Belleville washer

Encyclopedia

Spring (device)

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication...

shaped like a washer

Washer (mechanical)

A washer is a thin plate with a hole that is normally used to distribute the load of a threaded fastener, such as a screw or nut. Other uses are as a spacer, spring , wear pad, preload indicating device, locking device, and to reduce vibration...

. It has a frusto

Frustum

In geometry, a frustum is the portion of a solid that lies between two parallel planes cutting it....

-conical

Cone (geometry)

A cone is an n-dimensional geometric shape that tapers smoothly from a base to a point called the apex or vertex. Formally, it is the solid figure formed by the locus of all straight line segments that join the apex to the base...

shape which gives the washer a spring characteristic. The Belleville name comes from the inventor Julian F. Belleville.

Design and use

Some properties of Belleville washers include: high fatigue life, better space utilization, low creep tendency, high load capacity with a small spring deflection. and possibility for high hysteresis (damping) by stacking several belleville washers on top of each other in the same direction.

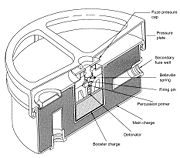

Belleville springs are also used in a number of landmines e.g. the American M19

M19 mine

The M19 is a large square plastic cased U.S. anti-tank blast mine. The design dates from the mid-1960s and has only two metal components: the copper detonator capsule and stainless steel firing pin which weighs 2.86 grams. It is a minimum metal mine, which makes it very difficult to detect after it...

, M15

M15 mine

The M15 mine is a large circular U.S. anti-tank blast mine, first deployed during the Korean War. Essentially, it is a larger version of the M6A2 anti-tank mine, which it superseded.-Description:...

, M14

M14 mine

The M14 mine is a U.S. small anti-personnel land mine first deployed circa 1955. The M14 mechanism uses a belleville spring to flip a firing pin downwards into a stab detonator when pressure is applied. Once deployed, the M14 is very difficult to detect because it is a minimum metal mine, i.e. most...

, M1

M1 mine

The M1,M1A1 and M4 are circular steel cased U.S. anti-tank blast mines with a distinctive cross shaped pressure spider. The mine was used during the Second World War and a copy produced in Argentina was used during the Falklands War. Another copy is produced in China. designated the No.4 mine...

and the Swedish Tret-Mi.59. The target (a person or vehicle) exerts pressure on the belleville spring, causing it to exceed a trigger threshold and flip the adjacent firing pin

Firing pin

A firing pin or striker is part of the firing mechanism used in a firearm or explosive device e.g. an M14 landmine or bomb fuze. Firing pins may take many forms, though the types used in landmines, bombs, grenade fuzes or other single-use devices generally have a sharpened point...

downwards into a stab detonator

Detonator

A detonator is a device used to trigger an explosive device. Detonators can be chemically, mechanically, or electrically initiated, the latter two being the most common....

, firing both it and the surrounding booster charge

Explosive booster

An explosive booster acts as a bridge between a low energy explosive and a low sensitivity explosive such as TNT. It increases the explosive shockwave from an initiating explosive to the degree sufficient to detonate the secondary charge.Unlike C4 plastic explosive, not all explosives can be...

and main explosive filling.

Some makers of bolt-action target rifles use Belleville washer stacks in the bolt instead of a more traditional spring to release the firing pin, as they reduce the time between trigger actuation and firing pin impact on the cartridge.

They may also be used as locking devices, but only in applications with low dynamic loads, such as down-tube shifters for bicycles. Belleville washers are seen on Formula One

Formula One

Formula One, also known as Formula 1 or F1 and referred to officially as the FIA Formula One World Championship, is the highest class of single seater auto racing sanctioned by the Fédération Internationale de l'Automobile . The "formula" designation in the name refers to a set of rules with which...

cars, as they provide extremely detailed tuning ability. The World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

-vintage German Junkers Ju 88

Junkers Ju 88

The Junkers Ju 88 was a World War II German Luftwaffe twin-engine, multi-role aircraft. Designed by Hugo Junkers' company through the services of two American aviation engineers in the mid-1930s, it suffered from a number of technical problems during the later stages of its development and early...

aircraft's single strut main gear made primary use of belleville washers as its main shock absorption mechanism. At least one modern aircraft design, the Cirrus SR2x series, uses a Belleville washer setup to damp out nose gear oscillations (or "shimmy").

