Cadmium telluride photovoltaics

Encyclopedia

Cadmium telluride

Cadmium telluride is a crystalline compound formed from cadmium and tellurium. It is used as an infrared optical window and a solar cell material. It is usually sandwiched with cadmium sulfide to form a p-n junction photovoltaic solar cell...

thin film

Thin film

A thin film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness. Electronic semiconductor devices and optical coatings are the main applications benefiting from thin film construction....

, a semiconductor layer

Layer

Layer may refer to:* A layer of archaeological deposits in an excavation* A layer hen, a hen raised to produce eggs* Stratum, a layer of rock or soil with internally consistent characteristics...

designed to absorb and convert sunlight into electricity. Cadmium telluride

Cadmium telluride

Cadmium telluride is a crystalline compound formed from cadmium and tellurium. It is used as an infrared optical window and a solar cell material. It is usually sandwiched with cadmium sulfide to form a p-n junction photovoltaic solar cell...

PV is the first and only thin film photovoltaic technology to surpass crystalline silicon PV in cheapness for a significant portion of the PV market, namely in multi-kilowatt systems.

Background

The first thin film technology to be extensively developed and manufactured was amorphous silicon

Amorphous silicon

Amorphous silicon is the non-crystalline allotropic form of silicon. It can be deposited in thin films at low temperatures onto a variety of substrates, offering some unique capabilities for a variety of electronics.-Description:...

. However, this technology suffers from low efficiencies and slow deposition rates (leading to high capital costs) and has not become a market leader. Instead, the PV market has grown to almost 4 gigawatts with wafer-based crystalline silicon comprising almost 90% of sales. Installation trails production by a slight time lag, and the same source estimates about 3 gigawatts were installed in 2007.

During this period, two other thin films continued in development (cadmium telluride, and copper indium diselenide

Copper indium gallium selenide

Copper indium gallium selenide is a I-III-VI2 semiconductor material composed of copper, indium, gallium, and selenium. The material is a solid solution of copper indium selenide and copper gallium selenide...

or CIS-alloys). The latter is beginning to be produced in start-up volumes of 1–30 megawatts per year by individual companies and remains an unproven, but promising market competitor due to very high, small-area cell efficiencies approaching 20% in the laboratory.

History

Heterojunction

A heterojunction is the interface that occurs between two layers or regions of dissimilar crystalline semiconductors. These semiconducting materials have unequal band gaps as opposed to a homojunction...

design evolved in which p-type CdTe was matched with n-type cadmium sulfide

Cadmium sulfide

Cadmium sulfide is the inorganic compound with the formula CdS. Cadmium sulfide is a yellow solid. It occurs in nature with two different crystal structures as the rare minerals greenockite and hawleyite, but is more prevalent as an impurity substituent in the similarly structured zinc ores...

(CdS). The cell was completed by adding top and bottom contacts. Early leaders in CdS/CdTe cell efficiencies were GE

Gê

Gê are the people who spoke Ge languages of the northern South American Caribbean coast and Brazil. In Brazil the Gê were found in Rio de Janeiro, Minas Gerais, Bahia, Piaui, Mato Grosso, Goias, Tocantins, Maranhão, and as far south as Paraguay....

in the 1960s, and then Kodak, Monosolar, Matsushita

Matsushita Electric Industrial Co.

, formerly known as , is a Japanese multinational consumer electronics corporation headquartered in Kadoma, Osaka, Japan. Its main business is in electronics manufacturing....

, and AMETEK

AMETEK

AMETEK, Inc is a manufacturer of electronic instruments and electromechanical devices with headquarters in the United States and over 80 manufacturing sites worldwide....

.

By 1981, Kodak used close spaced sublimation (CSS) and made the first 10% cells and first multi-cell devices (12 cells, 8% efficiency, 30 cm2). Monosolar and AMETEK used electrodeposition

Electrophoretic deposition

Electrophoretic deposition , is a term for a broad range of industrial processes which includes electrocoating, e-coating, cathodic electrodeposition, and electrophoretic coating, or electrophoretic painting...

