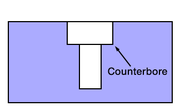

Counterbore

Encyclopedia

Description

For a spot face, material is removed from a surface to make it flat and smooth, usually for a fastener

Fastener

A fastener is a hardware device that mechanically joins or affixes two or more objects together.Fasteners can also be used to close a container such as a bag, a box, or an envelope; or they may involve keeping together the sides of an opening of flexible material, attaching a lid to a container,...

or a bearing

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

. Spot facing is usually required on workpieces that are forged

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. Forging is often classified according to the temperature at which it is performed: '"cold," "warm," or "hot" forging. Forged parts can range in weight from less than a kilogram to 580 metric tons...

or cast

Casting

In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process...

. A tool referred to as a counterbore

Counterbore

A counterbore can refer to a cylindrical flat-bottomed hole, which enlarges another hole, or the tool used to create that feature. A spot face is a very shallow counterbore...

is typically used to cut the spot face, although an endmill

Endmill

An endmill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit, in its application, geometry, and manufacture...

may also be used. Only enough material is removed to make the surface flat.

A counterbore is also used to create a perpendicular surface for a fastener head on a non-perpendicular surface. If this is not feasible then a self-aligning nut

Self-aligning nut

A self-aligning nut, also known as a spherical nut or leveling nut, is a type of nut that is used in applications where the fastener is not perpendicular to the surface the nut anchors to. It achieves this action by using a flanged nut inside a specially shaped dished out washer. They are commonly...

may be required.

By comparison, a countersink

Countersink

A countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common usage is to allow the head of a countersunk bolt or screw, when placed in the hole, to sit flush with or below the surface of the surrounding material...

makes a conical hole and is used to seat a flathead screw.

Machining

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

where rigidity is assured and hole center location is already achieved via X-Y positioning.

The uppermost counterbore tools shown in the image are the same device. The smaller top item is an insert, the middle shows another three-fluted counterbore insert, assembled in the holder. The shank of this holder is a Morse taper, although there are other machine tapers that are used in the industry. The lower counterbore is designed to fit into a drill chuck, and being smaller, is economical to make as one piece.