Belleville washers have been used as return springs in artillery pieces, one example being the French Canet range of marine/coastal cannon from the late 1800's (75 mm, 120mm, 152 mm).

Another example where they aid locking is a joint that experiences a large amount of thermal expansion and contraction. They will supply the required pre-load, but the bolt may have an additional locking mechanism (like Loctite

Loctite

Loctite is a brand of adhesives, sealants and surface treatments that include acrylic, anaerobic, cyanoacrylate, epoxy, hot melt, silicone, urethane and UV/light curing technologies...

) that would fail without the Belleville.

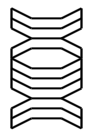

Stacking

Multiple Belleville washers may be stacked to modify the spring constant or amount of deflectionDeflection

Deflection or deflexion may refer to:* Deflection , the displacement of a structural element under load* Deflection , a technique of shooting ahead of a moving target so that the target and projectile will collide...

. Stacking in the same direction will add the spring constant in parallel, creating a stiffer joint (with the same deflection). Stacking in an alternating direction is the same as adding springs in series, resulting in a lower spring constant and greater deflection. Mixing and matching directions allow a specific spring constant and deflection capacity to be designed.

Example:

1 Spring is considered to be 1 in Parallel, 1 in Series. (This notation is needed for load calculations)

If n = # of springs in a stack, then:

Parallel Stack (n in parallel, 1 in series) - Deflection is equal to that of one spring, Load is equal to that of n x 1 spring.

i.e. Stack of 4 in parallel, 1 in series will have the same deflection as that of one spring and the load will be 4 times higher than that of one spring.

Series Stack (1 in parallel, n in series) - Deflection is equal to n x 1 spring, load is equal to that of one spring.

i.e. Stack of 1 in parallel, 4 in series will have the same load of one spring and the deflection will be 4 times greater.

Performance considerations

In a parallel stack, hysteresis (load losses) will occur due to friction between the springs. The hysteresis losses can be advantageous in some systems because of the added damping and dissipation of vibration energy. This loss due to friction can be calculated using hysteresis methods. Ideally, no more than 4 springs should be placed in parallel. If a greater load is required, then factor of safety must be increased in order to compensate for loss of load due to friction. Friction loss is not as much of an issue in series stacksIn a series stack, the deflection is not exactly proportional to the number of springs. This is because of a bottoming out effect when the springs are compressed to flat. The contact surface area increases once the spring is deflected beyond 95%. This decreases the moment arm and the spring will offer a greater spring resistance. Hysteresis can be used to calculate predicted deflections in a series stack. The number of springs used in a series stack is not as much of an issue as in parallel stacks.

Belleville washers are useful for adjustments because different thicknesses can be swapped in and out and they can be configured differently to achieve essentially infinite tunability of spring rate while only filling up a small part of the technician's tool box. They are ideal in situations where a heavy spring force is required with minimal free length and compression before reaching solid height. The downside, though, is weight, and they are severely travel limited compared to a conventional coil spring when free length is not an issue.

A wave washer also acts as a spring, but wave washers of comparable size do not produce as much force as Belleville washers.

Calculation

The total spring coefficient is:

Where

-

= the number of washers in the ith group

= the number of washers in the ith group - g = the number of groups

- k = the spring constant of one washer

So, a 2-3-1-2 stack (or, since addition is commutative, a 3-2-2-1 stack) gives a spring constant of 3/7 that of a single washer. These same 8 washers can be arranged in a 3-3-2 configuration (K = 6/7*k), a 4-4 configuration (K = 2*k), a 2-2-2-2 configuration (K = 1/2*k), and various other configurations. The number of unique ways to stack n washers is defined by the integer partition function p(n) and increases rapidly with large n, allowing fine-tuning of the spring constant. However, each configuration will have a different length, requiring the use of shims in most cases.

Standards

- DINDinDIN or Din or din can have several meanings:* A din is a loud noise.* Dīn, an Arabic term meaning "religion" or "way of life".* Din is one of the ten aspects of the Ein Sof in Kabbalah ....

2092 — Disc springs — Calculation - DIN 2093 — Disc springs - Quality specifications - Dimensions

- DIN 6796 — Conical spring washers for bolted connections