surface oxides (mill scale

) and clean the steel surface. Steel which has undergone the EPS process acquires a high degree of resistance to subsequent development of surface oxide (rust), so long as it does not come into direct contact with moisture. EPS was developed by The Material Works, Ltd., which has filed several patent applications covering the process. It is primarily intended to be a replacement of the familiar acid pickling

process wherein steel strip is immersed in solutions of hydrochloric

and sulfuric acids to chemically remove oxides.

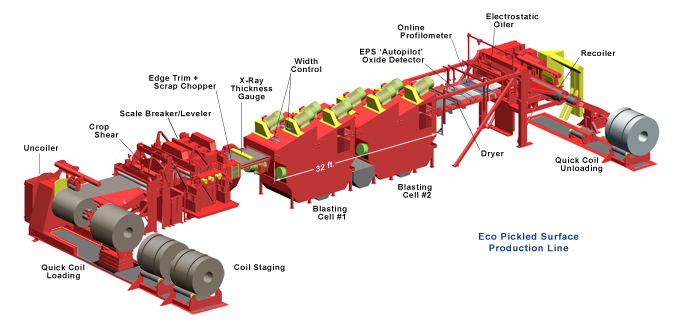

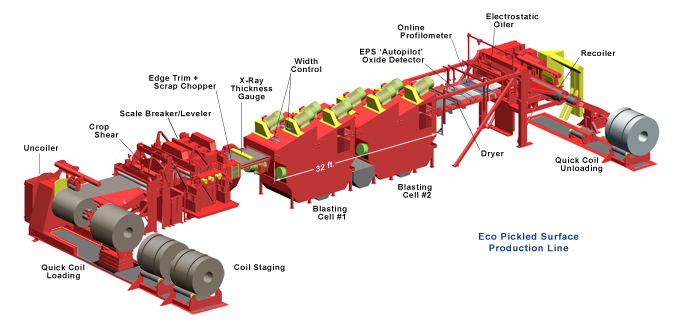

The EPS process (see Figure 2) begins with hot rolled strip steel in coil form. This steel pays off of an uncoiler, then passes through a machine which serves dual purpose as a "scale breaker" and "leveler". This machine (see Figure 2) works the material between sets of hardened rollers. This has the effect of removing the curvature of the strip ("coil set") and breaking loose the outer layers of mill scale which encase the steel strip.

The EPS process (see Figure 2) begins with hot rolled strip steel in coil form. This steel pays off of an uncoiler, then passes through a machine which serves dual purpose as a "scale breaker" and "leveler". This machine (see Figure 2) works the material between sets of hardened rollers. This has the effect of removing the curvature of the strip ("coil set") and breaking loose the outer layers of mill scale which encase the steel strip.

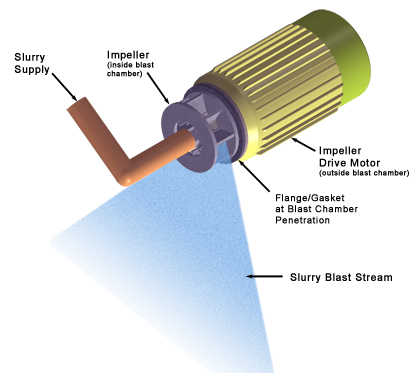

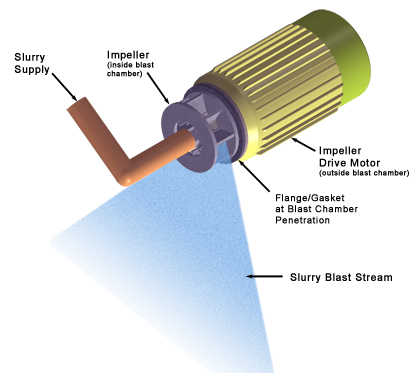

After passing through the "scale breaker/leveler" machine, the steel strip enters the first of at least two (and optionally more) "Slurry Blasting Cells". Slurry blasting is a wet abrasive blasting

process that combines a fine-particle metallic abrasive with a “carrier liquid” (the most common one being water). This abrasive + water slurry mixture is fed into a rotating impeller which propels it at high velocity across the object to be cleaned (see Figure 3). Slurry Blasting is a method for removing rust/scale, for blast cleaning and shot peening. Cleaning agents can be introduced into the carrier liquid to reduce smut and aid in rust prevention.