, a popular early method. Matsushita started with screen printing but shifted in the 1990s to CSS. Cells of about 10% sunlight-to-electricity efficiency were being made by the early 1980s at Kodak, Matsushita, Monosolar, and Ametek.

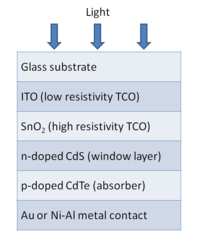

An important step forward occurred when cells were being scaled-up in size to make larger area products called modules. These products require higher currents than small cells and it was found that an additional layer, called a transparent conductive oxide (TCO), could facilitate the movement of current across the top of the cell (instead of a metal grid). One such TCO, tin oxide

Tin dioxide

Tin dioxide is the inorganic compound with the formula SnO2. The mineral form of SnO2 is called cassiterite, and this is the main ore of tin. With many other names , this oxide of tin is the most important raw material in tin chemistry...

, was already being applied to glass for other uses (thermally reflective windows). Made more conductive for PV, tin oxide became and remains the norm in CdTe PV modules.

Professor Ting L. Chu of Southern Methodist University

Southern Methodist University

Southern Methodist University is a private university in Dallas, Texas, United States. Founded in 1911 by the Methodist Episcopal Church, South, SMU operates campuses in Dallas, Plano, and Taos, New Mexico. SMU is owned by the South Central Jurisdiction of the United Methodist Church...

and subsequently of University of South Florida

University of South Florida

The University of South Florida, also known as USF, is a member institution of the State University System of Florida, one of the state's three flagship universities for public research, and is located in Tampa, Florida, USA...

, Tampa, made significant contributions to moving the efficiency of CdTe cells to above 15% in 1992, a critical level of success in terms of potential commercial competitiveness. This was done when he added an intervening or buffer layer to the TCO/CdS/CdTe stack and then thinned the CdS to allow more light through. Chu used resistive tin oxide as the buffer layer and then thinned the CdS from several micrometres to under half a micrometre in thickness. Thick CdS, as it was used in prior devices, blocked about 5 mA/cm2 of light, or about 20% of the light usable by a CdTe device. By removing this loss while maintaining the other properties of the device, Chu reached 15% efficiency in 1991, the first thin film to do so, as verified at the National Renewable Energy Laboratory

National Renewable Energy Laboratory

The National Renewable Energy Laboratory , located in Golden, Colorado, is the United States' primary laboratory for renewable energy and energy efficiency research and development. The National Renewable Energy Laboratory is a government-owned, contractor-operated facility; it is funded through...

(NREL). Chu used CSS for depositing the CdTe. For his achievements in taking CdTe from its status as “also-ran” to a primary candidate for commercialization, some think of Ting L. Chu as the key technologist in the history of CdTe development.

In the early 1990s, another set of entrants were active in CdTe commercial development, but with mixed results. A short-lived company, Golden Photon replaced Photon Energy, when it was bought by the Coors Company

Coors Brewing Company

The Coors Brewing Company is a regional division of the world's fifth-largest brewing company, the Canadian Molson Coors Brewing Company and is the third-largest brewer in the United States...

in 1992. Golden Photon, led by Scot Albright and John Jordan, actually held the record for a short period for the best CdTe module measured at NREL at 7.7% using a spray deposition technique. Meanwhile Matsushita, BP Solar

BP Solar

BP has been involved in solar power since 1973 and its subsidiary, BP Solar, is a solar power company with production facilities in India and the People's Republic of China, employing a workforce of over 2,000 people worldwide. BP Solar is worldwide manufacturer and installer of photovoltaic solar...

, and Solar Cells Inc

First Solar

First Solar, Inc. is an American manufacturer of thin film photovoltaic modules, or solar panels, and a provider to PV power plants of supporting services that include finance, construction, maintenance and end-of-life panel recycling...

