.gif)

Cutoff (steam engine)

Encyclopedia

In a steam engine

, cutoff is the point in the piston

stroke at which the inlet valve is closed. On a steam locomotive

, the cutoff is controlled by the reverser.

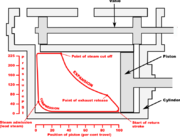

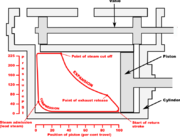

The point at which the inlet valve closes and stops the entry of steam into the cylinder from the boiler plays a crucial role in the control of a steam engine. Once the valve has closed, steam trapped in the cylinder expands adiabatically

. The steam pressure drops as it expands. A late cutoff delivers full steam pressure to move the piston through its entire stroke, for maximum start-up forces. But, since there will still be unexploited pressure in the cylinder at the end of the stroke, this is achieved at the expense of engine efficiency. In this situation the steam will still have considerable pressure remaining when it is exhausted resulting in the characteristic “chuff chuff” sound of a steam engine. An early cutoff has greater thermodynamic efficiency but provides less average force on the piston and is used for running the engine at higher speeds. The steam engine is the only thermodynamic engine design that can provide its maximum torque

at zero revolutions.

Cutoff is one of the four valve events. Early cutoff is used to increase the efficiency of the engine by allowing the steam to expand for the rest of the power stroke, yielding more of its energy and conserving steam. This is known as expansive working. Late cutoff is used to provide maximum torque to the shaft at the expense of efficiency and is used to start the engine under load.

Cutoff is one of the four valve events. Early cutoff is used to increase the efficiency of the engine by allowing the steam to expand for the rest of the power stroke, yielding more of its energy and conserving steam. This is known as expansive working. Late cutoff is used to provide maximum torque to the shaft at the expense of efficiency and is used to start the engine under load.

Cutoff is conventionally expressed as percentage of the power stroke of the piston; if the piston is at a quarter of its stroke at the cutoff point, the cutoff is stated as 25%.

Smaller stationary steam engine

s generally have a fixed cutoff point while, in large ones, the speed and power output is generally governed by altering the cutoff, frequently under governor

control using an expansion valve

or trip gear

. In steam engines for transport, it is desirable to be able to alter the cutoff over a wide range. For starting and at low speed and heavy load, the cylinders need steam supply at maximum pressure for almost the full length of the stroke. In a two-cylinder locomotive, for example, the maximum or 'full gear' cutoff is typically about 85%. At high speeds, the cutoff may be 15% percent of the piston stroke or less. Steam engines used in boats and ships operate under a constant, unvarying load through the propeller

and so have a fixed cutoff, with speed being controlled through the regulator.

Providing variable cutoff is an important function of the valve gear

. Most valve gear designs provide it, the exception being early Stephenson valve gear

.

The advantages of this design are that change between forward and reverse gear can be made very quickly as is needed in, for example, a shunting engine. Disadvantages are that, because the lever must rest at one of the notches, fine adjustment of the cutoff to offer best running and economy is not possible. On large locomotives it can be difficult to prevent the mechanism from jumping into full forward gear (“nose-diving”) when adjusting the cutoff once the locomotive has gathered speed: with such engines it was the practice of drivers to select an appropriate degree of cutoff before opening the regulator

and to leave it in that position for the duration of the journey.

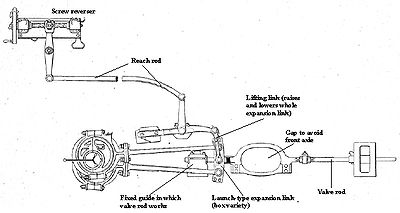

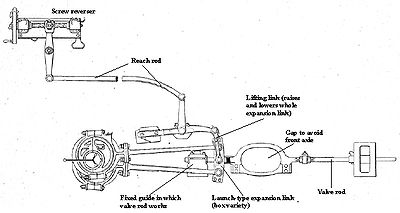

In this mechanism the reversing rod is controlled by a screw and nut, worked by a wheel in the cab. The nut either operates on the reversing rod directly or through a lever, as above. The screw and nut may be cut with a double thread and a coarse pitch to move the mechanism as quickly as possible. The wheel is fitted with a locking lever to prevent creep and there is an indicator to show the percentage of cutoff in use. This method of altering the cutoff offers finer control than the sector lever, but it has the disadvantage of slow operation. It is most suitable for long-distance passenger engines where frequent changes of cutoff are not required and where fine adjustments offer the most benefit. On locomotives fitted with Westinghouse air brake equipment and Stephenson valve gear