An EPS Slurry Blasting Cell is composed of eight of the Slurry Discharge Heads shown in Figure 3 – four for the top surface and four for the bottom surface of the strip. Inside the Slurry Blasting Cells jets of water cleanse the steel strip of both the abrasive particles and the dislodged mill scale. The strip emerges the final Blasting Cell and is dried using high-velocity air blowers. At this point the strip passes between real-time oxide detector modules (one on top, one on bottom), which provide feedback to the line control so full oxide removal is assured. The strip then passes through an in-line, real-time profilometer

module which measures surface roughness (Ra) and feeds a signal back to process control to vary impeller rotation speed to produce the desired range of roughness.

To conclude the process, the strip may, optionally, have an oil film or lubricant applied, then it is recoiled. Of note is that tension created by the force of the recoiler pulling the strip through the scale breaker/leveler serves to flatten the strip, removing bow, edge wave and minor coil breaks. Also, not shown in Figure 2 is the slurry delivery/recirculation/filtering system. This closed-loop system collects the carrier liquid, abrasive and removed scale, filters out the removed scale, other contaminants and "undersized" abrasive particles, and returns a cleansed slurry mixture back to the Blasting Cells.

To conclude the process, the strip may, optionally, have an oil film or lubricant applied, then it is recoiled. Of note is that tension created by the force of the recoiler pulling the strip through the scale breaker/leveler serves to flatten the strip, removing bow, edge wave and minor coil breaks. Also, not shown in Figure 2 is the slurry delivery/recirculation/filtering system. This closed-loop system collects the carrier liquid, abrasive and removed scale, filters out the removed scale, other contaminants and "undersized" abrasive particles, and returns a cleansed slurry mixture back to the Blasting Cells.

, cold reducing and painting of EPS-processed steel strip show it to be interchangeable with acid-pickled steel strip. This also holds true for common sheet metal fabrication processes, such as laser cutting

, plasma cutting

, stamping

, welding

, bending

, and roll forming

- no meaningful difference between steel strip utilizing the EPS process and steel strip utilizing acid pickling.

An area where the difference between EPS-processed steel strip and acid-pickled steel strip is apparent is visual appearance. Steel which has undergone EPS processing exhibits a more uniform, lustrous appearance, as shown in Figure 4. In the EPS process, the impact of the abrasive particles on the steel surface serves to "smooth out" minor surface imperfections such as scratches, pits, roll marks and silicone streaks.

Another area of difference between EPS-treated steel strip and acid-pickled steel strip is rust resistance. Conventional acid-pickled steel strip is frequently coated with a thin film of oil to serve as a barrier to contact with oxygen so as to prevent rusting. EPS-processed steel is inherently rust-inhibitive and, therefore, needs no oil or other coating to prevent rusting. Many "downstream" processes and steel fabrication processes must have the steel's oil coating (or other surface contaminants) removed as a precursor step of the process. Use of EPS-treated steel in these processes precludes the need for any such "oil-stripping" precursor step, thereby simplifying the process.

, although less "robust" than stainless steel.

Stainless steel does not rust because of the interaction between its alloying elements and the environment. Stainless steel contains iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a very thin (roughly 200 Angstrom

) stable film that consists of such corrosion products as metal oxides and hydroxides. Chromium plays a dominant role in reacting with oxygen to form this thin film. (In fact, all stainless steels by definition contain at least 10 percent chromium). The presence of the stable film prevents additional corrosion by acting as a barrier that limits oxygen and water access to the underlying metal surface. Because the film forms so readily and tightly, even only a few atomic layers reduce the rate of corrosion to very low levels. The fact that the film is much thinner than the wavelength of light makes it difficult to observe without the aid of the very specialized instrument that was utilized in the investigation of EPS-processed strip.

In the case of EPS-processed steel, trace amounts of silicon, chromium, manganese and aluminum – all constituents of carbon steel at some level – were observed to remain intact on the EPS surface. These trace elements react with oxygen to form a very thin protective layer – a stable "film" – that inhibits further corrosion. The chemical reactions involved in acid pickling remove much of these trace elements from the surface of steel strip, thus a comparable protective film cannot develop.

There is another mechanism at work with acid pickling that tends to invite oxidation. The primary pickling agent is hydrochloric acid

(HCl). Although the steel strip is thoroughly rinsed with clean water after immersion in the HCl bath, some residual amount of chlorine (Cl) remains on the surface of the strip. Chlorine reacts very readily with oxygen to form chlorides, so the free Cl acts as something of a "magnet" for oxygen. This mechanism makes acid-pickled steel more prone to picking up oxygen, whereas there is no comparable mechanism at work with EPS mechanical pickling.