. were active. Matsushita claimed an 11% module efficiency using CSS and then dropped out of the technology, perhaps due to internal corporate pressures over cadmium

Cadmium

Cadmium is a chemical element with the symbol Cd and atomic number 48. This soft, bluish-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Similar to zinc, it prefers oxidation state +2 in most of its compounds and similar to mercury it shows a low...

. A similar efficiency and fate eventually occurred at BP Solar. BP used electrodeposition inherited from Monosolar by a circuitous route when it purchased SOHIO. SOHIO had previously bought Monosolar. BP Solar however never made a complete commitment to their CdTe technology despite its achievements and dropped it in the early 2000s. Another ineffective corporate evolution occurred at a European entrant, Antec. Founded by CdTe pioneer Dieter Bonnet (who made cells in the 1960s), Antec was able to make about 7%-efficient modules, but went bankrupt when it started producing commercially during a short, sharp downturn in the market in 2002. Purchased from bankruptcy, it never regained the technical traction needed to make further progress. However, as of 2008 Antec does make and sell CdTe PV modules.

There are a number of start-ups in CdTe today: Q-Cells' Calyxo (Germany), GE’s PrimeStar Solar (Arvada, Colorado), Arendi (Italy), and Abound Solar

Abound Solar

Abound Solar is a manufacturer of CdTe thin-film photovoltaic modules. At its production facility in Longmont, Colorado, Abound is using a proprietary semiconductor deposition process utilizing CdTe to produce reliable, low-cost solar modules designed for commercial- and utility-scale installations...

(Fort Collins, Colorado). Including Antec, their total production represents less than 70 megawatts per year.

In February 2009, Roth & Rau

Roth & Rau

Roth & Rau is a German solar energy company. It manufactures machines and equipments used in solar panel production. Its product portfolio includes PECVD coating plants....

announced to develop turnkey CdTe production lines and launch the business before end of 2009.

There has been a lot of research on fabricating CdTe cells on flexible substrate since 1999. In 2009, EMPA, the Swiss Federal Laboratories for Materials Testing and Research, demonstrated a 12.4% efficient solar cell on flexible polyimide substrate.

SCI and First Solar

The major commercial success to emerge from the turmoil of the 1990s was Solar Cells Incorporated (SCI). Founded in 1990 as an outgrowth of a prior company, Glasstech Solar (founded 1984), led by inventor/entrepreneur Harold McMasterHarold McMaster

Harold A. McMaster was an inventor with over 100 patents and entrepreneur who founded four companies. Fortune Magazine called him "The Glass Genius". He also worked on developing commercial-scale solar cell technology, and developed a new type of engine, the "McMaster Rotary Engine."McMaster was...

, it switched from amorphous silicon to CdTe as a better solution to the higher-cost crystalline silicon PV. McMaster championed CdTe for its high-rate, high-throughput processing. Technical leadership came from a team that included Jim Nolan, Rick Powell, Jim Foote, and Peter Meyers, with consulting help from Ting Chu and Al Compaan (U. Toledo

University of Toledo

The University of Toledo is a public university in Toledo, Ohio, United States. The Carnegie Foundation classified the university as "Doctoral/Research Extensive."-National recognition:...

). SCI started with an adaptation of the CSS method then shifted to a vapor transport approach, inspired by Powell. In February 1999, McMaster sold the company to True North Partners, an investment arm of the Walton family

Walton family

The Walton Family is one of the richest families in the world, their wealth inherited from Bud and Sam Walton, founders of the world's largest retailer, Wal-Mart. The five most prominent members The Walton Family is one of the richest families in the world, their wealth inherited from Bud and Sam...

, owners of Wal-Mart. John T. Walton

John T. Walton

John Thomas Walton was a decorated United States war veteran and a son of Walmart founder Sam Walton. He was also the chairman of True North Partners, a venture capital firm...

joined the Board of the new company, and Mike Ahearn of True North became the CEO of the newly minted First Solar

First Solar

First Solar, Inc. is an American manufacturer of thin film photovoltaic modules, or solar panels, and a provider to PV power plants of supporting services that include finance, construction, maintenance and end-of-life panel recycling...