In this mechanism the reversing rod is controlled by a screw and nut, worked by a wheel in the cab. The nut either operates on the reversing rod directly or through a lever, as above. The screw and nut may be cut with a double thread and a coarse pitch to move the mechanism as quickly as possible. The wheel is fitted with a locking lever to prevent creep and there is an indicator to show the percentage of cutoff in use. This method of altering the cutoff offers finer control than the sector lever, but it has the disadvantage of slow operation. It is most suitable for long-distance passenger engines where frequent changes of cutoff are not required and where fine adjustments offer the most benefit. On locomotives fitted with Westinghouse air brake equipment and Stephenson valve gear

, it was common to use the screw housing as an air cylinder, with the nut extended to form a piston. Compressed air from the brake reservoirs was applied to one side of the piston to reduce the effort required to lift the heavy expansion link, with gravity assisting in the opposite direction.

of the Glasgow and South Western Railway

in 1873. Several engineers then tried them, including William Dean of the GWR

and Vincent Raven

of the North Eastern Railway

, but they found them little to their liking, mainly because of maintenance difficulties: any oil leakage from the locking cylinder, either through the piston gland

or the cock, allowed the mechanism to creep, or worse “nose-dive”, into full forward gear while running. Stirling moved to the South Eastern Railway

and Harry Smith Wainwright, his successor with that company, incorporated them into most of his designs, which were in production about thirty years after Stirling’s innovation. Later still the forward-looking Southern Railway engineer Oliver Bulleid

fitted them to his famous Merchant Navy Class

of locomotives, but they were mostly removed at rebuild.

Henszey's reversing gear, patented in 1882, illustrates a typical early solution. Henszey's device consists of two piston

s mounted on a single piston rod. Both pistons are double-ended. One is a steam piston to move the rod as required. The other, containing oil, holds the rod in a fixed position when the steam is turned off. Control is by a small three-way steam valve (“forward”, “stop”, “back”) and a separate indicator showing the position of the rod and thus the percentage of cutoff in use. When the steam valve is at “stop”, an oil cock

connecting the two ends of the locking piston is also closed, thus holding the mechanism in position. The piston rod connects by levers to the reversing gear, which operates in the usual way, according to the type of valve gear in use.

The Ragonnet power reverse, patented in 1909, was a true feedback

controlled servomechanism

. The power reverse amplified small motions of reversing lever in the locomotive cab made with modest force into much larger and more forceful motions of the reach rod that controlled the engine cutoff and direction. It was usually air powered, but could also be steam powered. The term servomotor was explicitly used by the developers of some later power reverse mechanisms. The use of feedback control in these later power reverse mechanisms eliminated the need for a second cylinder for a hydraulic locking mechanism, and it restored the simplicity of a single operating lever that both controlled the reversing linkage and indicated its position.

The development of articulated locomotive

s was a major impetus to the development of power reverse systems, because these typically had two or even three sets of reverse gear, instead of just one on a simple locomotive. The Baldwin Locomotive Works

used the Ragonnet reversing gear, and other American builders generally abandoned positive locking features. In British use, locking cylinders remained in use. The Hadfield reversing gear, patented in 1950, was in most particulars a Ragonnet reversing gear with added locking cylinder.

Most Beyer Garratt

locomotives used the Hadfield system.

Many American locomotives were built, or retro-fitted, with power reverse, e.g. PRR K4s

, PRR N1s

, PRR B6

, PRR L1s

.

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

, cutoff is the point in the piston

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

stroke at which the inlet valve is closed. On a steam locomotive

Steam locomotive

A steam locomotive is a railway locomotive that produces its power through a steam engine. These locomotives are fueled by burning some combustible material, usually coal, wood or oil, to produce steam in a boiler, which drives the steam engine...

, the cutoff is controlled by the reverser.