Finally, an additive is used in the EPS Slurry Blast carrier liquid to reduce the “smut” that would otherwise remain on the surface and dull the appearance of EPS-processed strip. This additive contains a rust inhibitor, a residual amount of which remains on the surface even after rinsing. It is believed that the presence of the rust inhibitor adds to the overall EPS-processed strip’s ability to resist rusting. The additive has been demonstrated to have no impact on paint performance.

In addition, the EPS process is considered less damaging to the environment than acid pickling for these reasons:

Mill scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, iron oxides consisting of Iron oxide, hematite, and magnetite....

) and clean the steel surface. Steel which has undergone the EPS process acquires a high degree of resistance to subsequent development of surface oxide (rust), so long as it does not come into direct contact with moisture. EPS was developed by The Material Works, Ltd., which has filed several patent applications covering the process. It is primarily intended to be a replacement of the familiar acid pickling

Pickling (metal)

Tarnision is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from ferrous metals, copper, and aluminum alloys. A solution called Tarnision liquor, which contains strong acids, is used to remove the surface impurities...

process wherein steel strip is immersed in solutions of hydrochloric

Hydrochloric acid

Hydrochloric acid is a solution of hydrogen chloride in water, that is a highly corrosive, strong mineral acid with many industrial uses. It is found naturally in gastric acid....

and sulfuric acids to chemically remove oxides.

Overview of the EPS Process

After passing through the "scale breaker/leveler" machine, the steel strip enters the first of at least two (and optionally more) "Slurry Blasting Cells". Slurry blasting is a wet abrasive blasting

Abrasive blasting

Abrasive blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically air, or a centrifugal wheel is used to...

process that combines a fine-particle metallic abrasive with a “carrier liquid” (the most common one being water). This abrasive + water slurry mixture is fed into a rotating impeller which propels it at high velocity across the object to be cleaned (see Figure 3). Slurry Blasting is a method for removing rust/scale, for blast cleaning and shot peening. Cleaning agents can be introduced into the carrier liquid to reduce smut and aid in rust prevention.

An EPS Slurry Blasting Cell is composed of eight of the Slurry Discharge Heads shown in Figure 3 – four for the top surface and four for the bottom surface of the strip. Inside the Slurry Blasting Cells jets of water cleanse the steel strip of both the abrasive particles and the dislodged mill scale. The strip emerges the final Blasting Cell and is dried using high-velocity air blowers. At this point the strip passes between real-time oxide detector modules (one on top, one on bottom), which provide feedback to the line control so full oxide removal is assured. The strip then passes through an in-line, real-time profilometer

Profilometer

Profilometer is a measuring instrument used to measure a surface's profile, in order to quantify its roughness.While the historical notion of a profilometer was a device similar to a phonograph that measures a surface as the surface is moved relative to the contact profilometer's stylus, this...

module which measures surface roughness (Ra) and feeds a signal back to process control to vary impeller rotation speed to produce the desired range of roughness.

Characteristics of EPS-processed steel strip

Steel which utilizes the EPS process to remove surface scale shows few differences from steel which utilizes acid pickling to remove surface scale. "Downstream" industrial processes such as galvanizingHot-dip galvanizing

Hot-dip galvanizing is a form of galvanization. It is the process of coating iron, steel, or aluminum with a thin zinc layer, by passing the metal through a molten bath of zinc at a temperature of around 860 °F...

, cold reducing and painting of EPS-processed steel strip show it to be interchangeable with acid-pickled steel strip. This also holds true for common sheet metal fabrication processes, such as laser cutting

Laser cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses and hobbyists. Laser cutting works by directing the output of a high-power laser, by computer, at the...

, plasma cutting

Plasma cutting

Plasma cutting is a process that is used to cut steel and other metals of different thicknesses using a plasma torch...

, stamping

Stamping press

A stamping press is a metalworking machine tool used to shape or cut metal by deforming it with a die.-Bolster plate:The bolster plate is a large block of metal upon which the bottom portion of a die is clamped; the bolster plate is stationary...

, welding

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

, bending

Brake press

A press brake, also known as a brake press or just brake, is a machine tool for bending sheet and plate material, most commonly sheet metal....

, and roll forming

Roll forming

Roll forming, also spelled rollforming, is a continuous bending operation in which a long strip of sheet metal is passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section profile is obtained...