.

In its early years First Solar suffered setbacks, and initial module efficiencies were modest, about 7%. Commercial product became available in 2002. But production did not reach 25 megawatts until 2005. The company built an additional line in Perrysburg, Ohio

Perrysburg, Ohio

As of the census of 2000, there were 16,945 people, 6,592 households, and 4,561 families residing in the city. The population density was 1,899.2 people per square mile . There were 6,964 housing units at an average density of 780.5 per square mile...

, then four lines in Germany, supported by the then substantial German production incentives (about 50% of capital costs). In 2006 First Solar reached 75 MW of annual production and announced a further 16 lines in Malaysia. The more recently announced lines have been operational ahead of schedule. As of 2008, First Solar is producing at nearly half a gigawatt annual rate, and in 2006 and 2007 was among the largest PV module manufacturers in the world.

GE announced plans to spend $600 million on a new plant and enter this market

Cell efficiency

Best cell efficiency has plateaued at 16.5% since 2001. The opportunity to increase current has been almost fully exploited, but more difficult challenges associated with junction quality, with properties of CdTe and with contacting have not been as successful. However, until recently the number of active scientists in CdTe PV was small. Improved doping of CdTe and increased understanding of key processing steps (e.g., cadmium chloride recrystallization and contacting) are key to progress. Since CdTe has the optimal band gap for single-junction devices, it may be expected that efficiencies close to exceeding 20% (such as already shown in CIS alloys) should be achievable in practical CdTe cells. Modules of 15% would then be possible.Process optimization

Process optimization allows greater throughput at smaller cost. Typical improvements are broader substrates (since capital costs scale sublinearly, and installation costs can be reduced), thinner layers (to save material, electricity, and throughput time), and better material utilization (to save material and cleaning costs). Making components rather than buying them is also a traditional way for great manufacturers to shave costs. Today’s CdTe module costs are about $110/m2 (normalized to a square meter). Costs are expected to reduce to $75/m2.Thus a practical, long-term (10–20 year) goal for CdTe modules resulting from combining cost and efficiency goals would be $75 per 150 watts, or about $0.5 per watt. With commodity-like margins and combined with balance-of-system (BOS) costs, installed systems near $1.5/W seem achievable. With Southern California sunlight, this would be in the 6 to 8 US cents per kWh range (e.g., based on economic and other assumptions used in algorithms such as in the United States Department of Energy

United States Department of Energy

The United States Department of Energy is a Cabinet-level department of the United States government concerned with the United States' policies regarding energy and safety in handling nuclear material...

and NREL's Solar Advisory Model).

Tellurium supply

Perhaps the most subtle and least understood problem with CdTe PV is the supply of tellurium. Tellurium (Te) is an element not currently used for many applications. Only a small amount, estimated to be about 800 metric tons per year, is available. According to USGS, global tellurium production in 2007 was 135 metric tons. Most of it comes as a by-product of copper, with smaller byproduct amounts from lead and gold. One gigawatt (GW) of CdTe PV modules would require about 93 metric tons (at current efficiencies and thicknesses), so this seems like a limiting factor. However, because tellurium has had so few uses, it has not been the focus of geologic exploration. In the last decade, new supplies of tellurium-rich ores have been located, e.g., in Xinju, China. Since CdTe is now regarded as an important technology in terms of PV’s future impact on global energy and environment, the issue of tellurium availability is significant. Recently, researchers have added an unusual twist – astrophysicists identify tellurium as the most abundant element in the universe with an atomic number over 40. This surpasses, e.g., heavier materials like tin, bismuth, and lead, which are common. Researchers have shown that well-known undersea ridges (which are now being evaluated for their economic recoverability) are rich in tellurium and by themselves could supply more tellurium than we could ever use for all of our global energy. It is not yet known whether this undersea tellurium is recoverable, nor whether there is much more tellurium elsewhere that can be recovered.Cadmium

Another issue frequently mentioned, is the use and recycling of the extremely toxic metal cadmiumCadmium

Cadmium is a chemical element with the symbol Cd and atomic number 48. This soft, bluish-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Similar to zinc, it prefers oxidation state +2 in most of its compounds and similar to mercury it shows a low...