The point at which the inlet valve closes and stops the entry of steam into the cylinder from the boiler plays a crucial role in the control of a steam engine. Once the valve has closed, steam trapped in the cylinder expands adiabatically

Adiabatic process

In thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,...

. The steam pressure drops as it expands. A late cutoff delivers full steam pressure to move the piston through its entire stroke, for maximum start-up forces. But, since there will still be unexploited pressure in the cylinder at the end of the stroke, this is achieved at the expense of engine efficiency. In this situation the steam will still have considerable pressure remaining when it is exhausted resulting in the characteristic “chuff chuff” sound of a steam engine. An early cutoff has greater thermodynamic efficiency but provides less average force on the piston and is used for running the engine at higher speeds. The steam engine is the only thermodynamic engine design that can provide its maximum torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

at zero revolutions.

Explanation

Cutoff is conventionally expressed as percentage of the power stroke of the piston; if the piston is at a quarter of its stroke at the cutoff point, the cutoff is stated as 25%.

Smaller stationary steam engine

Stationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars , agricultural engines used for ploughing or...

s generally have a fixed cutoff point while, in large ones, the speed and power output is generally governed by altering the cutoff, frequently under governor

Centrifugal governor

A centrifugal governor is a specific type of governor that controls the speed of an engine by regulating the amount of fuel admitted, so as to maintain a near constant speed whatever the load or fuel supply conditions...

control using an expansion valve

Expansion valve

An expansion valve is a slide valve used in a steam engine to control the cut-off. It rides on the back of an adapted main slide valve and is driven by an additional eccentric that has more advance than the main eccentric. The cut-off is adjusted in one of two ways...

or trip gear

Trip valve

Trip valve mechanisms are a class of steam engine valve gear developed to improve efficiency. The trip mechanism allows the inlet valve to be closed rapidly, giving a short, sharp cut-off. The valve itself can be a drop valve or a Corliss valve....

. In steam engines for transport, it is desirable to be able to alter the cutoff over a wide range. For starting and at low speed and heavy load, the cylinders need steam supply at maximum pressure for almost the full length of the stroke. In a two-cylinder locomotive, for example, the maximum or 'full gear' cutoff is typically about 85%. At high speeds, the cutoff may be 15% percent of the piston stroke or less. Steam engines used in boats and ships operate under a constant, unvarying load through the propeller

Propeller

A propeller is a type of fan that transmits power by converting rotational motion into thrust. A pressure difference is produced between the forward and rear surfaces of the airfoil-shaped blade, and a fluid is accelerated behind the blade. Propeller dynamics can be modeled by both Bernoulli's...

and so have a fixed cutoff, with speed being controlled through the regulator.

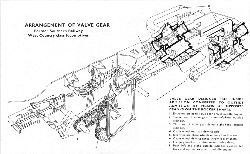

Providing variable cutoff is an important function of the valve gear

Valve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle...

. Most valve gear designs provide it, the exception being early Stephenson valve gear

Stephenson valve gear

The Stephenson valve gear or Stephenson link or shifting link is a simple design of valve gear that was widely used throughout the world for all kinds of steam engine. It is named after Robert Stephenson but was actually invented by his employees....

.

Reversing lever

This is the most common form of reverser. It consists of a long lever mounted, parallel to the direction of travel, on the driver’s side of the cab. It has a handle and sprung trigger at the top and is pivoted at the bottom so as to pass between two notched sector plates. The reversing rod, which connects to the valve gear, is attached to this lever, either above or below the pivot, in such a position as to give good leverage. A square pin is arranged so as to engage with the notches in the plates and hold the lever in the desired position when the trigger is released.The advantages of this design are that change between forward and reverse gear can be made very quickly as is needed in, for example, a shunting engine. Disadvantages are that, because the lever must rest at one of the notches, fine adjustment of the cutoff to offer best running and economy is not possible. On large locomotives it can be difficult to prevent the mechanism from jumping into full forward gear (“nose-diving”) when adjusting the cutoff once the locomotive has gathered speed: with such engines it was the practice of drivers to select an appropriate degree of cutoff before opening the regulator

Steam locomotive components

A listing of the components found on typical steam locomotives.center|720px|Schematic steam locomotiveGuide to steam locomotive components .A listing of the components found on typical steam...

and to leave it in that position for the duration of the journey.