- no meaningful difference between steel strip utilizing the EPS process and steel strip utilizing acid pickling.

An area where the difference between EPS-processed steel strip and acid-pickled steel strip is apparent is visual appearance. Steel which has undergone EPS processing exhibits a more uniform, lustrous appearance, as shown in Figure 4. In the EPS process, the impact of the abrasive particles on the steel surface serves to "smooth out" minor surface imperfections such as scratches, pits, roll marks and silicone streaks.

Another area of difference between EPS-treated steel strip and acid-pickled steel strip is rust resistance. Conventional acid-pickled steel strip is frequently coated with a thin film of oil to serve as a barrier to contact with oxygen so as to prevent rusting. EPS-processed steel is inherently rust-inhibitive and, therefore, needs no oil or other coating to prevent rusting. Many "downstream" processes and steel fabrication processes must have the steel's oil coating (or other surface contaminants) removed as a precursor step of the process. Use of EPS-treated steel in these processes precludes the need for any such "oil-stripping" precursor step, thereby simplifying the process.

The rust inhibitive property of EPS-processed strip

Metallurgical investigations of EPS-processed steel were conducted to determine the mechanism by which the surface is rendered rust-inhibitive. The most conclusive of these investigations was conducted in a reputable metallurgical research laboratory, using highly specialized equipment able to characterize the surface constituents on an atomic level. The conclusion was that EPS-processed steel achieves rust-resistance in a manner that is analogous to stainless steelStainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

, although less "robust" than stainless steel.

Stainless steel does not rust because of the interaction between its alloying elements and the environment. Stainless steel contains iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a very thin (roughly 200 Angstrom

Ångström

The angstrom or ångström, is a unit of length equal to 1/10,000,000,000 of a meter . Its symbol is the Swedish letter Å....

) stable film that consists of such corrosion products as metal oxides and hydroxides. Chromium plays a dominant role in reacting with oxygen to form this thin film. (In fact, all stainless steels by definition contain at least 10 percent chromium). The presence of the stable film prevents additional corrosion by acting as a barrier that limits oxygen and water access to the underlying metal surface. Because the film forms so readily and tightly, even only a few atomic layers reduce the rate of corrosion to very low levels. The fact that the film is much thinner than the wavelength of light makes it difficult to observe without the aid of the very specialized instrument that was utilized in the investigation of EPS-processed strip.

In the case of EPS-processed steel, trace amounts of silicon, chromium, manganese and aluminum – all constituents of carbon steel at some level – were observed to remain intact on the EPS surface. These trace elements react with oxygen to form a very thin protective layer – a stable "film" – that inhibits further corrosion. The chemical reactions involved in acid pickling remove much of these trace elements from the surface of steel strip, thus a comparable protective film cannot develop.

There is another mechanism at work with acid pickling that tends to invite oxidation. The primary pickling agent is hydrochloric acid

Hydrochloric acid

Hydrochloric acid is a solution of hydrogen chloride in water, that is a highly corrosive, strong mineral acid with many industrial uses. It is found naturally in gastric acid....

(HCl). Although the steel strip is thoroughly rinsed with clean water after immersion in the HCl bath, some residual amount of chlorine (Cl) remains on the surface of the strip. Chlorine reacts very readily with oxygen to form chlorides, so the free Cl acts as something of a "magnet" for oxygen. This mechanism makes acid-pickled steel more prone to picking up oxygen, whereas there is no comparable mechanism at work with EPS mechanical pickling.

Finally, an additive is used in the EPS Slurry Blast carrier liquid to reduce the “smut” that would otherwise remain on the surface and dull the appearance of EPS-processed strip. This additive contains a rust inhibitor, a residual amount of which remains on the surface even after rinsing. It is believed that the presence of the rust inhibitor adds to the overall EPS-processed strip’s ability to resist rusting. The additive has been demonstrated to have no impact on paint performance.

The EPS process as a replacement for acid pickling

The EPS process produces scale-free steel strip which is interchageable with acid-pickled steel strip, yet the EPS process entails lower capital and operating (variable) cost than an acid-pickling line of equivalent output. For this reason the EPS process is considered to be a direct replacement of acid pickling.In addition, the EPS process is considered less damaging to the environment than acid pickling for these reasons:

- lower energy consumption;

- no hazardous/acidic substances used in the process;

- no potential exposure to acid fumes for people, equipment or buildings;

- no hazardous or polluting outputs or byproducts of the process with disposal or fume stack liabilities.