, one of the six most toxic materials banned by European Union

European Union

The European Union is an economic and political union of 27 independent member states which are located primarily in Europe. The EU traces its origins from the European Coal and Steel Community and the European Economic Community , formed by six countries in 1958...

's RoHS regulation. According to First Solar's annual report, the CdTe solar panel is not in RoHS compliance, not listed in the exemption product list, but not currently listed in the restricted product list either. So the product's future RoHS compliance status is uncertain. First Solar has a self-imposed recycling regimen that provides a deposited amount (<$0.05 a watt) that covers the costs of transport and recycling of the module at the end of its useful life. Recycling has been fully demonstrated on scrap modules although recent work has questioned the economic viability of recycling CdTe PV modules and called for producer responsibility policy to ensure all CdTe PV is recycled. In a validating test, Vasilis Fthenakis of the Brookhaven National Laboratory

Brookhaven National Laboratory

Brookhaven National Laboratory , is a United States national laboratory located in Upton, New York on Long Island, and was formally established in 1947 at the site of Camp Upton, a former U.S. Army base...

showed that the glass plates surrounding CdTe material sandwiched between them (as they are in all commercial modules) seal during a fire and do not allow any cadmium release. All other uses and exposures related to cadmium are minor and similar in kind and magnitude to exposures from other materials in the broader PV value chain, e.g., to toxic gases, lead solder, or solvents (most of which are not used in CdTe manufacturing).

Price vulnerability

A subtle issue with CdTe and with all thin films in relation to greater efficiency PV module technologies is the potential impact of commodity inflation. Greater efficiency modules incur a better balance of system commodity cost per unit output. Thus such inflation can have a greater percentage impact on system cost. This is another reason that continued efficiency improvements are important.Solar tracking

Almost all thin film photovoltaic module systems to-date have been non-solar trackingSolar tracker

A solar tracker is a generic term used to describe devices that orient various payloads toward the sun. Payloads can be photovoltaic panels, reflectors, lenses or other optical devices....

, because the output of modules has been too low to offset tracker capital and operating costs. But relatively inexpensive single-axis tracking systems can add 25% output per installed watt. This is climate-dependent. Tracking also produces a smoother output plateau around midday, allowing afternoon peaks to be met.

Market viability

Success of cadmium telluride PV has been due to the low cost achievable with the CdTe technology, made possible by combining adequate efficiency with lower module area costs. Direct manufacturing cost for CdTe PV modules reached $0.76 per watt in 2010, and capital cost per new watt of capacity is near $0.9 per watt (including land and buildings).However, module cost alone is not enough to assure the lowest installed system price. Thin films, including CdTe, are less efficient than most wafer silicon modules. Typical wafer silicon modules are 13% to 20% efficient, while the best CdTe modules were about 10.7% efficient; recent modules produced at First Solar and measured by NREL have shown CdTe modules with efficiencies at 12.5% or greater. Many components of an installed PV system (e.g., support structures, installation labor, land) scale with system area; and less-efficient modules require more area to produce the same output (all other things being equal). The impact of area-related costs on CdTe systems is about $0.5 per watt of extra cost.

Notable systems

Recent installations of large CdTe PV systems by First SolarFirst Solar

First Solar, Inc. is an American manufacturer of thin film photovoltaic modules, or solar panels, and a provider to PV power plants of supporting services that include finance, construction, maintenance and end-of-life panel recycling...

confirm the competitiveness of CdTe PV with other forms of solar energy and how close it is to being competitive with conventional natural gas peakers:

- A 40MW system being installed by juwi group in Waldpolenz Solar ParkWaldpolenz Solar ParkWaldpolenz Solar Park, which is the world’s largest thin-film photovoltaic power system, was built by German developer and operator Juwi at a former military air base to the east of Leipzig in Germany. The power plant is a 40 MW solar power system using state-of-the-art thin film technology, and...