Screw reverser

Stephenson valve gear

The Stephenson valve gear or Stephenson link or shifting link is a simple design of valve gear that was widely used throughout the world for all kinds of steam engine. It is named after Robert Stephenson but was actually invented by his employees....

, it was common to use the screw housing as an air cylinder, with the nut extended to form a piston. Compressed air from the brake reservoirs was applied to one side of the piston to reduce the effort required to lift the heavy expansion link, with gravity assisting in the opposite direction.

Power reverse gear

With larger engines, the linkages involved in controlling cutoff and direction grew progressively heavier and there was a need for power assistance in adjusting them. Steam (or later, compressed air) powered reversing gear was developed in the late 19th and early 20th centuries. Typically, the operator worked a valve that admitted steam to one side or the other of a cylinder connected to the reversing mechanism until the indicator showed the intended position. A second mechanism, usually a piston in an oil-filled cylinder held in position by closing a control cock, was required to keep the linkages in place. The first locomotive engineer to fit such a device was James StirlingJames Stirling (1835-1917)

James Stirling was a Scottish mechanical engineer. He was Locomotive Superintendent of the Glasgow and South Western Railway and later the South Eastern Railway.-Biography:...

of the Glasgow and South Western Railway

Glasgow and South Western Railway

The Glasgow and South Western Railway , one of the pre-grouping railway companies, served a triangular area of south-west Scotland, between Glasgow, Stranraer and Carlisle...

in 1873. Several engineers then tried them, including William Dean of the GWR

Great Western Railway

The Great Western Railway was a British railway company that linked London with the south-west and west of England and most of Wales. It was founded in 1833, received its enabling Act of Parliament in 1835 and ran its first trains in 1838...

and Vincent Raven

Vincent Raven

Sir Vincent Litchfield Raven KBE was chief mechanical engineer of the North Eastern Railway from 1910 to 1922.- Biography :...

of the North Eastern Railway

North Eastern Railway (UK)

The North Eastern Railway , was an English railway company. It was incorporated in 1854, when four existing companies were combined, and was absorbed into the London and North Eastern Railway at the Grouping in 1923...

, but they found them little to their liking, mainly because of maintenance difficulties: any oil leakage from the locking cylinder, either through the piston gland

Stuffing box

A stuffing box is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements.-Boats:...

or the cock, allowed the mechanism to creep, or worse “nose-dive”, into full forward gear while running. Stirling moved to the South Eastern Railway

South Eastern Railway (UK)

The South Eastern Railway was a railway company in south-eastern England from 1836 until 1922. The company was formed to construct a route from London to Dover. Branch lines were later opened to Tunbridge Wells, Hastings, Canterbury and other places in Kent...

and Harry Smith Wainwright, his successor with that company, incorporated them into most of his designs, which were in production about thirty years after Stirling’s innovation. Later still the forward-looking Southern Railway engineer Oliver Bulleid

Oliver Bulleid

Oliver Vaughan Snell Bulleid was a British railway and mechanical engineer best known as the Chief Mechanical Engineer of the Southern Railway between 1937 and the 1948 nationalisation, developing many well-known locomotives.- Early life and Great Northern Railway :He was born in Invercargill,...

fitted them to his famous Merchant Navy Class

SR Merchant Navy class

The SR Merchant Navy class , was a class of air-smoothed 4-6-2 Pacific steam locomotives designed for the Southern Railway of the United Kingdom by Oliver Bulleid...

of locomotives, but they were mostly removed at rebuild.

Henszey's reversing gear, patented in 1882, illustrates a typical early solution. Henszey's device consists of two piston

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

s mounted on a single piston rod. Both pistons are double-ended. One is a steam piston to move the rod as required. The other, containing oil, holds the rod in a fixed position when the steam is turned off. Control is by a small three-way steam valve (“forward”, “stop”, “back”) and a separate indicator showing the position of the rod and thus the percentage of cutoff in use. When the steam valve is at “stop”, an oil cock

Tap (valve)

A tap is a valve controlling release of liquids or gas. In the British Isles and most of the Commonwealth, the word is used for any everyday type of valve, particularly the fittings that control water supply to bathtubs and sinks. In the U.S., the term "tap" is more often used for beer taps,...

connecting the two ends of the locking piston is also closed, thus holding the mechanism in position. The piston rod connects by levers to the reversing gear, which operates in the usual way, according to the type of valve gear in use.

