Ball differential

Encyclopedia

Differential (mechanics)

A differential is a device, usually, but not necessarily, employing gears, capable of transmitting torque and rotation through three shafts, almost always used in one of two ways: in one way, it receives one input and provides two outputs—this is found in most automobiles—and in the other way, it...

typically used on radio-controlled car

Radio-controlled car

Radio-controlled cars are self-powered model cars or trucks that can be controlled from a distance using a specialized transmitter...

s. It differs from a geared differential by using several small ball bearings rotating between two plates, instead of bevel gear

Bevel gear

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped.Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well...

s.

History

The first ball differential was patented by Cecil Schumacher, a British motorsport engineer, designed a ball differential for radio-controlled model cars. Radio-controlled cars were still a new application for the ball differential and Cecil Schumacher is the modern day inventor of the concept. Such was the popularity of the ball differential, originally applied in 1/12 on-road cars that Cecil Schumacher formed a company, Schumacher Racing ProductsSchumacher Racing Products

Schumacher Racing Products is a well established manufacturer and distributor of radio-controlled cars and accessories.- History :...

.

To this date ball differentials remain very popular in the radio-controlled car market. They are used on almost every 1/12 on-road, scale touring car and electric off-road produced by many manufacturers. In these classes they are regarded as the industry standard. Schumacher Racing Products even use ball differentials on their nitro truck range, these however use strong materials and larger and harder ball bearings.

Basic principles

Radio-controlled car manufacturers use the same basic design Schumacher created in the 1980s. The main part of the differential is a drive gearGear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

(or pulley in a belt transmission

Belt (mechanical)

A belt is a loop of flexible material used to link two or more rotating shafts mechanically. Belts may be used as a source of motion, to transmit power efficiently, or to track relative movement. Belts are looped over pulleys. In a two pulley system, the belt can either drive the pulleys in the...

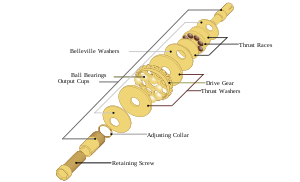

) with multiple holes cut through it, following its outside diameter. These holes are slightly larger than the width of the ball bearings, so that the balls, commonly around 2 mm diameter in a model car, sit inside the holes of the gear/pulley.

On either side of the gear are the thrust washers

Washer (hardware)

A washer is a thin plate with a hole that is normally used to distribute the load of a threaded fastener, such as a screw or nut. Other uses are as a spacer, spring , wear pad, preload indicating device, locking device, and to reduce vibration...

. The thrust washers are pushed against the ball bearings inside the gear by Belleville washer

Belleville washer

A Belleville washer, also known as a coned-disc spring, conical spring washer, disc spring, Belleville spring or cupped spring washer, is a type of spring shaped like a washer. It has a frusto-conical shape which gives the washer a spring characteristic. The Belleville name comes from the inventor...

s. On one side of the gear is an adjusting collar, which allows for adjustments in the amount of slip allowed by the differential. A thrust bearing

Thrust bearing

A thrust bearing is a particular type of rotary bearing. Like other bearings they permit rotation between parts, but they are designed to support a high axial load while doing this.Thrust bearings come in several varieties....

(or thrust race), on the opposite side of the gear, is used to stop the differential from loosening the retaining screw

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

holding the output cups, used to attach the differential to the axle, onto the differential.

As the screw is tightened it pushes the Belleville and thrust washers onto the gear/pulley. This creates contact between the washers and ball bearings inside of the gear/pulley. The friction created by the contact between the washers and ball bearings is, aided by grease

Petroleum

Petroleum or crude oil is a naturally occurring, flammable liquid consisting of a complex mixture of hydrocarbons of various molecular weights and other liquid organic compounds, that are found in geologic formations beneath the Earth's surface. Petroleum is recovered mostly through oil drilling...

(commonly silicone grease

Silicone grease

Silicone grease is a waterproof grease made by combining a silicone oil with a thickener. Most commonly, the silicone oil is polydimethylsiloxane and the thickener is amorphous fumed silica...

), designed so that as one washer moves, the ball bearings rotate.

As the washer on one side of the gear rotates, the rotation of the balls causes the other washer to rotate in the opposite direction, because any rotating ball will have opposite sides moving in opposite directions .

Differential movement is achieved through the process of the thrust washers rotating with the ball bearings. The retaining screw is designed so the differential can be easily adjusted by tightening or loosening the screw, consequently changing force. This makes the differential more adjustable than geared differentials, but there is a lower limit since the drive is by friction so there is always some limited slip action.

External links

- Schumacher Racing Products

- The Ball Differential, detailed information, (German language) CGI-graphics and animation that show the ball differential's inner workings

- http://www.rctek.com/general/differential_ball_description.html, a similar exploded diagram and general information on other types of differentials