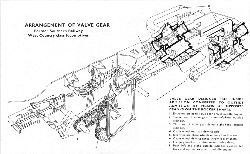

Bulleid chain-driven valve gear

Encyclopedia

Steam locomotive

A steam locomotive is a railway locomotive that produces its power through a steam engine. These locomotives are fueled by burning some combustible material, usually coal, wood or oil, to produce steam in a boiler, which drives the steam engine...

valve gear

Valve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle...

designed by Oliver Bulleid

Oliver Bulleid

Oliver Vaughan Snell Bulleid was a British railway and mechanical engineer best known as the Chief Mechanical Engineer of the Southern Railway between 1937 and the 1948 nationalisation, developing many well-known locomotives.- Early life and Great Northern Railway :He was born in Invercargill,...

for use on his Pacific (4-6-2)

4-6-2

4-6-2, in the Whyte notation for the classification of steam locomotives, represents the wheel arrangement of four leading wheels on two axles , six powered and coupled driving wheels on three axles, and two trailing wheels on one axle .These locomotives are also known as Pacifics...

designs during the Second World War. They were peculiar to the Southern Railway in Britain

United Kingdom of Great Britain and Ireland

The United Kingdom of Great Britain and Ireland was the formal name of the United Kingdom during the period when what is now the Republic of Ireland formed a part of it....

, and were based upon motor-vehicle practice in an attempt to create a compact, but efficient design with a minimum of service requirements.

Design principles

Oliver Bulleid's decision to have three cylinders, all driving the middle coupled axleAxle

An axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

of his Merchant Navy

SR Merchant Navy class

The SR Merchant Navy class , was a class of air-smoothed 4-6-2 Pacific steam locomotives designed for the Southern Railway of the United Kingdom by Oliver Bulleid...

, West Country and Battle of Britain Classes, gave rise to several problems. As each cylinder was to have its own separate valve gear, this left very little space for the conventional inside set of motion. This prompted Oliver Bulleid to design a new miniaturised Walschaerts motion layout that was compact enough to enclose the whole system in a casing. All three sets of valve gear were worked from an auxiliary three-throw crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. A Morse inverted tooth drive chain

Chain drive

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles...

ran horizontally from a triple sprocket on the driving axle to an idler gear, from which a second chain ran downwards to the crankshaft. By the use of two chains the valve gear was isolated from the movement of the driving axle on its springs. The idler gear could be moved to give both chains the correct tension, but in practice only the vertical chain would be adjusted.

The auxiliary crankshaft drove both eccentric rods and combination levers displacing the piston valves; these were of the outside admission type. The valve heads were connected by a double girder arrangement, each actuated by a vertical rocking shaft located between the two girders and midway between the two heads, with a further connecting link pivoted just behind the valve head nearest the front. A sealed oscillating shaft drove the offset upper rocker arm and link, and the whole assembly worked inside the exhaust space of the steam chest. The advantage of having admission steam working on the outside faces of the valves meant that the volume under maximum pressure was completely sealed at the ends with no glands susceptible to leakage.

Valve motion and the inside connecting rod

Connecting rod

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion....

were enclosed in an oil bath

Oil bath

An oil bath is a laboratory heating device which uses boiling oil as the temperature regulator. Since different oils have different boiling points it is possible to obtain a temperature near to the desired temperature by selecting an oil with a boiling point as close as possible to the desired...

consisting of a vertical steel box located between the main frame members, containing 40 gallons (182 litres) of oil. About 2 inches (50 mm) depth of oil lay in the bath; the inside big end was splash-lubricated, and two pumps sprayed oil through perforated pipes over the various valve motion pins. None of this was particularly revolutionary, being borrowed from internal-combustion engine practice and for use with steam it was established practice at the Sentinel Waggon Works

Sentinel Waggon Works

Sentinel Waggon Works Ltd was a British company based in Shrewsbury, Shropshire that made steam-powered lorries, railway locomotives, and later, diesel engined lorries and locomotives.-Alley & MacLellan, Sentinel Works, Jessie Street Glasgow:...

. It was thought that the arrangement would obviate the daily need to oil all moving parts and as they were protected from the elements, they should be able to run 100,000 miles (160,000 km) without attention. It was this consideration that meant the continued use of the system, albeit in modified form, on Bulleid's Leader Class

SR Leader Class

The Leader was a class of experimental 0-6-6-0T articulated steam locomotive, produced in the United Kingdom to the design of the innovative engineer Oliver Bulleid. The Leader was an attempt to extend the life of steam traction by eliminating many of the operational drawbacks associated with...

.

Problems

In practice, the arrangement had a number of disadvantages. Cracks developed in the oil bath casing due to incorrect welding procedure. CondensationCondensation

Condensation is the change of the physical state of matter from gaseous phase into liquid phase, and is the reverse of vaporization. When the transition happens from the gaseous phase into the solid phase directly, the change is called deposition....

caused corrosion, and oil

Oil

An oil is any substance that is liquid at ambient temperatures and does not mix with water but may mix with other oils and organic solvents. This general definition includes vegetable oils, volatile essential oils, petrochemical oils, and synthetic oils....

leaked out through inadequate seals, causing wheelslip and fire

Fire

Fire is the rapid oxidation of a material in the chemical process of combustion, releasing heat, light, and various reaction products. Slower oxidative processes like rusting or digestion are not included by this definition....

hazards. Valve timing was highly unpredictable; this has been attributed to chain stretch, although Bulleid claimed that it was allowed for. The chains were replaced as part of a valve and piston examination at around 30,000 to 36,000 miles, by which time they were considerably worn. This wear, in the chain pins and sprockets, could result in an elongation of the chains by as much as 6 inches. Bulleid asserted that a slack of 3 inches would be absorbed by the chain coming under load, with the remaining valve irregularity corrected by adjusting the cut-off.

Whilst chain-stretch is widely considered to be the cause of the gear's inefficiencies, another likely cause may have been geometrical due to the sequential proportions of levers, especially the final rockers transmitting the limited movement of the "miniaturised" valve gear to the union link driving the long travel piston valve. This "anti-lever" alone would have made accurate valve timing difficult to achieve, giving rise to stress in the drive mechanism, the symptom of which would be an increase in the likelihood of chain-stretch. The maximum throw of the expansion links was 2.25 inches (5.7 cm). To provide the maximum valve travel of 6 inches (15.2 cm) the rocker arms multiplied the motion of the auxiliary crankshaft in the ratio 3:8. The effects of wear in the pin joints, also multiplied by the same ratio, caused valve openings to vary between cylinders even if the driver maintained the same cut-off.

A further complication was the unpredictable behaviour of the Eastleigh type of steam reverser employed. If this reverser misbehaved under the fluctuating pressures present in the steam chest, the locomotive seemed to have a will of its own. For example, if the reverser dropped into full gear, the slackness in the motion would make the valves overrun their designed full travel inside the cylinders. This would result in the locomotive taking off like an unleashed race horse, high coal consumption, throwing the fire out of the chimney and running the risk of a violent high-speed slipping.

These problems combined contributed to the gear's eventual replacement by three separate sets of Walschaerts gear mounted in the conventional manner.