The Ragonnet power reverse, patented in 1909, was a true feedback

Feedback

Feedback describes the situation when output from an event or phenomenon in the past will influence an occurrence or occurrences of the same Feedback describes the situation when output from (or information about the result of) an event or phenomenon in the past will influence an occurrence or...

controlled servomechanism

Servomechanism

thumb|right|200px|Industrial servomotorThe grey/green cylinder is the [[Brush |brush-type]] [[DC motor]]. The black section at the bottom contains the [[Epicyclic gearing|planetary]] [[Reduction drive|reduction gear]], and the black object on top of the motor is the optical [[rotary encoder]] for...

. The power reverse amplified small motions of reversing lever in the locomotive cab made with modest force into much larger and more forceful motions of the reach rod that controlled the engine cutoff and direction. It was usually air powered, but could also be steam powered. The term servomotor was explicitly used by the developers of some later power reverse mechanisms. The use of feedback control in these later power reverse mechanisms eliminated the need for a second cylinder for a hydraulic locking mechanism, and it restored the simplicity of a single operating lever that both controlled the reversing linkage and indicated its position.

The development of articulated locomotive

Articulated locomotive

Articulated locomotive usually means a steam locomotive with one or more engine units which can move independent of the main frame. This is done to allow a longer locomotive to negotiate tighter curves...

s was a major impetus to the development of power reverse systems, because these typically had two or even three sets of reverse gear, instead of just one on a simple locomotive. The Baldwin Locomotive Works

Baldwin Locomotive Works

The Baldwin Locomotive Works was an American builder of railroad locomotives. It was located in Philadelphia, Pennsylvania, originally, and later in nearby Eddystone, Pennsylvania. Although the company was very successful as a producer of steam locomotives, its transition to the production of...

used the Ragonnet reversing gear, and other American builders generally abandoned positive locking features. In British use, locking cylinders remained in use. The Hadfield reversing gear, patented in 1950, was in most particulars a Ragonnet reversing gear with added locking cylinder.

Most Beyer Garratt

Garratt

A Garratt is a type of steam locomotive that is articulated in three parts. Its boiler is mounted on the centre frame, and two steam engines are mounted on separate frames, one on each end of the boiler. Articulation permits larger locomotives to negotiate curves and lighter rails that might...

locomotives used the Hadfield system.

Many American locomotives were built, or retro-fitted, with power reverse, e.g. PRR K4s

PRR K4s

The Pennsylvania Railroad's K4s 4-6-2 "Pacific" was their premier passenger-hauling steam locomotive from 1914 through the end of steam on the PRR in 1957....

, PRR N1s

PRR N1s

The Pennsylvania Railroad's N1s was a class of steam locomotive built for Lines West. They were of 2-10-2 "Santa Fe" wheel arrangement, ten driving wheels with a two-wheel leading truck and a two-wheel cast KW-pattern trailing truck under a giant firebox...

, PRR B6

PRR B6

The Pennsylvania Railroad's class B6 was its most successful class of switcher, or as the PRR termed them, "shifter". The PRR preferred the 0-6-0 wheel arrangement for larger switchers, whereas on other roads the 0-8-0 gained preference...

, PRR L1s

PRR L1s

Class L1s on the Pennsylvania Railroad comprised 574 2-8-2 "Mikado" type steam locomotives constructed between 1914 and 1919 by the railroad's own Juniata Shops as well as the Baldwin Locomotive Works and the Lima Locomotive Works ....

.

Enginemen’s terminology

In the UK, a screw reverser is sometimes called a “bacon slicer”, particularly the type fitted to BR Standard locomotives. In the US, a reversing lever is called a “Johnson bar”.Sources

- Allen, Cecil J (1949). Locomotive Practice and Performance in the Twentieth Century.. W.Heffer and Sons Ltd, Cambridge.

- Bell, A. Morton (1950). Locomotives volume one. Seventh edition. London, Virtue and Company Ltd.