, Germany: at the time of its announcement, it was both the largest planned and lowest cost PV system in the world. The price of 3.25 euros translated then (when the euro was equal to US$1.3) to $4.2/watt, much lower than any other known system. - A 7.5-megawatt system to be installed in Blythe, CA, where the California Public Utilities CommissionCalifornia Public Utilities CommissionThe California Public Utilities Commission is a regulatory agency which regulates privately owned public utilities in the state of California, including electric power, telecommunications, natural gas and water companies...

has accepted a 12 US cent per kWh power purchase agreement with First Solar (after the application of all incentives). Defined in California as the "Market Referent Price," this is the price the PUC will pay for any daytime peaking power source, e.g., natural gas. Although PV systems are intermittent and not dispatchableDispatchable generationDispatchable generation refers to sources of electricity that can be dispatched at the request of power grid operators; that is, generating plants that can be turned on or off, or can adjust their power output on demand...

the way natural gas is, natural gas generators have an ongoing fuel price risk that PV does not have. - A contract for two megawatts of rooftop installations with Southern California EdisonSouthern California EdisonSouthern California Edison , the largest subsidiary of Edison International , is the primary electricity supply company for much of Southern California, USA. It provides 14 million people with electricity...

, where the SCE program is designed to install 250 megawatts at a total cost of $875M (averaging $3.5/watt), after incentives.

See also

- Cadmium tellurideCadmium tellurideCadmium telluride is a crystalline compound formed from cadmium and tellurium. It is used as an infrared optical window and a solar cell material. It is usually sandwiched with cadmium sulfide to form a p-n junction photovoltaic solar cell...

- Copper indium gallium selenideCopper indium gallium selenideCopper indium gallium selenide is a I-III-VI2 semiconductor material composed of copper, indium, gallium, and selenium. The material is a solid solution of copper indium selenide and copper gallium selenide...

(CIGSCIGSCIGS may refer to:* Chief of the Imperial General Staff, a pre-1964 military position in the British Army* Copper indium gallium selenide , a semiconductor absorber material for solar cells...

). - Energy harvestingEnergy harvestingEnergy harvesting is the process by which energy is derived from external sources , captured, and stored for small, wireless autonomous devices, like those used in wearable electronics and wireless sensor networks.Energy harvesters...

- High efficiency solar cells

- Low cost solar cell

- Renewable energyRenewable energyRenewable energy is energy which comes from natural resources such as sunlight, wind, rain, tides, and geothermal heat, which are renewable . About 16% of global final energy consumption comes from renewables, with 10% coming from traditional biomass, which is mainly used for heating, and 3.4% from...

- Solar energy

- Solar cellSolar cellA solar cell is a solid state electrical device that converts the energy of light directly into electricity by the photovoltaic effect....

- Solar panelPhotovoltaic moduleA solar panel is a packaged, connected assembly of solar cells, also known as photovoltaic cells...

- Thin film solar cellThin film solar cellA thin-film solar cell , also called a thin-film photovoltaic cell , is a solar cell that is made by depositing one or more thin layers of photovoltaic material on a substrate...

Further reading

- V. Fthenakis, H. C. Kim, 2007, “CdTe photovoltaics: Life cycle environmental profile and comparisons,” Thin Solid Films, Volume 515, Issue 15, 31 May 2007, Pages 5961-5963, doi:10.1016/j.tsf.2006.12.138; article at http://www.clca.columbia.edu/papers/CdTe_Photovoltaics_Life_Cycle_Environmental_Profile.pdf

- A. H. Hill, “Progress in Photovoltaic Energy Conversion,” NASA, Washington, DC, http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19660006117_1966006117.pdf

- Richard Stevenson, August 2008, “First Solar: Quest for the $1 Watt,” IEEE Spectrum Online, http://spectrum.ieee.org/aug08/6464